Spiral glue-shaped gluing nozzle

A technology of glue shape and glue nozzle, which is applied in the field of glue coating, can solve problems such as difficulty in meeting the application requirements of folding glue, single glue distribution structure, and difficulty in controlling the amount of glue applied, so as to achieve easy control of glue amount and precise control The amount of glue applied and the effect of improving the bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

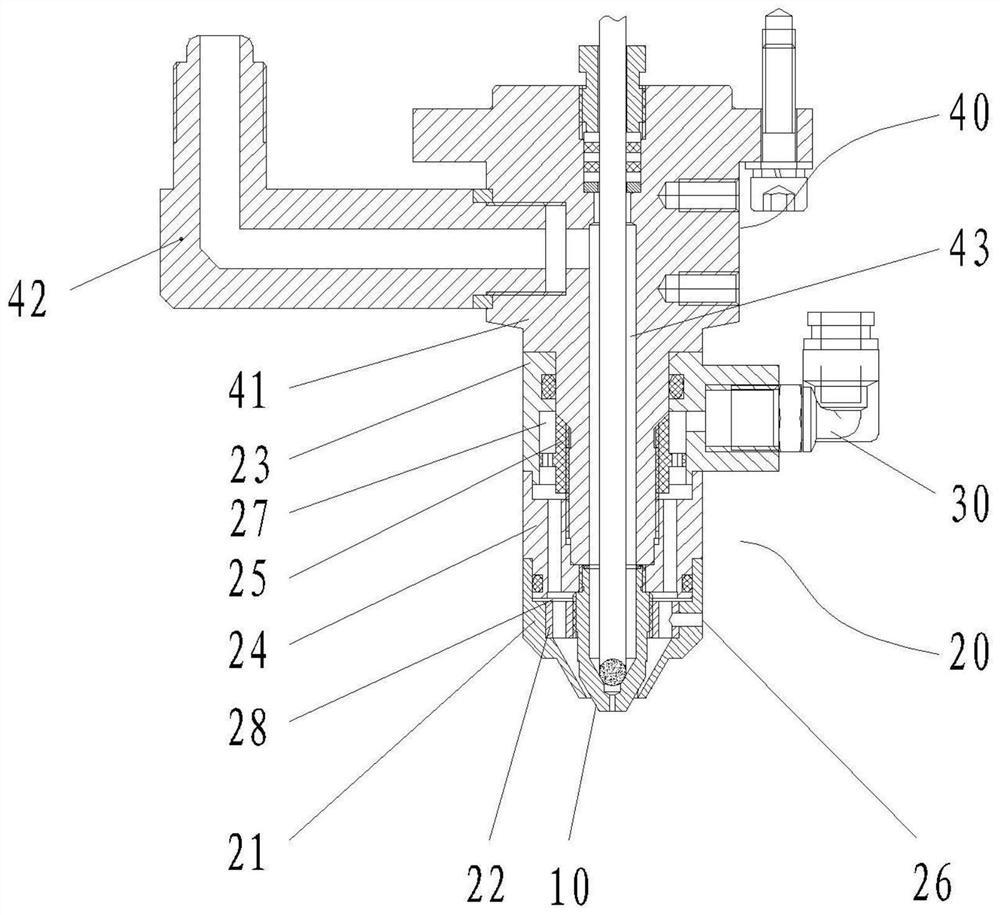

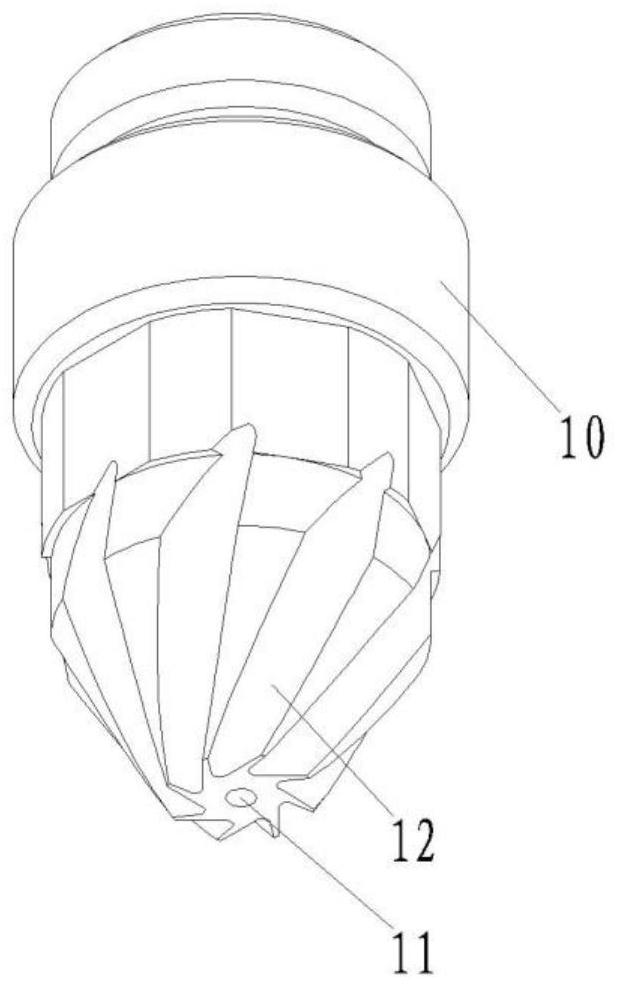

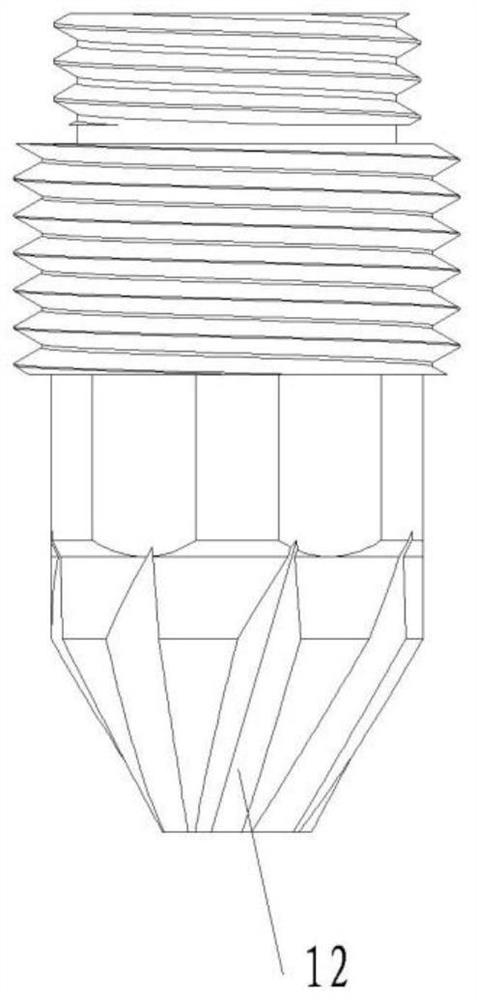

[0026] As shown in the figure, this embodiment provides a spiral glue-shaped gluing nozzle, including a mandrel body 10, a jacket assembly 20 outside the mandrel body, and an air supply head 30 arranged on the jacket assembly. The lower end of the shaft body extends downwards to the outside of the jacket assembly, an annular flow channel is formed between the mandrel body and the jacket assembly, the air supply head communicates with the annular flow channel, and a hole for colloid extrusion is provided at the lower end of the mandrel body. Extrusion port 11, the center of the outer circular surface of the mandrel body is symmetrically provided with a plurality of drainage grooves 12, and each drainage groove is offset from top to bottom to the same circumferential direction of the mandrel body, and the drainage grooves extend downward to the mandrel On the lower end surface of the main body, the lower ends of the drainage grooves are circumferentially distributed around the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com