Parallel translation type numerical control copying device for piston ring processing

A profiling device and piston ring technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as low efficiency of mechanical profiling, achieve great economic and social benefits, good stability, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

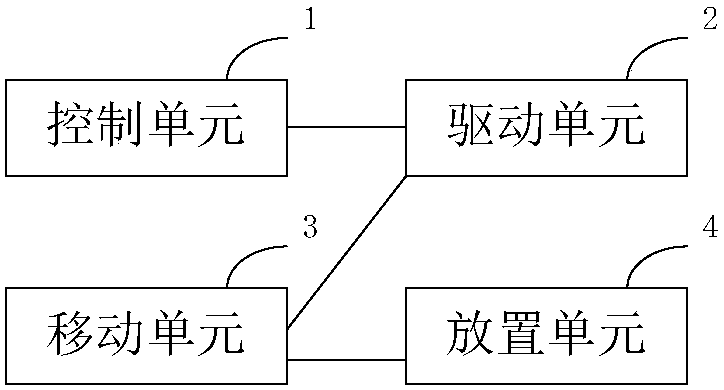

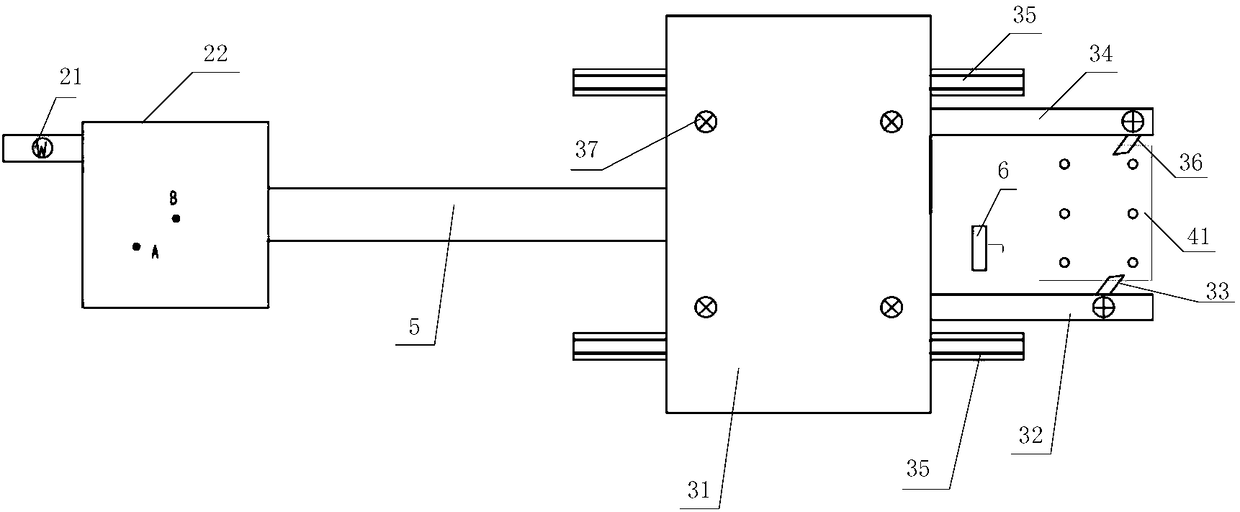

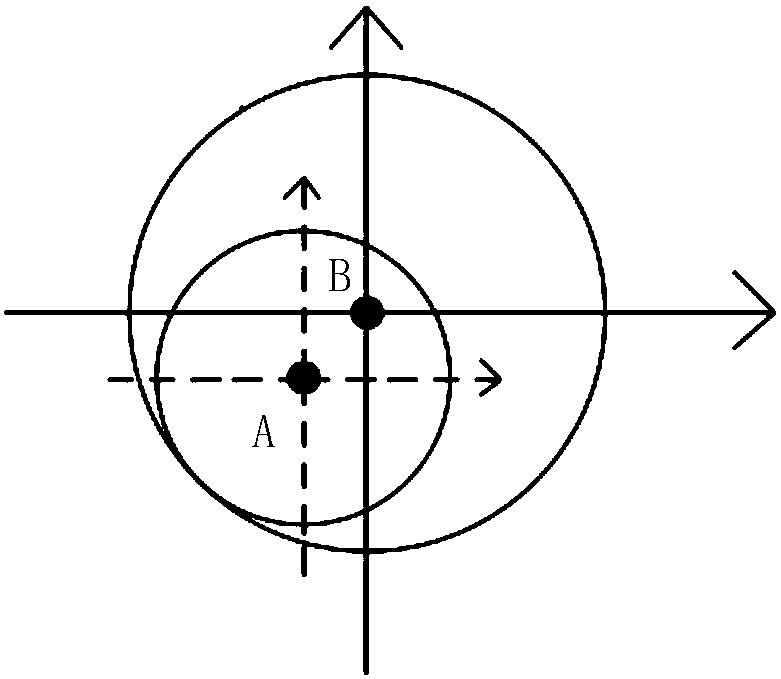

[0019] figure 1 A structural schematic diagram of a translational numerical control profiling device for piston ring processing provided by the embodiment of the present invention, as shown in figure 1 with figure 2 As shown, this embodiment provides a translational numerical control profiling device for piston ring processing, including: a control unit 1, a driving unit 2, a moving unit 3 and a placement unit 4, wherein the control unit 1 is used to control the driving The unit 2 moves, the drive unit 2 and the mobile unit 3 are connected through a flexible deformation plate 5, the mobile unit 3 includes a first blade 33; the placing unit 4 is used to place the piston ring blank; the driving unit 2 drives the mobile unit 3 to move, so that the first A blade 33 cuts the piston ring blank placed on the placement unit 4 .

[0020] Specifically, the control unit 1 can sele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com