Additive for increasing low temperature reduction pulverization ratio of sintering ore and preparation method of additive

A technology for additives and sintered ore, applied in the field of iron and steel metallurgy sintering, can solve problems such as poor low-temperature reduction and pulverization indicators, and achieve the effects of reducing the low-temperature reduction and pulverization rate and improving the performance of low-temperature reduction and pulverization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples.

[0020] An additive for improving the pulverization rate of sintered ore at low temperature reduction, the weight percentage of its composition is: CaO 30-32%, SiO 2 2~4%, MgO 15~25%, MnO 2 , V 2 o 5 、TiO 2 The sum of the components is 0.7-1.0%, and the rest is burning loss and unavoidable impurities. Additives with a particle size of less than 1.0mm account for more than 95% of the total, and additives with a particle size of less than 0.5mm account for 75% of the total. %, and additives with a particle size less than 0.1mm accounted for more than 20% of the total.

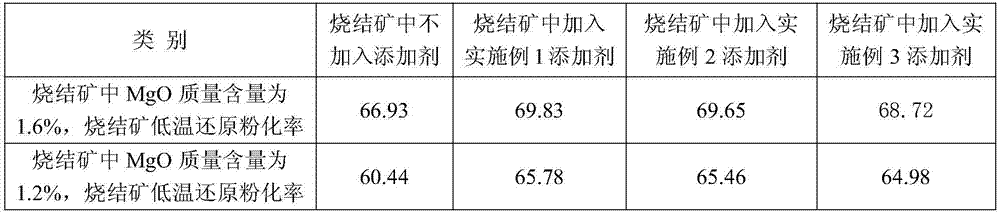

[0021] Table 1 is the composition (by weight percentage) of the additive of the embodiment of the present invention, and the balance is burning loss and unavoidable impurities.

[0022] Table 1 Components of additives in the examples of the present invention, unit: weight percent.

[0023] Classific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com