Method for acquiring bainite complex phase tissue with workpieces with different cross section thicknesses

A bainite and workpiece technology is applied in the field of obtaining bainite complex structure for workpieces with different cross-sectional thicknesses, which can solve the problem that the production process and environmental protection pressure are only suitable for small batch production, and achieve strong product performance, simple process and wide range. The effect of applying the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

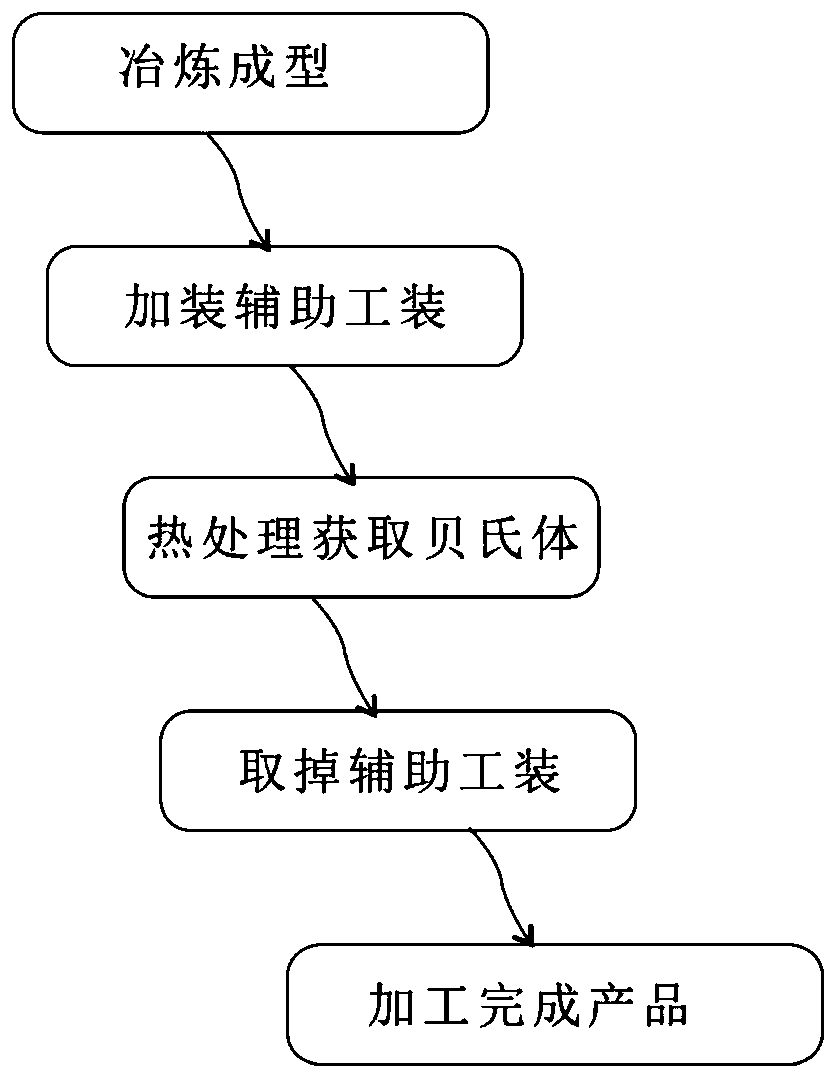

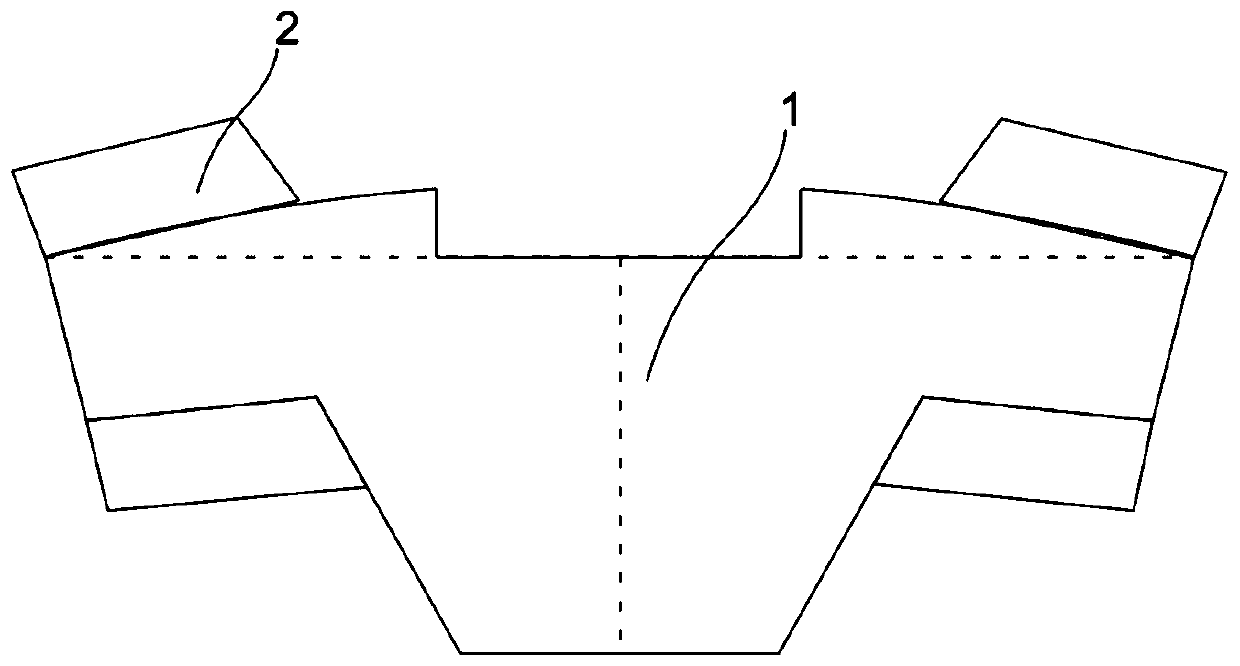

[0037] Example 1: Such as figure 1 , 2 As shown, this implementation takes the conventional technology used in the semi-self-grinding liner, and the semi-self-grinding T-type liner is taken as an example. The lower part of the liner is the lifting surface, which is responsible for lifting the ore and steel balls with high strength and good scratch resistance. The diameter of the cross section is about 350 mm. The higher the actual requirement, the better. The upper part belongs to the installation surface and the working surface. The working surface is responsible for the high impact wear resistance of mines and steel balls. The higher the toughness, the better. The diameter of the section is about 100 mm. The actual toughness is the better. The organization of the product requires the bainite complex structure. The specific processing flow is as follows: using conventional quenching water or oil or air cooling or quenching medium for quenching, the bottom section is 350 mm thi...

Embodiment 2

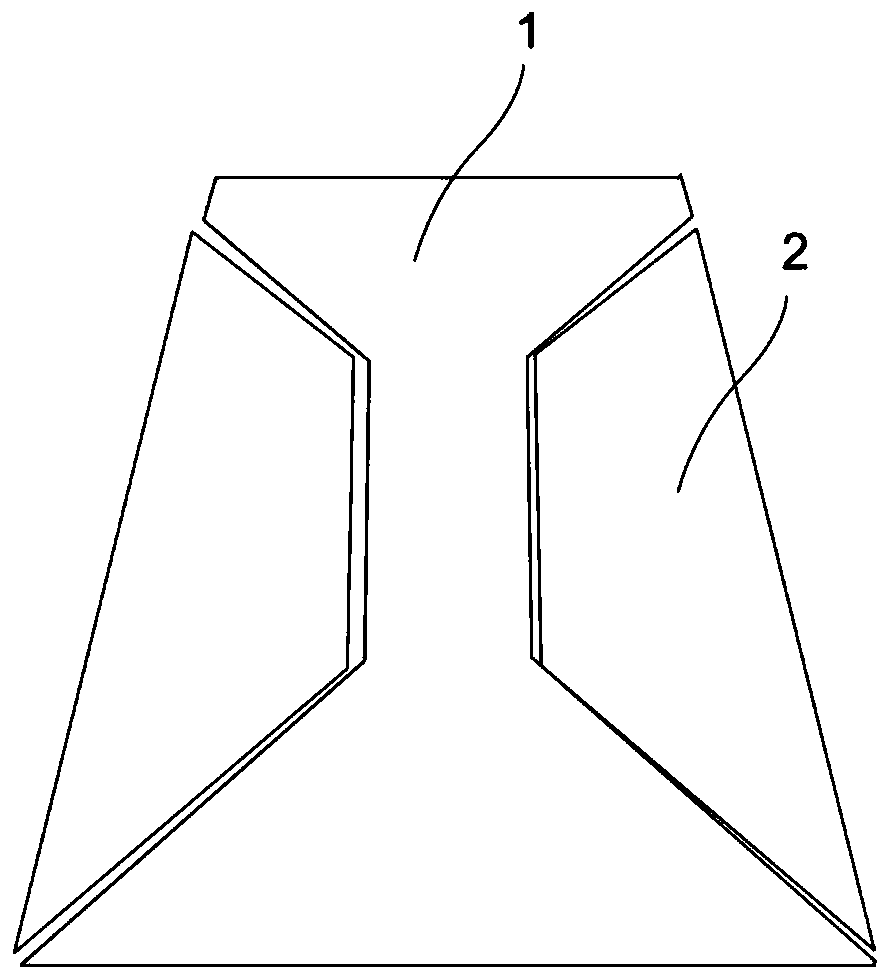

[0047] Such as figure 1 , 3 Shown: This embodiment takes the steel rail structure as an example. First, the material is formed; then the thinner part is installed with auxiliary tooling so that the thickness of the thinner part is basically the same as the thicker one, and then the steel rail with the auxiliary tooling The structure is put into the quenching process, when the temperature enters the bainite temperature, isothermal or slow cooling is performed, and most of the bainite complex structure is obtained and then slowly cooled to room temperature, then taken out, and the auxiliary tooling is removed to complete the production process of the rail.

[0048] Then compare the product with the existing rail structure and test as follows:

[0049]

[0050] It can be seen that the rail structure obtained by the method of this embodiment has higher strength and better toughness than the existing rail structure, so that the service life of the rail structure is longer. The applicati...

Embodiment 3

[0052] Such as figure 1 , 4 Shown: In this embodiment, the wheel structure is taken as an example. First, the material is annealed and then rough-processed and formed, leaving a small amount of finishing dimensions; then, auxiliary tooling is installed on the thinner part to make the thickness of the thinner part equal to The thicker one is basically the same, and then the wheel structure with the auxiliary tooling is mist-cooled. When the temperature enters the bainite temperature, it is isothermally cooled to room temperature for about 40 minutes, and then taken out. The auxiliary tooling is removed and then finished to complete the Processing of wheel structure.

[0053] Then compare the product with the existing wheel structure and test as follows:

[0054]

[0055] It can be seen that, compared with the existing wheel structure, the wheel structure obtained by the method of this embodiment has higher strength and better toughness in the middle part, which makes the service lif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com