Injection molding method for super-thick transparent bi-color cladding piece

A technology of injection molding and covering parts, which is applied in the field of injection molding of super-thick transparent two-color covering parts, can solve the problems of sink marks, difficult product optimization and process design, and bubbles are easy to appear in super-thick parts, so as to achieve simple shape and ensure the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

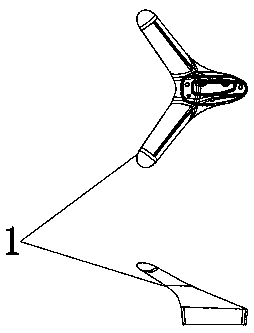

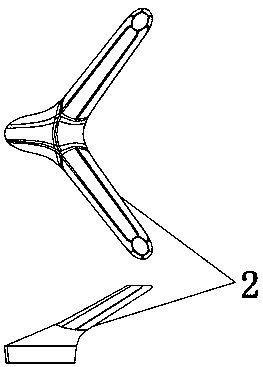

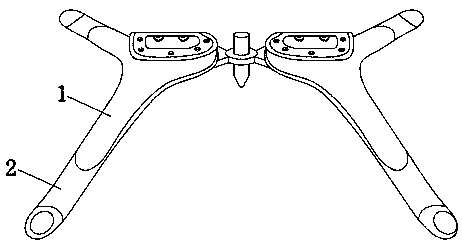

[0031] Embodiment 1, with reference to Figure 1-3 , an injection molding method for an ultra-thick transparent two-color covering part, comprising the following steps;

[0032] Step 1. Injection molding of colored inner layer:

[0033] S1. Evenly mix the high-strength resin and the dye together to prepare a preset color, and add the mixed high-strength resin into the prefabricated mold. The colored inner layer 1 can be changed according to the prefabricated color required. pigment, and increase the R angle at the sharp corner of the far end of the coating to improve the fusion between the two layers. When the colored inner layer 1 is injection molded, the gate is placed in the middle of the bifurcation of the foot to ensure the two-color transparent system There is no shrinkage and no air bubbles in the thickest part of the piece;

[0034] S2. Using high temperature and high pressure injection molding, the injection temperature is controlled at 270°C, the injection pressure...

Embodiment 2

[0041] Embodiment 2, with reference to Figure 1-3 , an injection molding method for an ultra-thick transparent two-color covering part, comprising the following steps;

[0042] Step 1. Injection molding of colored inner layer:

[0043] S1. Evenly mix the high-strength resin and the dye together to prepare a preset color, and add the mixed high-strength resin into the prefabricated mold. The colored inner layer 1 can be changed according to the prefabricated color required. pigment, and increase the R angle at the sharp corner of the far end of the coating to improve the fusion between the two layers. When the colored inner layer 1 is injection molded, the gate is placed in the middle of the bifurcation of the foot to ensure the two-color transparent system There is no shrinkage and no air bubbles in the thickest part of the piece;

[0044] S2. Using high temperature and high pressure injection molding, the injection temperature is controlled at 270°C, the injection pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com