Helical milling device and helical milling method

A helical milling hole and shaft adjustment technology, which is applied to milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the problems of poor rotation consistency between the eccentric adjustment shaft and the revolution shaft, low adjustment accuracy, error accumulation, etc., to achieve improved consistency Performance and stability, improve milling accuracy, and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

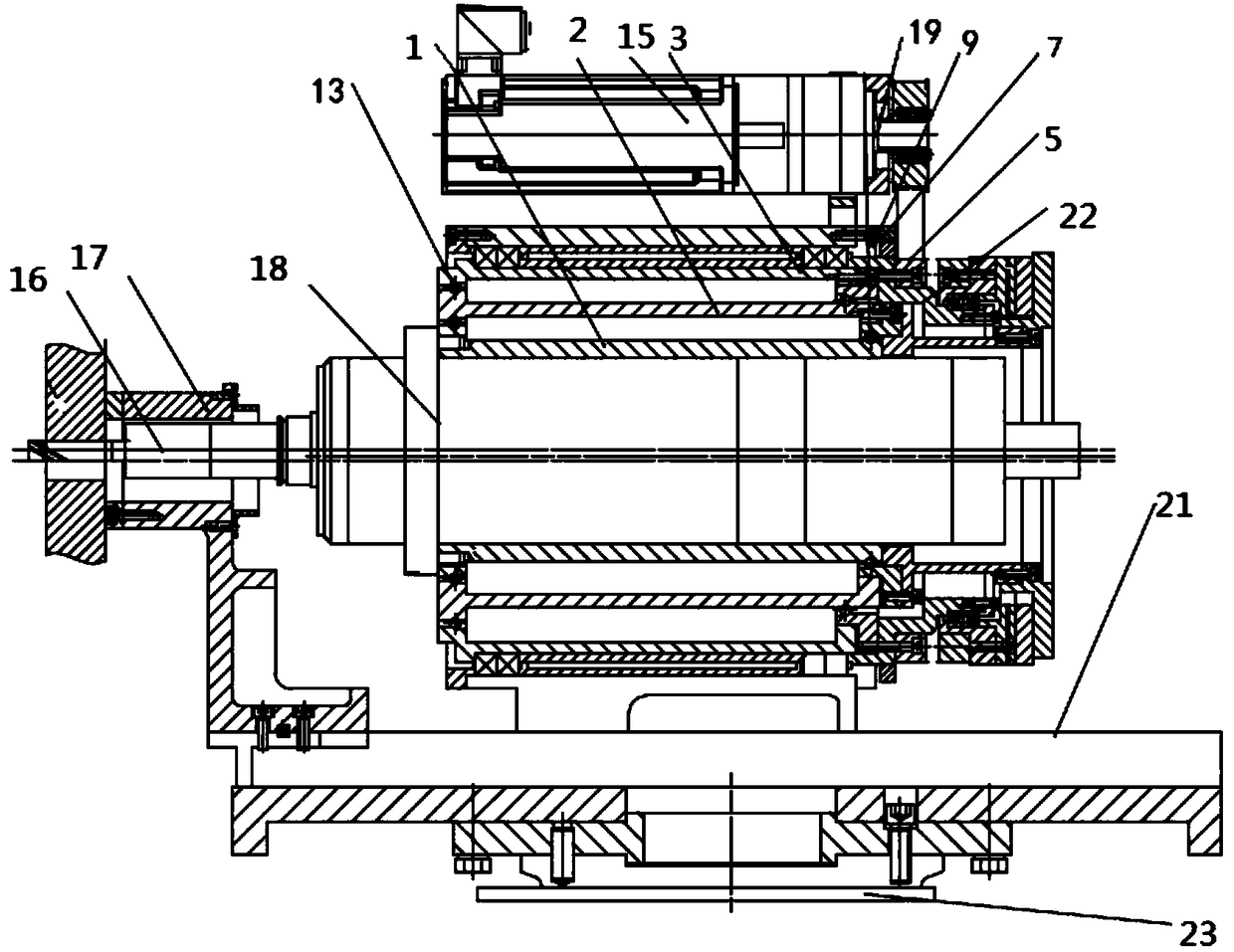

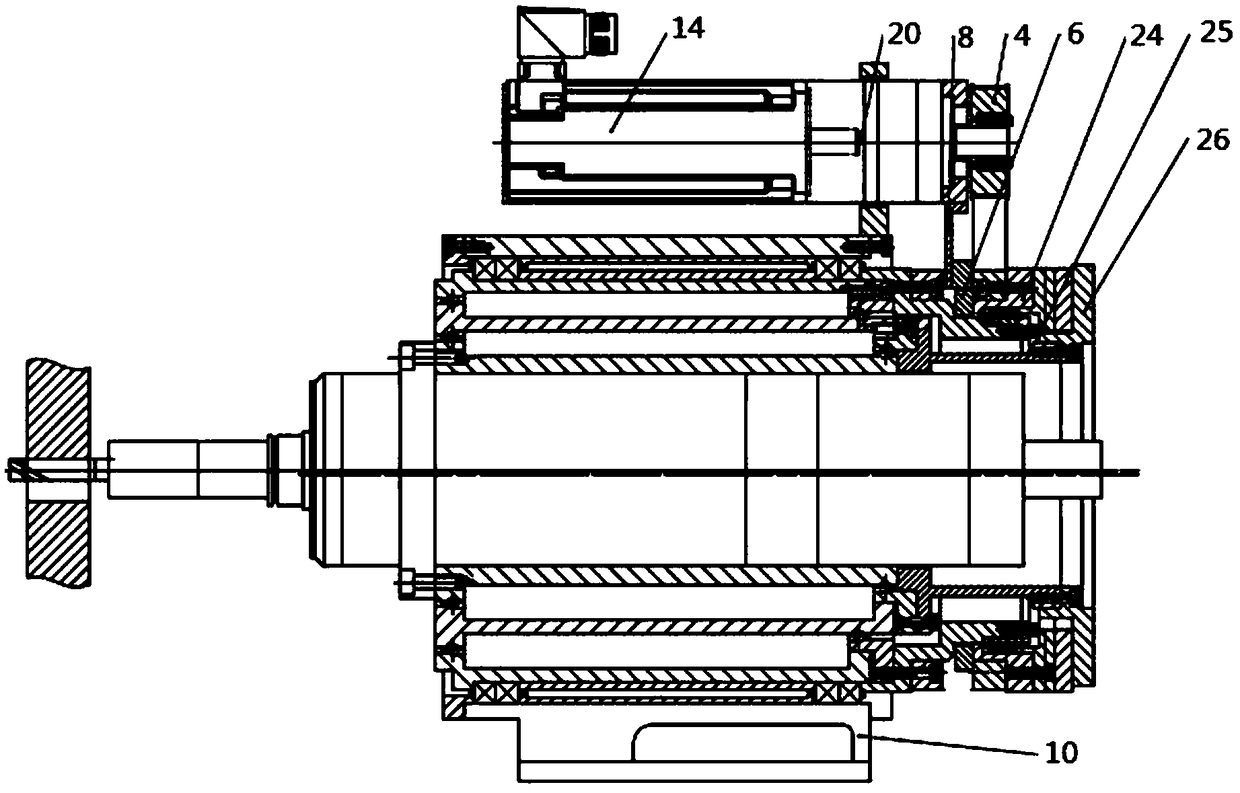

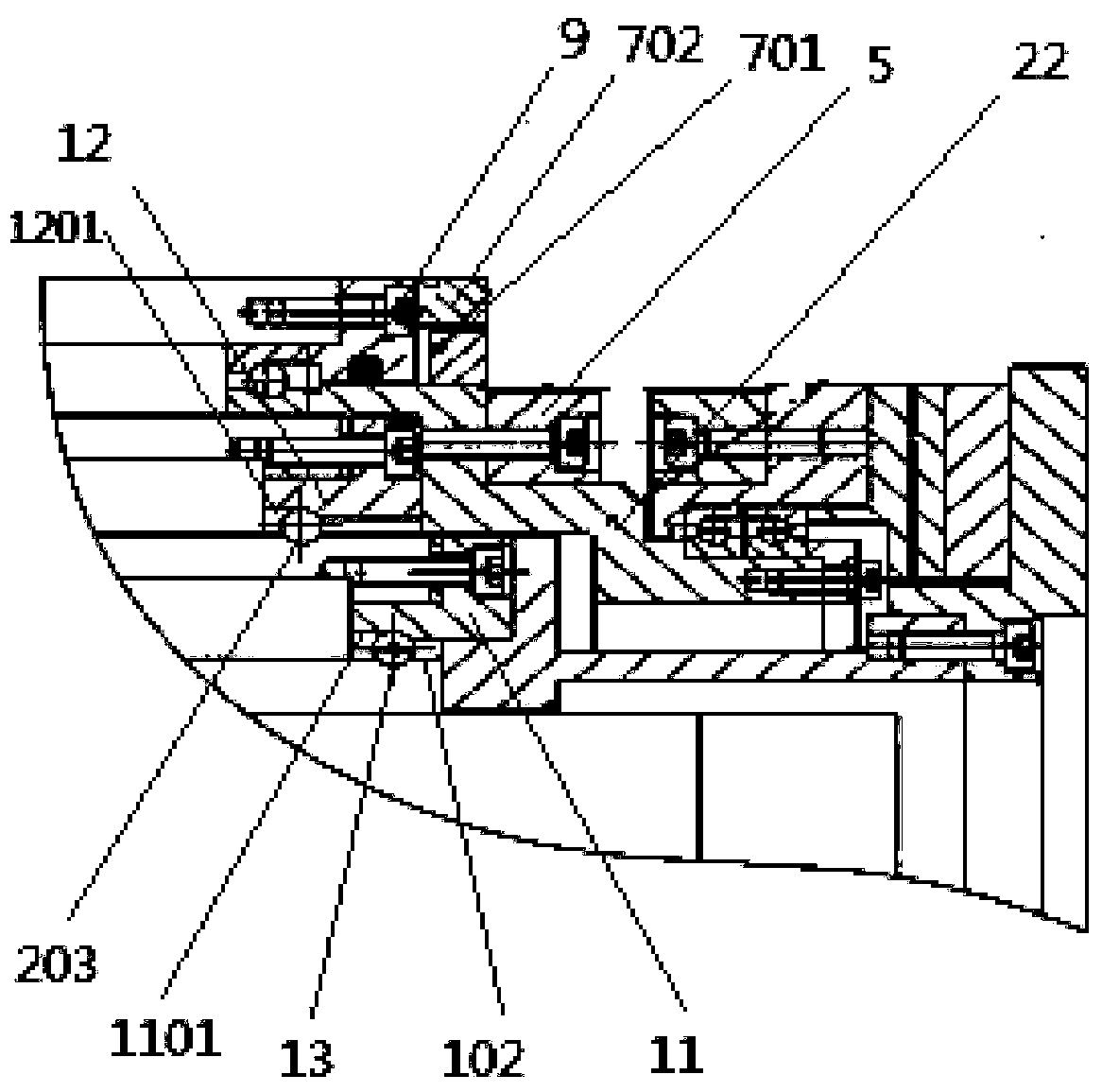

[0041] refer to figure 1 and figure 2 , a spiral milling device comprising: cutter 16, presser foot 17, electric spindle 18, rotation shaft 1, eccentric adjustment shaft 2, revolution shaft 3, revolution motor 15, first planetary reducer 19, revolution pulley 5, adjustment The motor 14 , the second planetary reducer 20 , the adjustment pulley 4 , the support housing 10 , the feed system 21 and the control system also include the adjustment axis detection grating scale 6 and the revolution axis detection grating scale 7 .

[0042] The presser foot 17 presses the workpiece, the tool 16 is installed on the front end of the electric spindle 18, and the outside of the electric spindle 18 is sequentially fitted with the rotation axis 1, the eccentric adjustment axis 2, and the revolution axis 3, wherein the rotation axis 1 is fixed to the electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com