Material storage mechanism achieving automatic gasket selecting and feeding

A gasket and material storage technology, which is applied in the field of automatic gasket selection and storage mechanism, can solve the problems of large number of cylinders, increased production cycle, and large space occupation, so as to optimize the overall structure, reduce production cycle, and occupy small space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

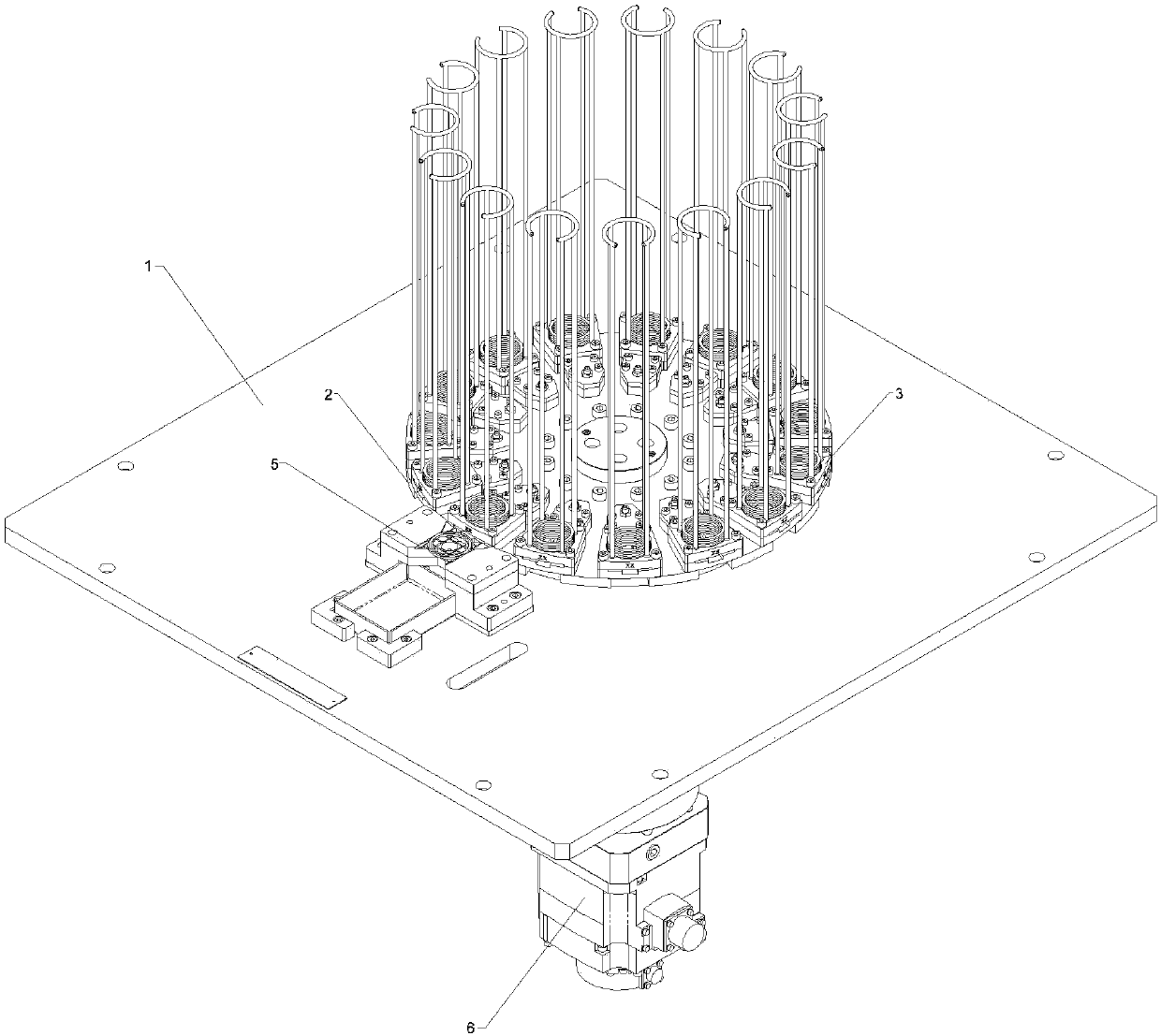

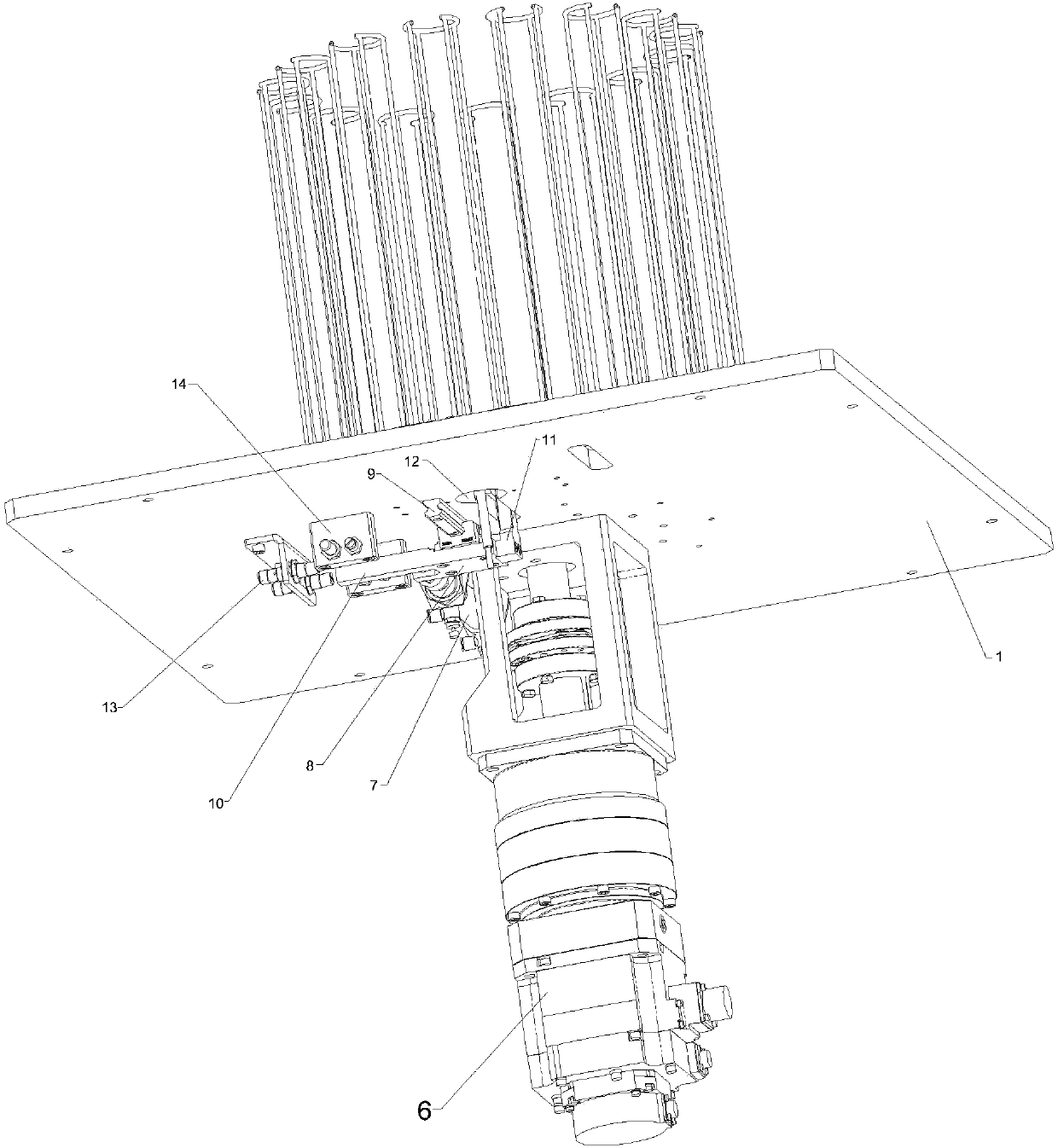

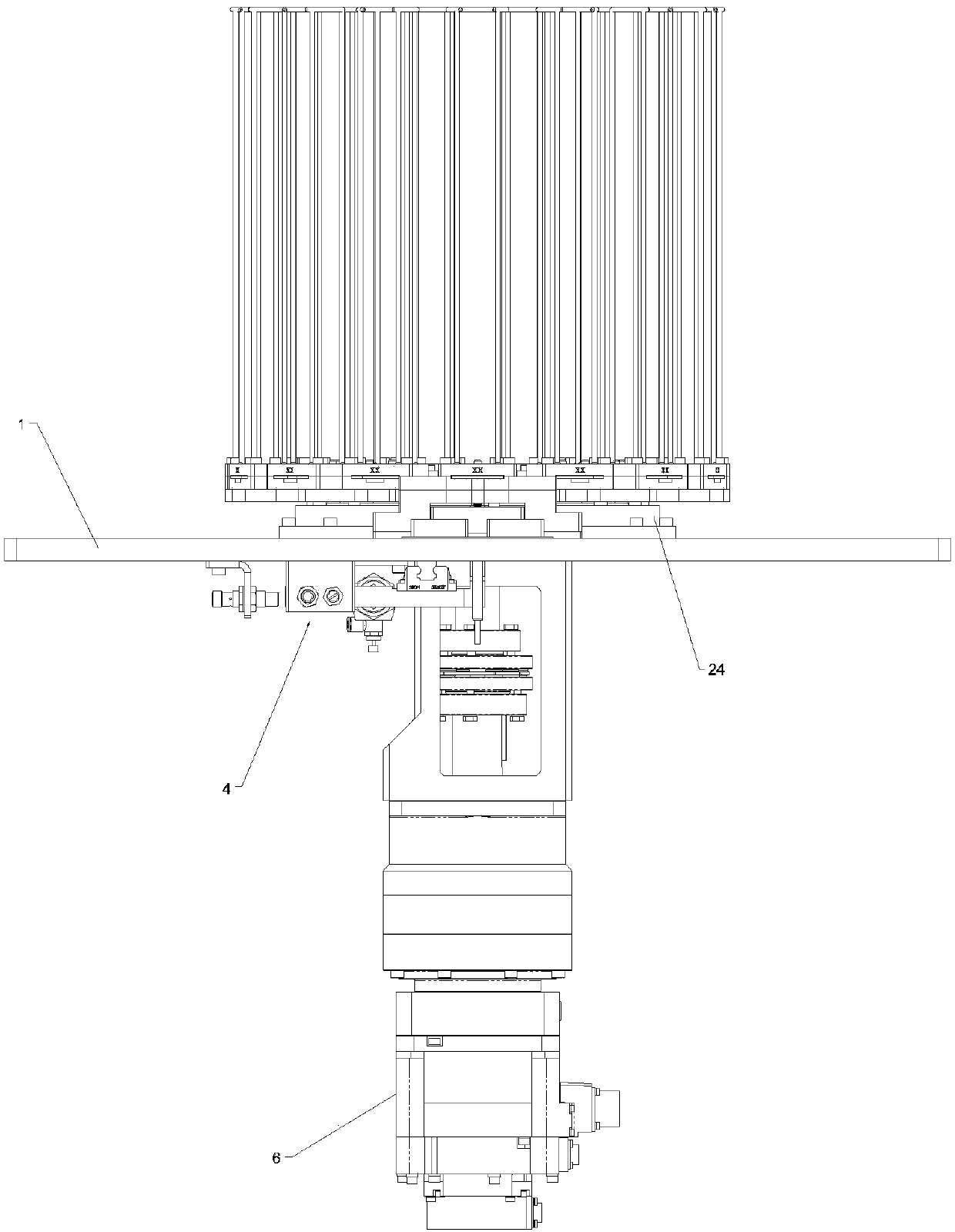

[0034] see Figure 1 to Figure 4 , a kind of automatic pad storage mechanism of the present embodiment, its structure is set to:

[0035] The rotatable turntable 2 driven by the motor 6 is supported on the top of the console 1 by bearings, and a plurality of gasket storage mechanisms 3 are distributed on the upper end of the turntable 2 at equal intervals along the circumferential direction;

[0036] A storage position 5 is set on the upper end of the console 1 and outside the turntable 2 to receive the selected pads. The pad storage mechanisms 3 that rotate with the turntable 2 are in the position facing the storage position 5. for the work position;

[0037] At the lower end of the console 1, an active push rod assembly 4 driven by the cylinder 7 to perform linear reciprocating motion is arranged, so that the active push rod assembly 4 that performs linear reciprocating motion pushes the gasket in the gasket storage mechanism 3 in the working position to the storage positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com