Battery string preparation method and battery string welding equipment

A welding equipment and battery technology, which is applied in the field of solar cells, can solve the problems of low production efficiency of battery strings, misalignment of welding strips, and missing welding, etc., and achieve the effects of shortening the production cycle, solving the displacement of welding strips, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

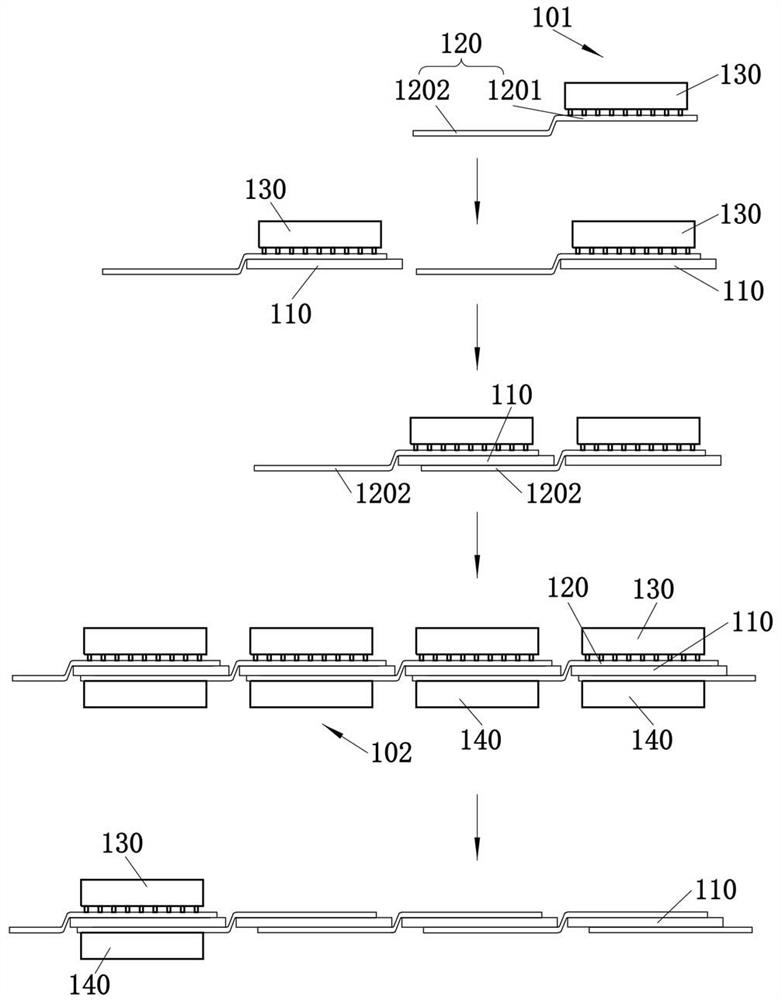

[0071] This embodiment provides a method for preparing a battery string, which is used for preparing the battery string. like figure 1 As shown, the battery string includes a plurality of battery sheets 110 , and two adjacent battery sheets 110 are connected in series by welding ribbons 120 . The welding strip 120 includes a front welding section 1201 and a back welding section 1202. The front welding section 1201 is fixed on the front of the previous cell 110 and is connected to the grid lines on the front of the cell 110. The back welding section 1202 is fixed to the latter cell 110. on the backside of the battery sheet 110 and connected to the back electrode on the backside of the battery sheet 110 to realize the series connection of the battery sheet 110 . In this embodiment, the upper surface of the battery sheet 110 is defined as the front surface of the battery sheet 110 , and the lower surface of the battery sheet 110 is defined as the back surface of the battery surf...

Embodiment 2

[0095] This embodiment provides a battery string welding device, which can use the battery string preparation method in the first embodiment.

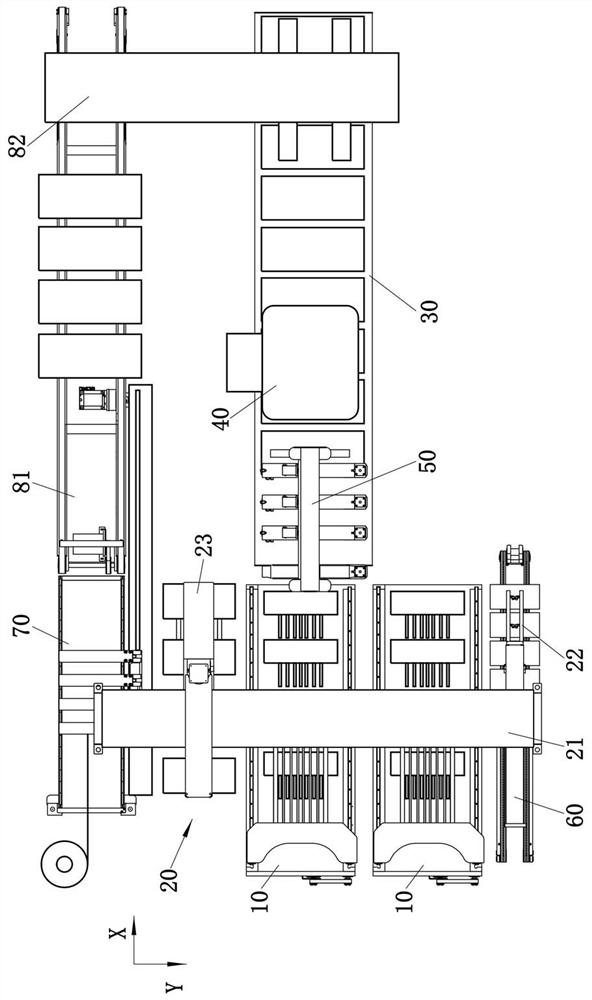

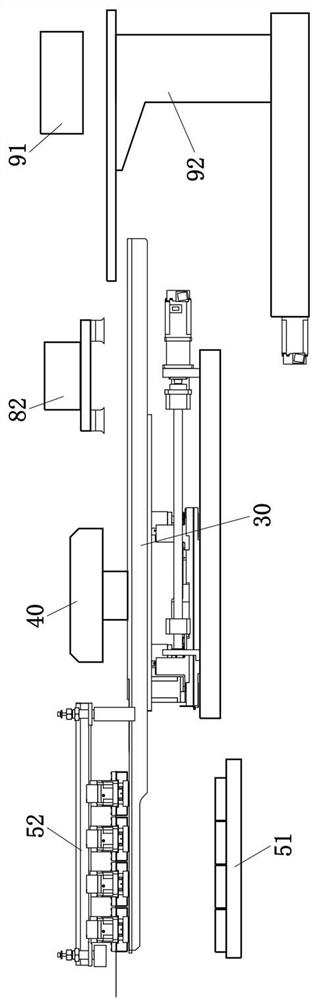

[0096] like figure 2 and image 3 As shown, the battery string laying equipment includes a laying platform 10 , a grabbing device 20 , a conveying device 30 , a lower mold supply device 50 and a welding device 40 . The grasping device 20 is used for grasping the battery sheet 110 , the welding tape 120 and the upper pressing tool 130 and placing it on the laying platform 10 , so that the welding tape 120 and the upper pressing tool 130 are stacked on the battery sheet 110 to form the laying unit 101 . The laying platform 10 is used to carry the laying units 101, and can stack the laying units 101, so that the back of the battery slices 110 in the subsequent laying unit 101 is placed on the back welding section 1202 in the previous laying unit 101; the lower mold The supply device 50 is used for providing the lower mold 140 to the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com