Gear selecting and shifting positioning mechanism for gear selecting and shifting actuator

A technology of positioning mechanism and gear selection and shifting, which is applied in the direction of instruments, controlled components, mechanical equipment, etc., and can solve the problems of shortening the service life of various parts, sliding friction of gear selection door parts, and easy scratches in gear selection and shifting, etc. Achieve the effects of reducing product failure rate, improving stability and consistency, and reducing abnormal noise when selecting and shifting gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

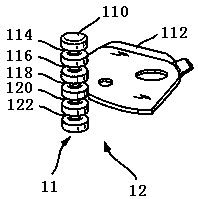

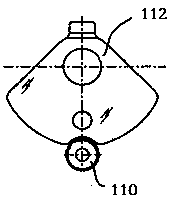

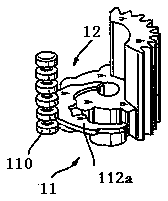

[0021] Please refer to Figure 4 to Figure 10 . A gear selection positioning mechanism for a gear selection actuator according to an embodiment of the present invention includes a gear selection shaft 1 , a gear selection gate 2 , a limit pin 3 , a gear 4 and a limit pin installation part.

[0022] The gear selection shaft 1 is rotatably arranged on the housing 5 of the gear selection actuator. In this embodiment, the first motor 61 drives the gear selection shaft 1 to move axially through a first transmission mechanism (not shown in the figure). The dial finger 8 is fixedly installed on the gear selection shaft 1, and can move and rotate together with the gear selection shaft 1, and then act on the gear shift track (not shown in the figure) of the gear selection actuator to realize gear selection.

[0023] The gear selection door 2 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com