Flyknit vamp with breathing scale structure and flyknit method thereof

A technology of scales and uppers, which is applied in the direction of shoe uppers, footwear, knitting, etc., to achieve the effect that is conducive to the breathable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

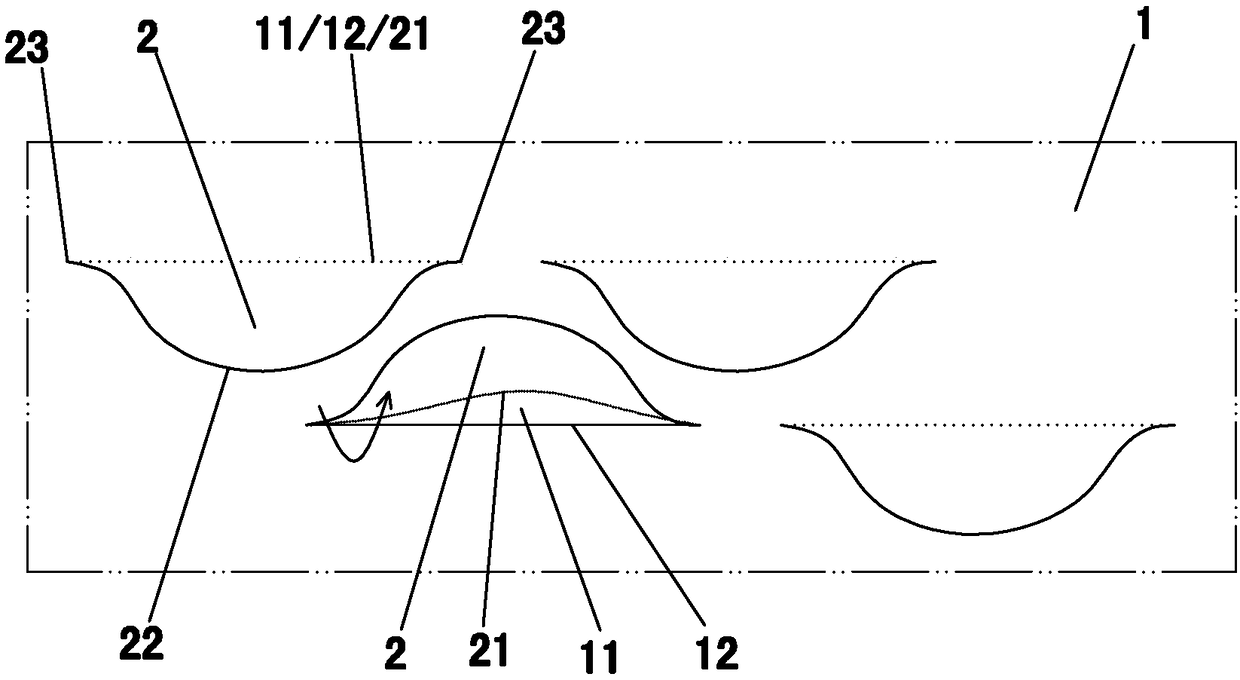

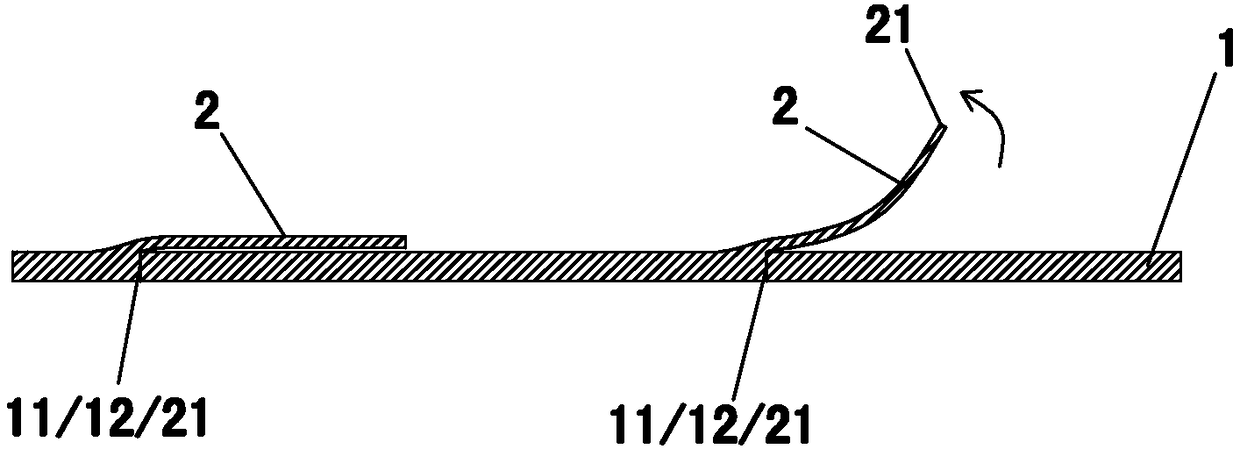

[0048] Embodiment one: if figure 1 with figure 2 As shown, a disclosed flying woven shoe upper with a breathable scale structure includes a shoe upper base 1 and a flake-like scale body 2 integrally formed on the shoe upper base 1 by flying weaving. The scale body 2 includes a shoe upper The connecting edge 21 connected together by the base 1, the free edge 22 opposite to the connecting edge 21 (that is, the free edge 22 is not connected to the vamp matrix 1) and the two ends corresponding to the connecting edge 21 and the free edge 22 are respectively braided. The extension end 23 of the shoe upper matrix 1 is woven with a through hole 11 at the position corresponding to the scale main body 2, and one side of the through hole 11 is a common connecting side 21 with the scale main body 2, and the through hole 11 and the connecting side The other side opposite to 21 is the initial side 12, where the through hole 11 has a linear structure, and its length can be long or short. T...

Embodiment 2

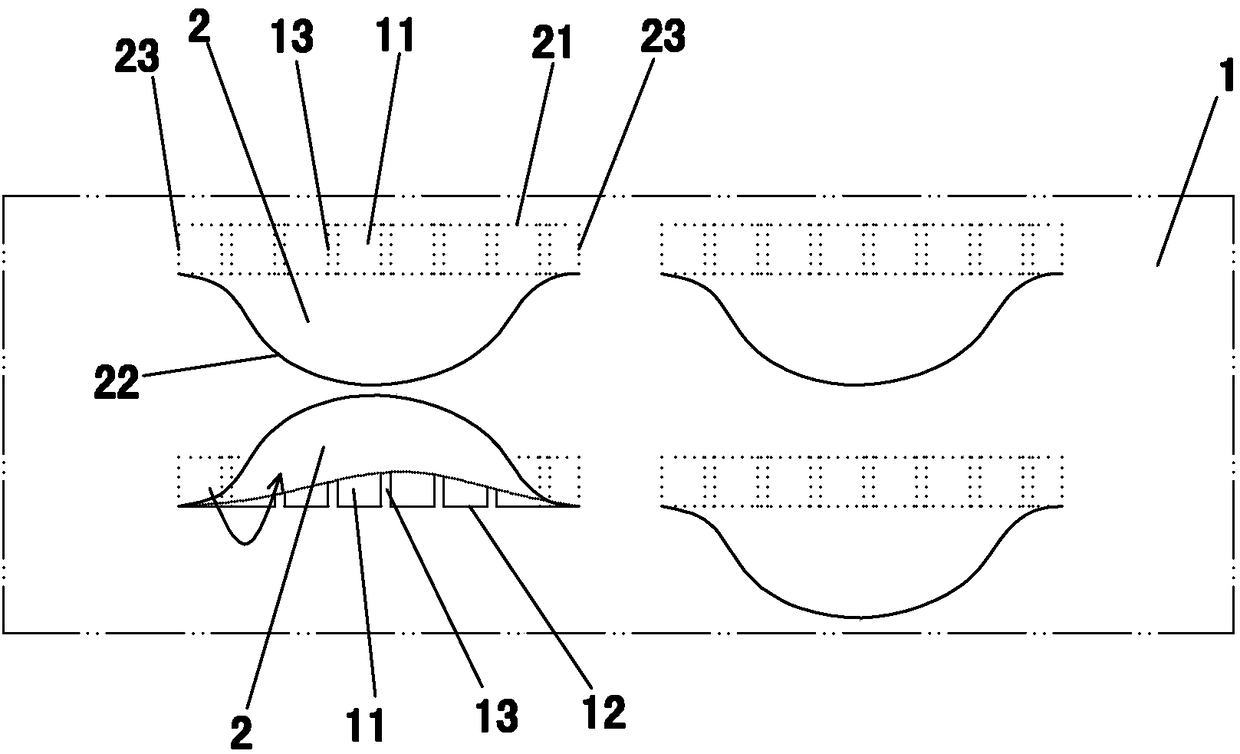

[0059] Embodiment two: if image 3 with Figure 4 As shown, it is different from Embodiment 1 in that the through holes 11 are woven with spacer strips 13 that divide the through holes 11 into multiple ones, one end of the spacer strips 13 is connected to the connecting edge 21, and the spacer The other end of bar 13 connects initial edge 12; The through hole 11 among the above-mentioned embodiment one is linear structure, if will form the bigger hole structure of the braiding of through hole 11 then need to weave many rows and just can form, and empty Multi-row braiding extension requires the spacer bar 13 to be realized, and the spacer bar 13 can also reach the limit of the through-hole 11 to cause a large deformation. For example, the spacer bar 13 is added to the through-hole 11 of the linear structure in the above-mentioned embodiment 1. In this way, when the through hole 11 is deformed, the size of the expanded hole is limited by the spacer bar 13 . In the fly weaving ...

Embodiment 3

[0062] Embodiment three: as Figure 5 with Image 6 As shown, on the basis of the above-mentioned embodiment one or embodiment two, it is also possible that the through holes 11 are braided to form the free side 22 of the corresponding position of the scale body 2 to the connecting side 21 and bind together. Waist strip 14 , the said waist strip 14 gathers the scale main body 2 into a multiple scale structure arranged side by side, one end of said waist strip 14 is connected to connecting edge 21 , and the other end of said waist strip 14 is connected to initial edge 12 . In the fly weaving method of the fly weaving shoe upper with the above structure, in step 3) process,

[0063] When knitting the line from the upper base 1 to the initial side 12 of the through hole 11, knitting to the corresponding through hole 12 and the waist 14 is also carried out by using several stitches of narrowing knitting and continuing knitting at intervals of several stitches, thereby forming the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com