An engraving robot with self-turning function

A robot and self-turning technology, applied in the field of intelligent engraving, can solve the problems of unoptimized engraving efficiency and complicated and lengthy engraving process, achieve excellent self-locking performance, improve engraving efficiency, and ensure compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

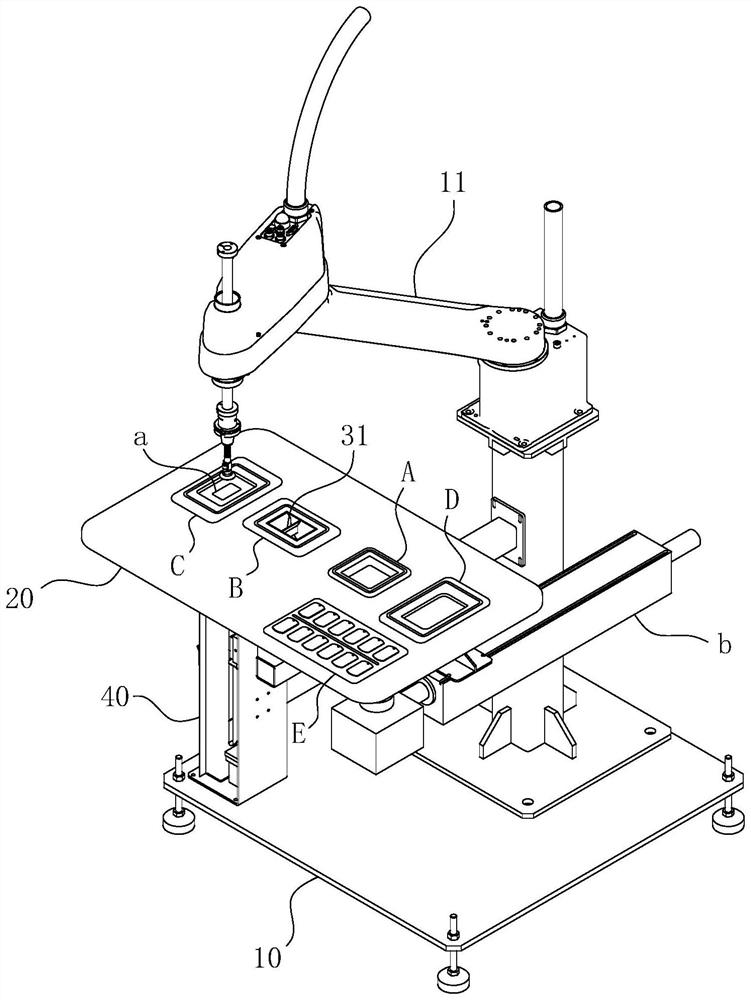

[0042] For ease of understanding, combined here Figure 1-8 , the concrete structure and working mode of the present invention are further described as follows:

[0043] The specific structure of the present invention is as Figure 1-7 As shown, its main structure includes a base 10 and a work surface 20 on the base 10 . Similar to traditional engraving robots, an engraving area A for engraving is provided on the worktable 20; figure 1 Shown is a schematic diagram of an embodiment when laser engraving is used. It can be clearly seen that the engraving area A is a laser engraving table, so the laser b is arranged below the engraving area A, so as to cooperate with the engraving robot 11 to achieve the purpose of online engraving of the engraving piece.

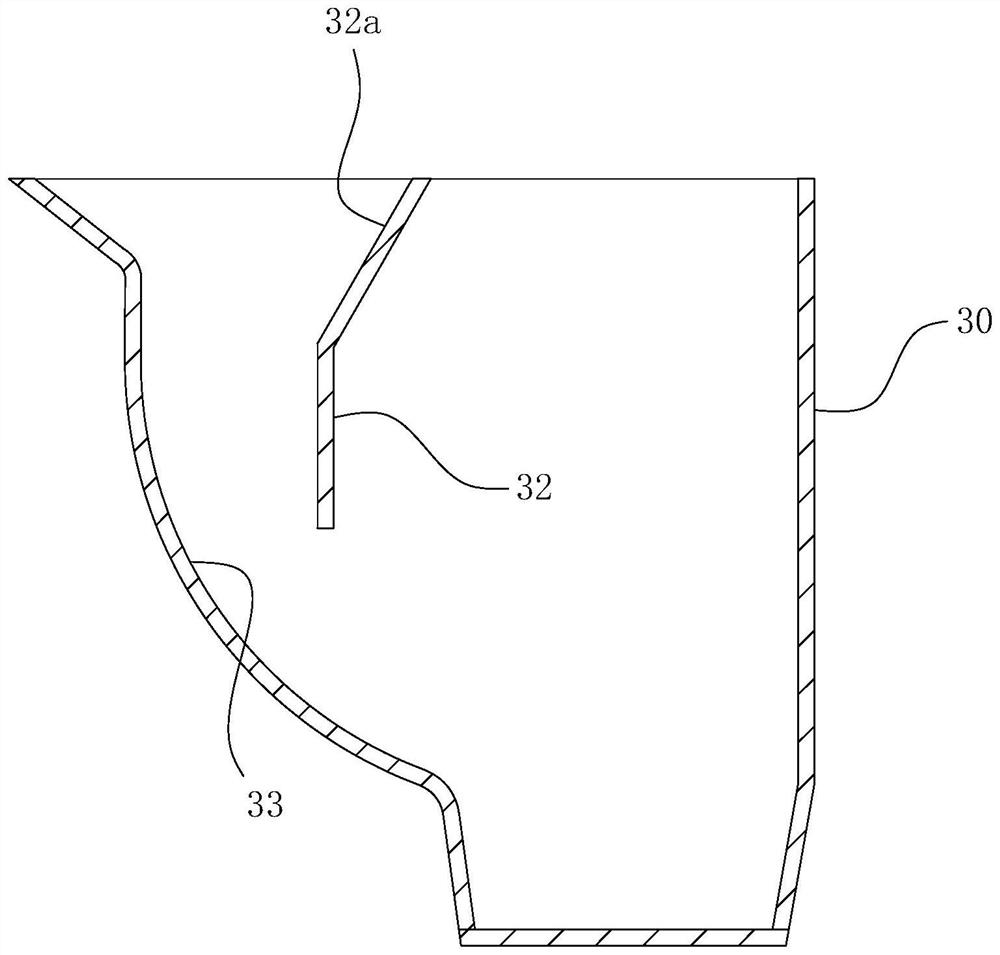

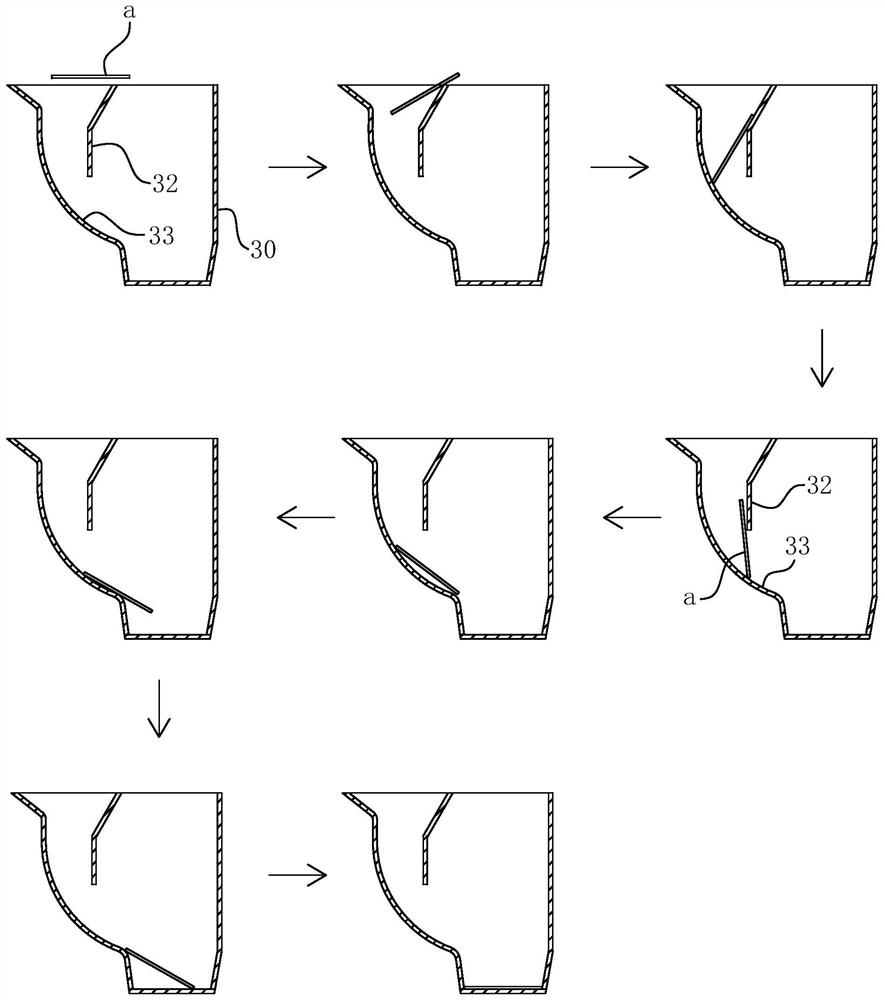

[0044] On the basis of the above structure, on the one hand, the present invention increases the turning material opening 31, thereby utilizing the structure of the unique material turning surface 33 in the material turning cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com