T-shaped piston rod processing positioning device

A positioning device and piston rod technology, applied in auxiliary devices, metal processing equipment, manufacturing tools, etc., can solve the problems of increased processing costs, low production efficiency, waste of manpower and material resources, etc., to reduce subsequent steps, improve work efficiency, prevent swaying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

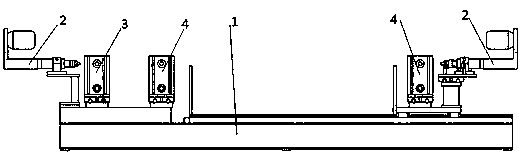

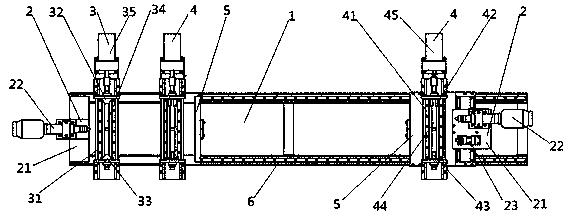

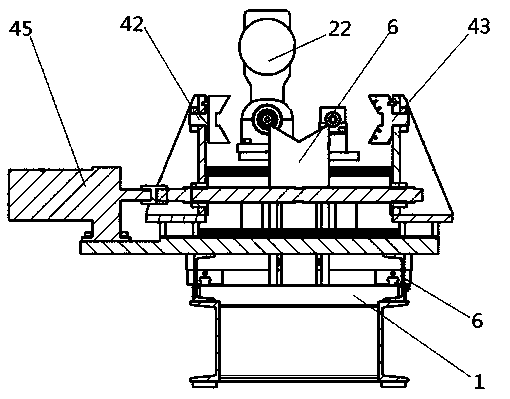

[0023] Such as figure 1 , figure 2 , image 3 As shown, the T-shaped piston rod processing and positioning device of the present invention is characterized in that it includes a base 1, the base 1 is a rectangular base, and the left and right sides of the upper part of the base 1 are symmetrically provided with a rod end positioning mechanism 2, sequentially from left to right A lug positioning mechanism 3 and a shaft positioning mechanism 4 are provided; the lug positioning mechanism 3 includes a lug positioning seat 31, a front top 32 and a rear top 33, and the lug positioning seat 31 is symmetrically provided with a front top 32 and a rear top 33 , a first lead screw 34 is arranged between the front top 32 and the rear top 33, one end of the first lead screw 34 is threadedly connected to the lower part of the front top 32, the other end is threaded to the lower part of the rear top 33, and one end of the first lead screw 34 is connected and set Lug positioning motor 35 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com