Pelletization method for vanadium titanium magnet ore concentrate mix with additive rough rice shell

A vanadium-titanium-magnetite concentrate and rice husk technology, applied in the field of metallurgy, can solve the problems of unstable granulation effect of vanadium-titanium magnetite concentrate mixture, unstable batching amount, bad working environment, etc. Stable, easy to control accurately, improve the effect of granulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

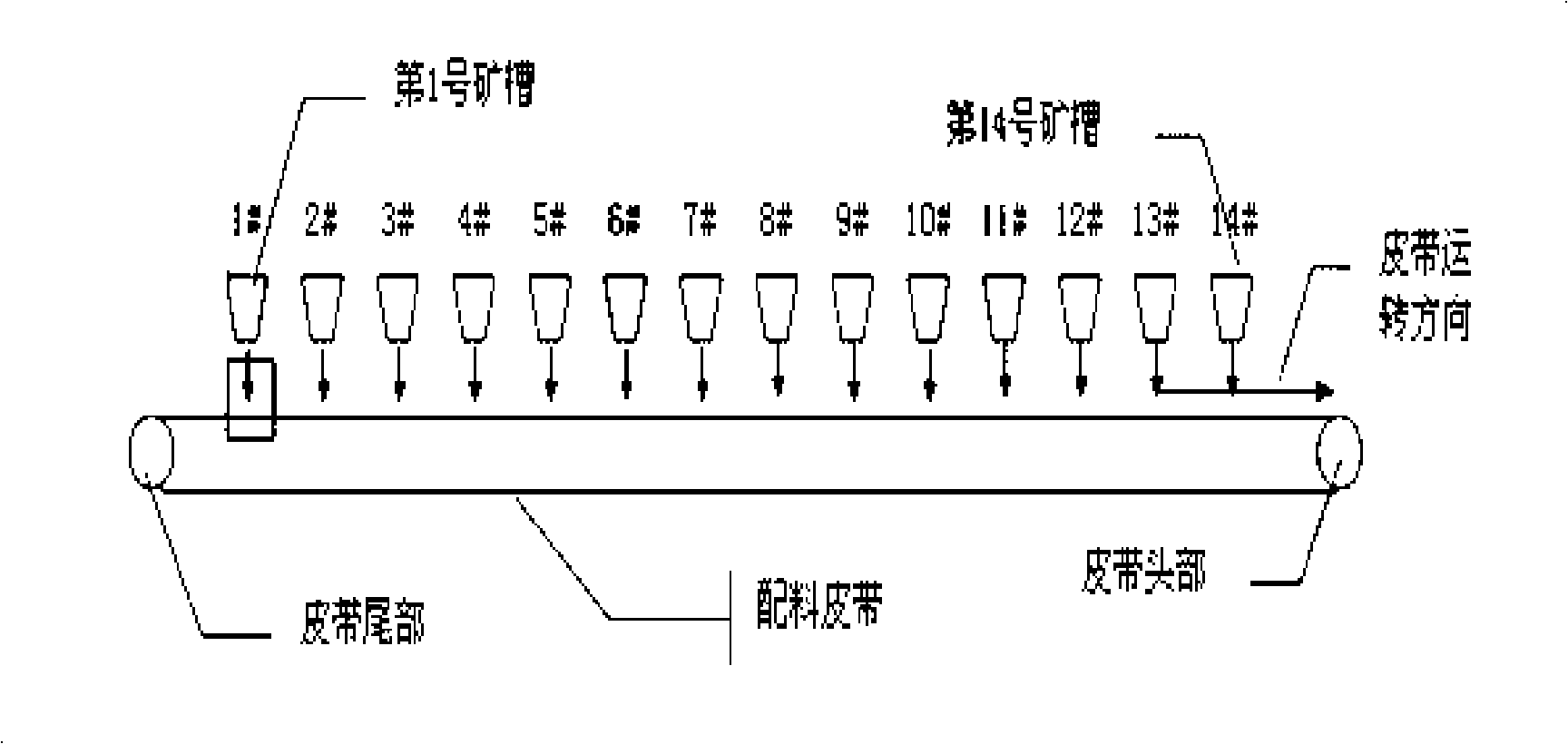

[0017] 1. Ratio of sintered material

[0018] In terms of weight percentage, 55% concentrate + 10% Australian ore + 12% domestic high-grade fine ore + 3% domestic medium-grade fine ore + 7% quicklime + 6% limestone + 5% coke powder

[0019] The rice husk is a by-product of rice processing by a rice production enterprise. The shape is a half-open state after the rice granules are removed. The skeleton has a strong performance of adhering the concentrate powder and quicklime.

[0020] In the sintering production, the proportion of rice husks can be divided into three modes: no addition, addition of 0.4%, and addition of 0.6%, and the proportion is the percentage of the weight of the raw material for sintering.

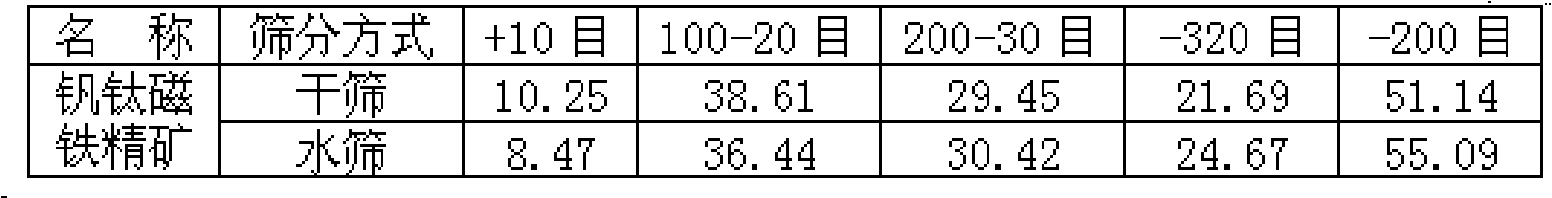

[0021] 2. See Table 1 and 2 for the particle size composition of raw materials.

[0022] Table 1 The particle size composition of vanadium-titanium magnetite concentrate (weight percent, %)

[0023]

[0024] Table 2 Composition of particle size of iron ore powder, ...

Embodiment 2

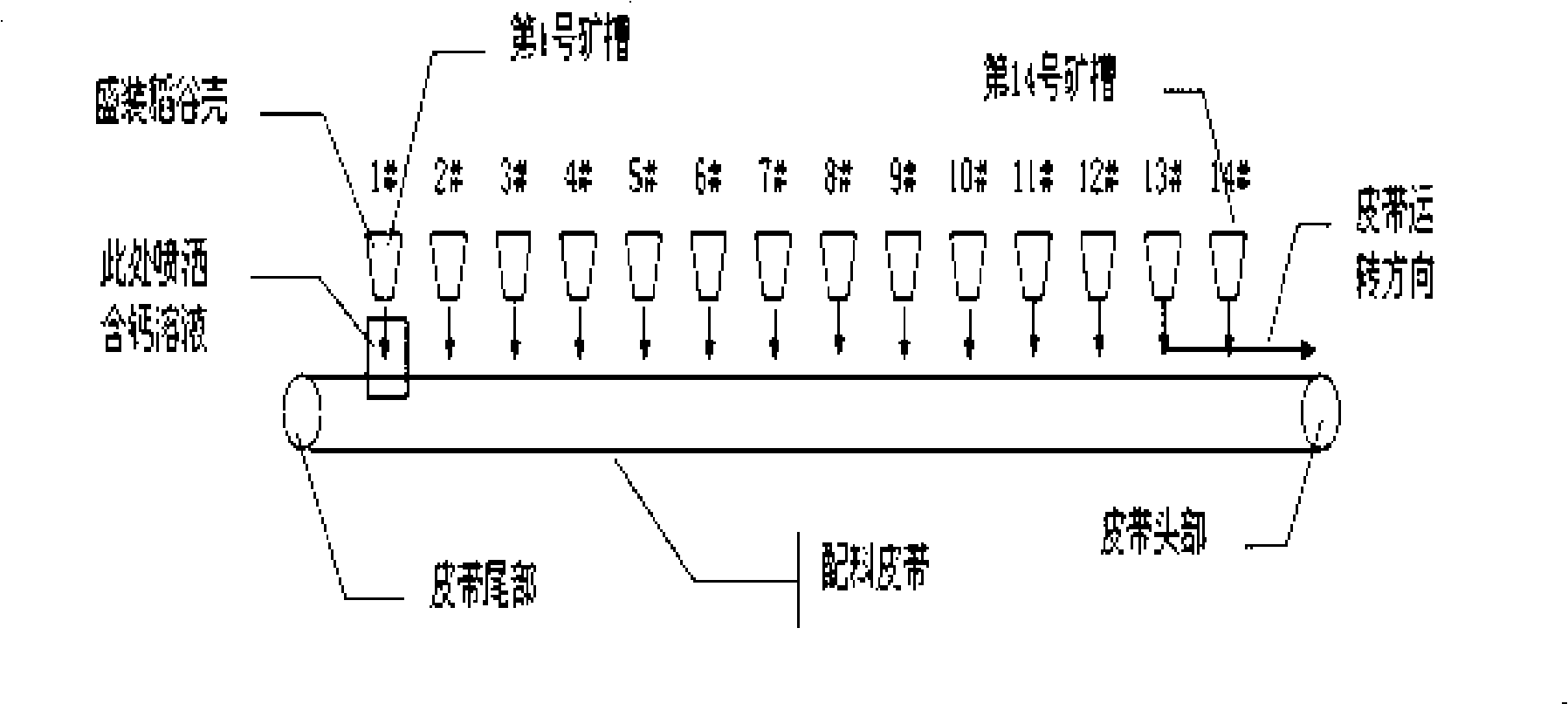

[0039] 1. Contrast test results of spraying and non-spraying calcium solution

[0040] Spray and do not spray calcium-containing solution (CaCl2 solution, mass concentration is 0.8%) to the mixture that adds rice chaff 0.4% (percentage by weight), manufactured 2 batches of sintered ore by the method of the present invention, the results are shown in Table 5, Table 6 .

[0041] Table 5 Particle size composition of rice husk spraying and non-spraying calcium-containing solution mixture

[0042]

[0043] Table 6 Sintering technical indicators of rice husk sprayed and not sprayed with calcium solution

[0044] batch

[0045] As can be seen from Table 5, the use of 0.4% rice hulls to spray calcium-containing solution (CaCl 2 solution), the particle size of the sintered mixture was thicker than that without calcium-containing solution, and the average particle size increased by 0.14mm, indicating that after spraying with calcium-containing solution, rice husks were le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com