Method for performing freezing-method well drilling by building permanent derrick foundation in frozen circle

A technology of freezing circle and freezing method, which is applied in well sinking, shaft equipment, mining equipment, etc., can solve the problems of insurmountable influence of derrick, large amount of steel consumption, and difficult design, so as to shorten the loan repayment time, reduce the construction period, The effect of saving steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

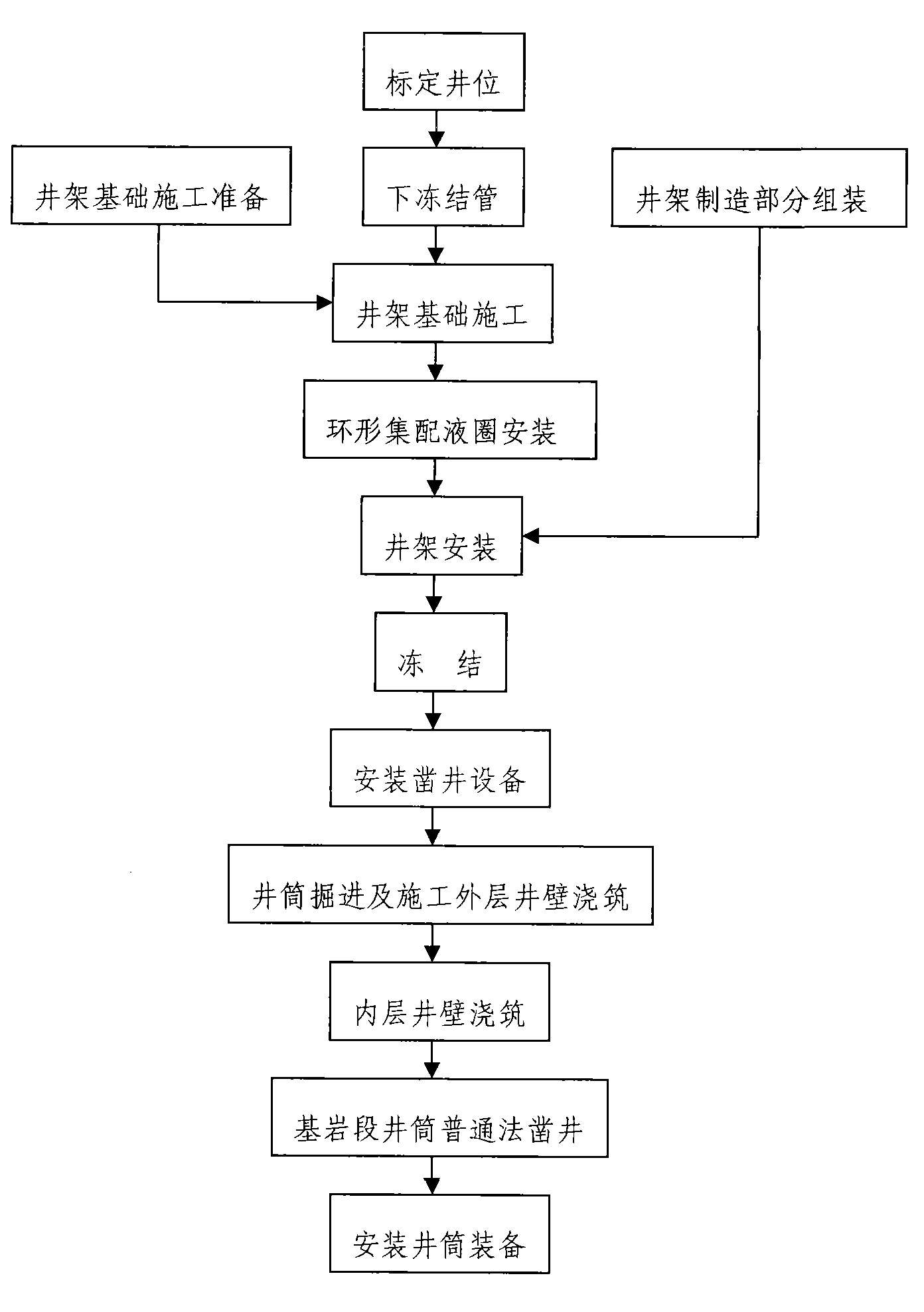

[0010] 1. Calibrate the well position;

[0011] 2. Lower the freezing tube;

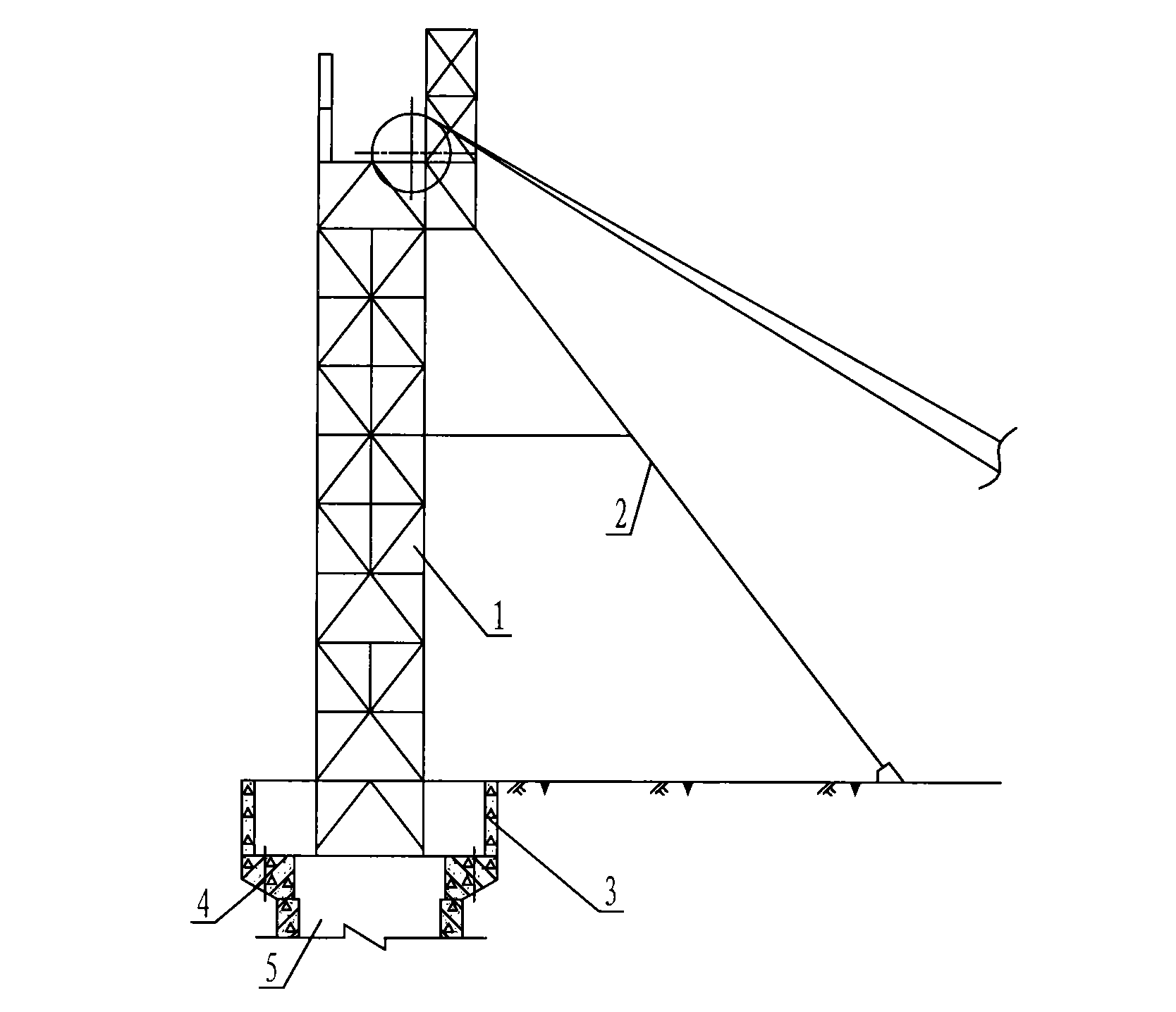

[0012] 3. The foundation of the permanent derrick 1 is constructed into a round platform (its longitudinal section is in an inverted convex shape) foundation 3, so that the frozen pipe 4 is located at the outer eaves of the platform. The foundation of the derrick is 2.5m deep, the inner diameter of the foundation is 4.7m, and the outer diameter is 10.1m.

[0013] 4. Construct the permanent derrick foundation in the freezing circle into an inverted circular platform (its longitudinal section is in an inverted convex shape) foundation, so that the frozen pipe is located in the circular platform foundation. With the gradual formation of the double-layer well wall, the derrick load is naturally transferred to the well wall superior. Between the derrick and the ground foundation there are diagonal braces 2 that are hinged to the foundation, and the diagonal braces generate a large horizontal thrust on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com