Composite hollow glass for building and preparation method thereof

A compound and hollow technology, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of affecting lighting effects, easy fogging of glass, and low sunlight transmittance of hollow glass, so as to improve light transmittance and avoid Unable to appreciate the outdoor scenery, the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

[0052] The problem solved by the composite insulating glass used in buildings in the embodiment of the present invention is that the sunlight transmittance of commonly used insulating glass is not high;

[0053] In order to solve the above technical problems, in one embodiment of the present invention, a composite insulating glass for buildings is provided, including:

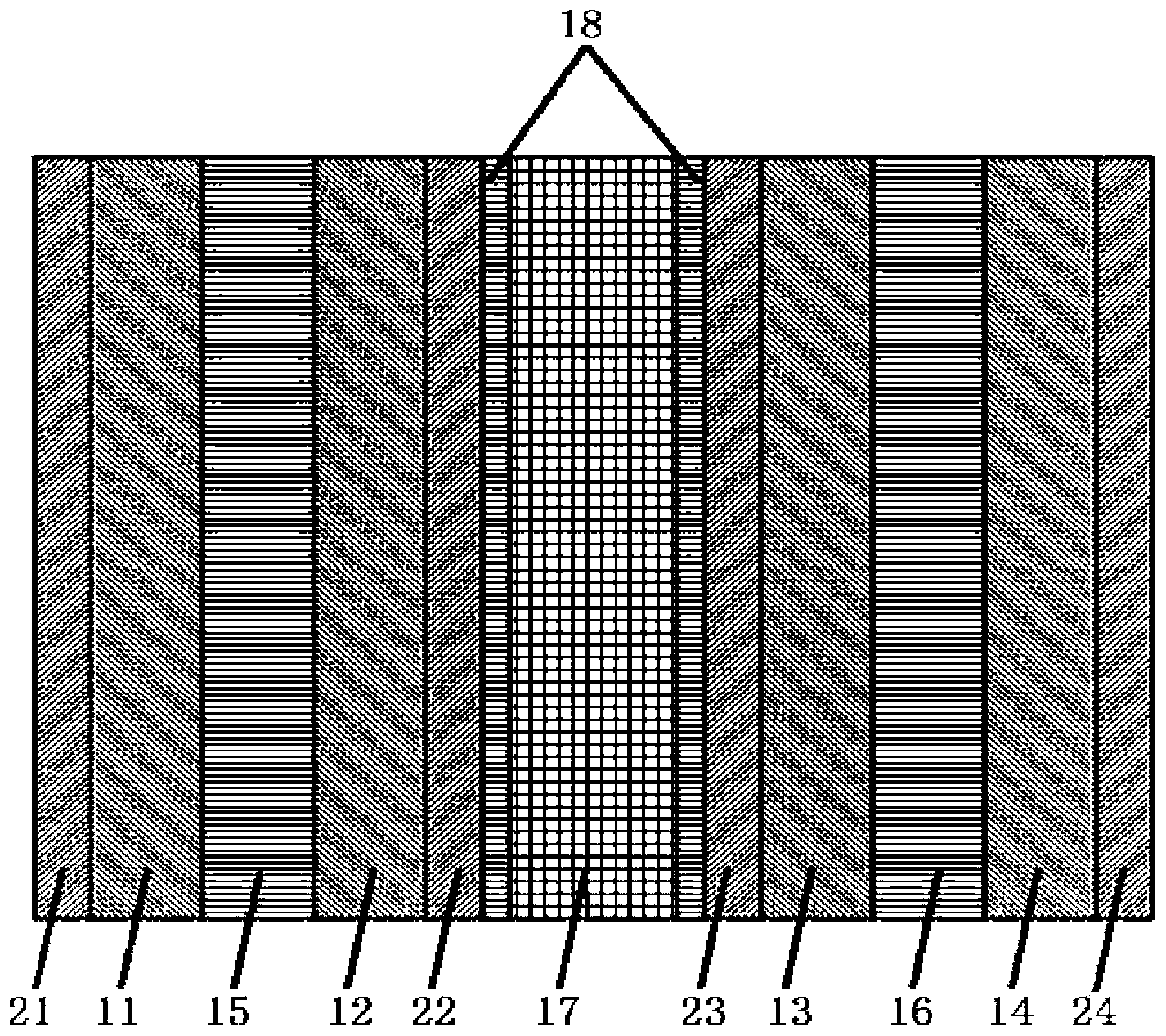

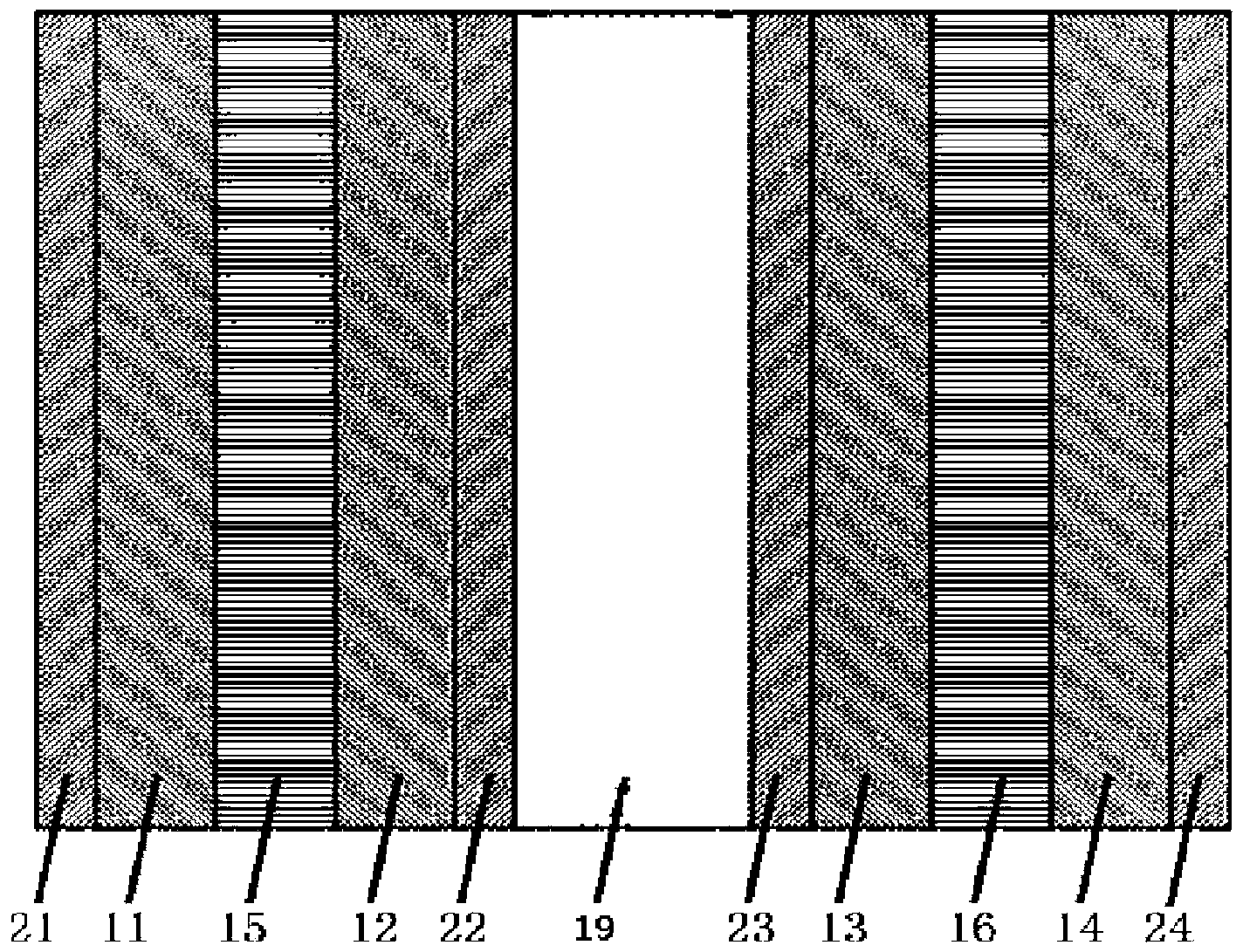

[0054] sequentially bonded first glass layer 11 , second glass layer 12 , third glass layer 13 and fourth glass layer 14 ;

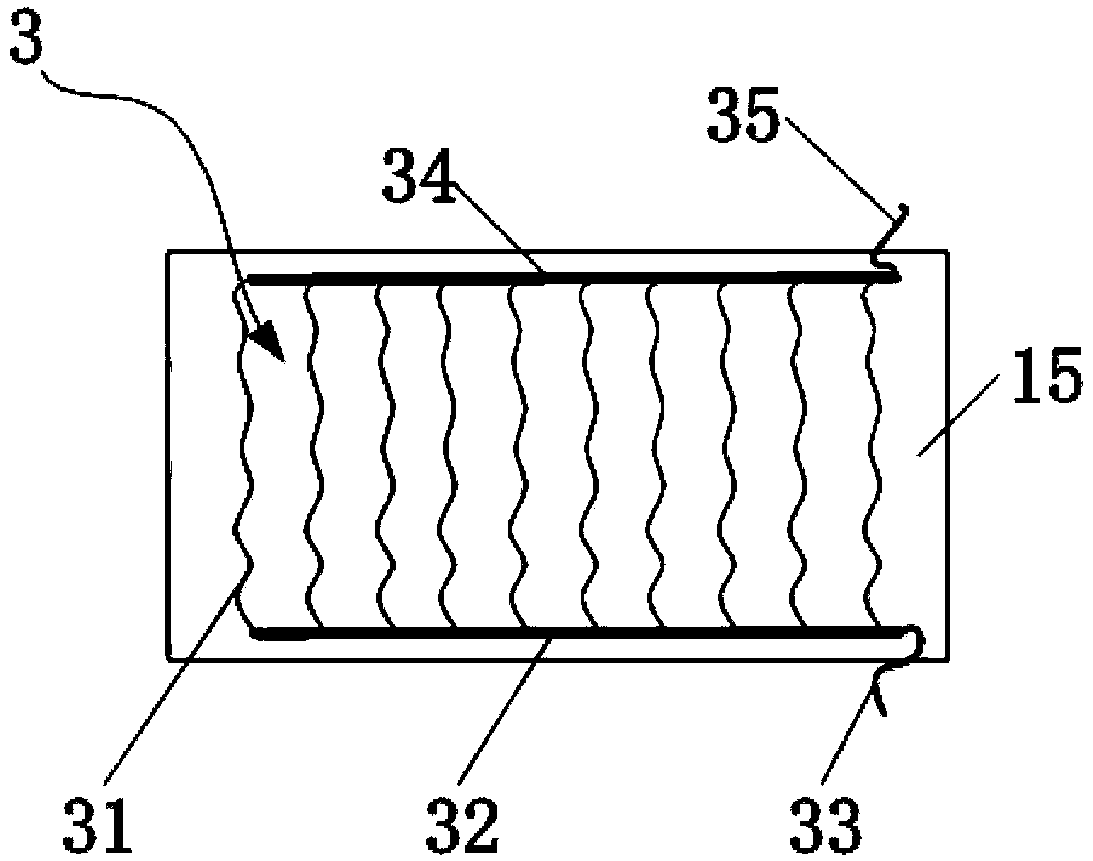

[0055] The first glass layer and the second glass layer are bonded by the first film layer 15; the first side of the first glass layer is coated with a first anti-reflection film 21, and the second side of the first glass layer Bonded to the first side of the second glass layer, the second side of the second glass layer is coate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface stress | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com