Method and apparatus for optimizing launch characteristics of a golf club

a golf club and launch characteristic technology, applied in the field of golf clubs, can solve the problems of insufficient skill of golfers in controlling the flight path of balls, affecting the accuracy of golf clubs, so as to improve the launch angle, less inadvertent loss of accuracy, and greater carry distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

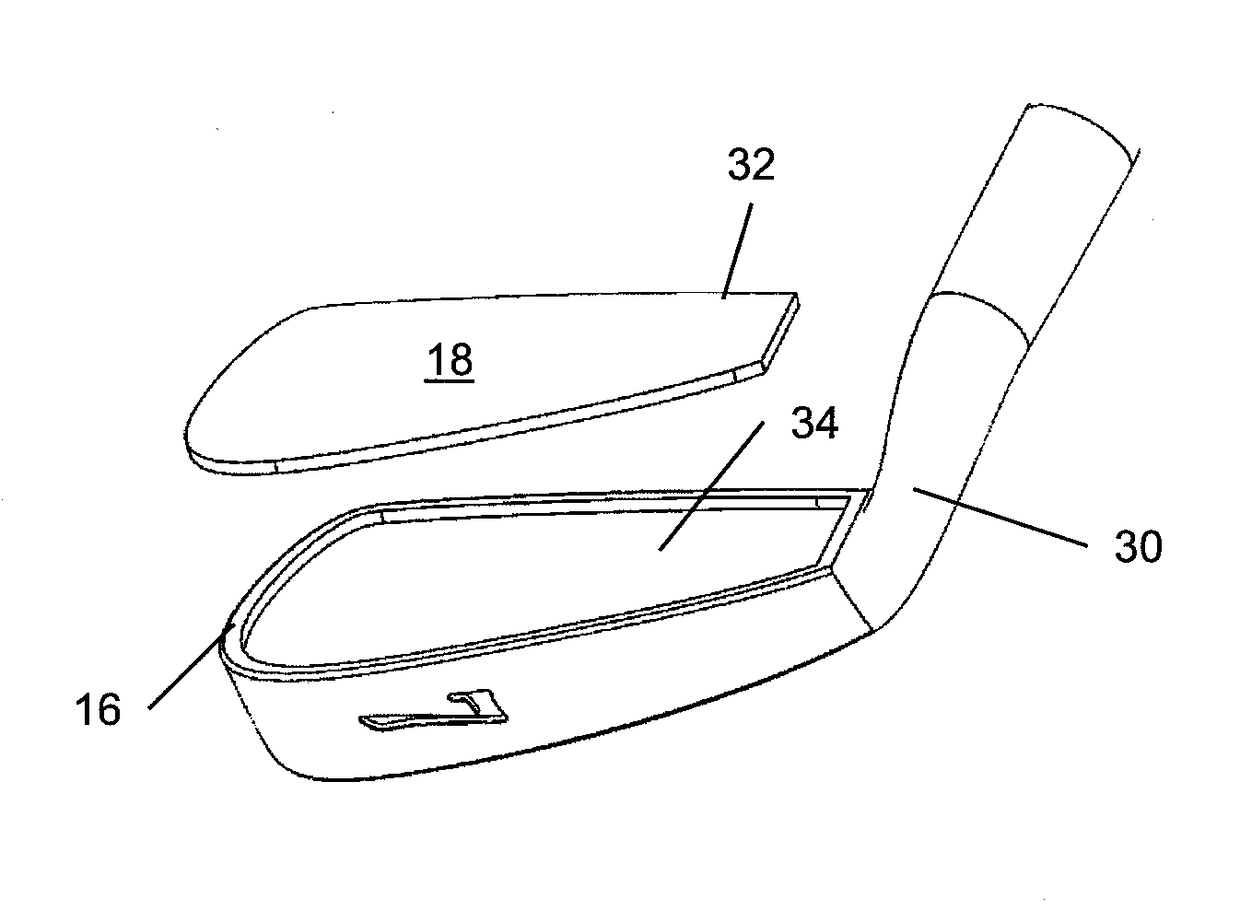

Image

Examples

example

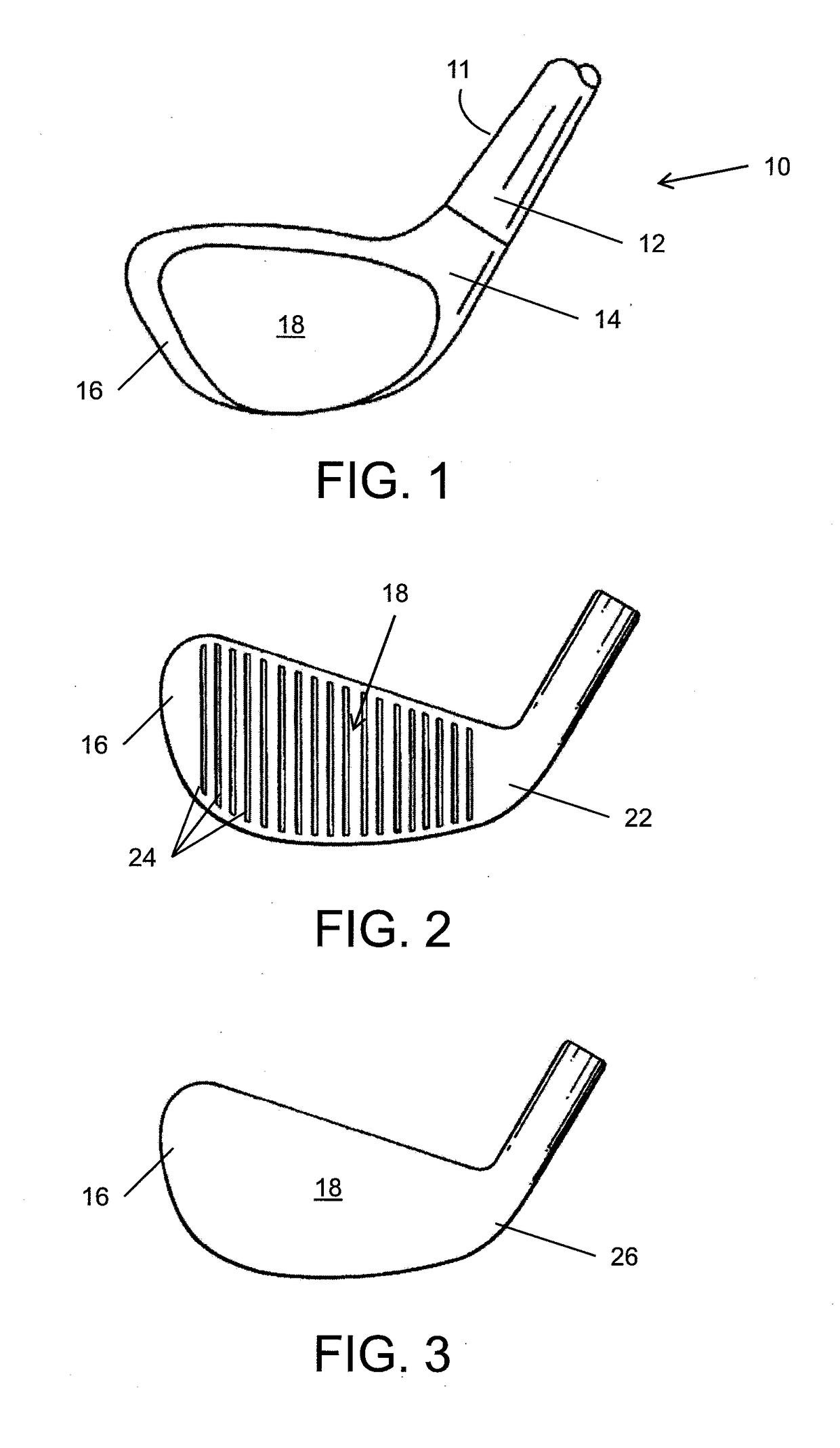

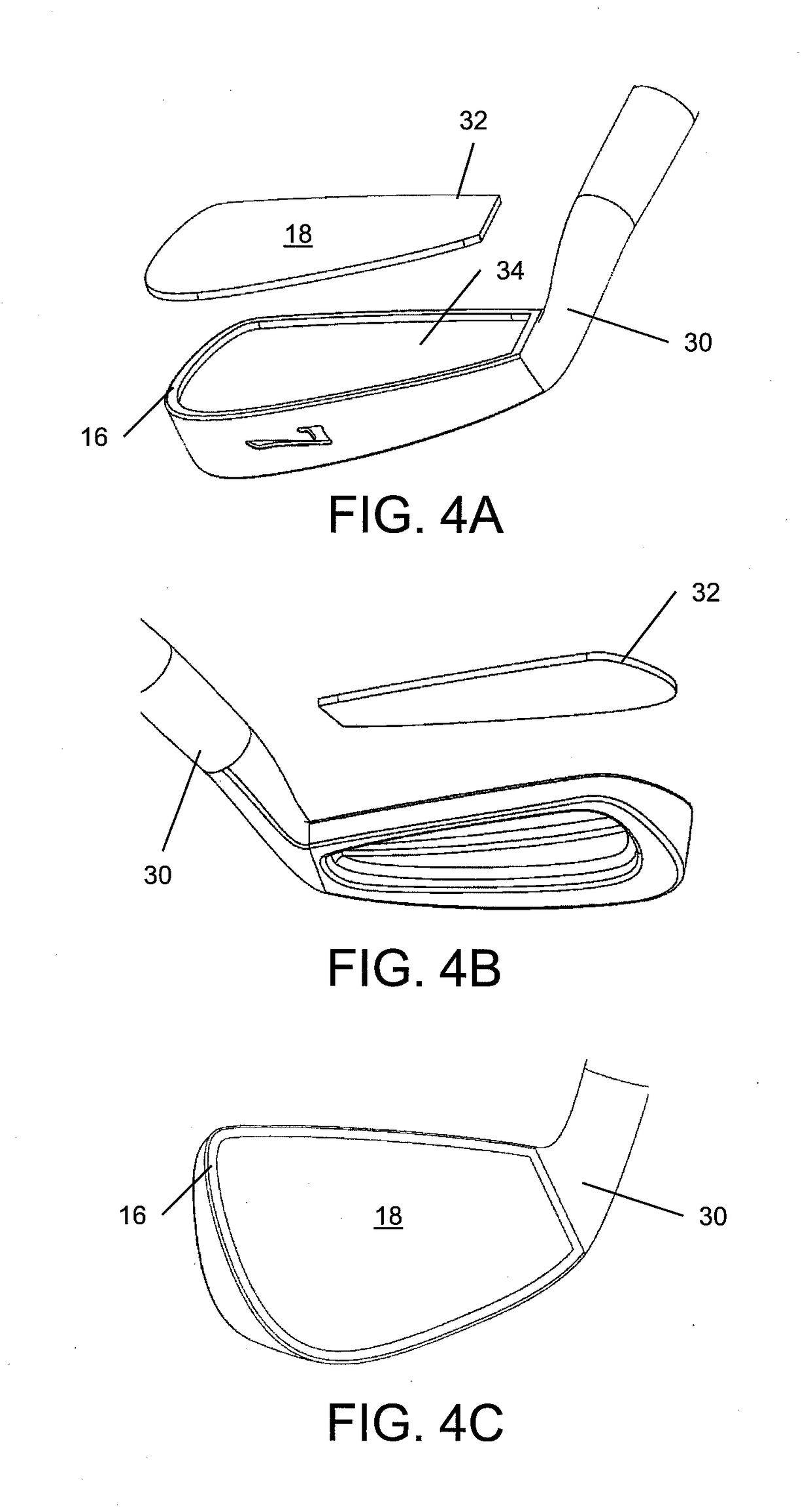

[0074]Tests were performed to show the advantage of utilizing a ball striking surface having the advantageous combination of properties disclosed herein, including hardness, smoothness, and durability. Various performance characteristics associated with the game of golf can be improved through the use of the ball striking surface having this advantageous combination of properties. Such performance characteristics include an increased launch angle of the golf ball, a decreased spin rate of the golf ball, and an increased carry distance (e.g., yardage) of the golf ball.

[0075]Two golf clubs of the same type and brand were acquired. In particular, two Callaway® 9-irons were used, each having a 39° loft. One of the golf clubs was modified to have the ball striking surface disclosed herein for comparison with the other golf club, which was left unmodified. To provide the modified golf club with the ball striking surface, a coating of polyurethane material commercially available under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com