Application of composite power cable GIS terminal with optical fiber arranged in center of conductor

A power cable and optical fiber technology, which is applied to the application field of composite power cable GIS terminals with optical fibers installed in the conductor center, which can solve the problems of inability to monitor the operating temperature of the terminal, complex processing of terminal posts, troublesome operation, etc., to achieve easy operation and reduce construction costs , Improve the effect of reliability and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

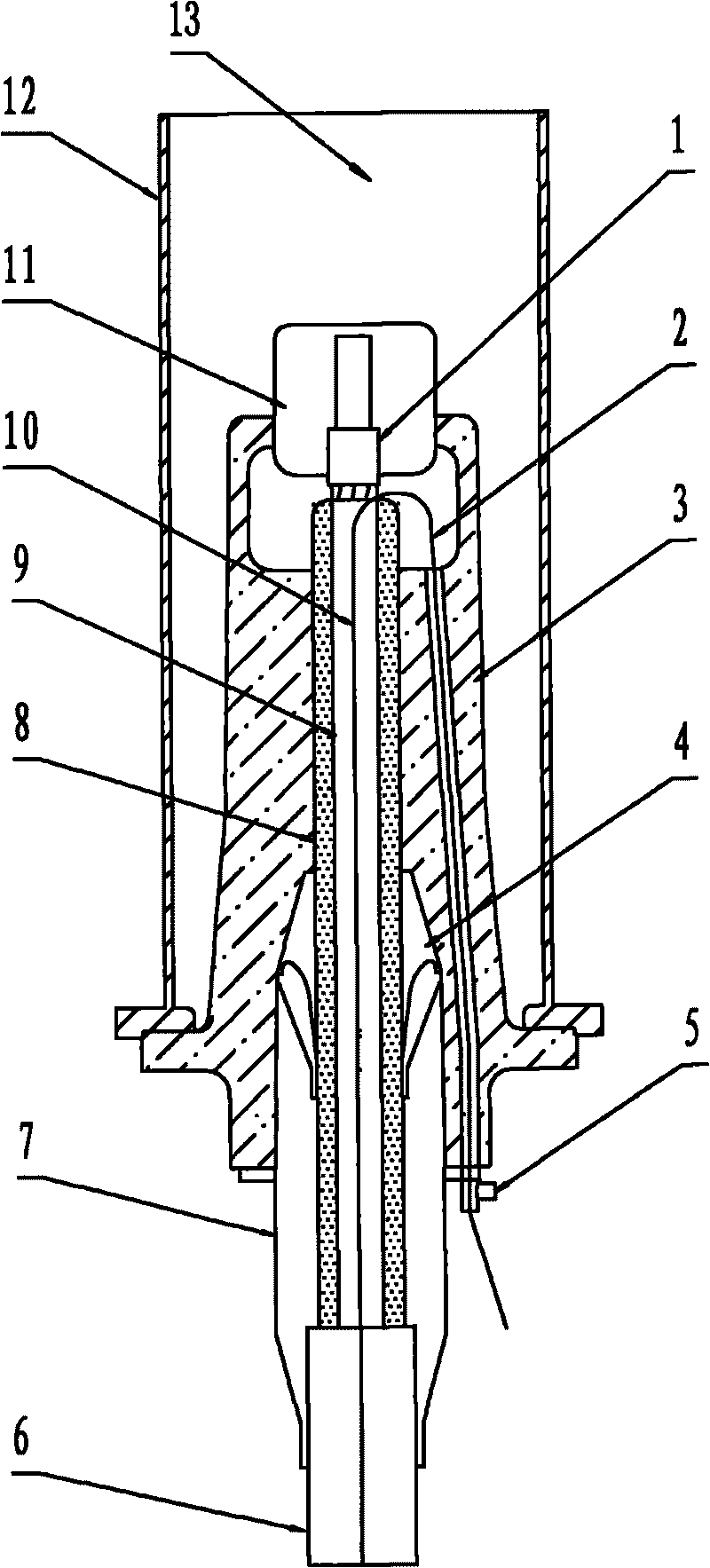

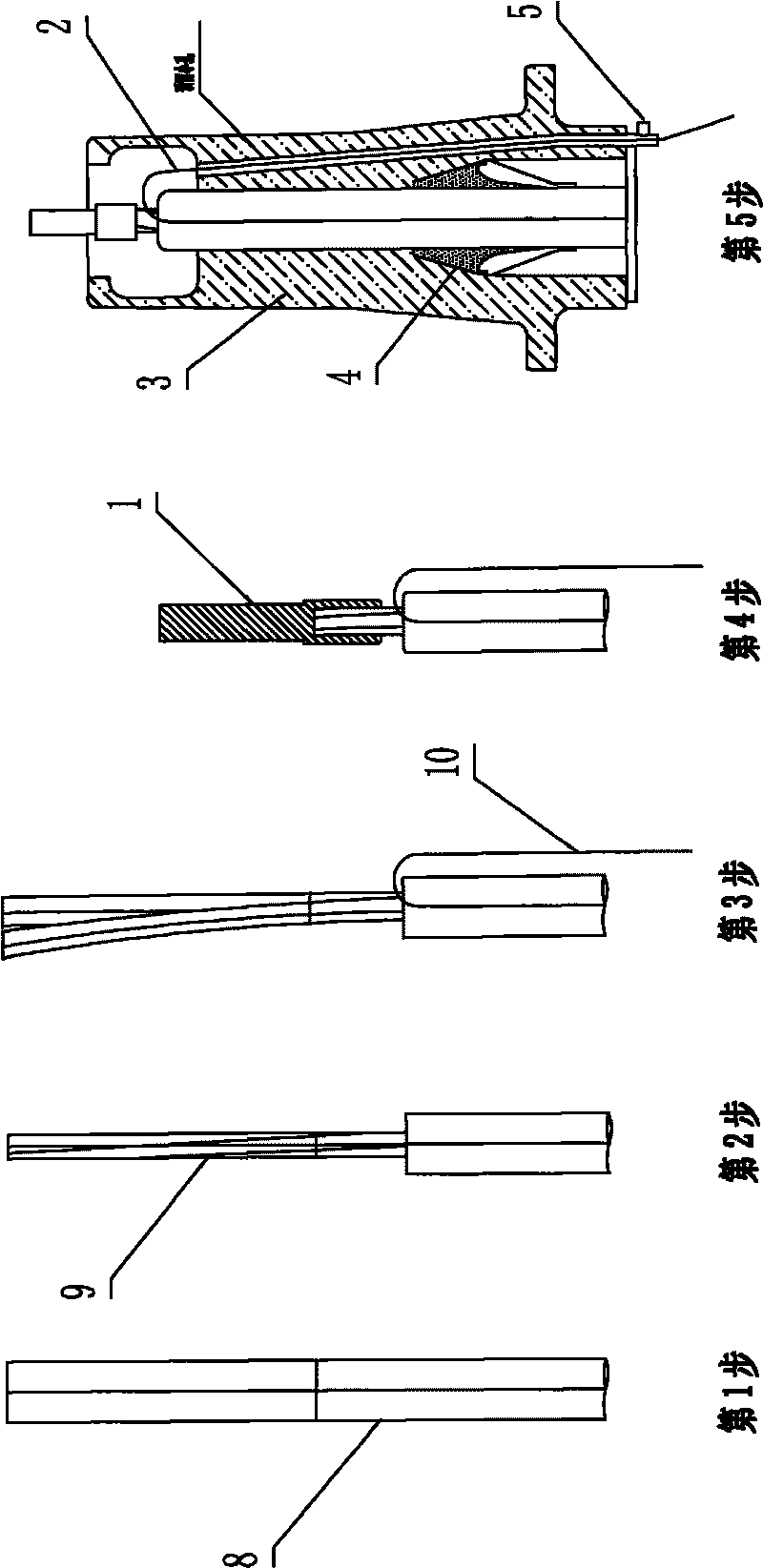

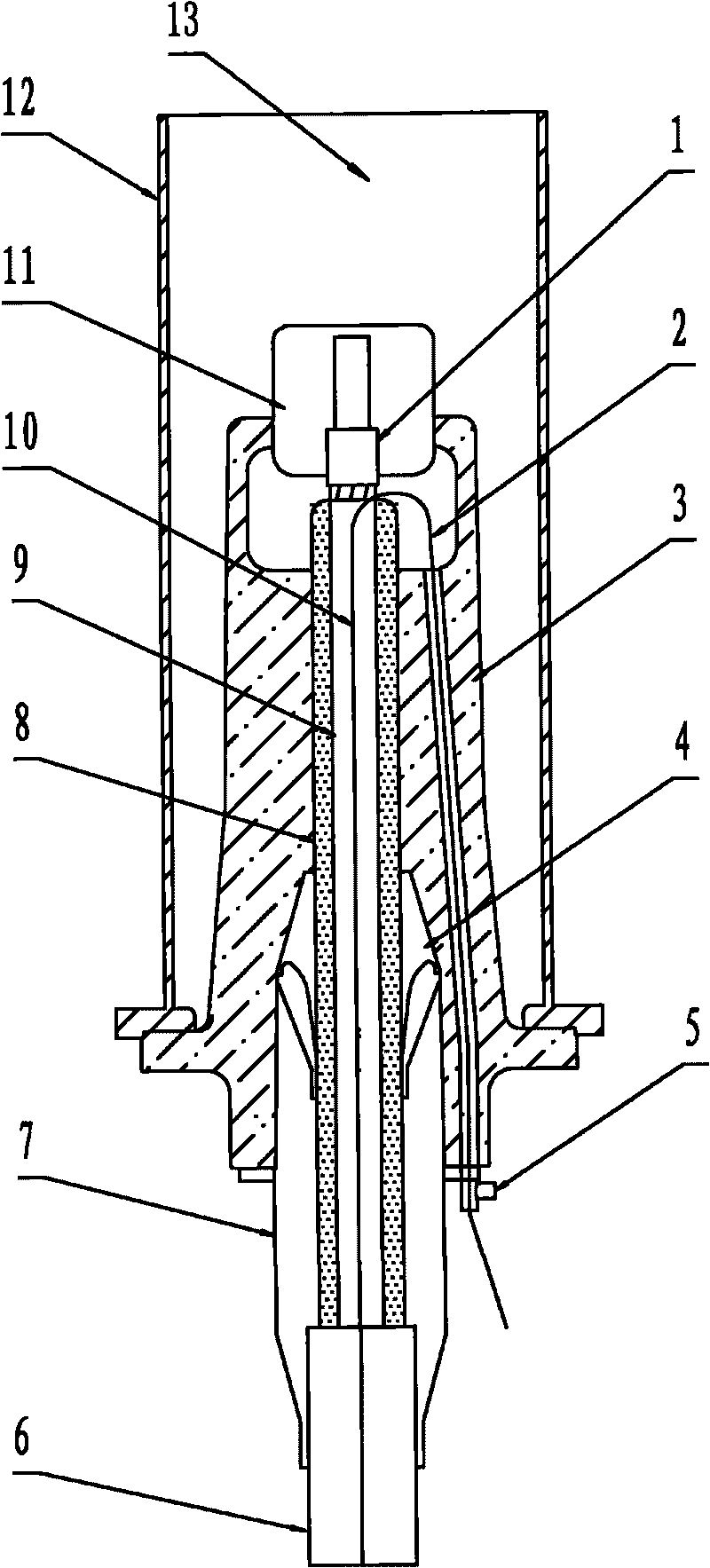

[0018] according to Figure 1~2 The specific structure of the present invention will be described in detail. The composite power cable GIS terminal with optical fiber in the center of the conductor is specially used for the composite power cable with optical fiber in the center of the conductor. 7. A terminal composed of a stress cone 4 set on the cable insulation 8 and a gas-tight cylinder 12 with a built-in gas insulating medium 13 .

[0019] The composite power cable in which the optical fiber is arranged in the center of the conductor in this embodiment adopts the "method for stranding the optical fiber in the conductor center of the composite power cable" by the inventor, and is processed by existing equipment and a commonly used cable stranding process in line with the existing Products specified in the standards for ultra-high voltage XLPE insulated power cables. To put it simply, the composite power cable with a cross-section of more than 800 square millimeters and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com