Hardware tool discharging device and feeding equipment special for hardware tool discharging device

A technology of hardware tools and feeding equipment, which is applied in the direction of metal processing equipment, feeding devices, manufacturing tools, etc., can solve problems such as large safety hazards, low work efficiency, and high labor intensity of workers, so as to improve production efficiency and reduce labor costs. Strength, material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

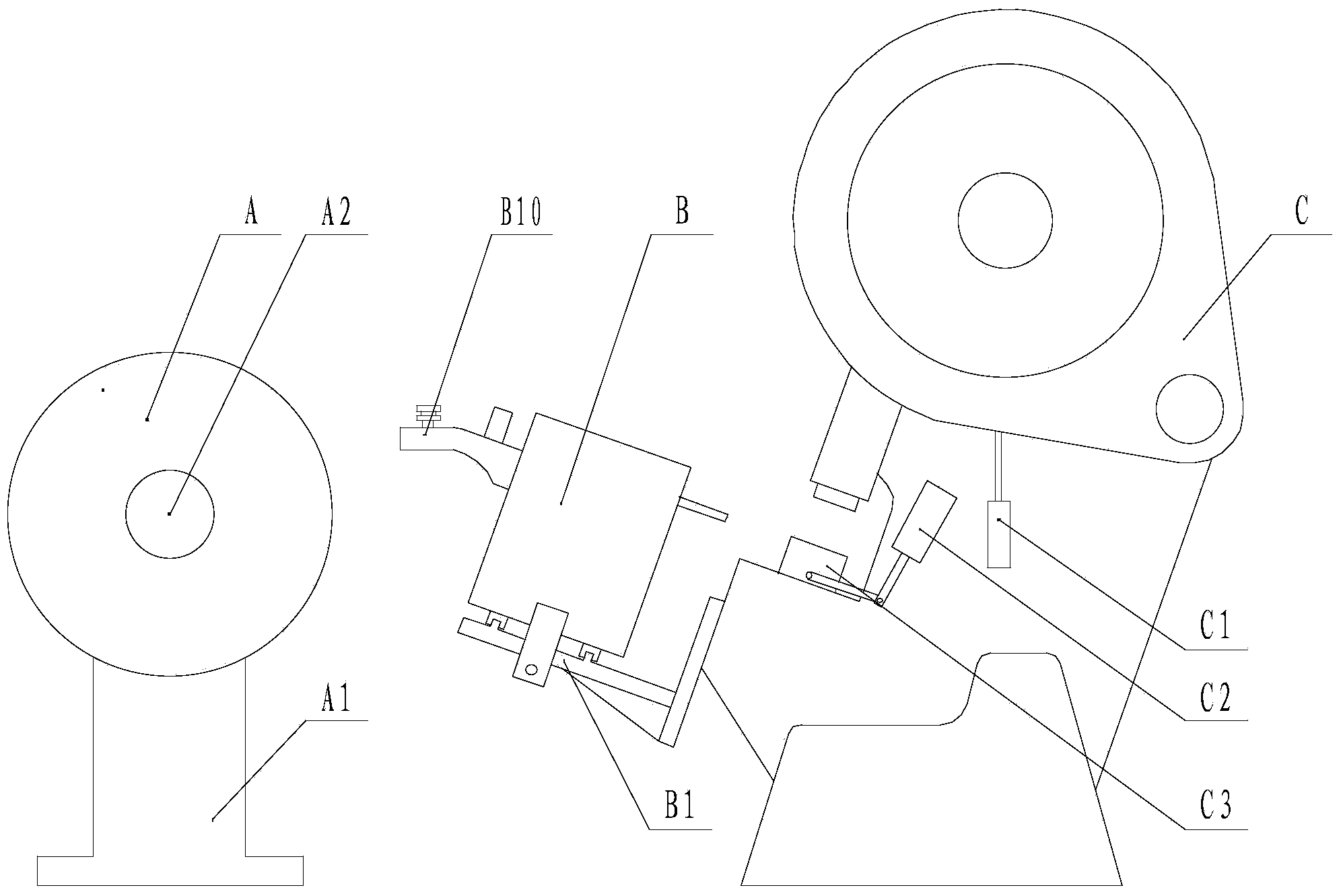

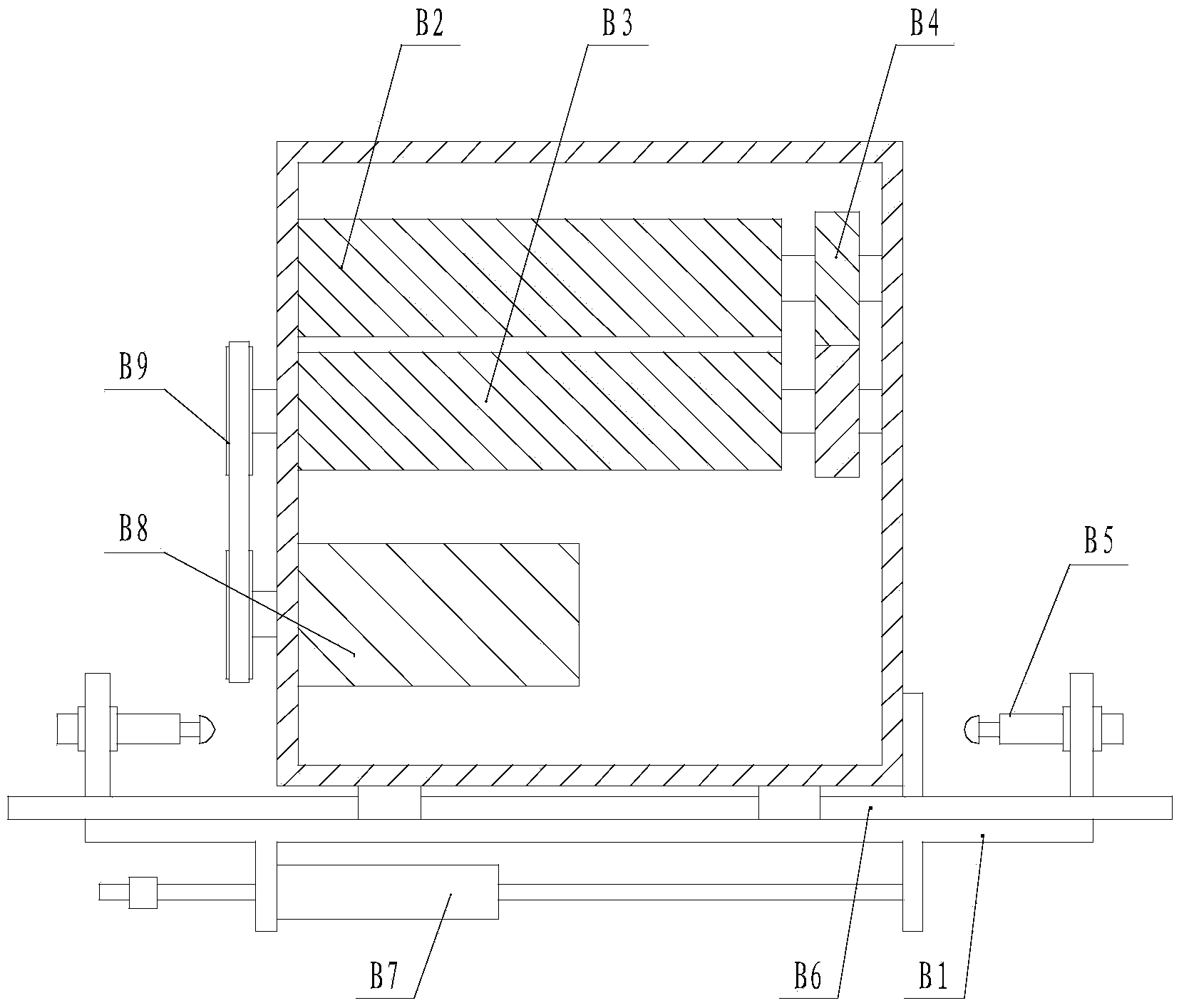

[0032] Embodiment 1: a hardware tool blanking device, including a punch C, on which a feed device B that can move left and right is provided; the feed device B includes a motor B8, a feed roller A B3 and a feed roller B B2, Motor B8 drives the feed roller B3 to rotate, and the feed roller B3 drives the feed roller B2 to rotate.

[0033] When this embodiment is in use, the function of moving left and right can be realized through the cooperation of the rollers with the cylinder or the oil cylinder.

Embodiment 2

[0034] Embodiment two: the feeding device B is installed on the punch press C through the frame A B1, a guide rail B6 is provided between the feeding device B and the frame A B1, and a cylinder C B7 is provided at the bottom of the frame A B1; A guiding device B10 is provided above the device B; a hydraulic buffer B5 is respectively provided on both sides of the feeding device B, and the hydraulic buffer B5 is fixedly connected to the frame A B1; the others are the same as the first embodiment.

Embodiment 3

[0035] Embodiment 3: The present invention also includes an automatic unwinding machine A, which includes a frame B A1 on which a turntable A2 is arranged; the others are the same as in Embodiment 2.

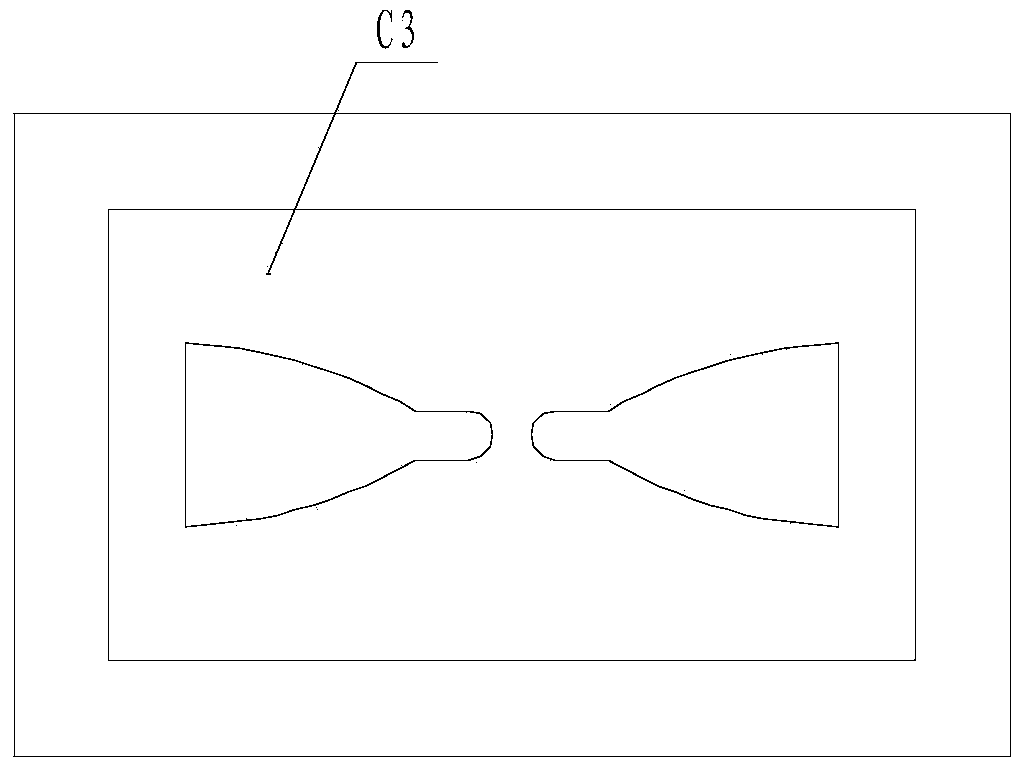

[0036] When the present invention is in use, it is used in conjunction with the automatic control system; for the convenience of calculation, the motor B8 is connected with the feed roller A B3 through the synchronous pulley B9, and the feed roller A B3 drives the feed roller B B2 through the gear B4; the punch C is provided with a cylinder A C1 is connected to cylinder B C2; cylinder B C2 is connected to the cam of symmetrical mold C3; cylinder A C1, cylinder B C2, cylinder C B7 and servo motor B8 are respectively connected to the automatic control system;

[0037] Design the specific automatic control system according to the specific mold, install the steel strip D on the turntable A2 of the automatic unwinding machine A, and the front end of the steel strip D passes through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com