A pipeline towing system for load testing on a ship's hull

A load test and hull technology, applied in ship construction, ship design, ship parts, etc., can solve problems such as complex calculation and strength check, heavy production and installation workload, time-consuming and cost-saving, and save shipyard equipment leasing , shorten the construction cycle, and save experiment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

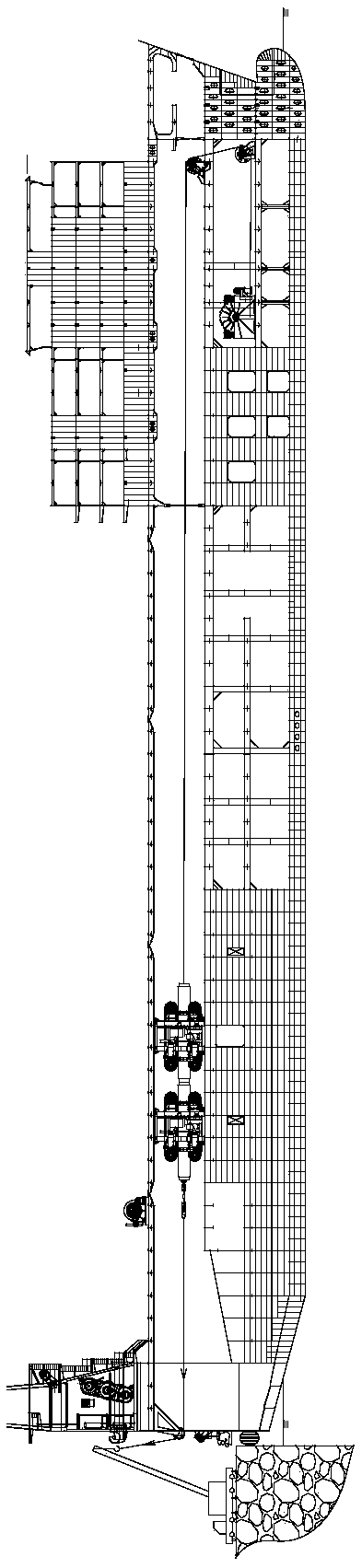

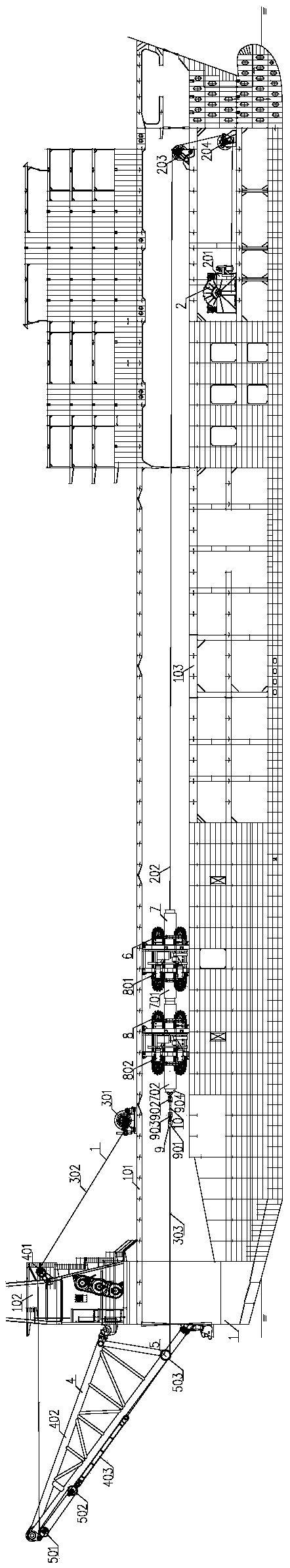

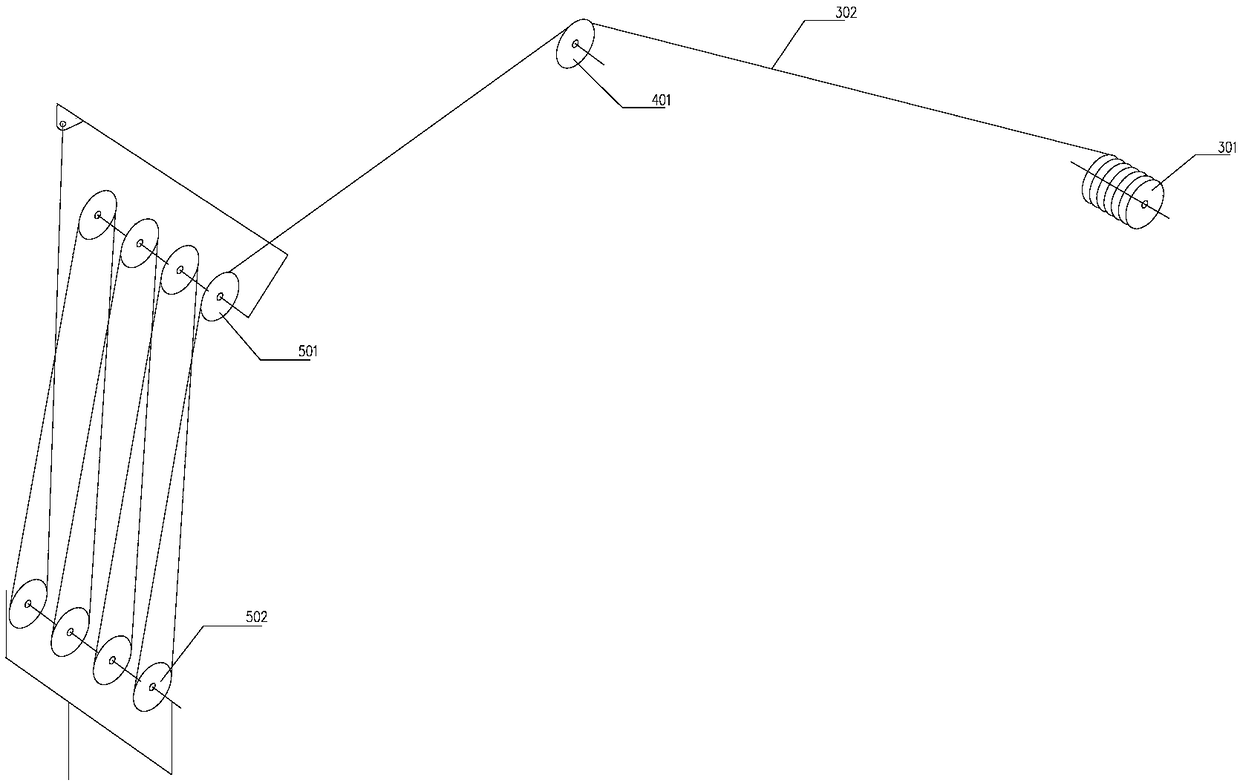

[0048] This embodiment provides a pipeline dragging system for carrying out a load test on a hull. Such as figure 2 , image 3 As shown, the pipeline dragging system of this embodiment includes: a hull 1, a front end winch mechanism 2, a rear end winch mechanism 3, a guiding device 4, a bracket pulley 5, a load device 6, a sea pipe 7, a tensioner 8, and a connecting mechanism 9 and dynamometer 10.

[0049] The hull 1 is provided with a working line ceiling 101 , a main crane foundation 102 and a main deck 103 .

[0050] The front-end winch mechanism 2 includes a front-end winch (A / R winch) 201, a front-end wire rope 202, a guide pulley 203 and a measuring pulley 204; the front-end winch 201 is located in the hull 1, and the front-end wire rope 202 is connected with the front-end winch 201; the guide pulley 203 is located on the main deck 103 , the measuring pulley 204 is located in the hull 1 ; the guiding pulley 203 and the measuring pulley 204 are connected by the wire r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com