Processing method for piston rod assembly

A processing method and piston rod technology, which is applied in the processing field of piston rod components, can solve problems such as overall grinding, long length, and great influence on success or failure, and achieve the effect of ensuring concentricity and torque requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

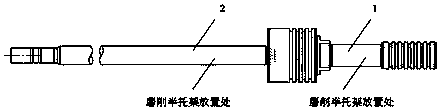

[0095] based on the following Figure 1 to Figure 5 , specifically explain the preferred embodiment of the present invention.

[0096] The invention provides a method for processing a piston rod assembly, the method comprising the following steps:

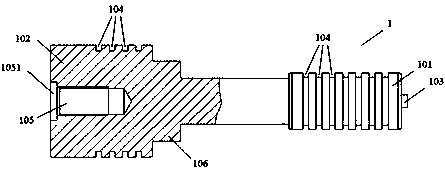

[0097] Such as figure 1 As shown, step 1, piston processing;

[0098] Step 1.1, several car processing;

[0099] Use CK7525 CNC machine tool for processing;

[0100] Step 1.1.1, the CNC machine tool first clamps the large end 102 of the piston, the calibration circle is ≤0.02, and after the end face of the small end 101 is removed by turning 2 mm, 90° thimbles are punched on the two ends of the large end 102 and the small end 101 Holes 103, one clip and one top, the ring groove 104 and the outer circle of the small end 101 of the car;

[0101] Step 1.1.2, turn the raw material over, turn around and clamp the small end 101, remove the end face of the large end 102 by 2 mm, control the total length of the piston, and complete th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com