Bridge crane reduction gearbox with intelligent monitoring function

A technology of intelligent monitoring and reduction gearboxes, applied in mechanical equipment, load suspension components, transmission parts, etc., can solve the problem that the reduction gearbox does not have intelligent monitoring, etc., to ensure safety and reliability, easy to view, and ensure completeness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

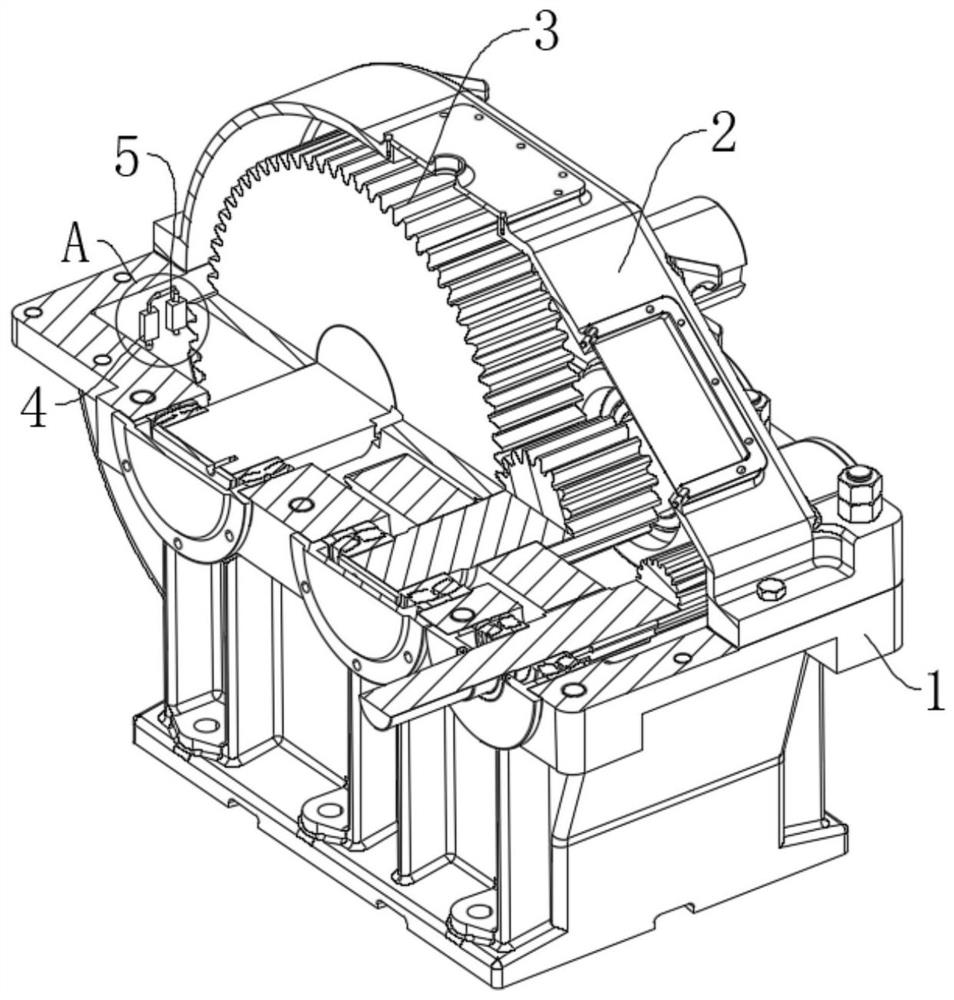

[0023] Such as figure 1 The shown bridge crane reduction box with intelligent monitoring includes a box body 1, a box cover 2 and a speed reduction mechanism 3; the speed reduction mechanism 3 is movably arranged inside the box body 1, and the box cover 2 is fastened on the upper end of the box body 1;

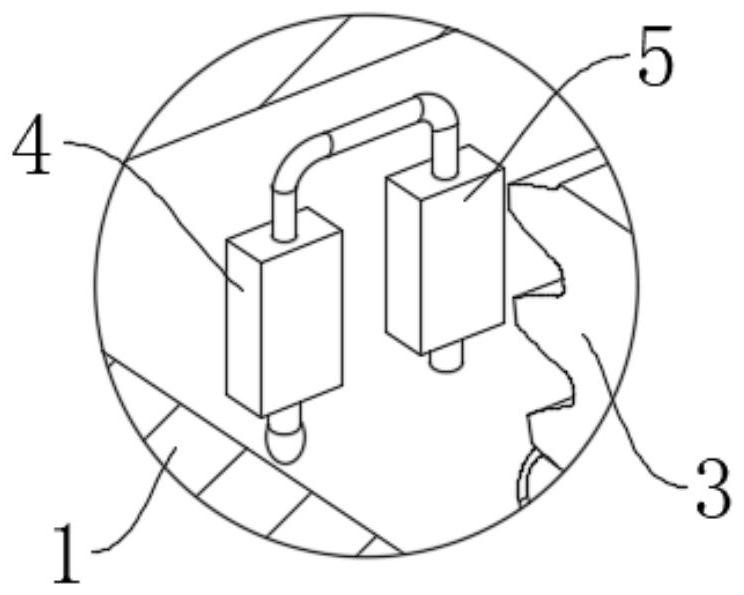

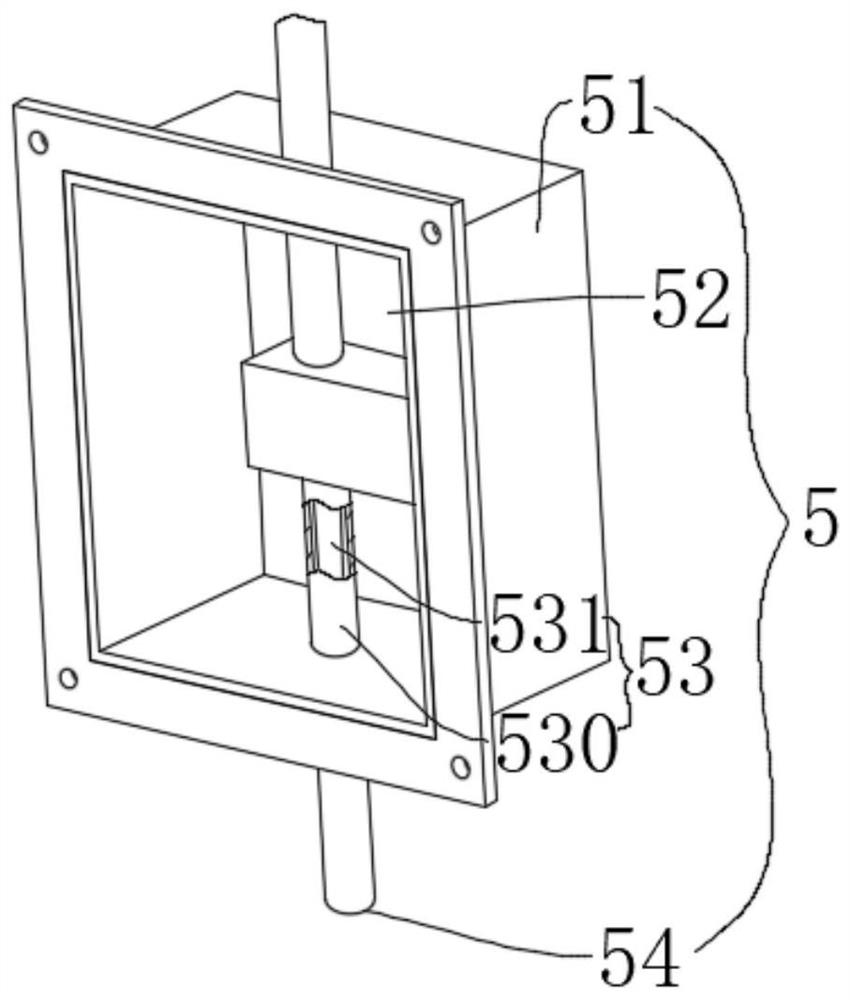

[0024] Among them, the bridge crane gearbox also includes monitoring components, such as figure 2 As shown, the monitoring component is composed of an oil collection device 5, a detection and analysis device 4, and a video unit, which are used to monitor the operation inside the box and the overall operation of the bridge crane itself in real time, so as to ensure the safety of the bridge crane during use. performance and reliability, the oil collection device 5 and the detection and analysis device 4 are built in the inside of the box 1, and the oil collection device 5 and the detection and analysis device 4 are all compatible with the video The unit signal is connected, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com