Double-station assembly table for rotary automobile front slide column

A front spool, dual-station technology, used in assembly machines, hand-held tools, manufacturing tools, etc., can solve the problems of dissatisfaction with the operator's workload, difficulty in balancing the production rhythm, and low work efficiency, achieving continuous distribution, The assembly process is simple and convenient, and the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

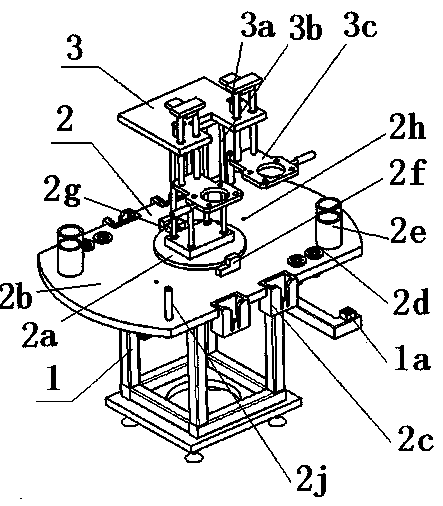

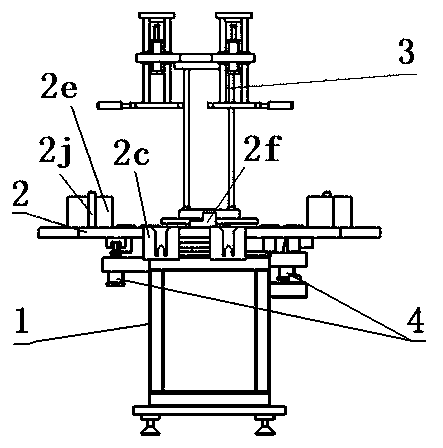

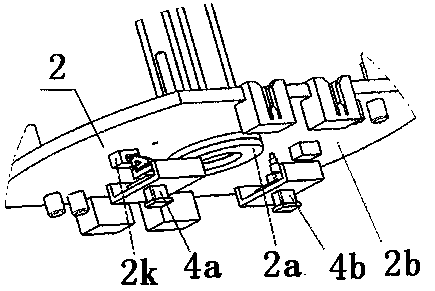

[0024] Examples of the present invention figure 1 , figure 2 , image 3 , Figure 4 As shown, it includes a base 1, a working platform 2, a shock absorber fork mounting platform 3, a limit mechanism 4, a rotating bearing, and a press; the working platform 2 includes a fixed platform 2a, a rotating platform 2b, and an identification sensor 2g; the rotating platform 2b The center has a mounting hole for a fixed platform 2a, the fixed platform 2a is installed in the fixed platform mounting hole at the center of the rotating platform 2b, and is fastened on the base 1; the shock absorber fork mounting platform 3 and the identification sensor 2g are installed on the fixed platform 2a; the shaft of the rotary bearing is installed on the base 1, the rotary platform 2b is tightly connected with the outer ring of the rotary bearing, and the rotary platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com