Automatic assembling structure for supercharger C-type ring

An automatic assembly and supercharger technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of unstable manual press-fitting production process, insufficient press-fitting scrap rate, artificial fatigue, etc., and achieve fast speed. , Automatic and accurate installation in place, high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the present invention more obvious and understandable, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

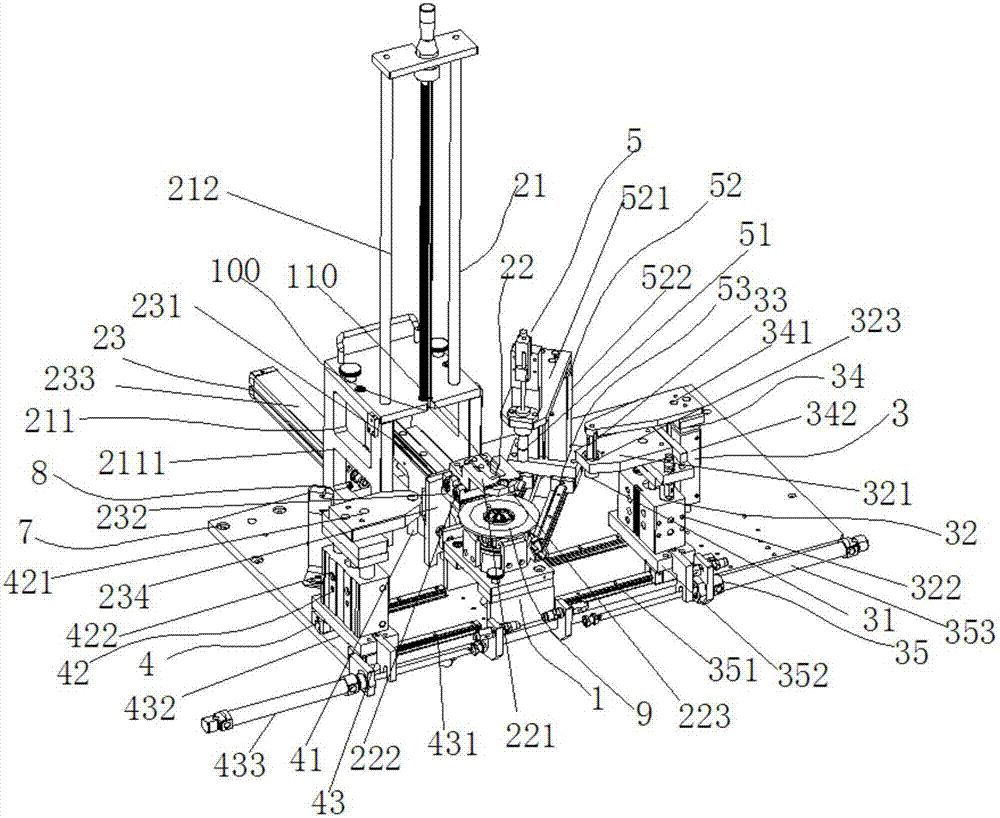

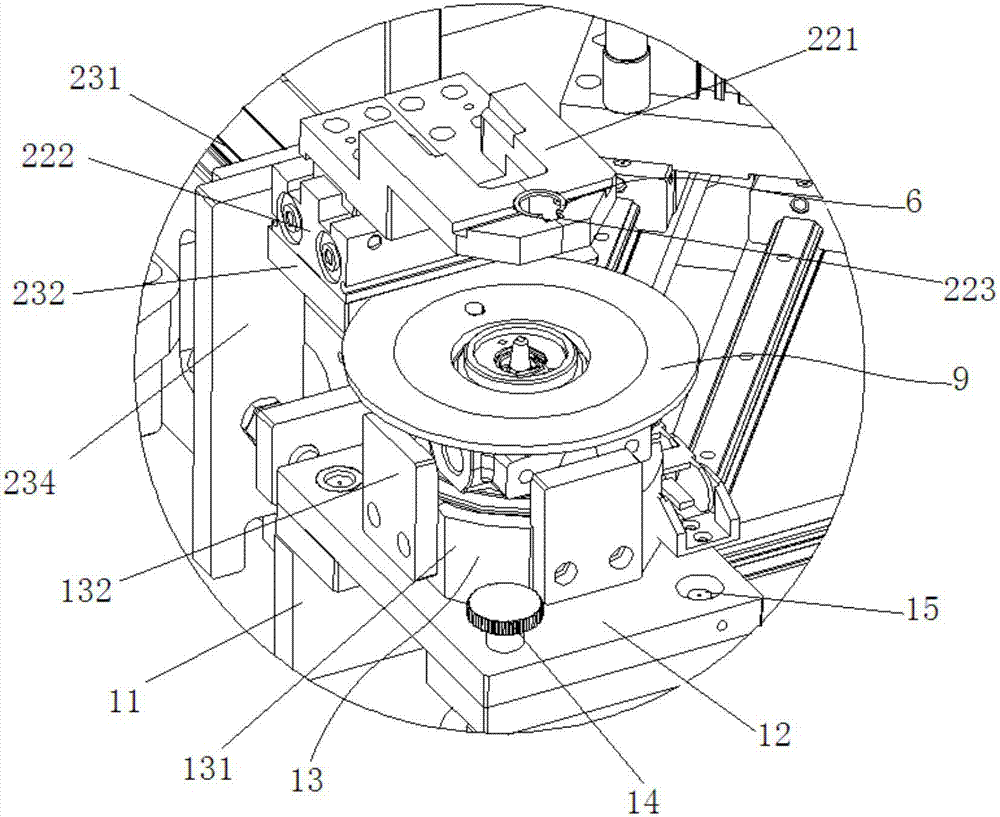

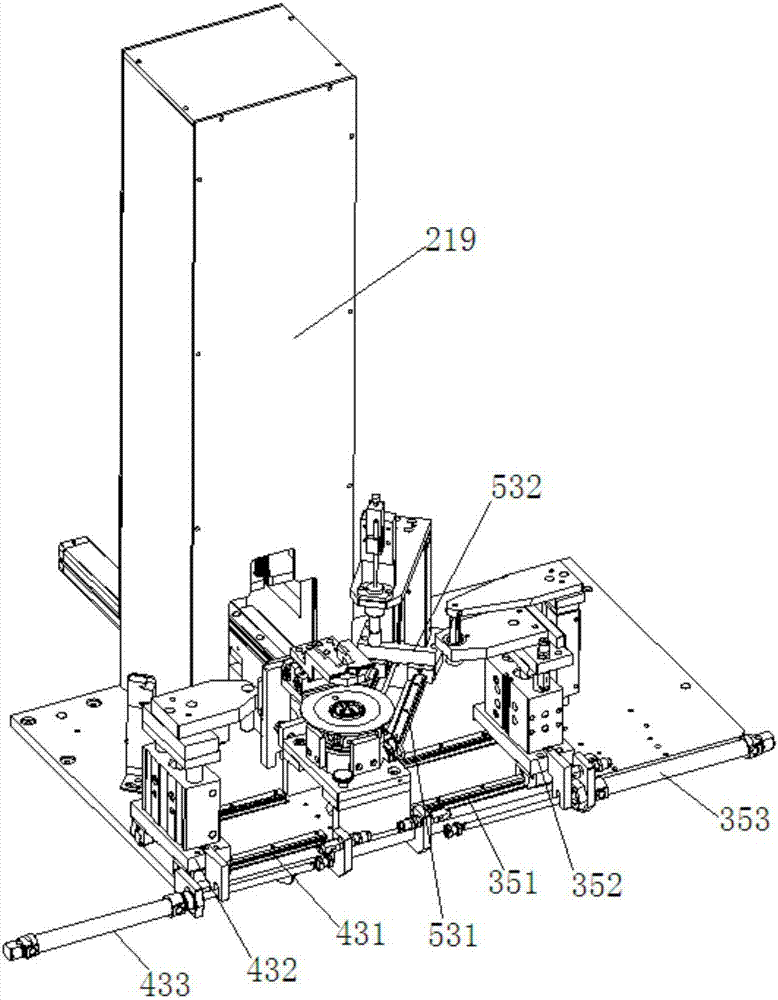

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a supercharger C-ring automatic assembly structure includes a positioning base 1 for positioning the middle shell 9 of the supercharger and a C-ring automatic feeding mechanism 2 arranged on the peripheral side of the positioning base, an automatic connection Material guiding mechanism 3, automatic press-fitting mechanism 4 and automatic detection mechanism 5, described C-shaped ring automatic feeding mechanism includes C-shaped ring clip device 21, C-shaped ring carrying mechanism 22 and feeding horizontal movement mechanism 23, described The C-ring clip device can send the C-rings 6 to the blanking position 100 one by one, and the C-ring bearing mechanism can accept the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com