Automatic firing system for spinning hot necking machine

A technology of heat closing and closing machine, which is applied in application, combustion and ignition, household appliances, etc., to achieve the effects of ensuring stability, uniform and sufficient heating, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

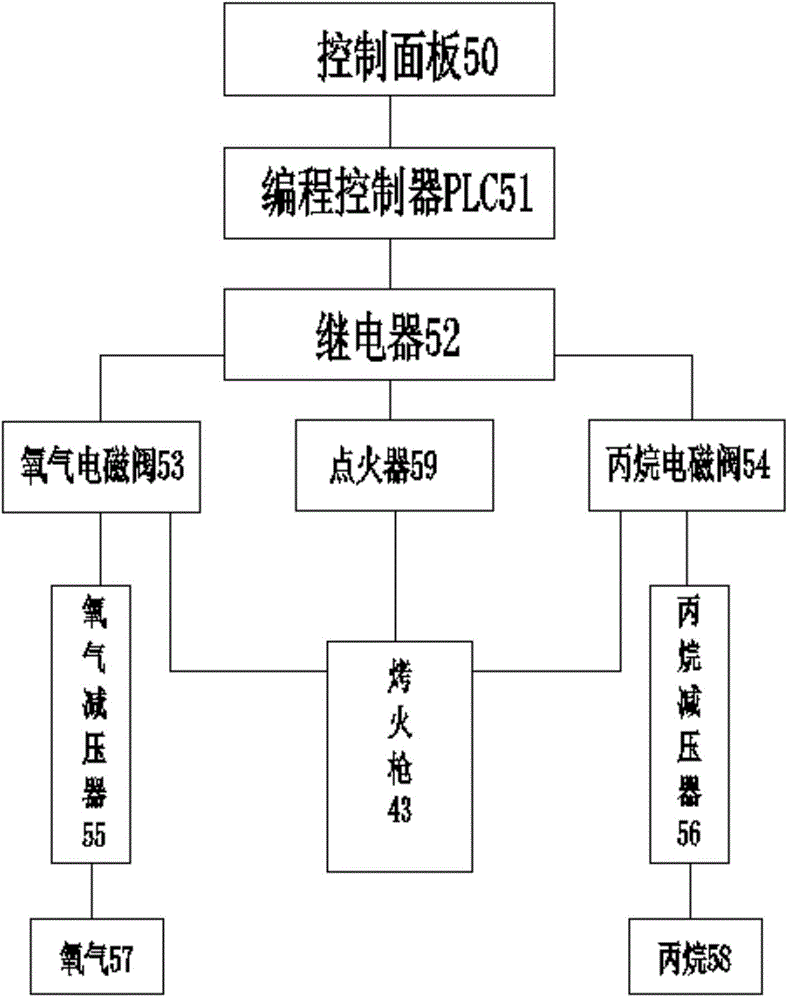

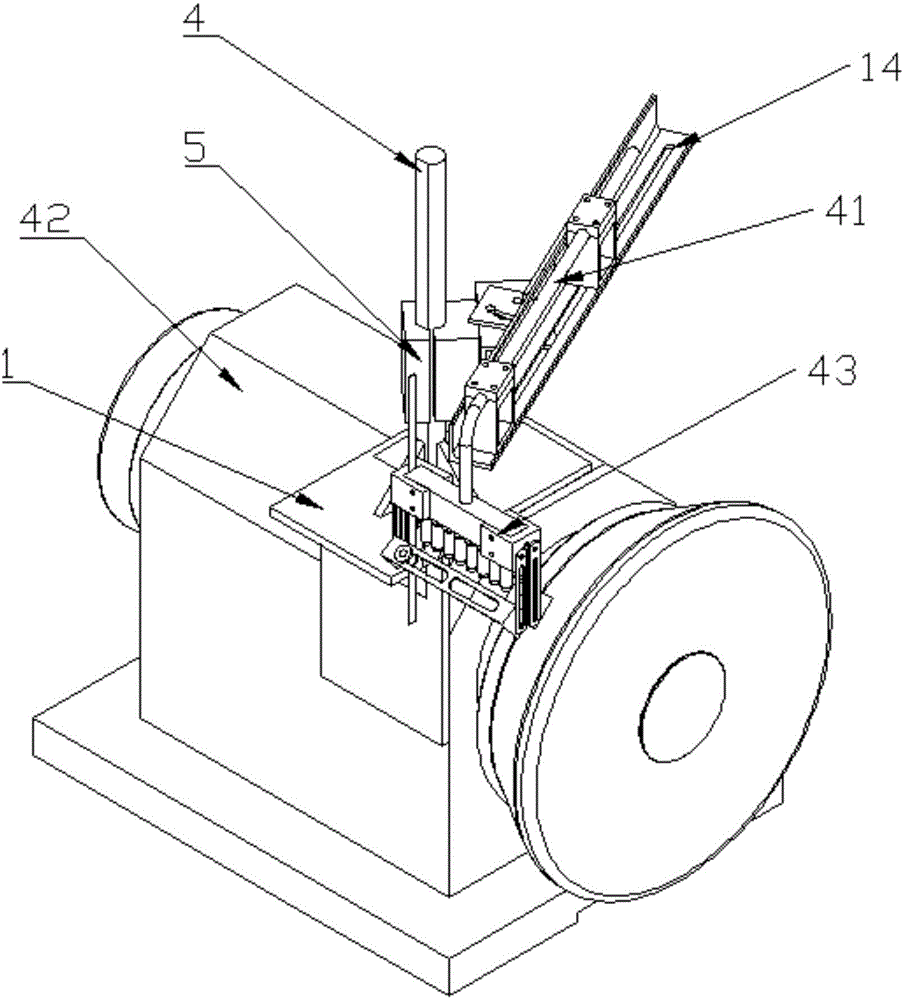

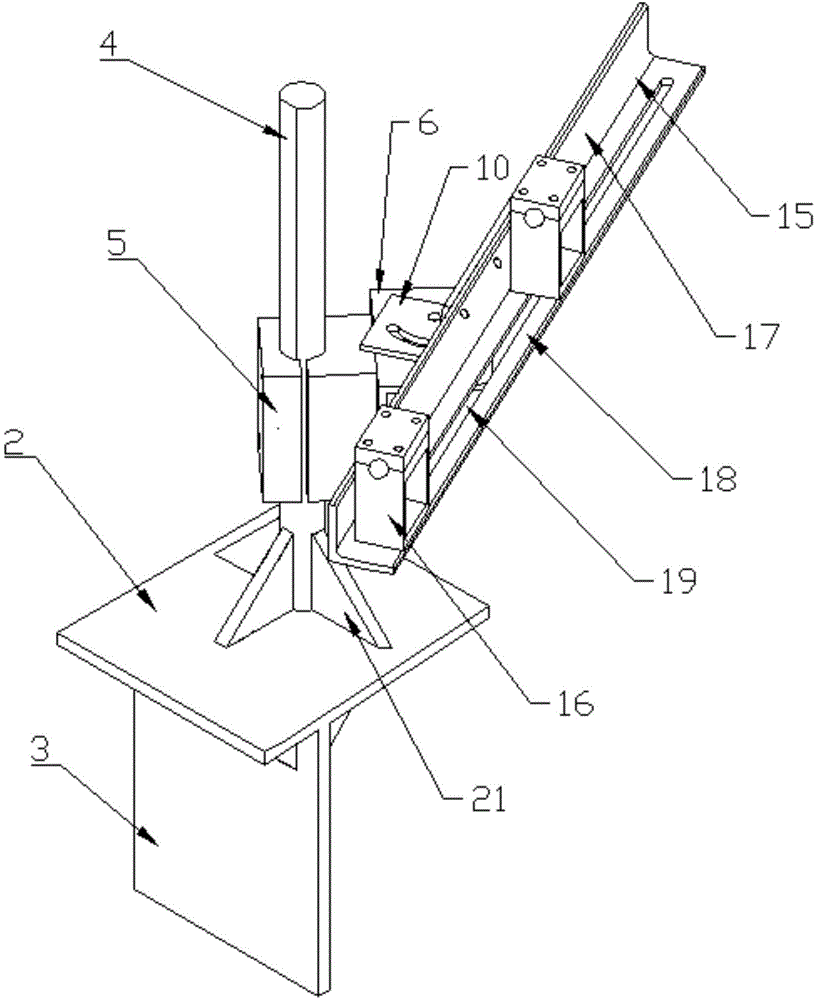

[0033] Such as Figure 1-2 Shown is an automatic roasting system for a spinning thermal closing machine, which has a supporting device arranged on the closing machine 42, a roasting gun 43 installed on the supporting device, and a roasting control system connected with the roasting gun 43. Roast gun 43 comprises gun head base 22, is arranged on the nozzle 25 on the gun head base 22, is positioned at the ignition stand of gun head base 22 sides, places the ignition electrode on the ignition stand, and gun head base 22 afterbody The connected gas pipeline 41; the fire control system includes a control panel 50, a programming controller PLC51 connected with the control panel 50 lines, a relay 52 connected with the programming controller PLC51 line, a gas solenoid valve and an igniter connected with the relay 52 lines respectively 59; the gas solenoid valve is respectively connected with the gas pipeline 41 and the gas bottle pipeline, and the igniter 59 is connected with the igni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com