Fire extinguishing bottle with position-adjustable external connector

A technology for external interface and fire extinguisher, which is applied in the field of fire extinguisher and interface structure, can solve the problems of inconvenient assembly and connection, and achieve the effect of ensuring consistency, density and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

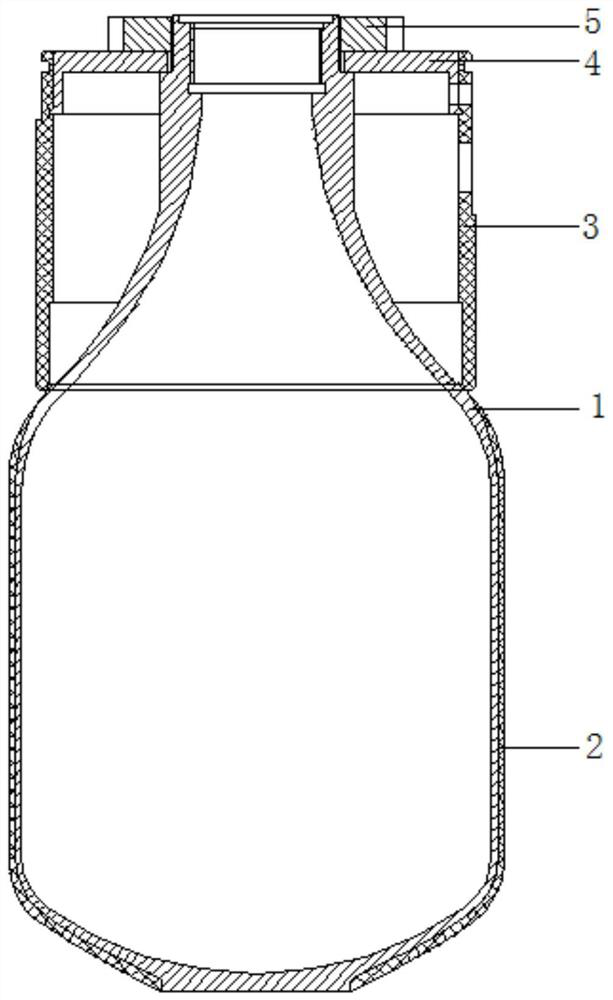

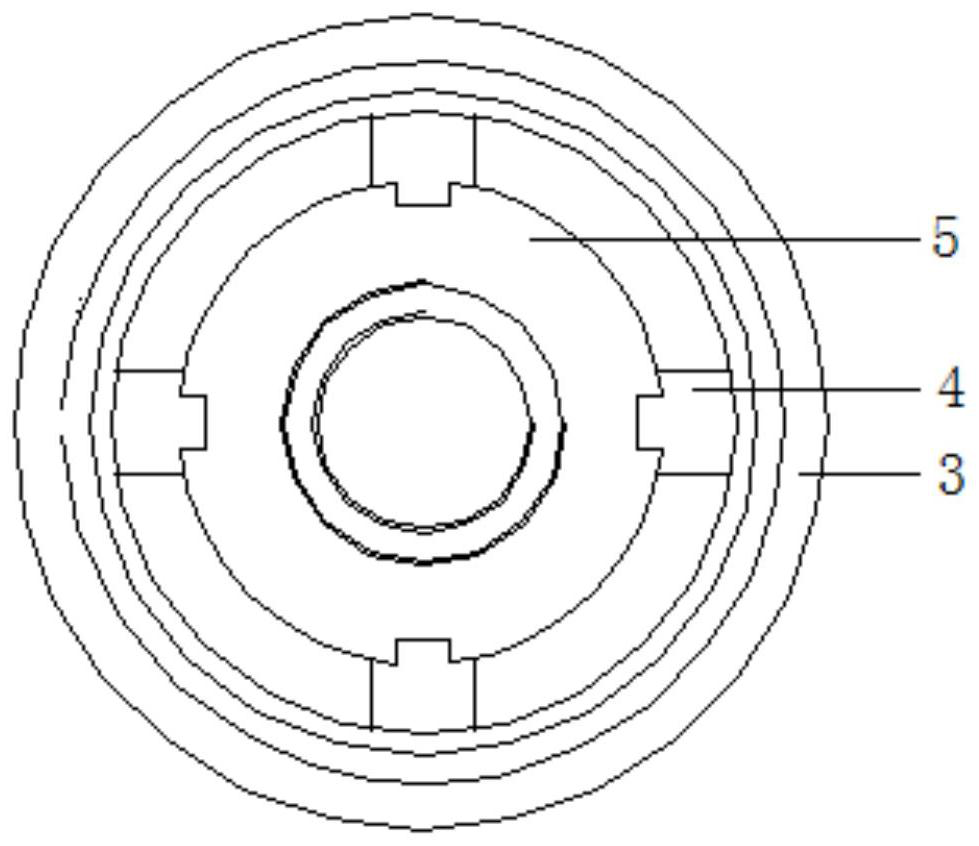

[0021] as attached figure 1 As shown, the present invention provides a fire extinguishing bottle with an adjustable external connection position. The fire extinguishing bottle includes a bottle liner 1 , a fiber layer 2 , a connecting sleeve and a locking nut 5 .

[0022] Wherein, the connecting sleeve is composed of a body 3 and a top cover 4, the body 3 is a cylindrical structure of equal diameter, and the inner hole at one end is processed with an internal thread segment;

[0023] The top cover 4 is a circular cover with a planar structure, and its surface is a cross-shaped hollow structure. The center of the hollow structure is a central hole. The external thread section is processed on the outer circumferential surface, and the external thread is used to match the internal thread of the connecting sleeve;

[0024] The outer surface of the bottle lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com