End cover pipe opening rolling matching device

A rolling fit and nozzle technology, which is applied in the field of automated assembly equipment for assembly lines, can solve problems such as labor consumption, production line delays, and increased production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

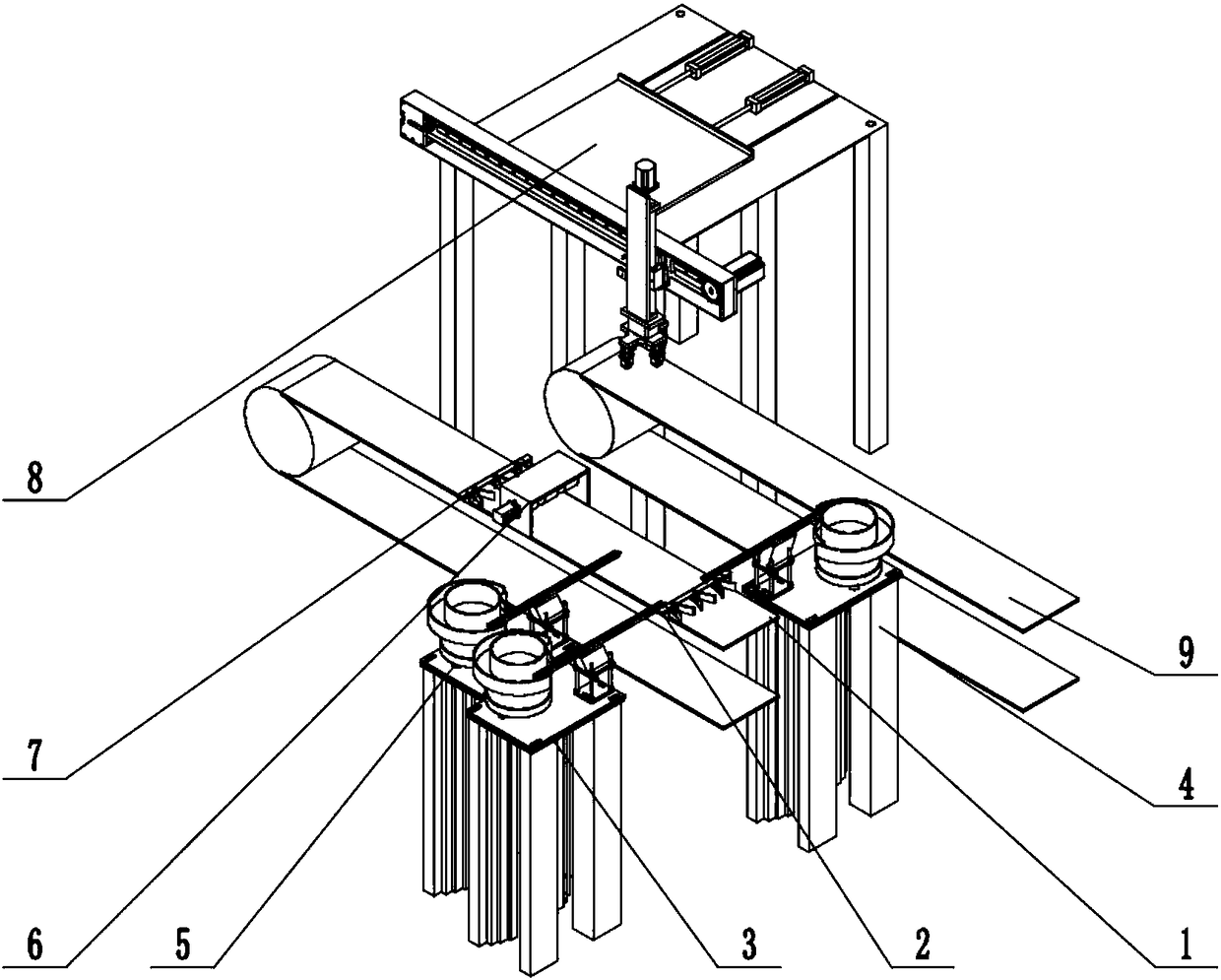

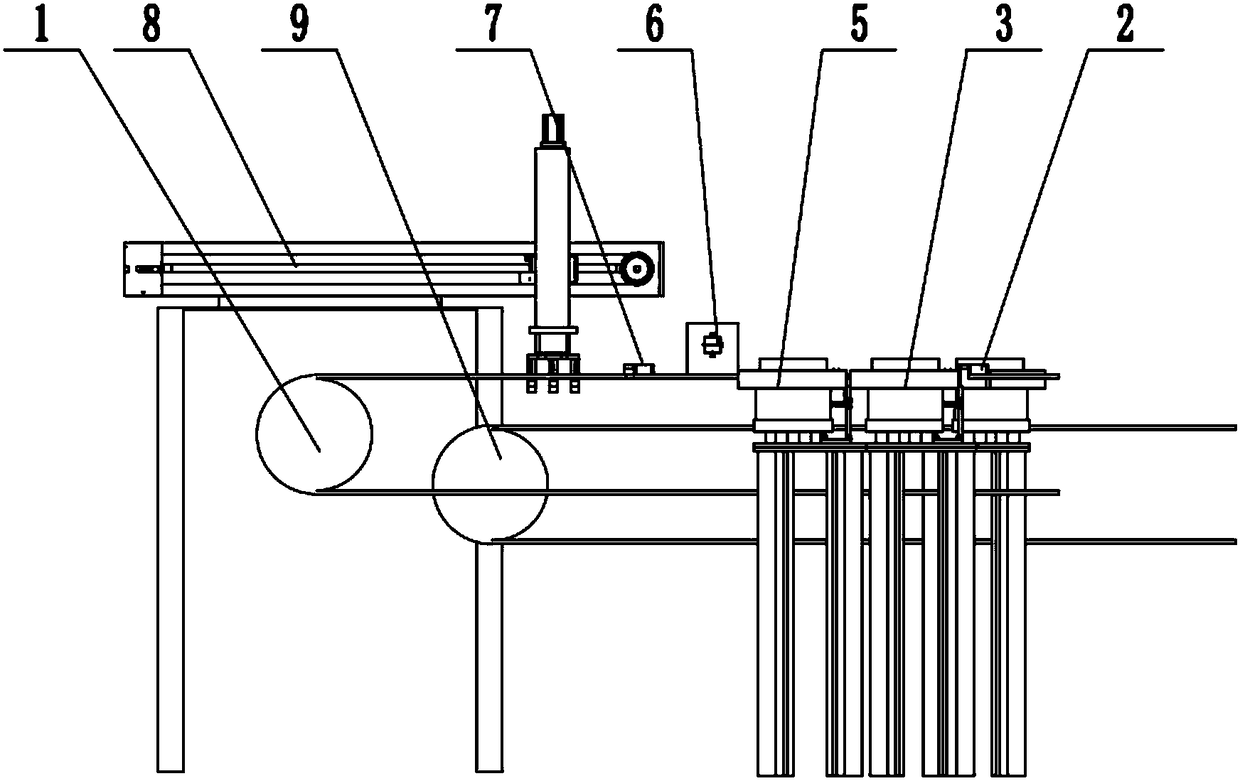

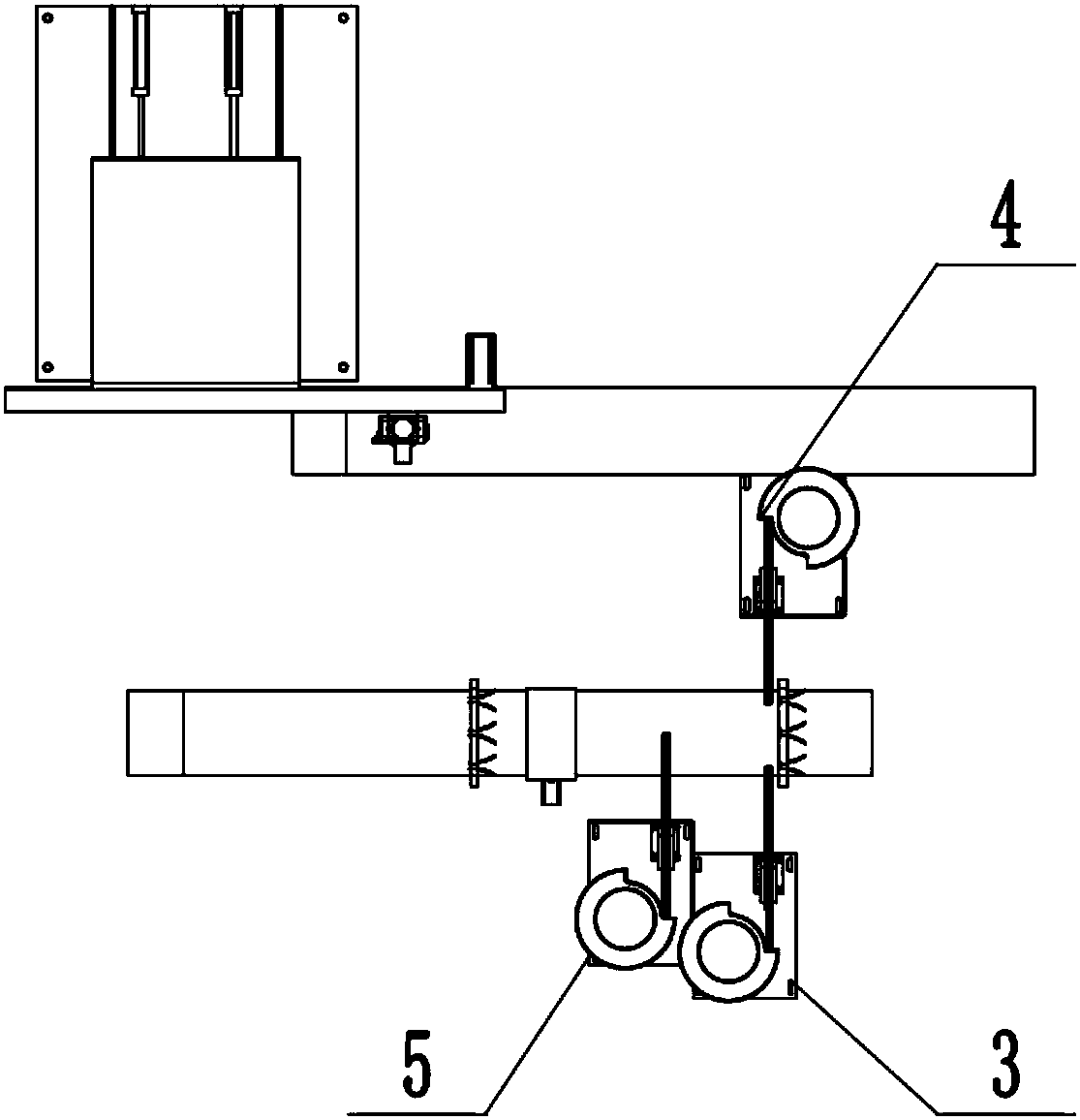

[0029]A rolling fitting device for the end cap nozzle, which is composed of 1 first conveyor belt, 2 front alignment mechanism, 3 left feeding mechanism, 4 right feeding mechanism, 5 middle feeding mechanism, 6 rolling pressing mechanism, 7 rear alignment mechanism , 8 pick-up mechanism and 9 second conveyor belt, the 3 left feeding mechanism is composed of a feeding bracket 301, a bottom plate 302, a vibrating plate 303, a guide rail bracket 304, a guide rail 305 and a front matching structure 306. The front matching structure 306 is composed of a matching seat 3061, a connecting piece 3062, a discharge support 3063, a discharge roller 3064, a rolling stepper motor 3065, a photoelectric switch support 3066, a telescopic cylinder 3067, and a cylinder slide rail sleeve 3068 , cylinder slide rail 3069, cylinder grip 30610, telescopic cylinder support 30611 and photoelectric switch 30612, the described pick-up mechanism 8 is made up of pick-up mechanism support 801, push-pull cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com