Construction method of offshore implantable socketed pile

A construction method and technology of rock-socketed piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems affecting the quality and strength of grouting, affecting the relative position of piles, and changing wind and wave environments, so as to save rent and use The effect of saving money, shortening the installation period, and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

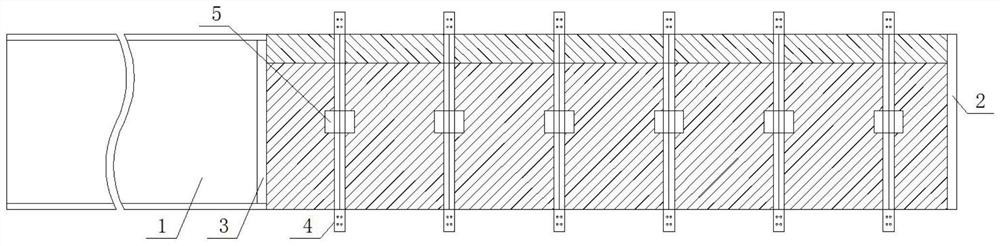

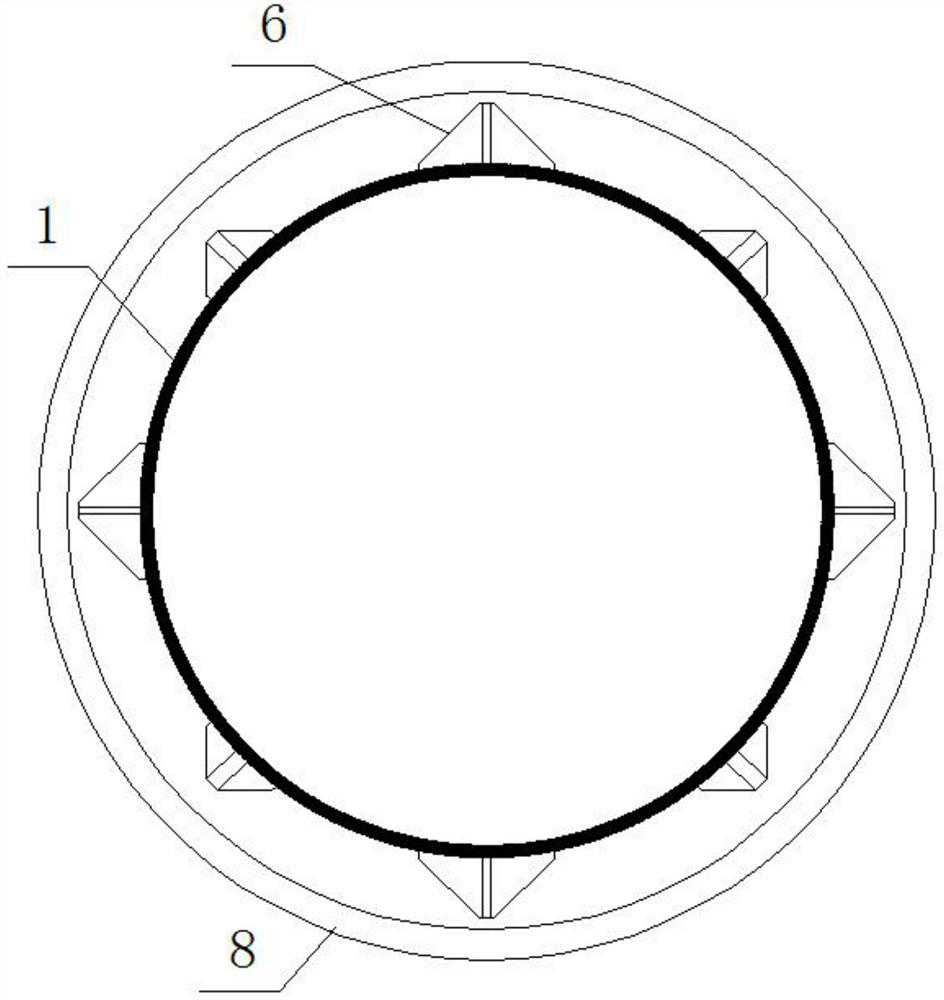

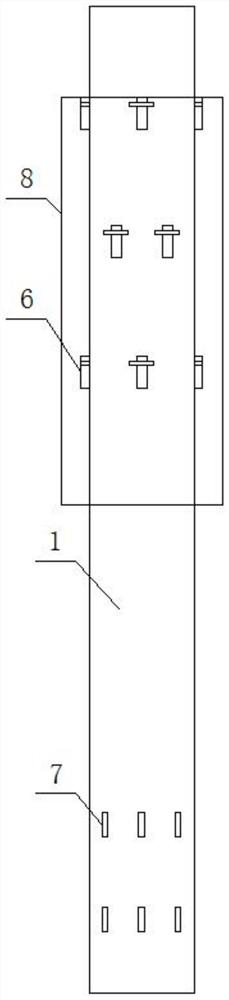

[0031] Embodiment 1, with reference to Figure 1-3 , a construction method for offshore implanted rock-socketed piles, comprising the following steps,

[0032] (1) Prefabrication of core piles: take the steel pipe pile 1 to be constructed, and set the outer formwork 2 for sealing the steel pipe pile 1 at the bottom of the steel pipe pile 1, and set the outer formwork 2 inside the steel pipe pile 1 2 Corresponding inner formwork 3 that forms a grouting space with the outer formwork 2, the cross sections of the outer formwork 2 and inner formwork 3 are set in a circular shape, and both the inner formwork 3 and the outer formwork 2 are perpendicular to the axis of the steel pipe pile 1 , the inner template 3 has a grouting hole, and the outer template 2 has another grouting hole and a grout overflow vent hole for grout overflow and exhaust. By pouring grout into the grouting space of the steel pipe pile 1, a convenient steel Core piles that level the bottom of pile 1 and prevent...

Embodiment 2

[0039] Embodiment 2, the construction method of an offshore implanted rock-socketed pile described in Embodiment 1, a flange ring is welded on the inner peripheral surface of the bottom end of the steel pipe pile 1, and the outer formwork 2 is connected with the flange ring by bolts , between the outer formwork 2 and the flange ring, a sealing ring is provided to prevent the grout from seeping out between the outer formwork 2 and the flange, and a valve is provided on the grouting hole for blocking the overflow grout and the outer formwork 2, when After the grout in the grouting space solidifies, the outer template 2 can be disassembled and recycled.

Embodiment 3

[0040] Embodiment 3, the construction method of an offshore implanted rock-socketed pile described in Embodiment 1, the outer peripheral surface of the inner template 3 is welded to the inner peripheral surface of the steel pipe pile 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com