Punching device with thin film positioning function and laser hole cutting function

A laser cutting and thin film technology, applied in the field of sheet metal processing, can solve the problems of many burrs on the edge of the hole, cannot be adjusted in real time, and low punching quality, and achieve the effect of less punching burrs, precise positioning, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

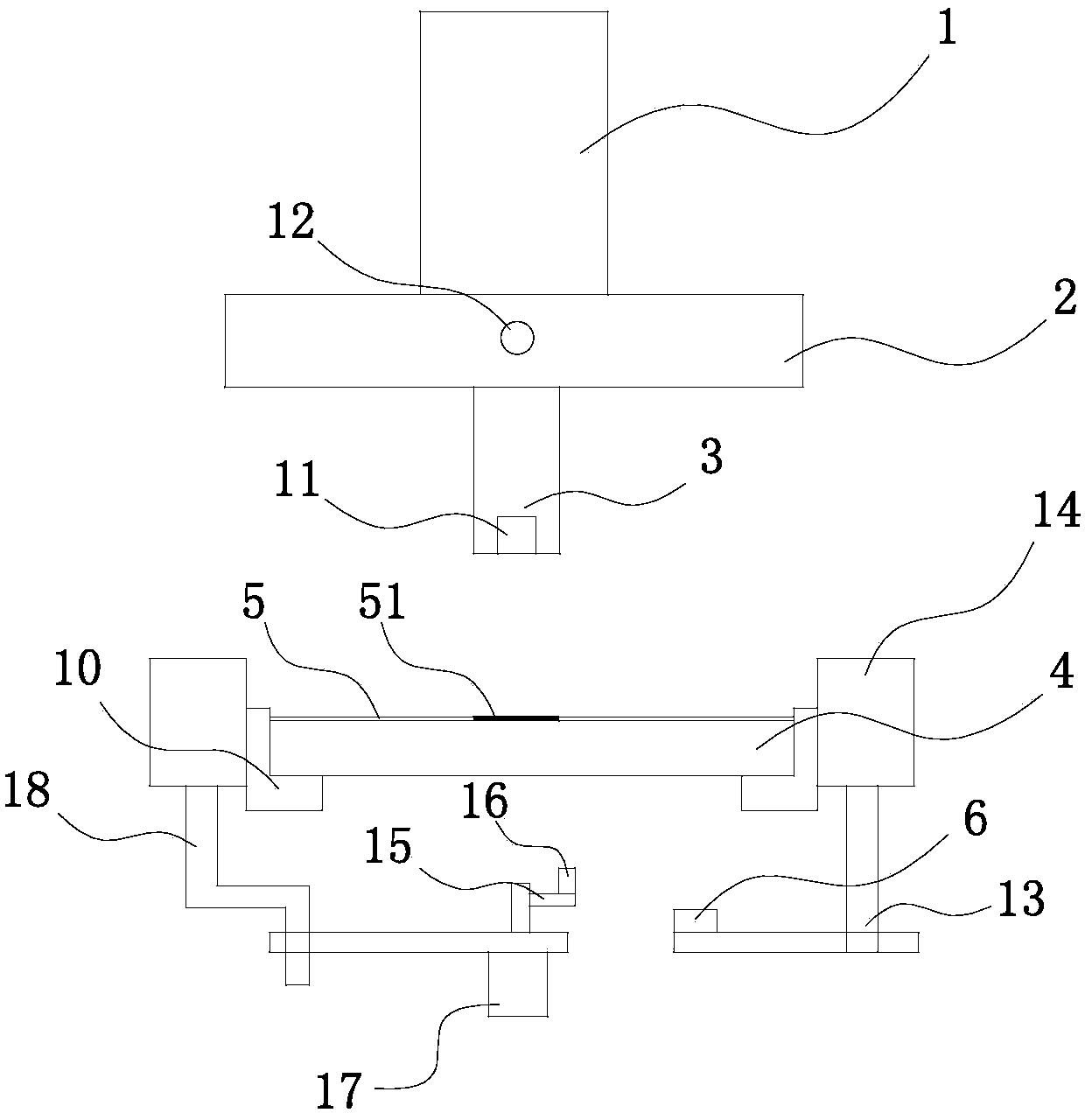

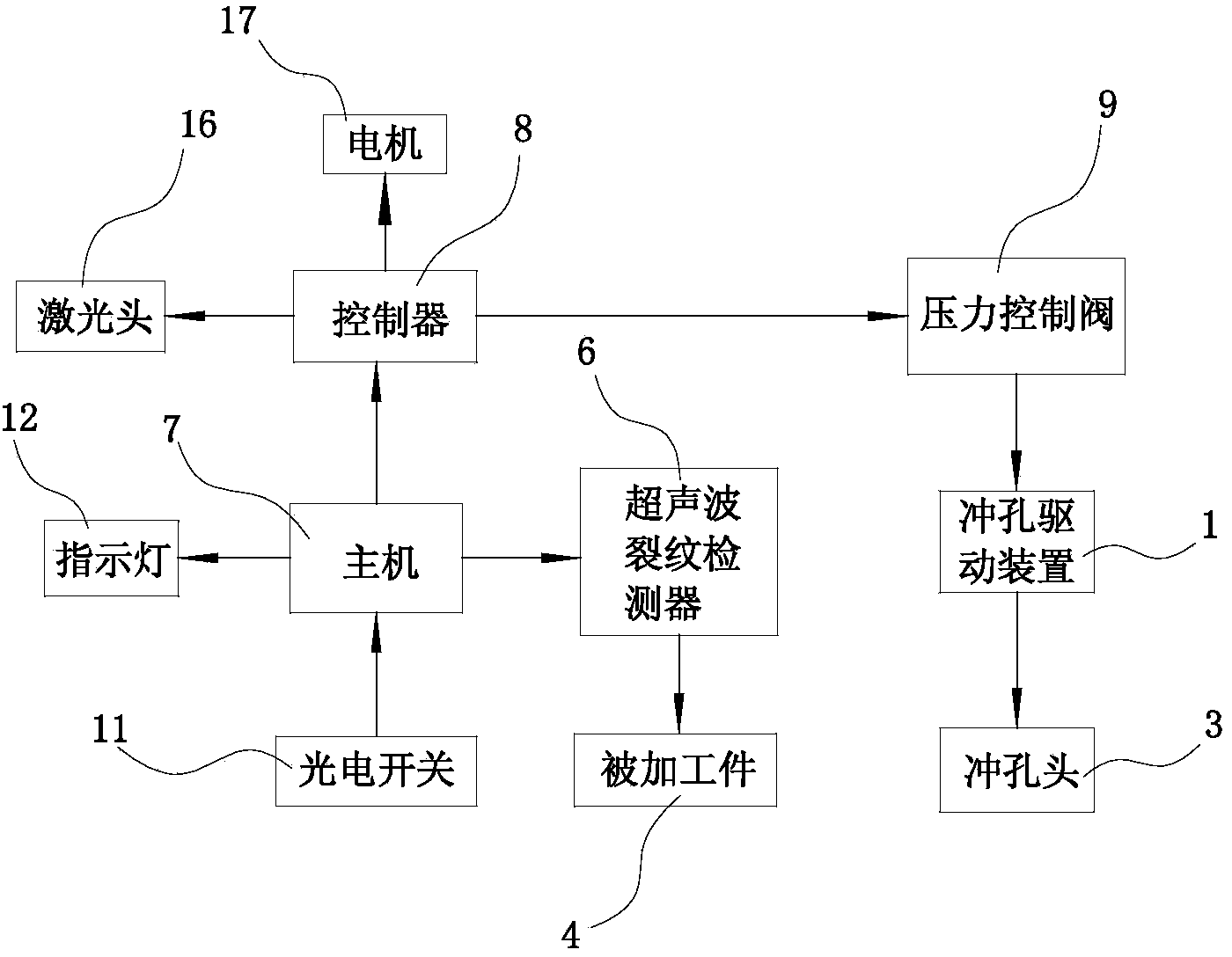

[0012] like figure 1 and figure 2 As shown, the punching device with film positioning and laser cutting in this embodiment includes a punching drive device 1, an upper template 2, a punching head 3, and a clamping device 10 located below the punching head 3. The workpiece 4 is installed in the device 10, and also includes a host computer 7, a controller 8, a pressure control valve 9 and an ultrasonic crack detector 6 located below the workpiece 4; the punching head 3 is equipped with a photoelectric switch 11, and the workpiece 4 Covered with a film 5, the film 5 has a color code 51 for photoelectric switch 11 detection; the clamping device 10 is installed on the support 14, and the lower surface side of the support 14 is equipped with an ultrasonic crack detector 6 by means of a connecting rod 13, and the other One side installs laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com