Locking disc spring for pipeline joint

A technology of pipe joints and disc springs, which is applied in the field of locking disc springs, can solve problems such as unclamping, failure of disc spring elastic properties, and joint flying out, so that it is not easy to be disengaged under pressure, well fixed and sealed, and secure The effect of concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below with reference to the embodiments in the accompanying drawings.

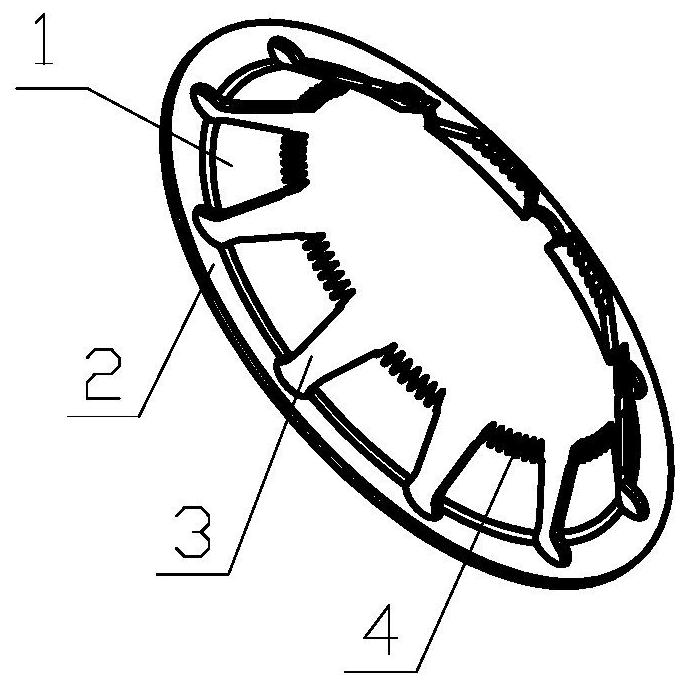

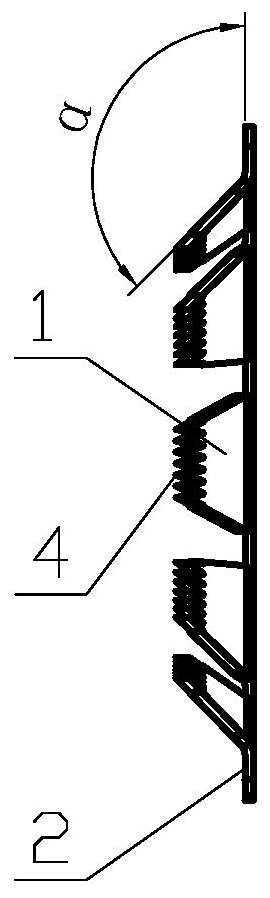

[0035] like figure 1 As shown in / 2, the first embodiment of the locking disc spring for pipe joints of the present invention has a circular positioning edge 2, and the inner side of the positioning edge 2 has a plurality of locking toothed discs extending toward the center Plate 1, the head of each locking toothed disc 1 has sharp teeth 4, a number of locking toothed discs 1 form a conical arrangement, and a disc is formed between two adjacent locking toothed discs 1 The angle α between the slot 3, the positioning edge 2 and the locking toothed disc 1 is 135°.

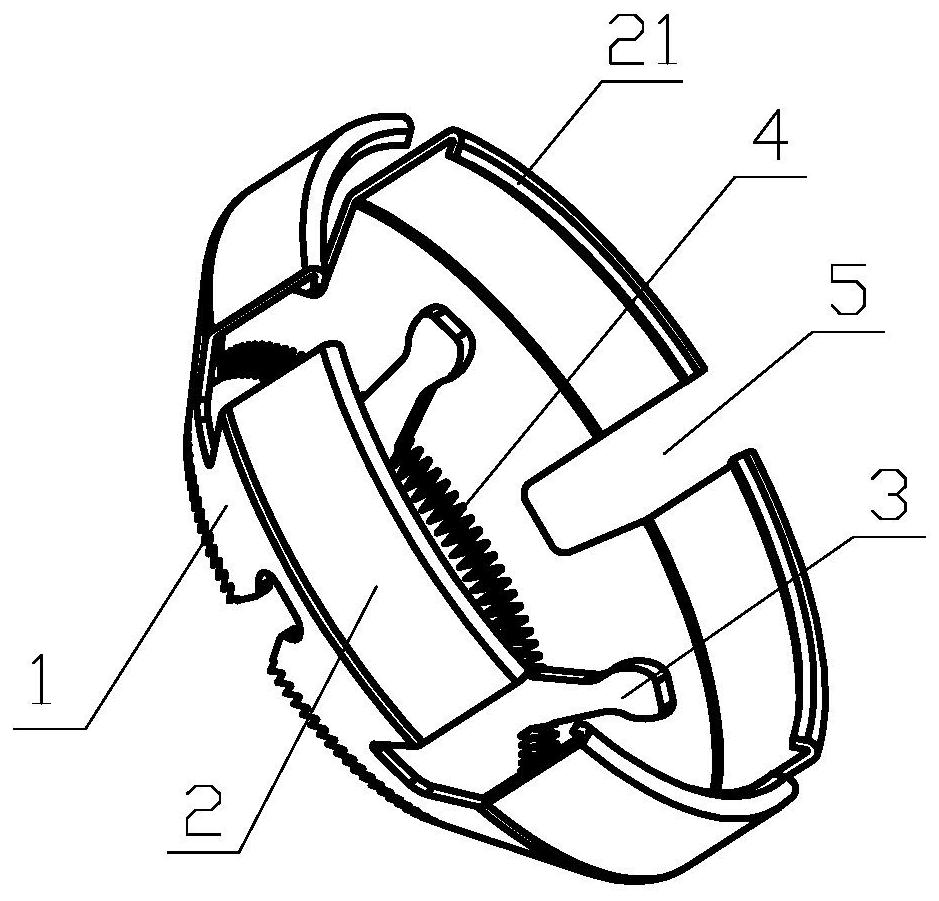

[0036] like image 3 As shown in / 4, the second embodiment of the locking disc spring for pipe joints according to the present invention, the disc spring has a cylindrical annular positioning edge 2, and the inner side of the positioning edge 2 has a plurality of locking toothed di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com