Ultrafine polyester draw textured yarns and method for processing same

A processing method and ultra-fine polyester technology, applied in filament/thread forming, single-component polyester rayon, textiles and papermaking, etc., can solve the problem of poor evenness, dyeing performance and other physical properties that cannot be improved Problems such as product grade and added value, difficulty in developing microfiber products, etc., to achieve excellent physical properties, improve product grade and added value, and fabric style.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further illustrate technical scheme of the present invention by specific embodiment:

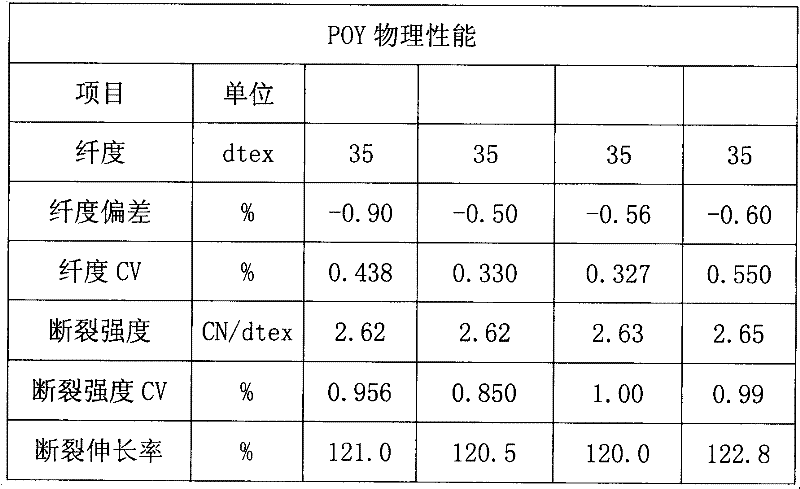

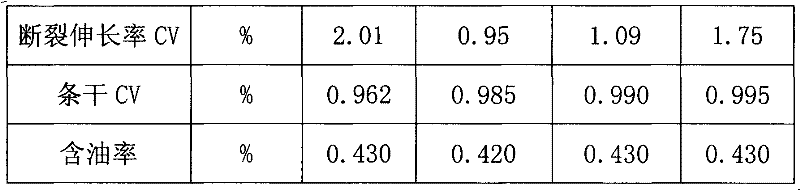

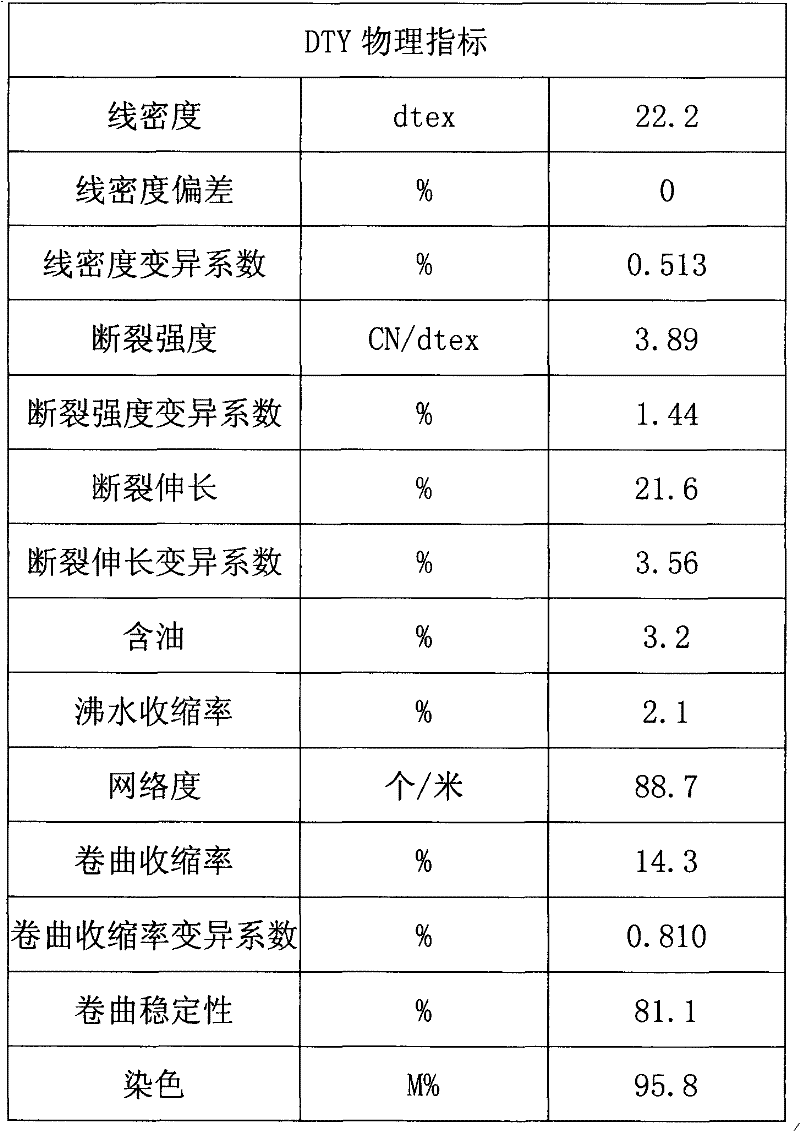

[0020] Use Barmag ring blowing equipment and winding machine to produce 20D / 144F ultra-fine polyester low-stretch yarn, firstly through the esterification reaction of purified terephthalic acid and ethylene glycol, and then through pre-condensation and final polycondensation to prepare a viscosity of 0.650 The polyester melt is directly spun, and it is produced by spinning-false twisting two-step process technology. When the melt is conveyed, the temperature of the pipeline is 288.5°C, the temperature of the box is 298°C, and the spinneret is PRB-88-144-0.10* 0.20, the metal sand ratio of the component is 100-120 mesh: 180μm / g, so that the pressure reaches 190bar, and the cooling is carried out by means of surrounding air blowing. The difference is 18pa, the height of the oil frame is 500mm, and the oil agent with an effective concentration of 88% is used. The oiling rate of the oil n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com