Wear-resistant structure of circular needle cylinder

A needle cylinder and circular technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of needle cylinder wear, product cost increase, unevenness, etc., to improve service life, fabric quality assurance, weaving smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

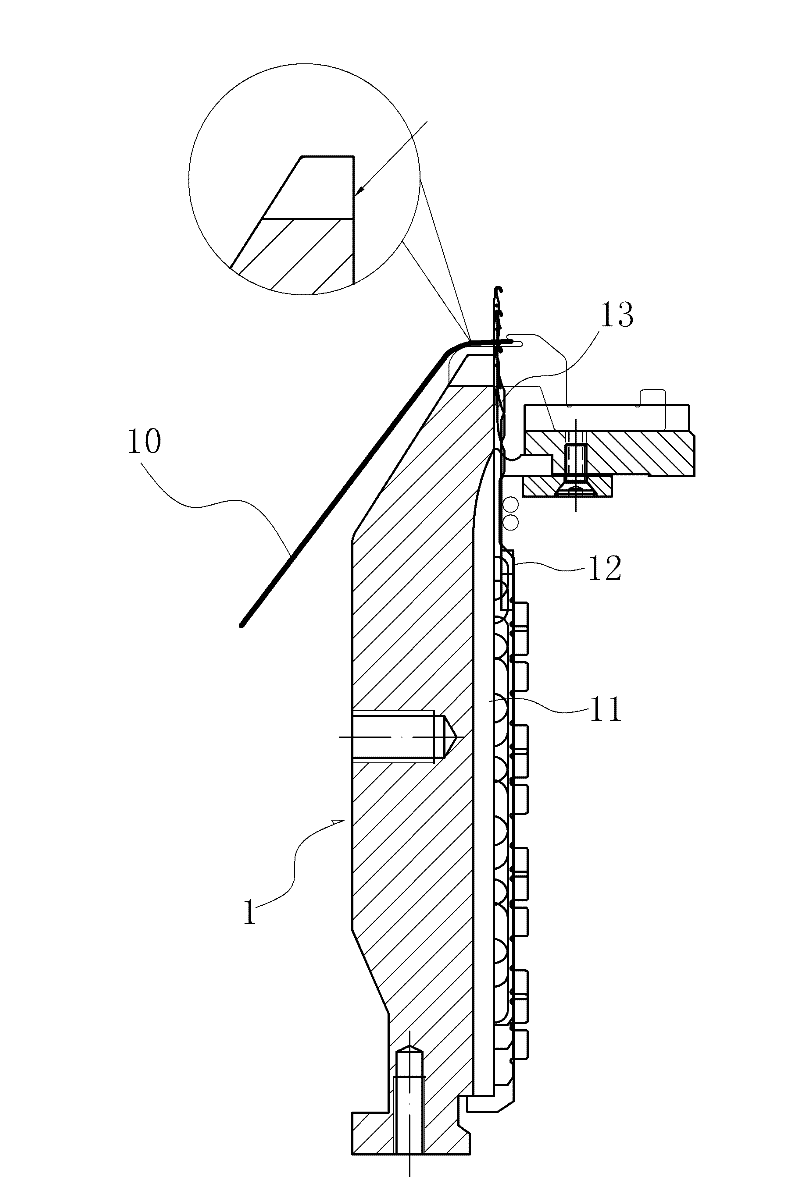

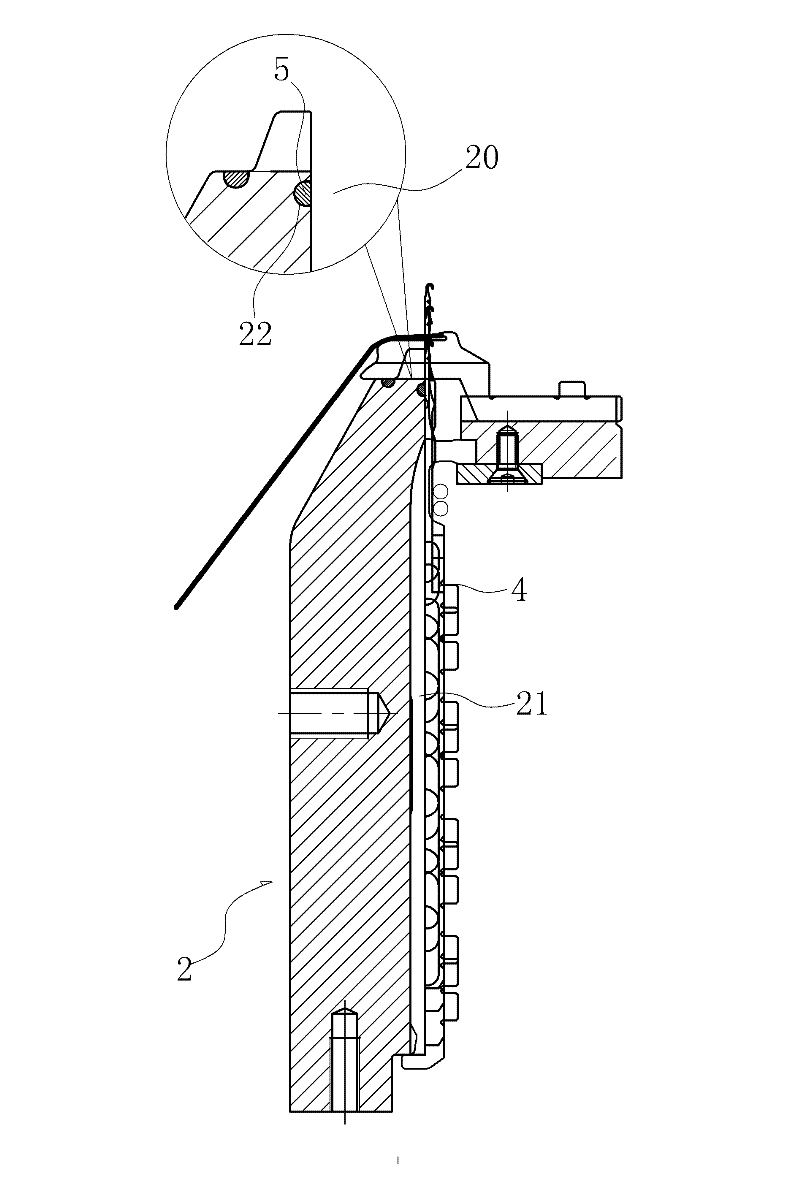

[0029] The technical solution adopted in the present invention is: an annular groove is provided near the mouth of the needle cylinder, and a wear-resistant steel wire is installed in the groove, and the wear-resistant steel wire forms frictional contact with the knitting needles to protect the needle cylinder and prevent wear and tear. . In the present invention, the syringe can be in various styles and models, which will be described with specific examples below.

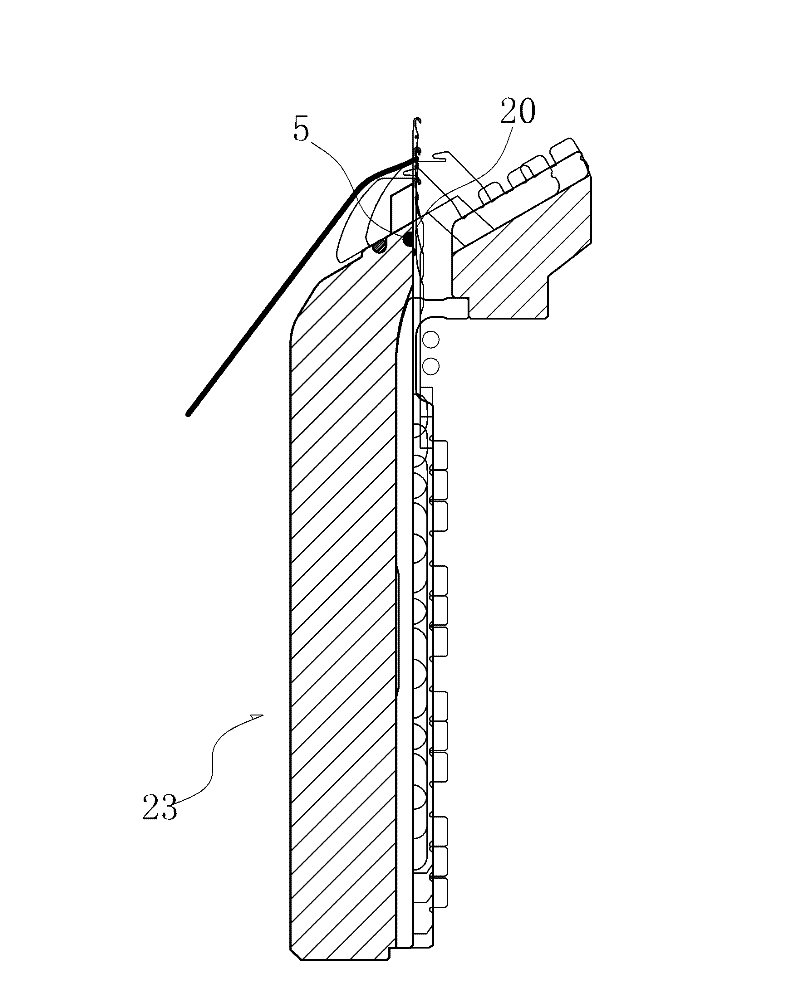

[0030] See figure 2 As shown, the first embodiment is a conventional vertical syringe 2 . The circumferential surface of the vertical needle cylinder 2 is vertically provided with a needle groove 21 for accommodating the knitting needle 4, and an annular groove 22 is provided on the surface above the needle groove 21 near the mouth of the needle cylinder 20. The annular groove 22 Along the peripheral surface of the vertical syringe 2, a wear-resistant steel wire 5 is arranged in the groove 22. The hardness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com