Design method of control simulation disc, and control simulation disc

A technology for controlling simulation and design methods, applied in nuclear reactor monitoring, reactors, nuclear power generation, etc., can solve problems such as poor identification, unfavorable monitoring, and difficult monitoring, and achieve the goal of overcoming single color indication, convenient operation and maintenance, and reducing The effect on production operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

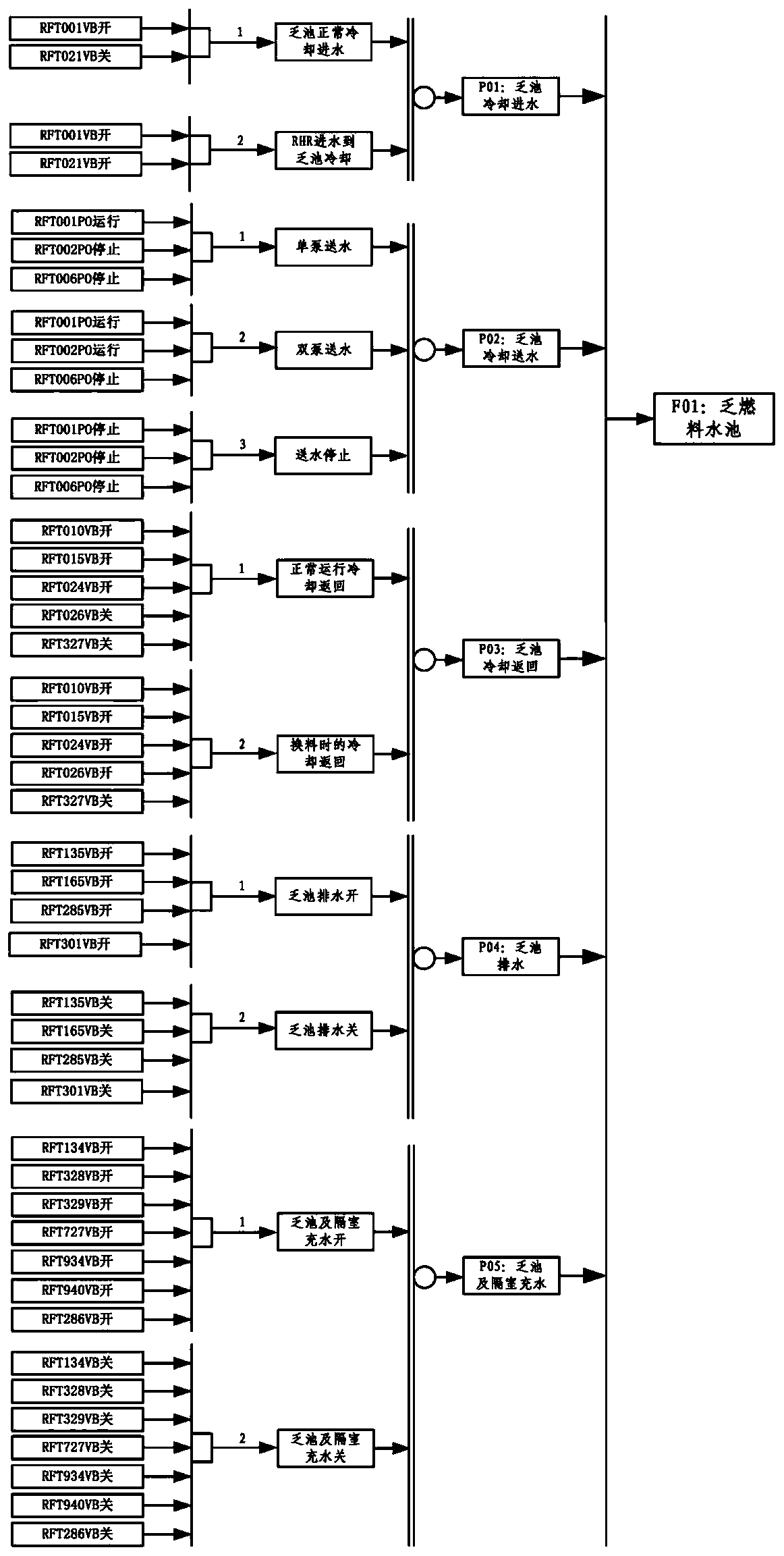

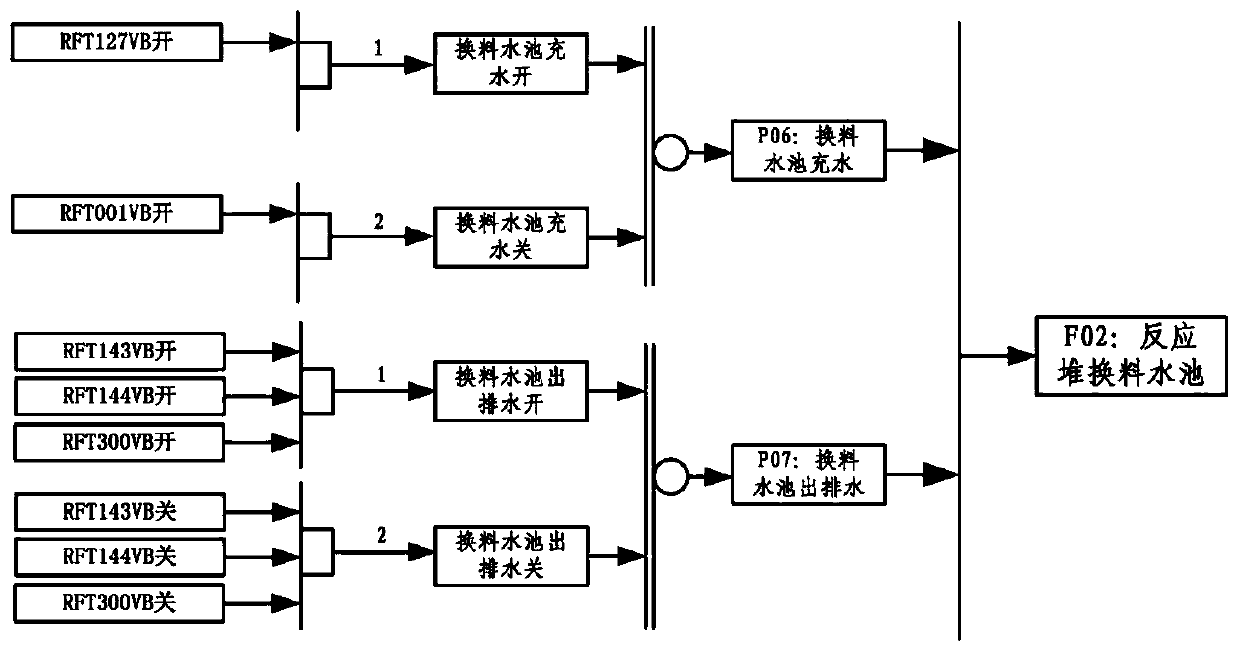

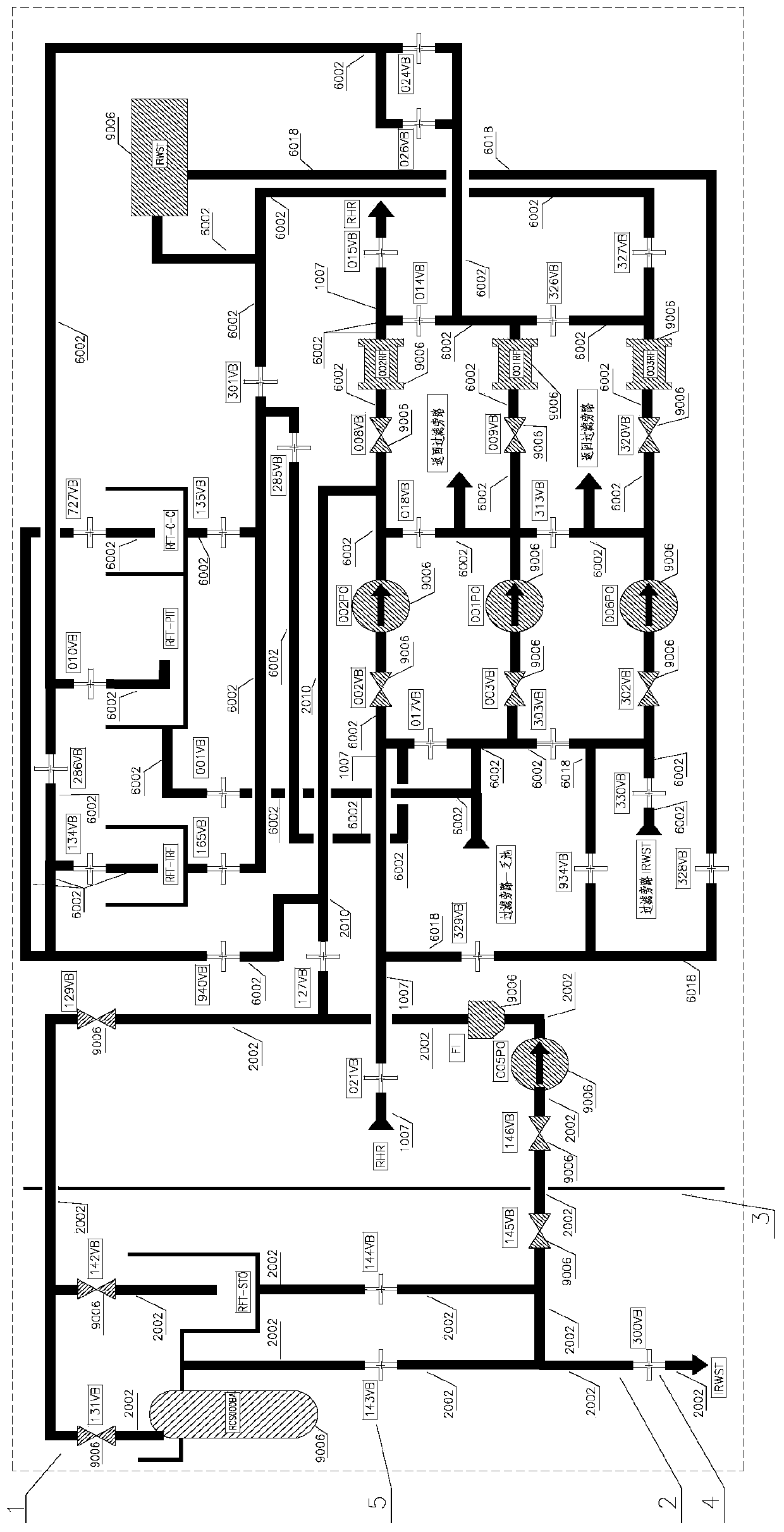

[0048] Such as figure 1 As shown, this embodiment provides a design method for controlling an analog disk, including the following steps:

[0049] S1, divide the functions of multiple fluid pipelines 2 on the panel 1 of the control simulation panel, so as to form multiple functional modules with different functions on the panel 1;

[0050] S2. Use color codes to mark the fluid pipelines 2, wherein the fluid pipelines 2 belonging to different functional modules use different color codes.

[0051] By using different color codes to identify the fluid pipelines 2 of different functional modules, the operator can intuitively distinguish the fluid pipelines 2 that perform different functions in the complex process system through different colors, so that the operator can according to Control the color identification of the fluid pipeline 2 on the simulation board to visually identify and grasp the actual production and operation conditions, and can clearly distinguish the actual si...

Embodiment 2

[0072] Such as figure 1 As shown, this embodiment provides a control simulation panel, including a panel 1, the panel 1 includes a plurality of functional modules with different functions, each functional module includes a plurality of fluid pipelines 2, and color codes are used for each fluid pipeline 2 To identify, and the fluid pipelines 2 in different functional modules adopt different color codes; in this embodiment, the fluid pipelines 2 with different functions on the control simulation panel 1 are marked with different color codes, and by directly marking the control simulation panel By identifying the fluid pipelines 2 with different color codes on the panel, you can directly know the execution status of each functional module in the production process from the control simulation panel, which is convenient for the operator to monitor the production process directly through the control simulation panel. ; At the same time, it also solves the problem that the control si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com