Method for restraining low temperature reduction pulverization of fluorine-containing magnet agglomerate

A technology of magnet sintering and sintering, which is applied in the field of iron and steel smelting, can solve the problems of high cost, achieve low cost, reduce hazards, and improve the effect of low-temperature reduction pulverization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

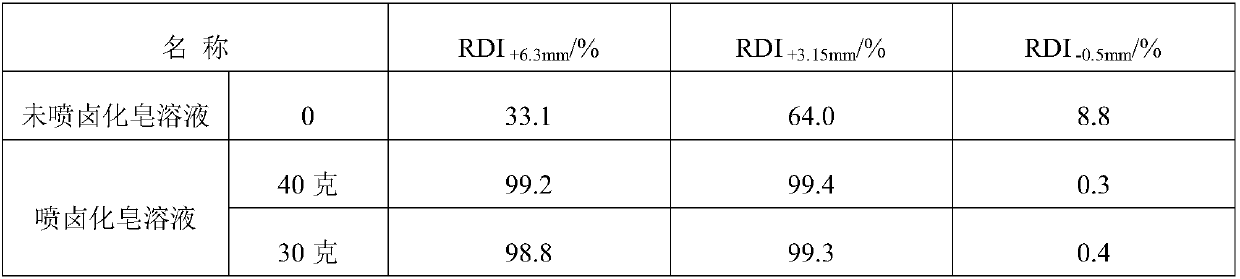

[0029] Select the sintered ore sample of the finished fluorine-containing magnet, crush the sintered ore sample to a particle size of 10.0-12.5mm, and dry it at a temperature of 100±5°C for 2 hours.

[0030] Reconstitution of halogenated soaps out of CaCl 2 The mass fraction is 3% solution, weighs two parts of sintered ore samples of 500 ± 0.5 grams, and sprays 30 grams of 3% halogenated soap solution for every 500 grams of sintered ore (equivalent to spraying 3% per ton of sintered ore 60 kilograms of halogenated soap solution) and 40 grams (equivalent to 80 kilograms of 3% halogenated soap solution sprayed per ton of sinter), put the sprayed sample into an oven, and dry it at a temperature of 100 ± 5°C.

[0031] Select the fluorine-containing magnetite sintered ore that has not been sprayed and sprayed with halogenated soap solution according to the method of this embodiment to detect the pulverization performance of low-temperature reduction, and the detection method is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com