Enhanced heavy-duty deep groove ball bearing

A deep groove ball bearing, enhanced technology, applied in the direction of ball bearings, bearing components, shafts and bearings, can solve the problems of difficult performance requirements, unable to replace cylindrical roller bearings, etc., to increase load, improve carrying capacity, increase The effect of large interior spaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

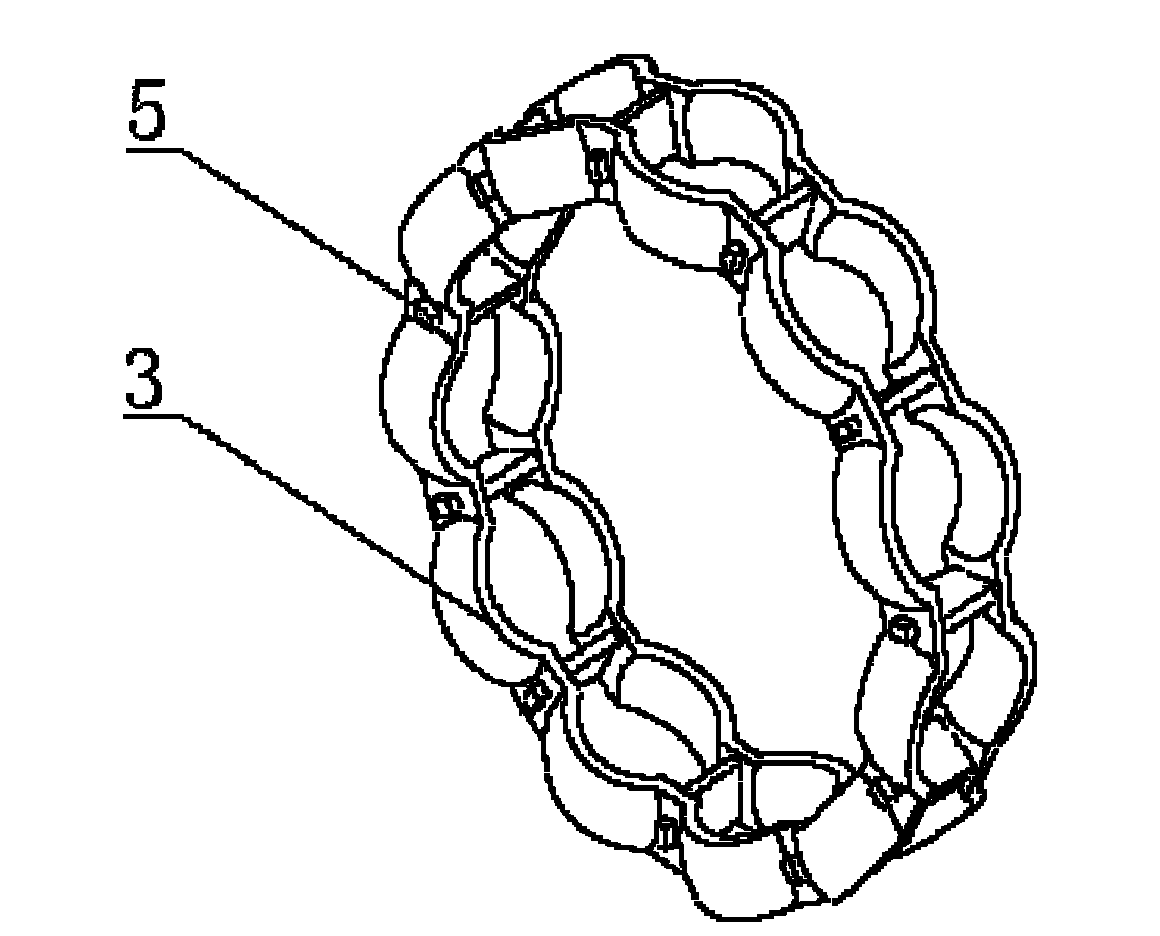

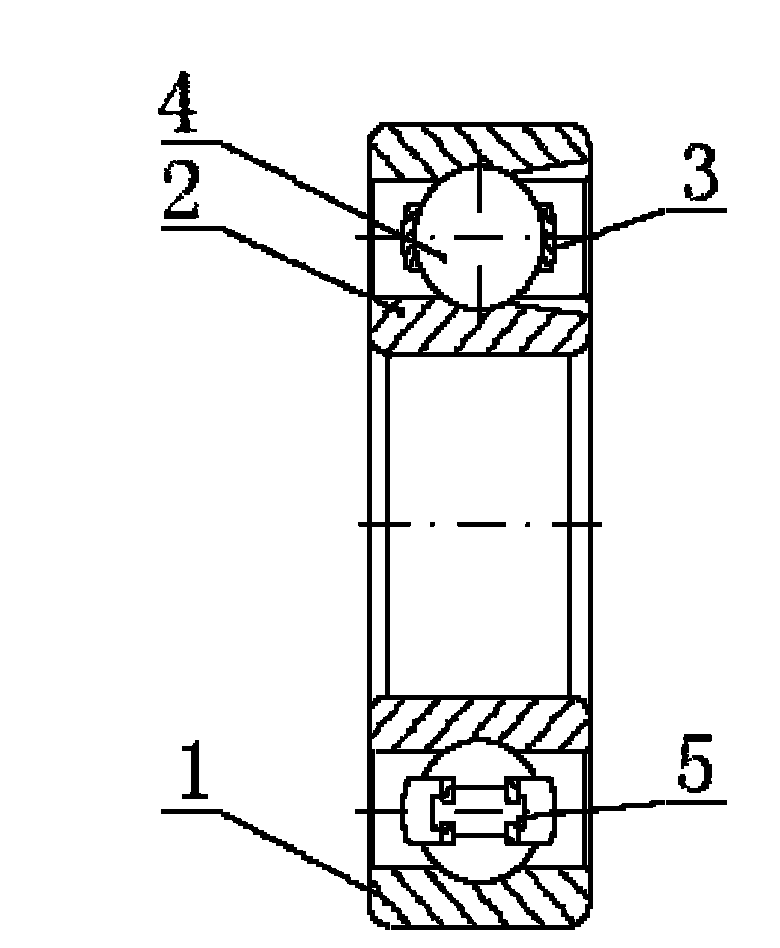

[0038] combine Figure 1-Figure 2 , this embodiment includes an outer ring 1, an inner ring 2, a rolling body 4, and a cage 3. The rolling body 4 is placed in a spherical pocket formed by two cages 3, and the inner ring 2 and the outer ring 1 are respectively arranged on the rolling body 4 and cage 3 form the inner and outer sides of the ring. The cage 3 includes two cages and rivets 5, the middle of the two cages is supported by rivets 5 and riveted, the two cages are shallow wave-shaped cages, the rivets 5 are sheet rivets, the outer ring 1 and the inner ring 2 There is a ball filling gap on the top, and the raceway of the inner ring 2 and the raceway of the outer ring 1 keep in contact with the rolling elements 4 respectively.

Embodiment 2

[0040] combine image 3 , The basic structure of this embodiment is the same as that of Embodiment 1, the difference is that the outer ring 1 is provided with a stop groove for axial positioning of the bearing on the ball filling gap side.

Embodiment 3

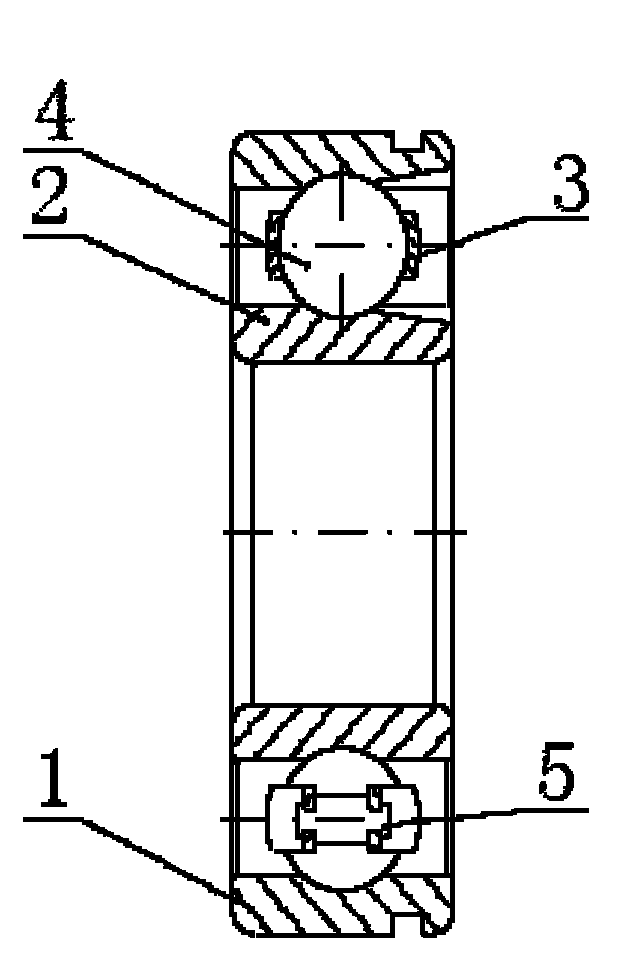

[0042] combine Figure 4 , The basic structure of this embodiment is the same as that of Embodiment 1, except that the non-balling notch side of the outer ring 1 is provided with a stop groove for axial positioning of the bearing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com