Yarn tension control mechanism of warp knitting machine

A yarn tension and control mechanism technology, applied in warp knitting, textiles, papermaking, knitting, etc., can solve the problems of time error, easy heating, long installation and debugging time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to better understand the present invention, the present invention will be further described in detail with reference to the accompanying drawings.

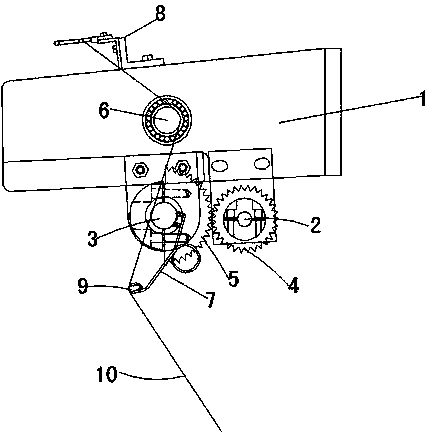

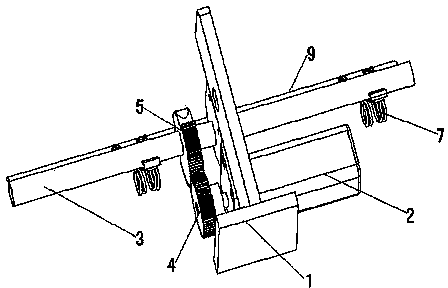

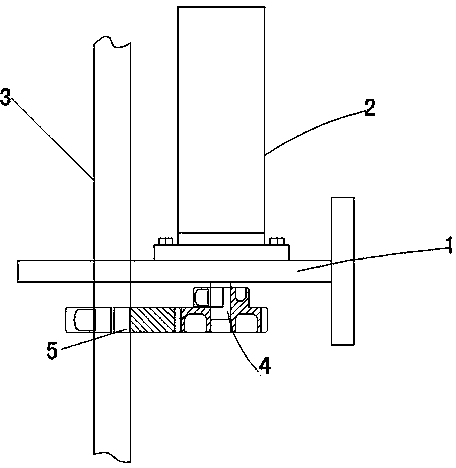

[0012] See Figure 1 to Figure 3 Shown: a yarn tension control mechanism of warp knitting machine, including tension seat (1), tension rod (3), tension spring (7), yarn guide cap (9), yarn passing rod (6), driving gear ( 4), driven gear (5), servo motor (2) and yarn splitting seat (8). The tension seat (1) is fixedly installed on the main beam of the warp knitting machine by bolts, and the tension seat (1) is provided with holes for installing the tension rod (3), the yarn passing rod (6) and the servo motor (2). The tension rod (3) is installed on the tension seat (1), and the passive gear (5) is installed on the tension rod (3). The passive gear (5) is a detachable semicircular gear, so that, The driven gear (5) can be conveniently installed on the tension rod (3) through bolts according to the needs of installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com