Single pendulous vertical type flat-pressing flat-die-cutting machine

The technology of flat pressing and die cutting machine is applied in the field of single pendulum vertical flat pressing flat die cutting machine, which can solve the problems of high production cost, low production efficiency, low degree of automation, etc., so as to improve production and processing efficiency. , reduce labor costs, improve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

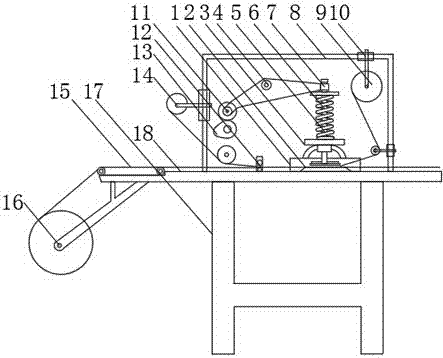

Embodiment 1

[0023] combined with figure 1 As shown, a single pendulum vertical flat die-cutting machine includes a workbench 18 and a frame 17, the workbench 18 is integrally connected with the frame 17, and the workbench 18 is provided with a frame 17 The opposite side is fixed with a casing 8, and the casing 8 is fixed with a film cylinder 14 perpendicular to any side of the work, and a transmission belt 15 is arranged on the workbench 18 on the same side as the film cylinder 14, and the transmission belt 15 The workbench 18 at the lower end is provided with a feed shaft 16; the inside of the frame 17 is provided with a cam 13, and the cam 13 is transmission-connected with a roller 11, and the roller 11 is fixedly connected with a crank that is fixed on the shell 8 and can swing 4. The other end of the crank 4 is provided with a bump 7, and the workbench 18 is provided with a support frame 1 vertically facing the bump 7, and a vertical bearing 3 is installed on the support frame 1, and ...

Embodiment 2

[0027] In order to make the laminating machine compact in structure, have a strong sense of space, and facilitate the installation and layout of components, on the basis of the structure and principle of Embodiment 1, further combined with the attached figure 1 As shown, the housing 8 of the die-cutting machine in this embodiment is rectangular in shape, and the housing 8 is respectively provided with openings on the side facing the conveyor belt 15 and on the side facing the guide wheels.

[0028] Structural principles:

[0029] The rectangular shell 8 is fixed on the workbench 18, the four sides of the rectangle are vertical to the workbench 18, the opening towards the conveyor belt 15 is the feed port, the opening towards the guide wheel is the discharge port, the outer wall of the rectangular shell 8 is flat, The space formed by the inner wall is simple and tidy. The film roller 14 is fixed on the shell 8 directly above the feed inlet, and the take-up shaft 9 is arranged p...

Embodiment 3

[0031] In order to make the feeding and cutting process of the die-cutting machine smoother, on the basis of the structure and principle of Embodiment 1, further combine the attached figure 1 As shown, in this embodiment, the transmission belt 15 is located above the feed shaft 16 , the crank 4 is provided with a bearing, and a fixed shaft is provided in the bearing, and one end of the fixed shaft is fixed on the casing 8 .

[0032] Structural principles:

[0033] The material to be coated surrounds the conveyor belt 15 from the feed shaft 16 at the lower end of the conveyor belt 15, and the beginning of the conveyor belt 15 is always in contact with the material to be coated, so that the material to be coated is continuously transmitted, and the casing 8 The internal crank 4 is fixed with the housing 8 through the bearing and the fixed shaft, so that the crank 4 rotates on the fixed shaft through the bearing, and the pressing force applied by the cam 13 to the roller 11 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com