Aerodynamic balanced wood form and/or iron form golf club

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

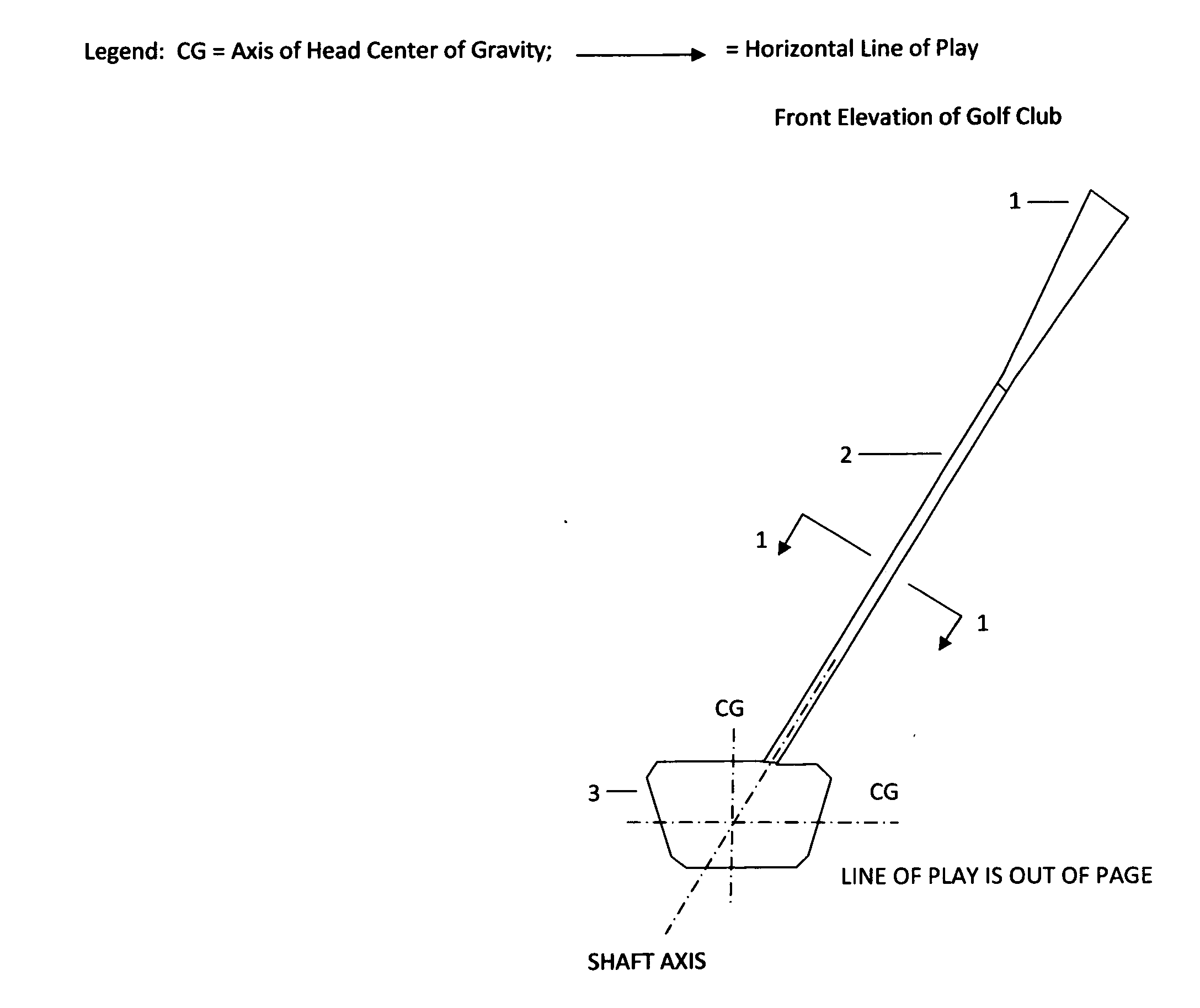

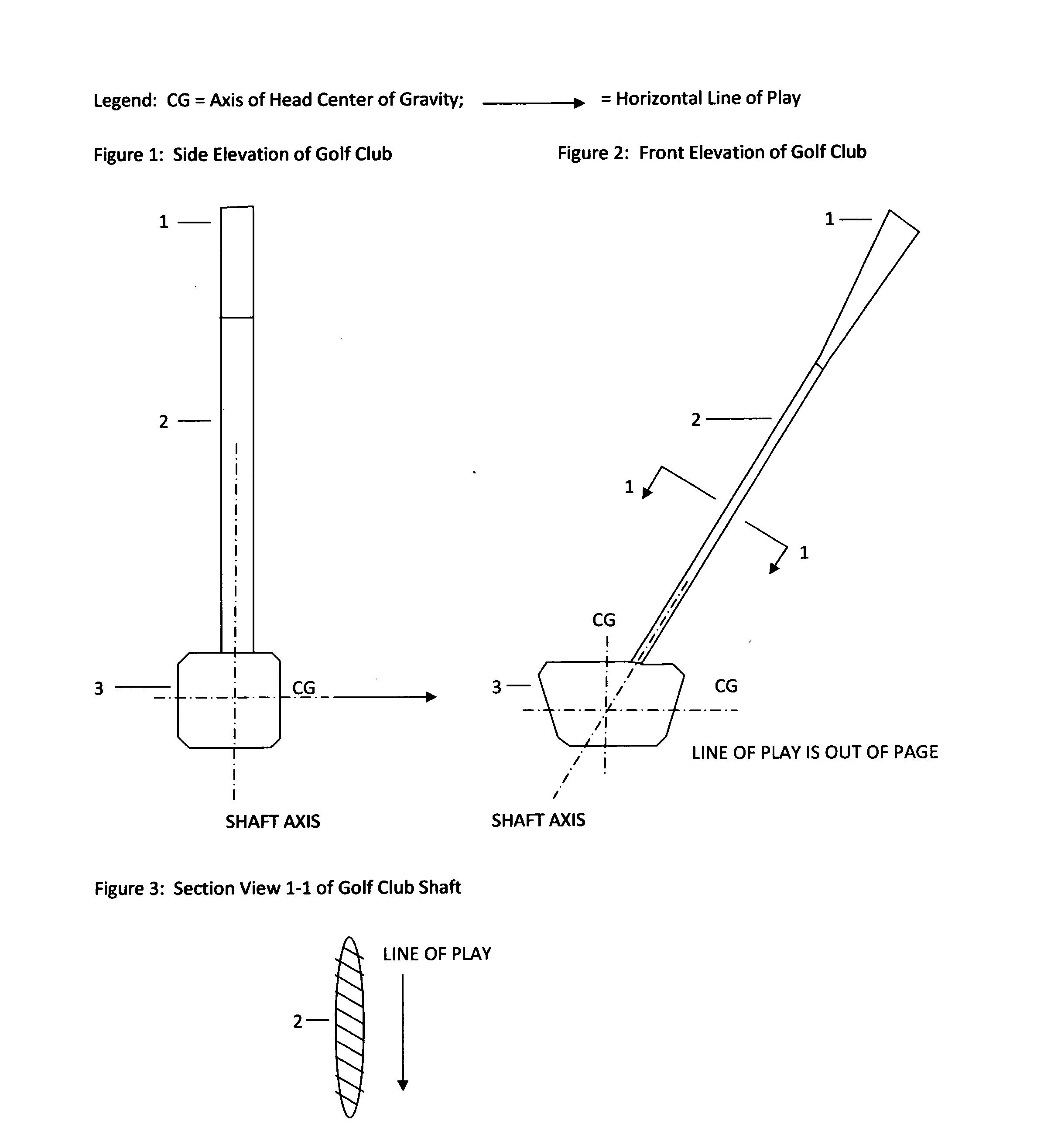

[0016]This invention is a new cross-section for a golf club shaft and a new configuration of shaft and head. This invention does not change the method of using the current golf club. Materials of construction are the same as current golf clubs. The methods of fabrication and assembly for the grip, 1 in FIG. 1 and FIG. 2, shaft, 2 in FIG. 1, FIG. 2, and FIG. 3, and head, 3 in FIG. 1 and FIG. 2, can be achieved with conventional manufacturing processes.

[0017]This invention is a gulf club shaft of typical length that has a reduced width transverse to the direction of motion and a greater depth parallel to the direction of motion. The club shaft therefore has a reduced frontal area that creates less aerodynamic drag, permits higher head velocity on impact, greater momentum transfer to the ball, higher ball velocity, and longer drives of the golf ball then current clubs that have symmetrical cone shaped shafts. The invented shaft cross-section provides higher resistance to bending away f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com