Fiberglass insulating tube with multi-layer ring shaped braiding structure

A technology of circular braiding and fiberglass, which is applied to the shape/style/structure of winding insulation, insulators, insulators, etc., can solve the problems of low production efficiency, low dimensional accuracy, and increased costs, and achieve improved manufacturing efficiency, simple production process, The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

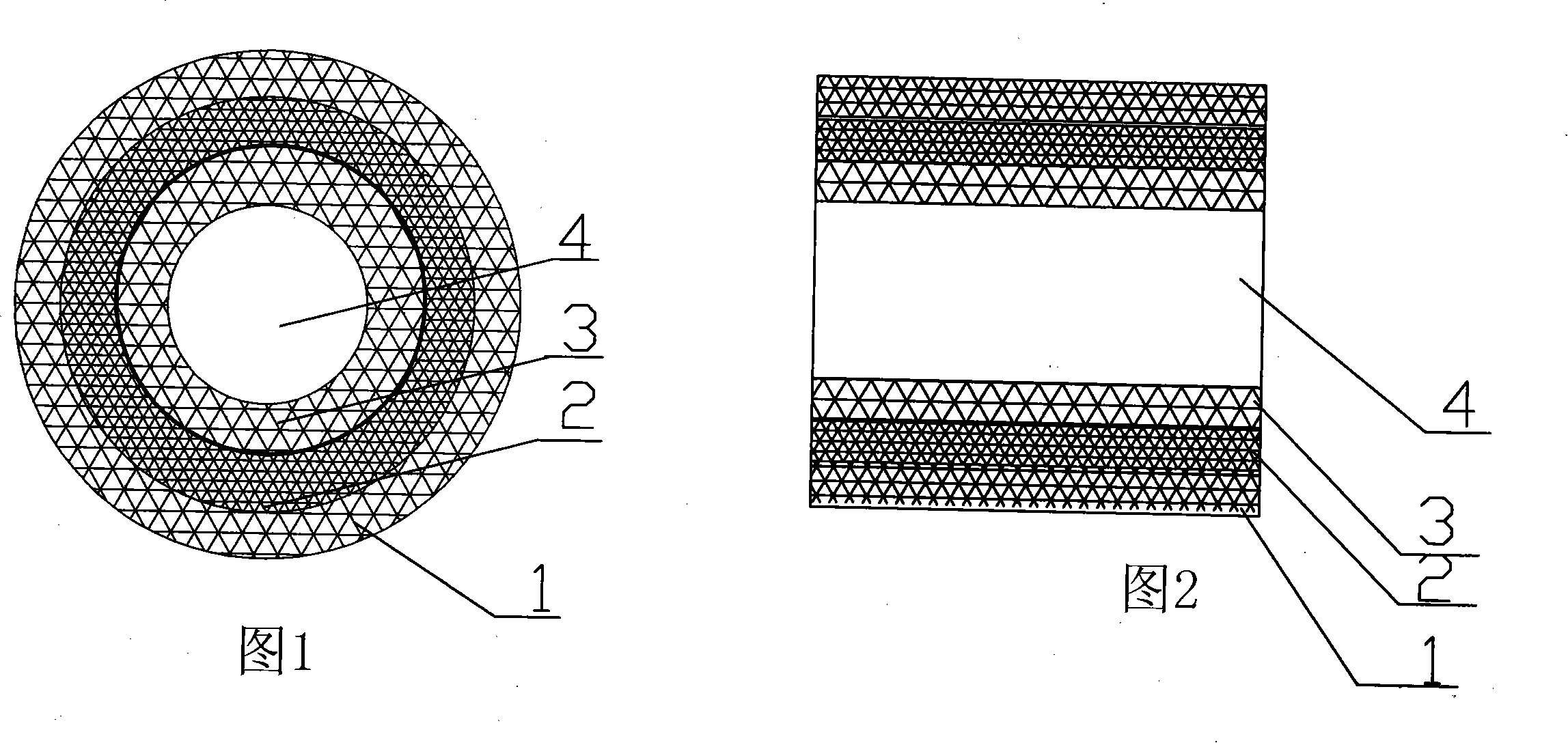

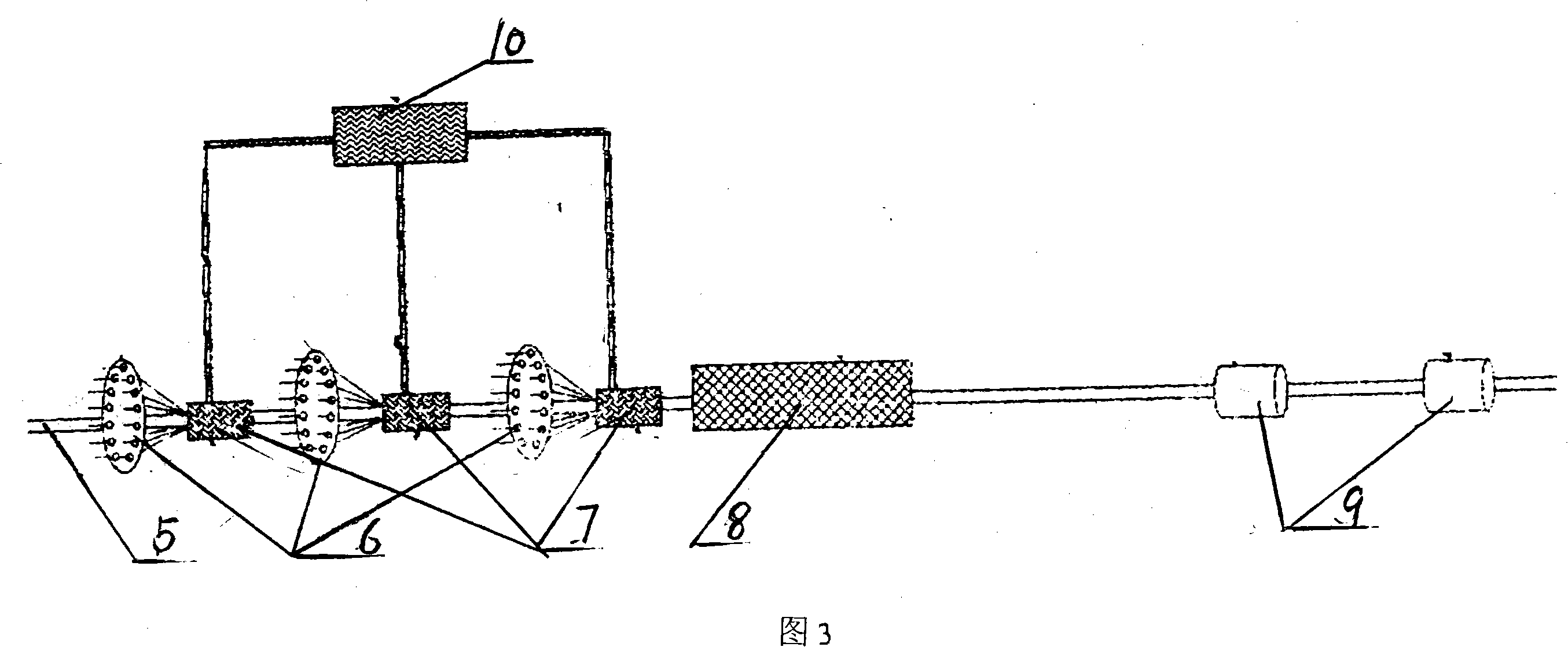

[0022] As can be seen from Fig. 1 and Fig. 2: the multi-layer FRP insulating pipe 4 is composited by three layers of FRP insulating pipes (1, 2, 3), and each layer of FRP insulating pipe of the composite FRP insulating pipe is It is a fiberglass insulated braided pipe circularly braided by warp and weft on a horizontal knitting machine. The diameter of the composite fiberglass insulated pipe can be between 2 and 600 mm. It can be seen from Figure 3 that each layer of fiberglass insulated braided pipe is composited The fiberglass insulating braided pipe impregnated with the adhesive before, and the composite fiberglass insulating pipe are compounded under the same uniform straight mandrel, and finally shaped and solidified by the pultrusion die to form the fiberglass insulating pipe.

[0023] It can also be seen from Fig. 3 that the present invention adopts three computer-controlled two-dimensional horizontal braiding machines 6 to circularly weave three layers of fiber braided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com