Automatic feeding and blanking system for centerless grinding machine screws

An automatic loading and unloading, centerless grinding machine technology, applied in the direction of grinding feed movement, grinding machine parts, grinding/polishing equipment, etc., to achieve the effect of beautiful appearance, good rigidity, compact and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

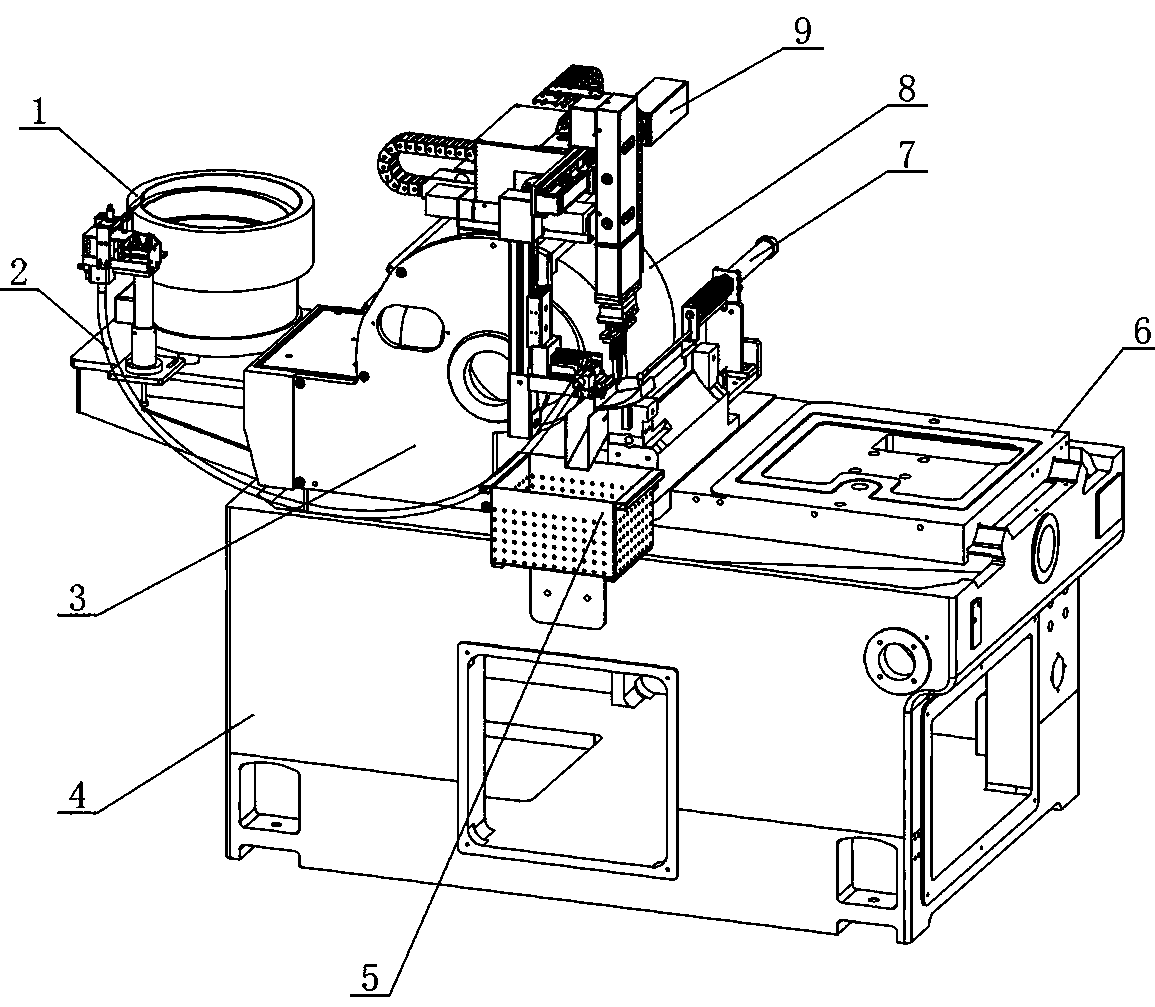

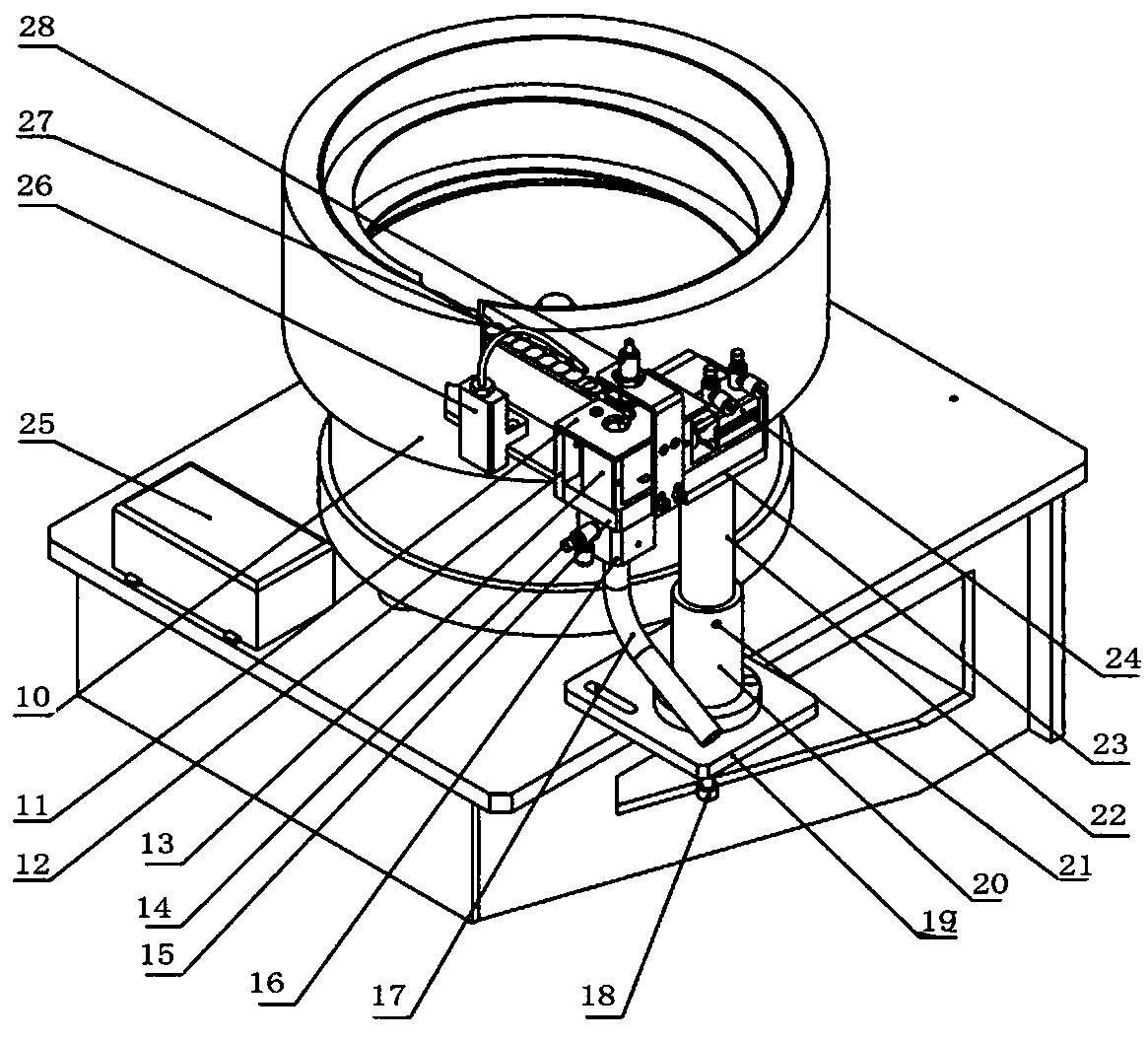

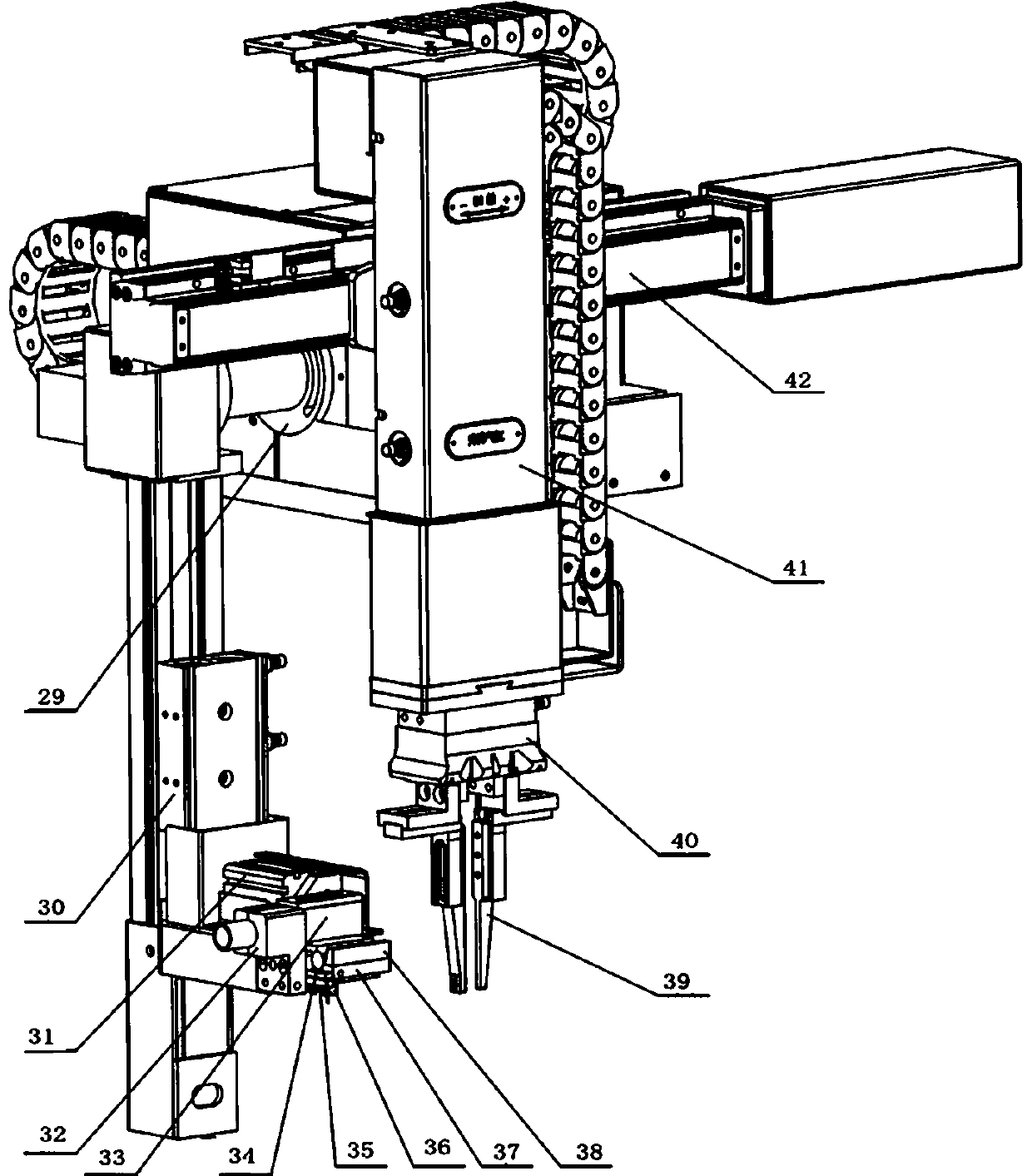

[0020] The specific implementation, structure, features and effects of a centerless grinding machine screw automatic loading and unloading system according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0021] See attached Figure 1-4 , The automatic loading and unloading system for centerless grinder screws provided by the present invention mainly includes a vibrating feeding part 1, a feeding pipe 2, a grinding wheel box cover 3, a machine tool body 4, a receiving box 5, an upper slide plate 6, and a rear positioning feeding device 7 , grinding wheel 8, manipulator feeding part 9; it is characterized in that: for the convenience of manual operation and replacement of grinding wheel 8, the vibration feeding part 1 is located at the left end of the machine tool body 4, and the workpiece is transported to the front clamping limit V of the grinding machine by means of air blowing conveyance Po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com