System for realizing PVC flooring inspecting and conveying, and stacker blanking

A stacker and mechanical system technology, applied in the field of PVC floor loading system, can solve the problems of cumbersome work, long time-consuming, and inability to stack neatly for operators, and achieve the goal of improving inspection efficiency, reducing labor force, and realizing intelligence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

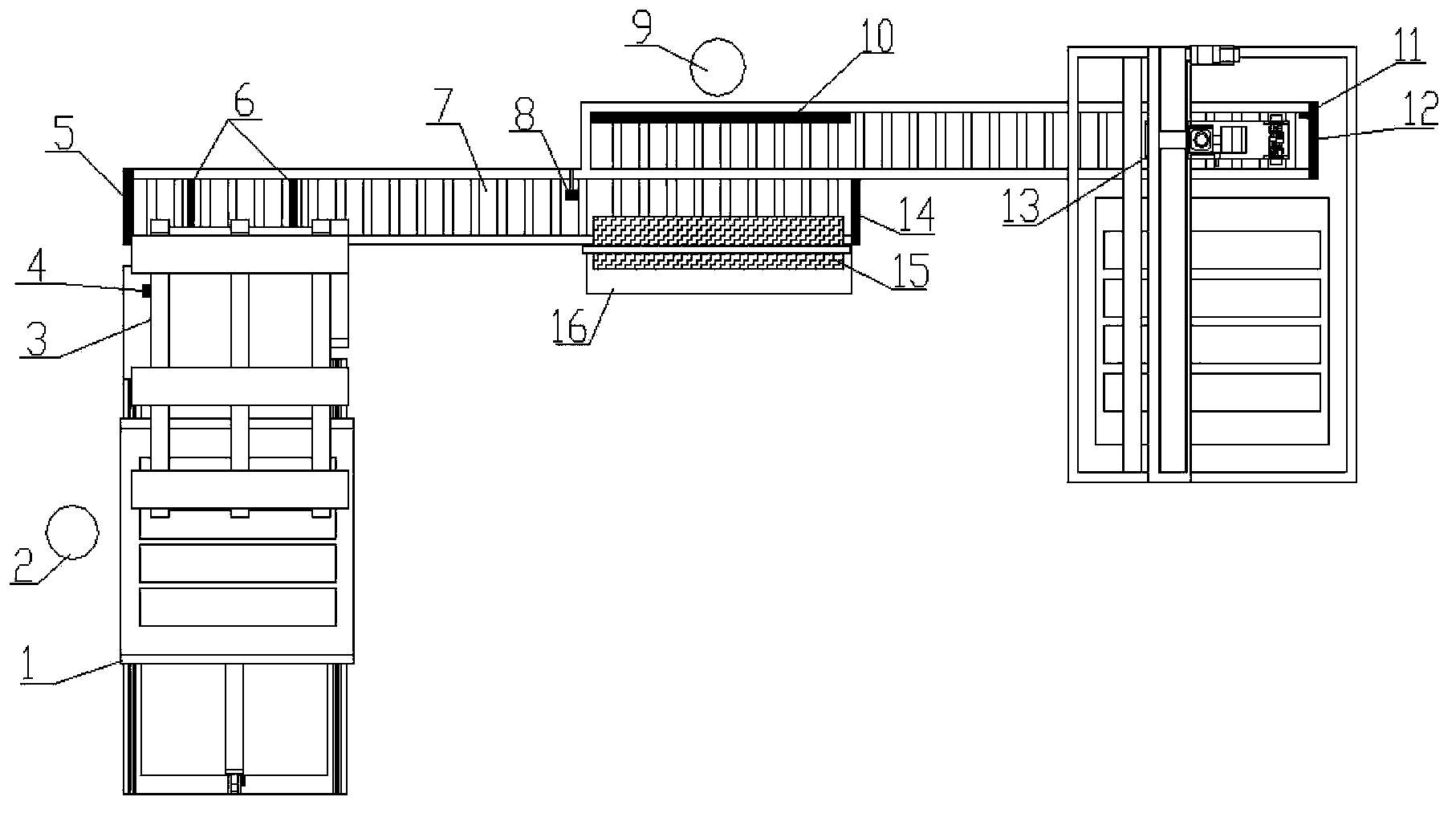

[0024] Such as figure 1 As shown, a PVC floor inspection conveying and stacker unloading system of the present invention includes a loading scissor lift 1, an operator 2&9, a conveyor pulley 3, a photosensor 4&8&11, a cylinder-driven lifting plate 6, and a motor-driven Roller bed 7, positioning baffle 5 & 10 & 12 & 14, stacking manipulator 13, lighting lamp 15, waste table 16.

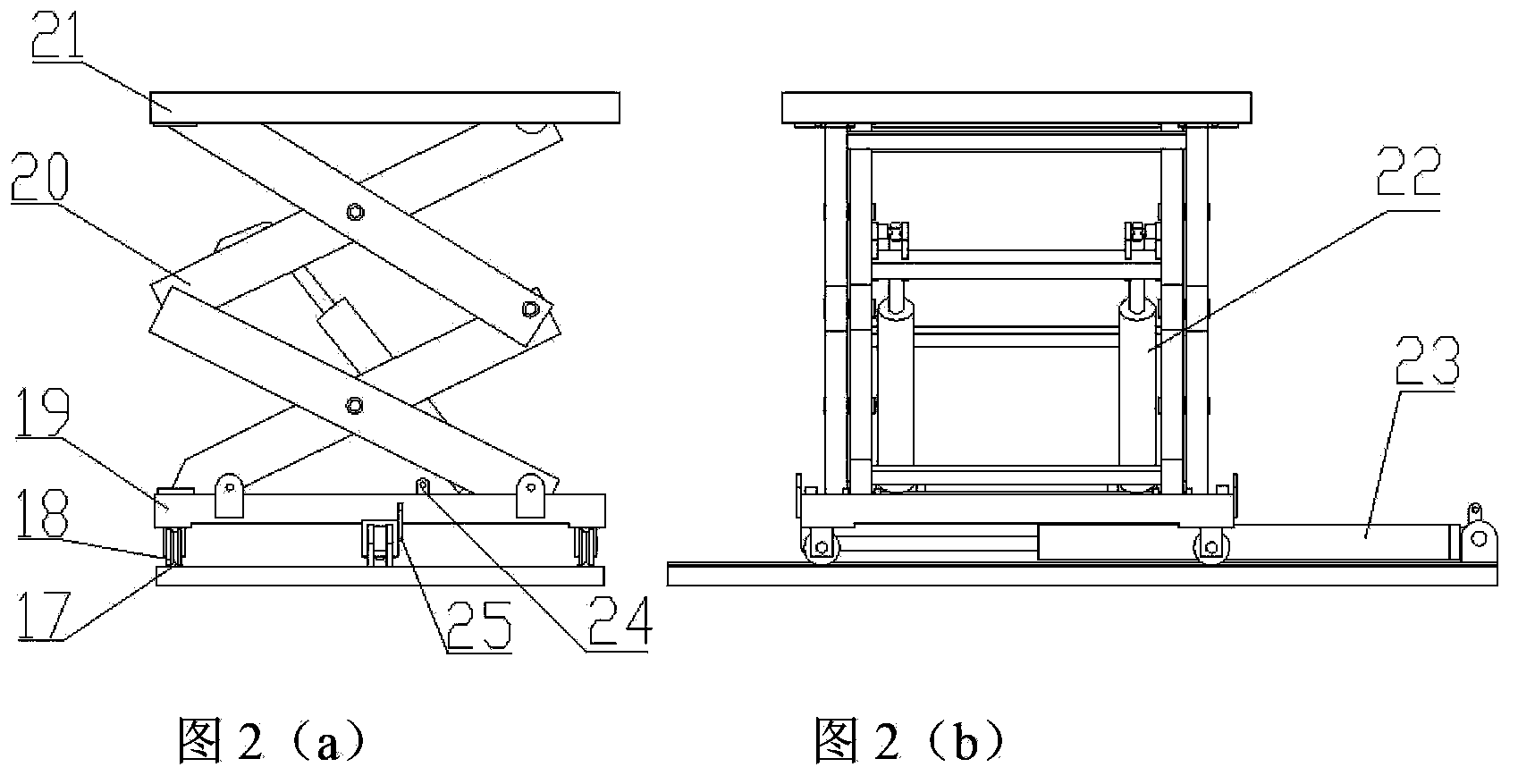

[0025] As shown in Figure 2 (a) and (b), the scissor lift equipment for loading is composed of linear guide rail 17, roller 18, chassis 19, scissor arm 20, material transport platform 21, hydraulic system 22&23, and lift platform height positioner 24. Anti-collision locator 25 constitutes.

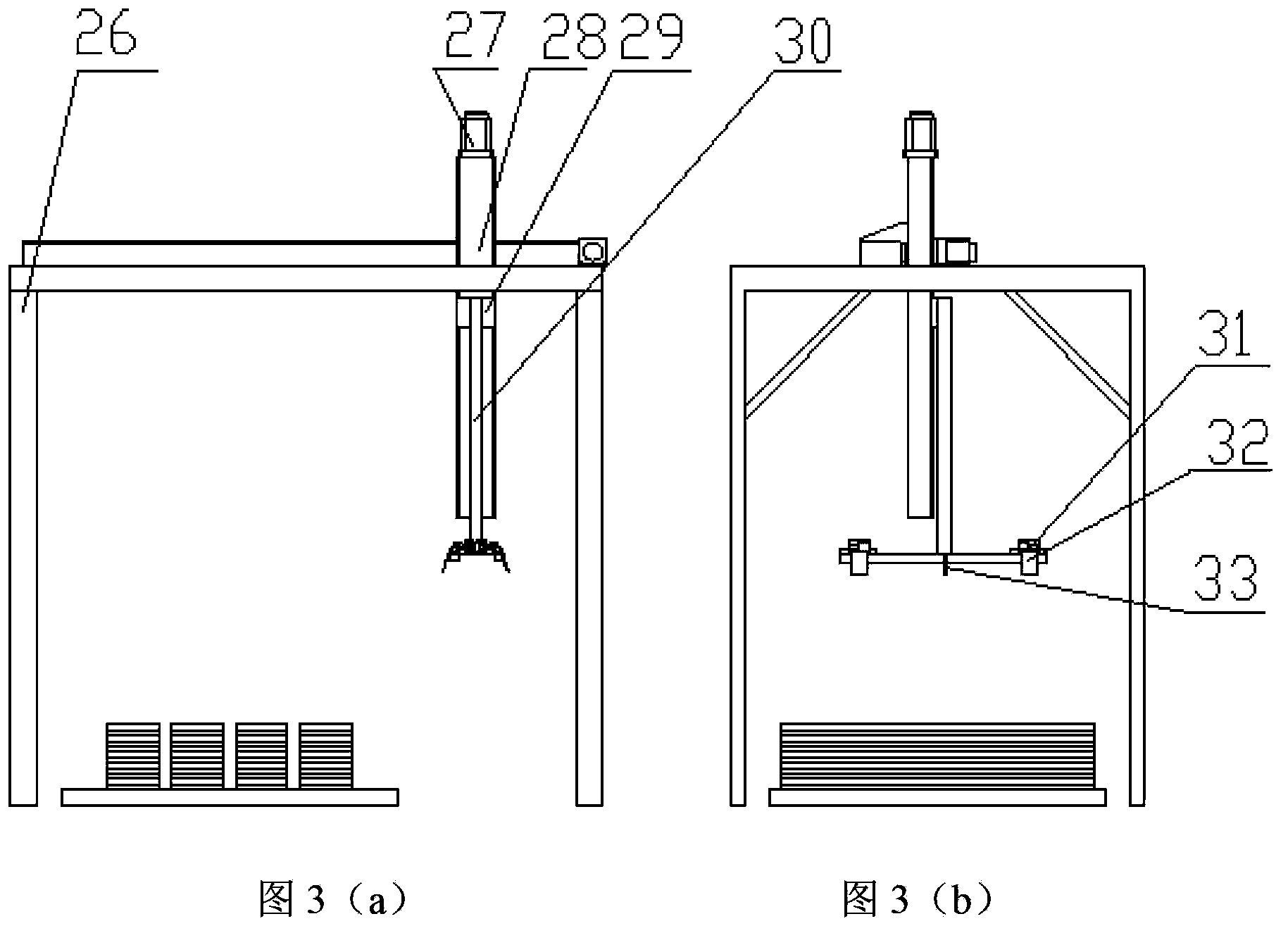

[0026] As shown in Figure 3 (a) (b) (c), the stacker for unloading includes a bracket 26, a servo motor 27&36, an upper and lower guide device 28 (including a ball screw and a guide rail), a slider 29&34, a manipulator bracket 30, Air pressure system 31, gripper 32, travel switch 33, front and rear guiding device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com