Patents

Literature

37results about How to "Realize automatic swing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

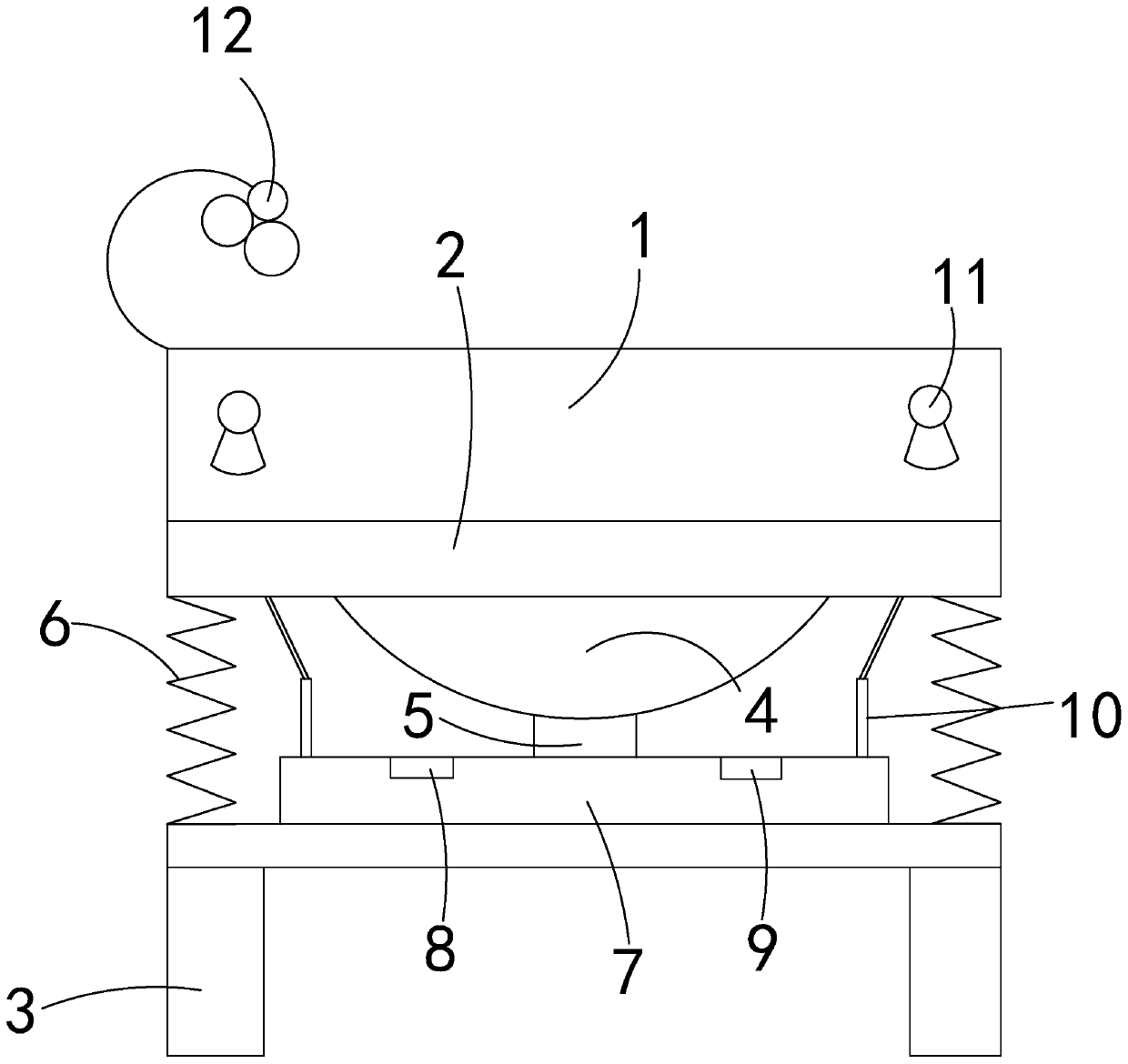

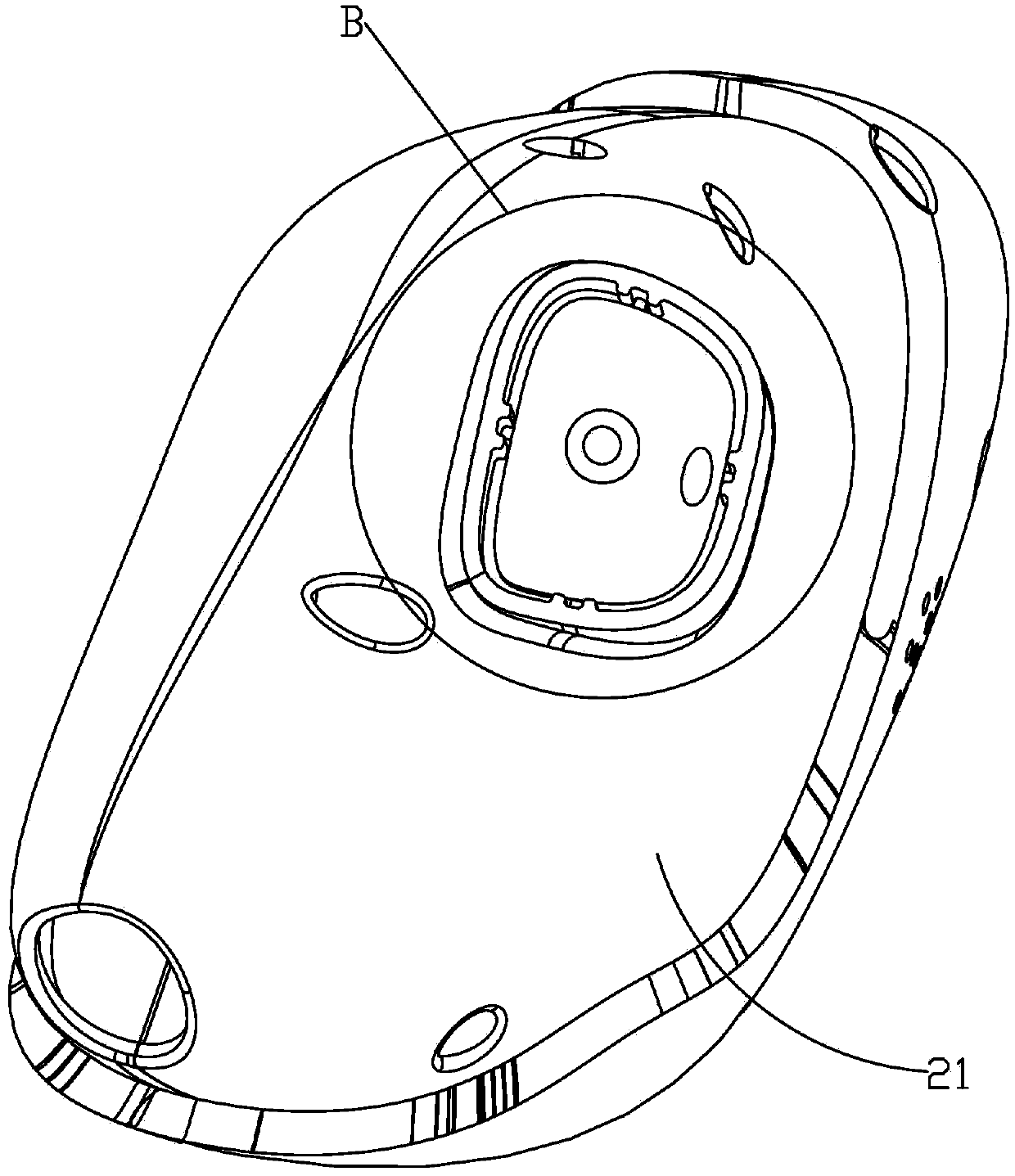

Swing-amplitude-adjustable baby hammock

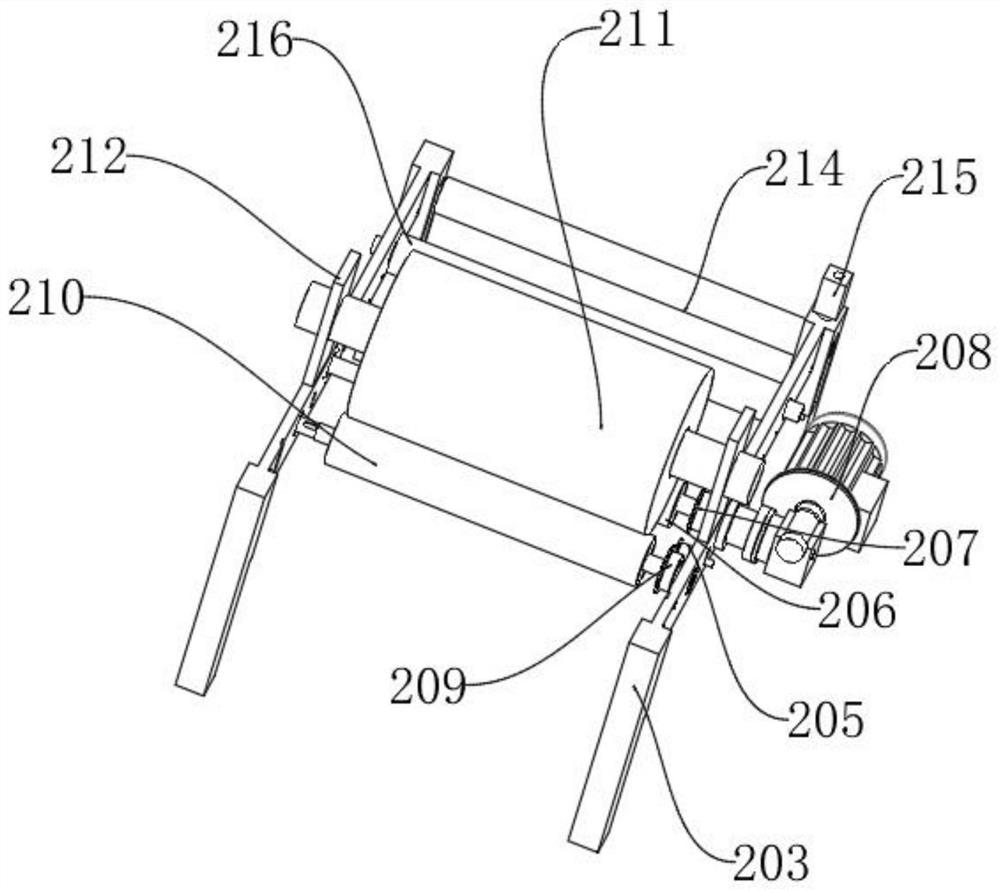

The invention discloses a swing-amplitude-adjustable baby hammock which comprises a base, a transmission adjusting structure, a driving structure, a driven structure, a baby hammock body, a protectionstructure and two driving sliders. The swing-amplitude-adjustable baby hammock has the advantages that a baby bed can be automatically swung, a baby is comforted to fall asleep, the baby hammock relieves burden of an adult for soothing the baby to fall asleep, swing amplitude can be adjusted according to actual situations such as age and body weight of a baby, so that sleep of the baby is more comfortable, the transmission adjusting structure is fixedly connected at the left end of the base, left ends of the two driving sliders are slidably connected on the base, the right ends of the two driving sliders are fixedly connected with the driving structure, the transmission adjusting structure is slidably connected in the two driving sliders, the driving structure is slidably connected on thebase, the right end of the driving structure is hinged to the baby hammock, the right end of the baby hammock is hinged to the driven structure, the driven structure is slidably connected on the base, and the protection structure is inserted into the left end of the base.

Owner:章雪霞

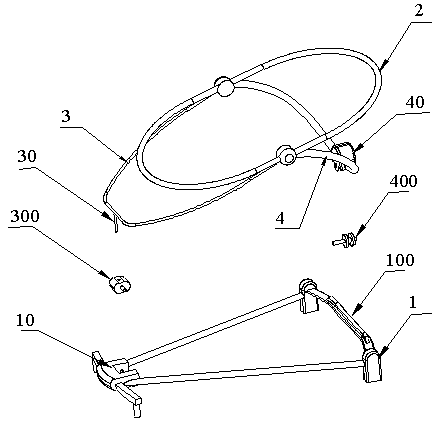

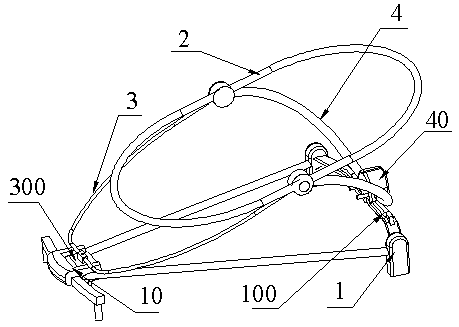

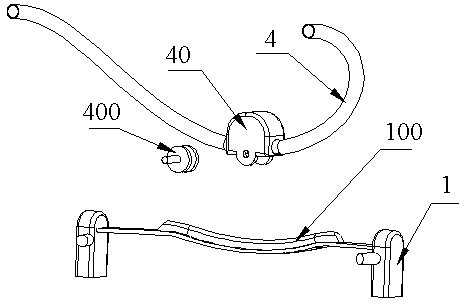

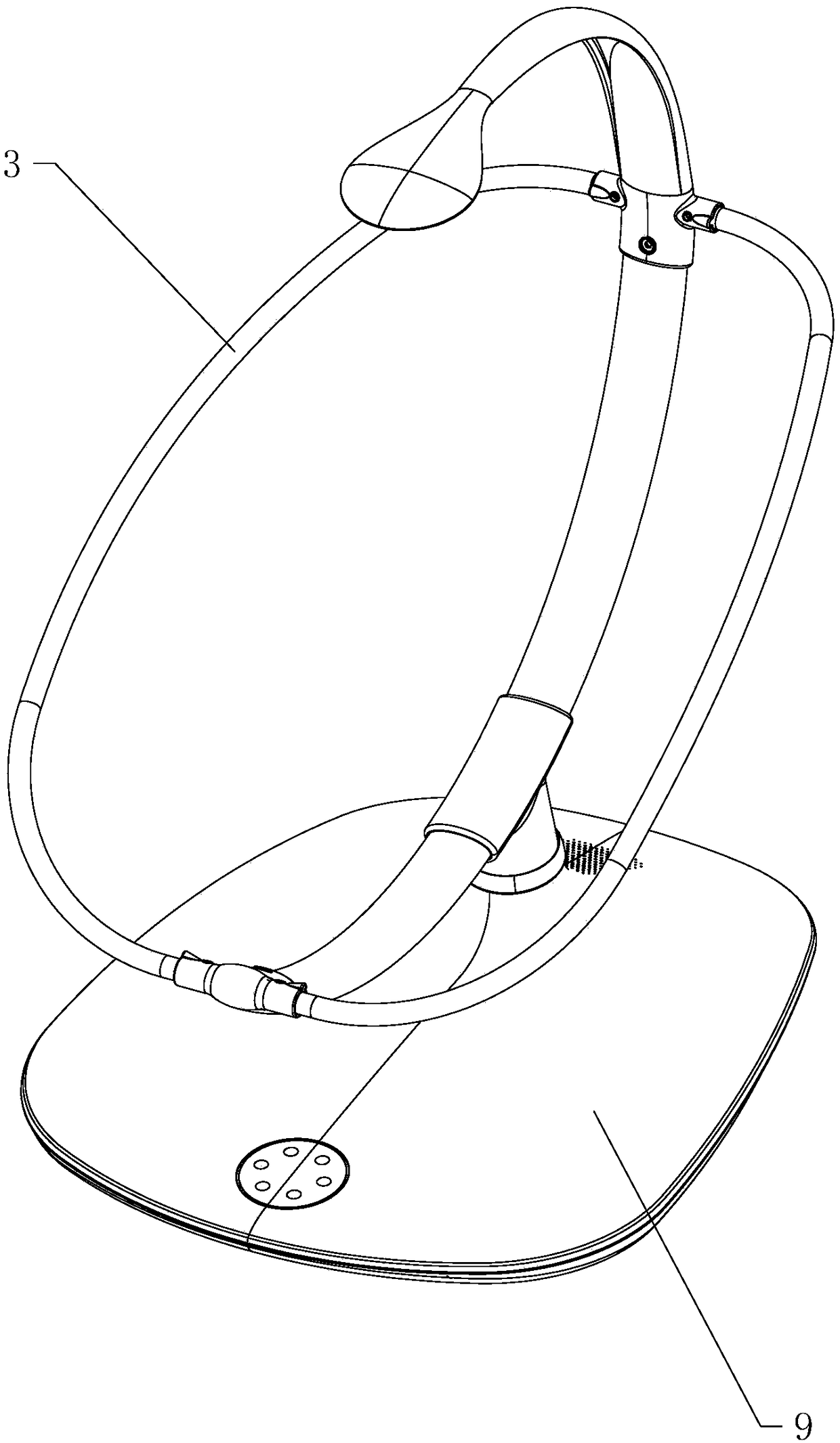

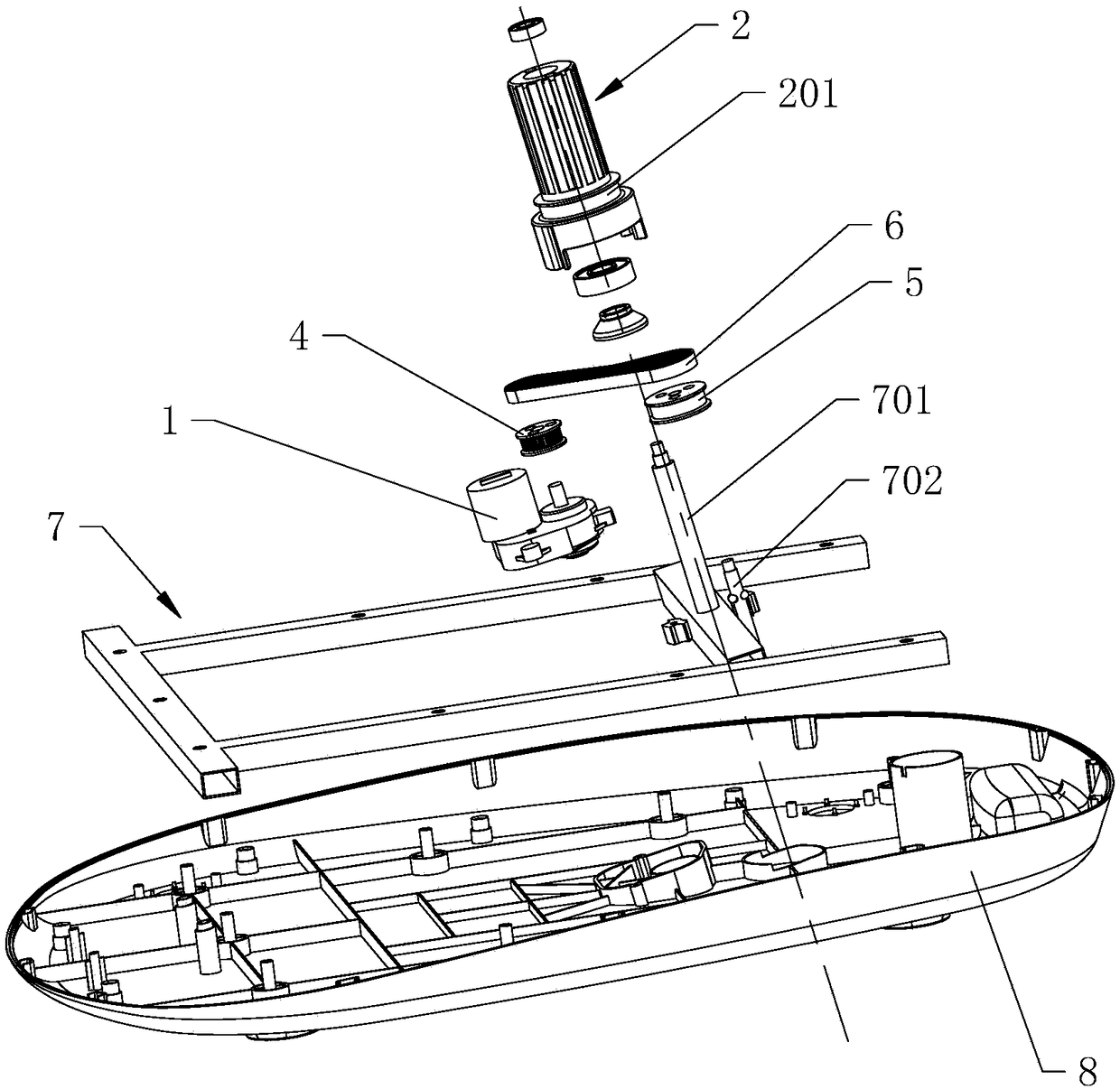

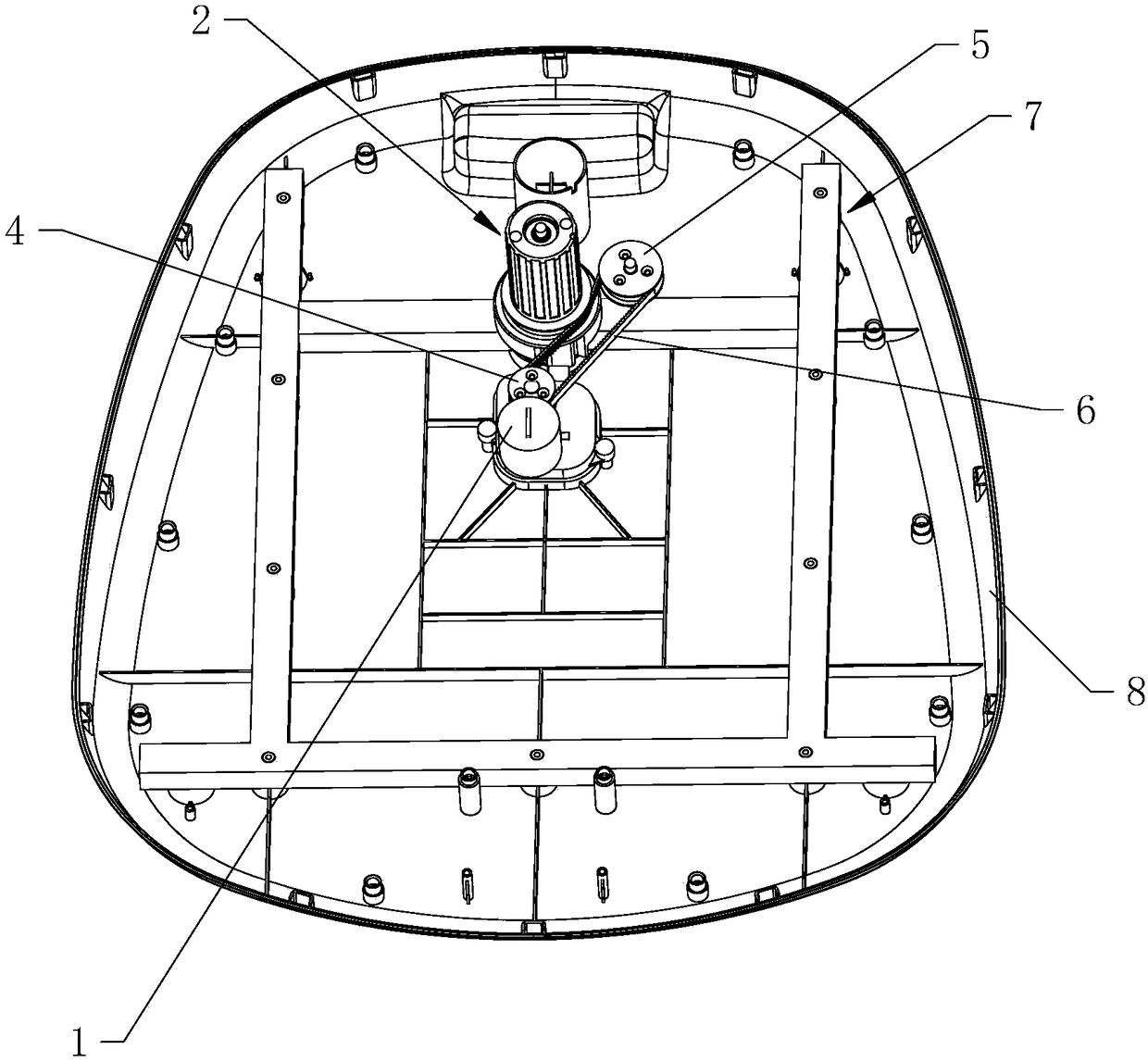

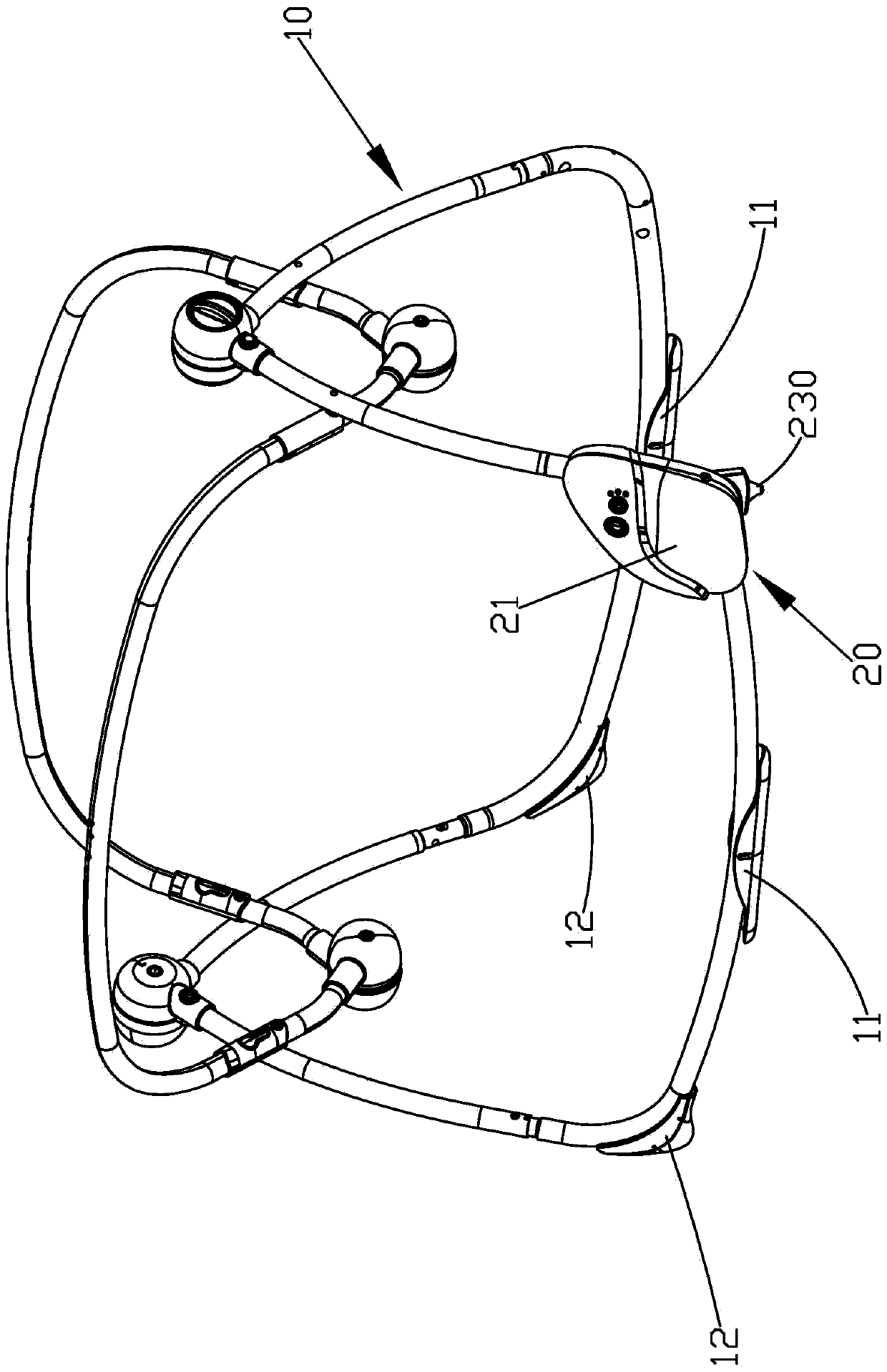

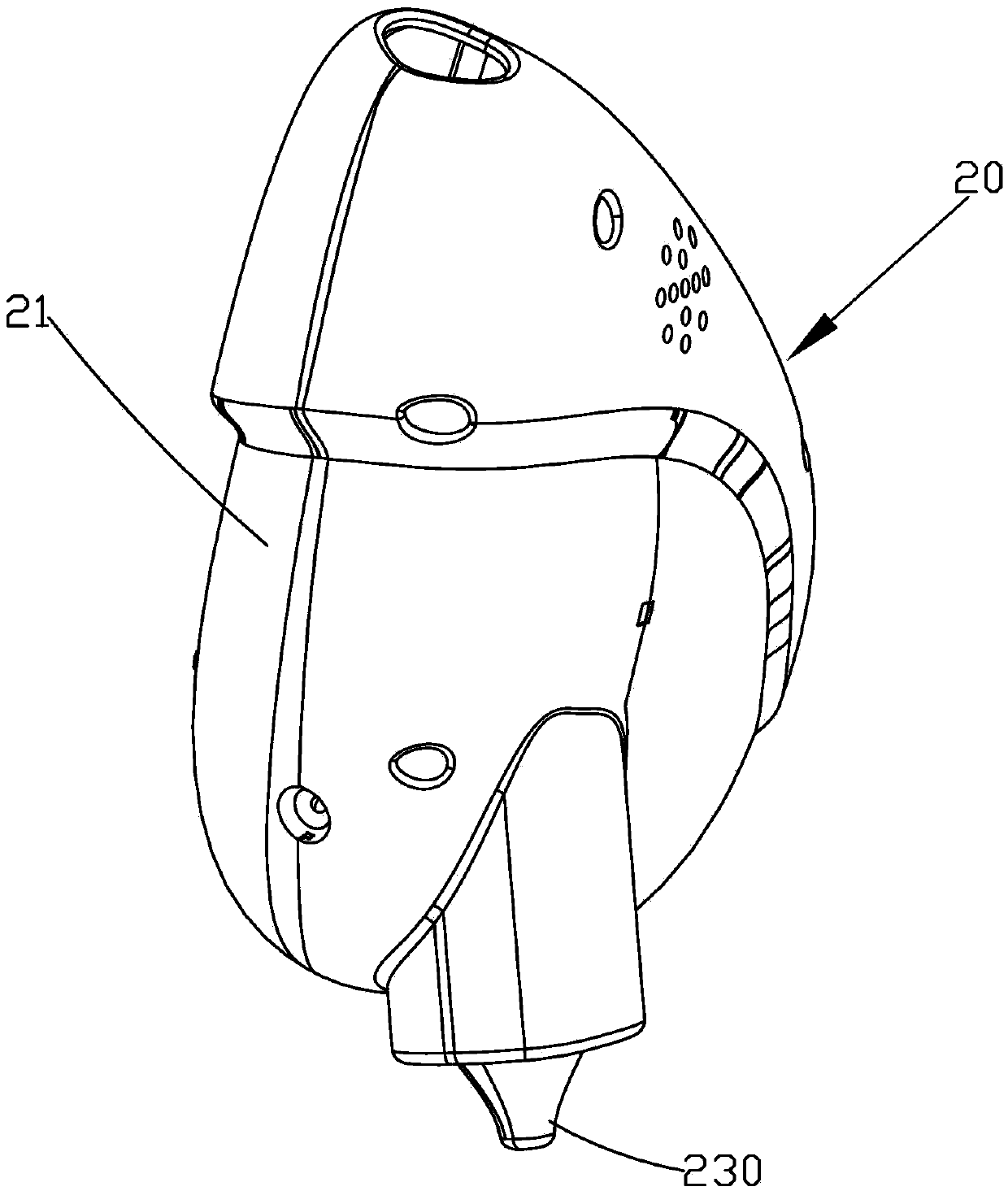

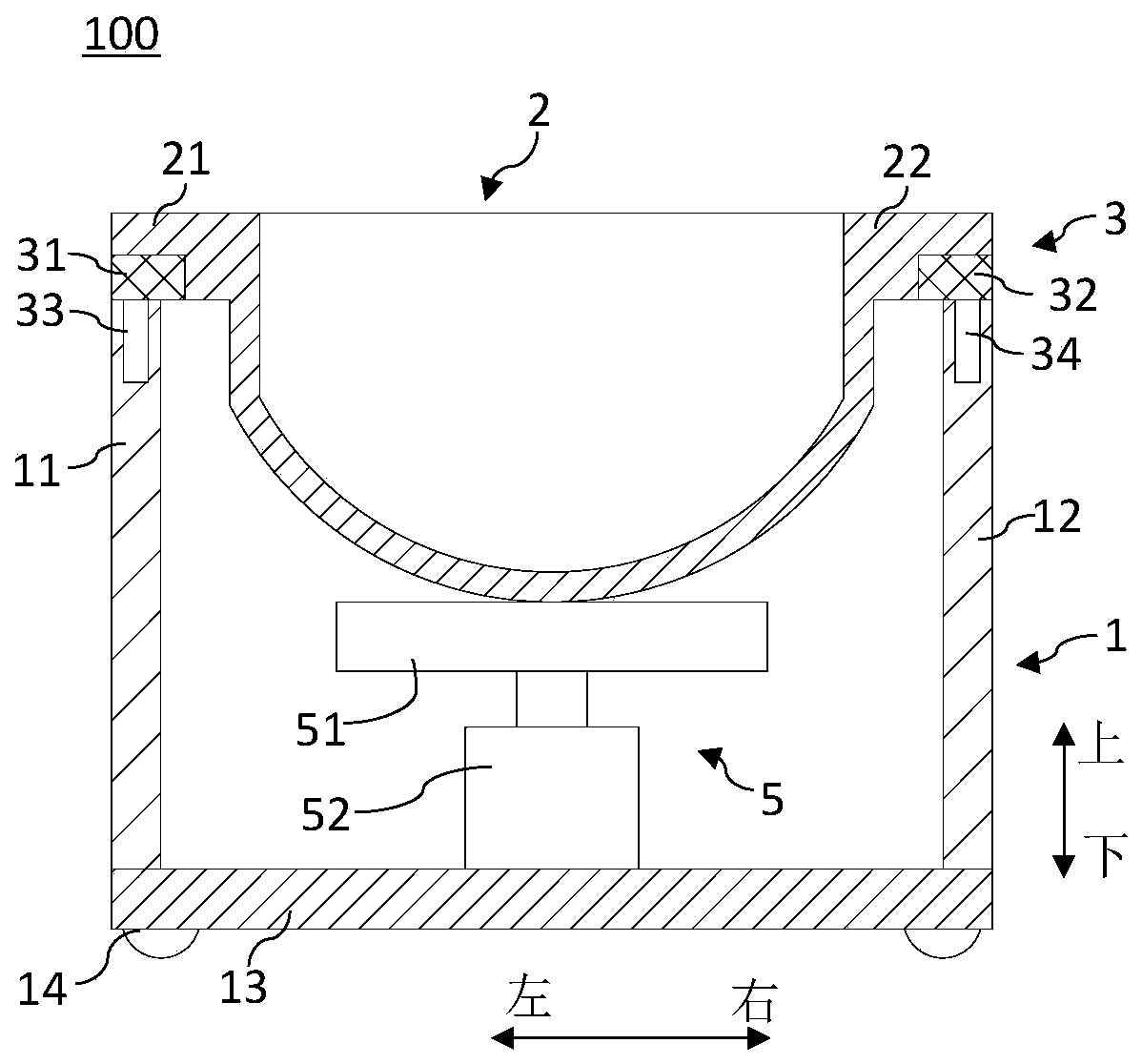

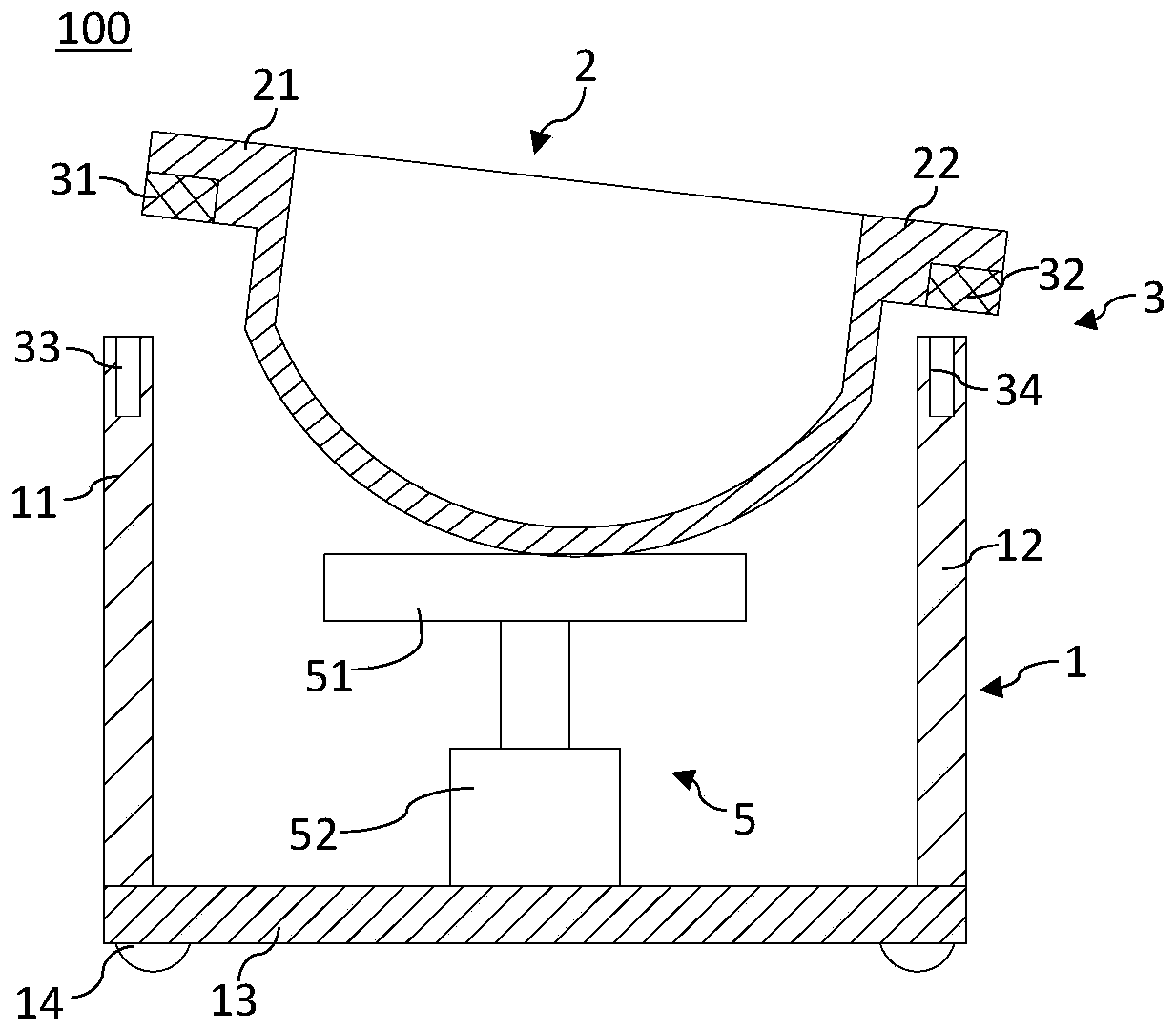

Rocking device of baby rocking chair, baby rocking chair and baby carriage

ActiveCN102697330ASoothingStrong comfortCarriage/perambulator accessoriesChildren furnitureCouplingEngineering

The invention discloses a rocking device of a baby rocking chair, a baby rocking chair and a baby carriage. A pulley of the rocking device can slide back and forth on a slide rail, a rotating shaft can rotate relative to a coupler, the rotating shaft is connected with the pulleys or the coupler through a driving device to drive the pulley to slide or drive the rotating shaft to rotate, so that a seat frame can rock automatically without man power, thus providing convenience for a user; and the rocking device of the baby rocking chair is simple in structure and convenient in use. Moreover, the slide rail in the vertical direction is a cursive line of which the height of the middle is lower than that of two ends, and the coupler can rotate relative to an under frame, so that the pulley slides along the slide rail to drive the seat frame to rock and move up and down, thus strengthening the comforting performance of the seat frame. The baby rocking chair provided by the invention comprises the rocking device and has the advantages of good soothing performance, strengthened comfort and automatic rocking. The baby carriage provided by the invnetion comprise the rocking device and has the advantages that the driving device drives the seat frame to rock, so that the soothing and the comfort performances are strengthened.

Owner:ZHONGSHAN CITY BOBIE BABY PROD CO LTD

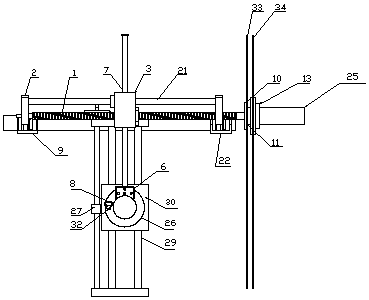

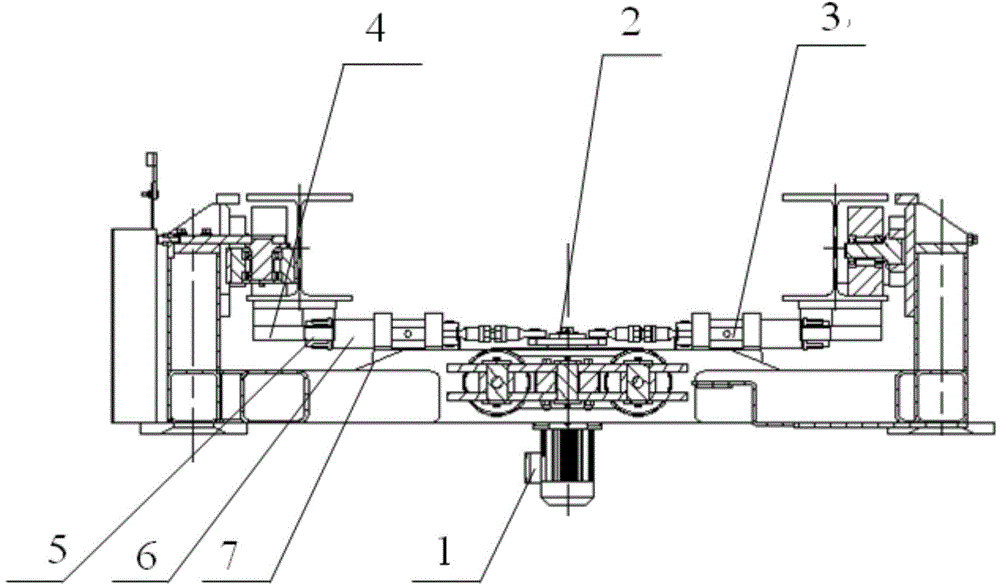

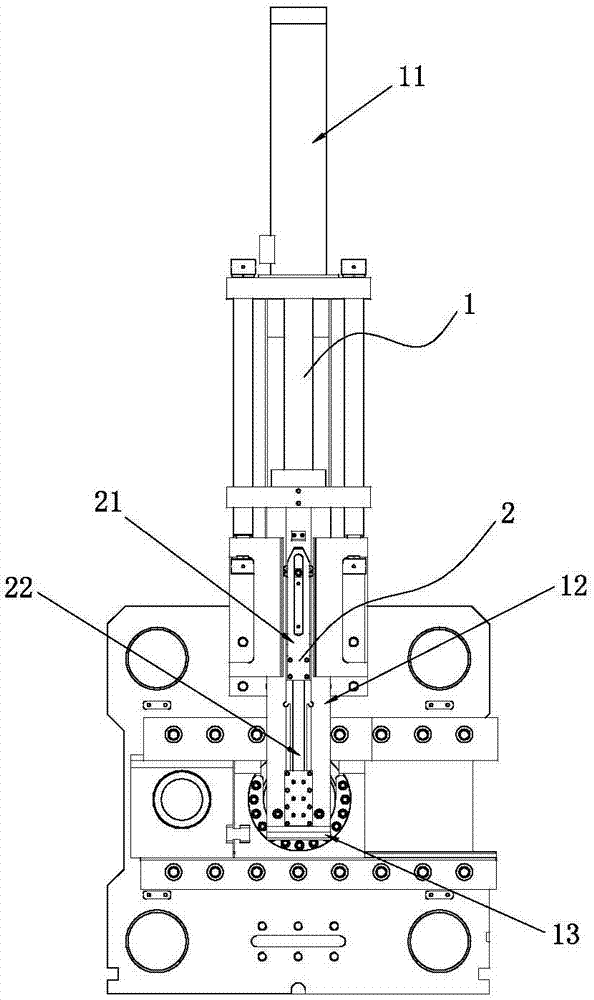

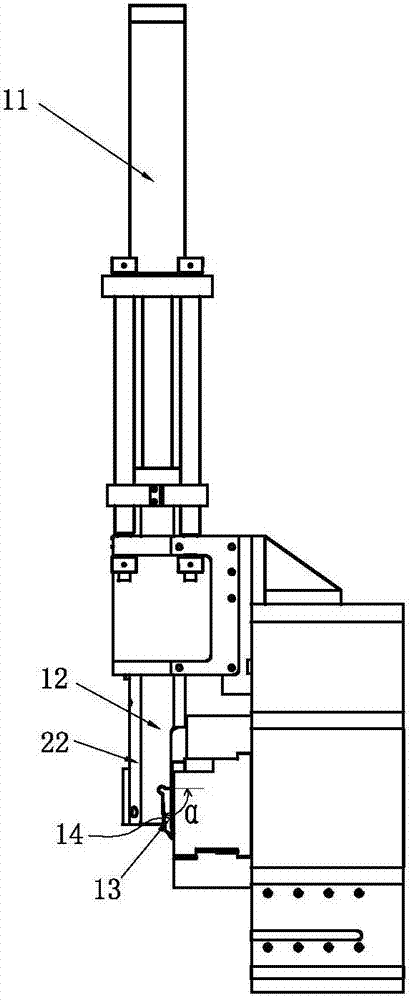

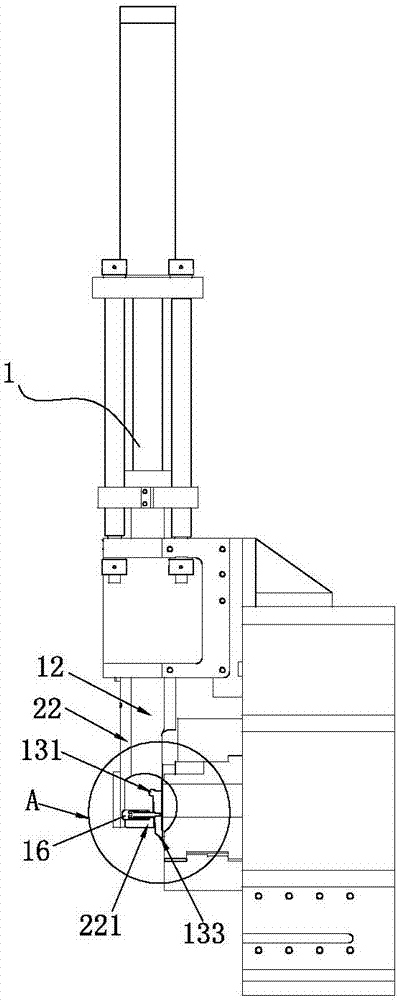

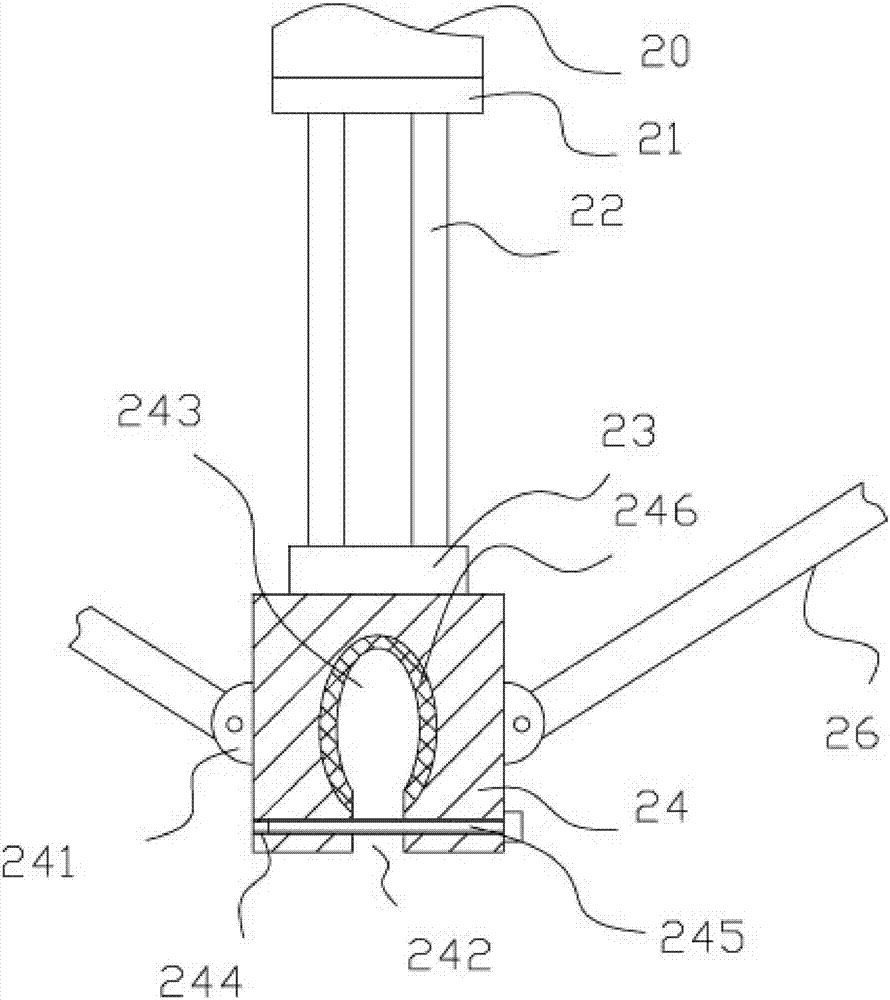

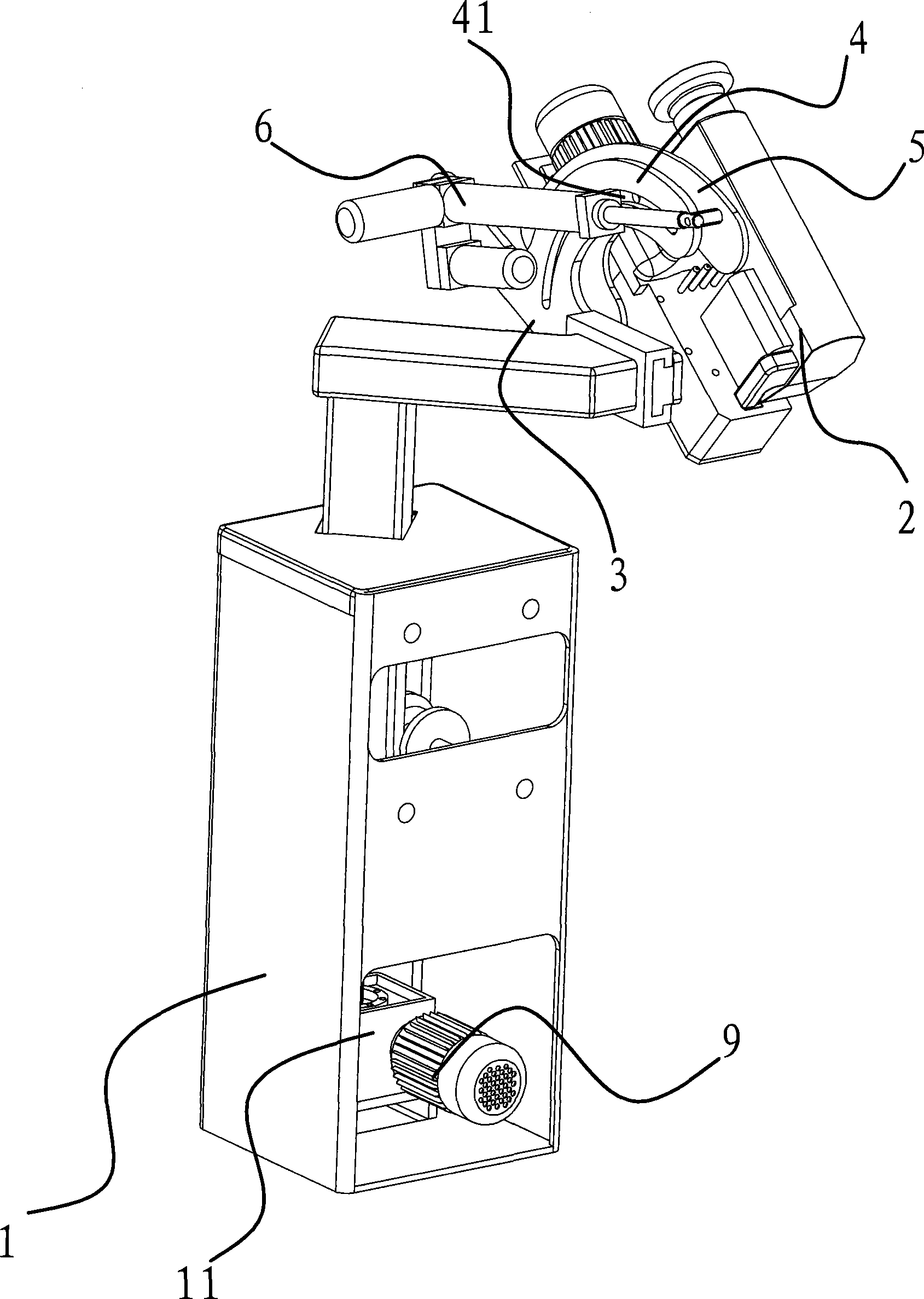

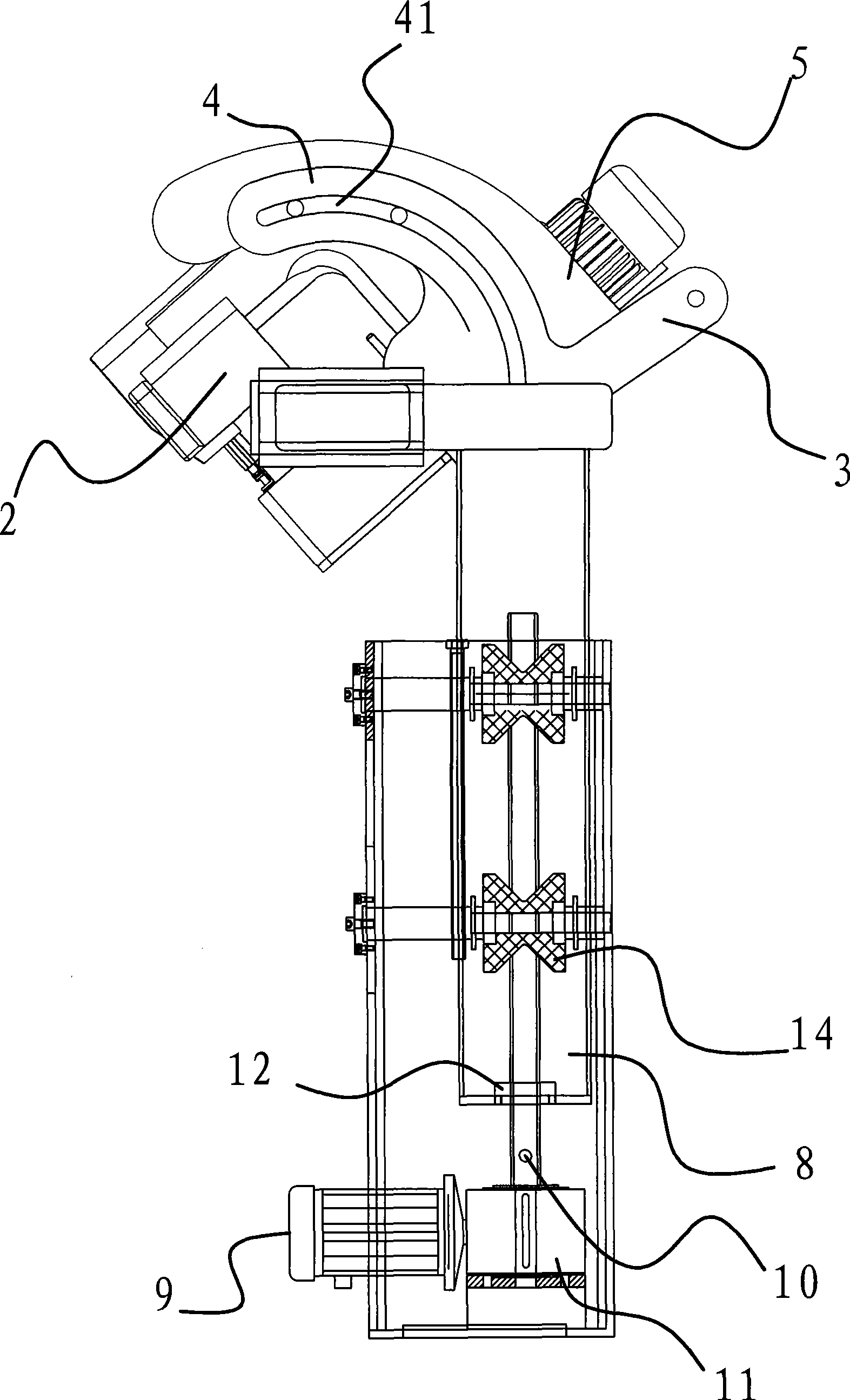

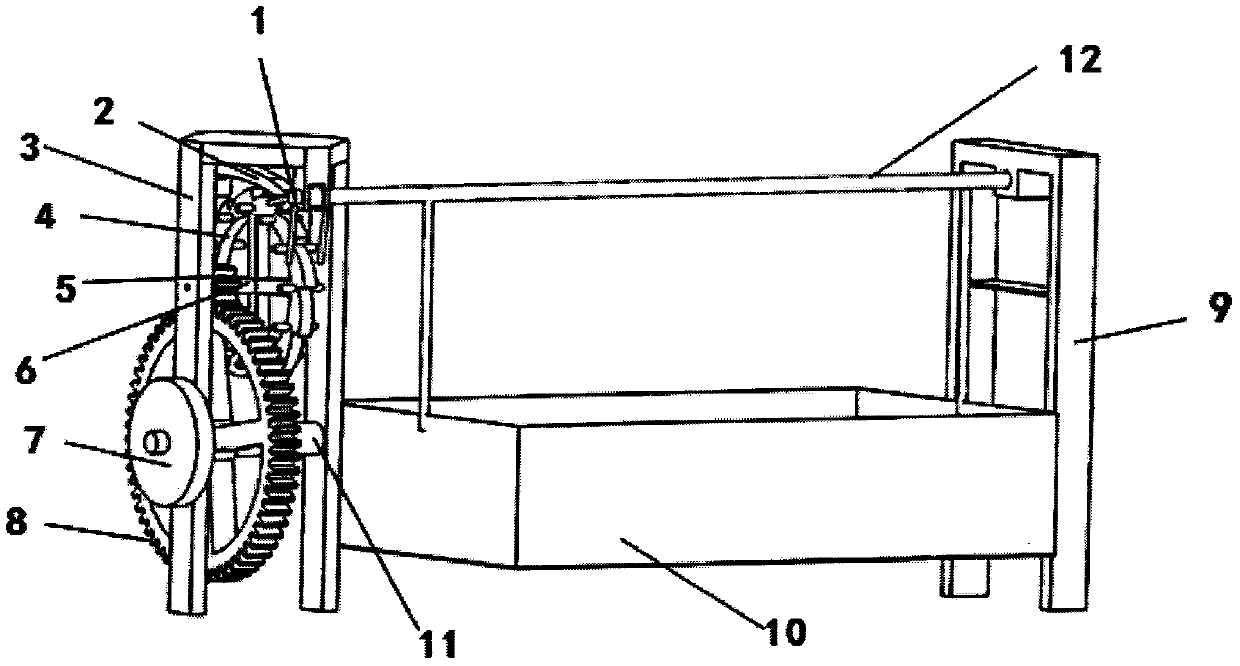

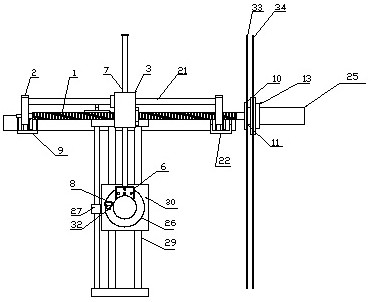

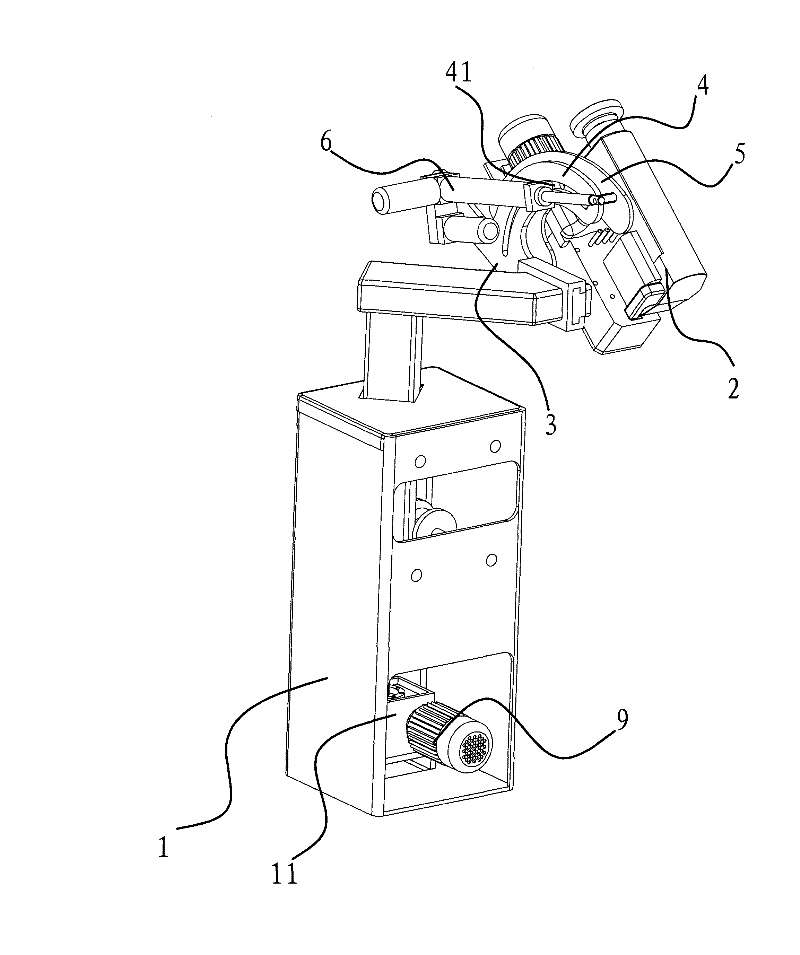

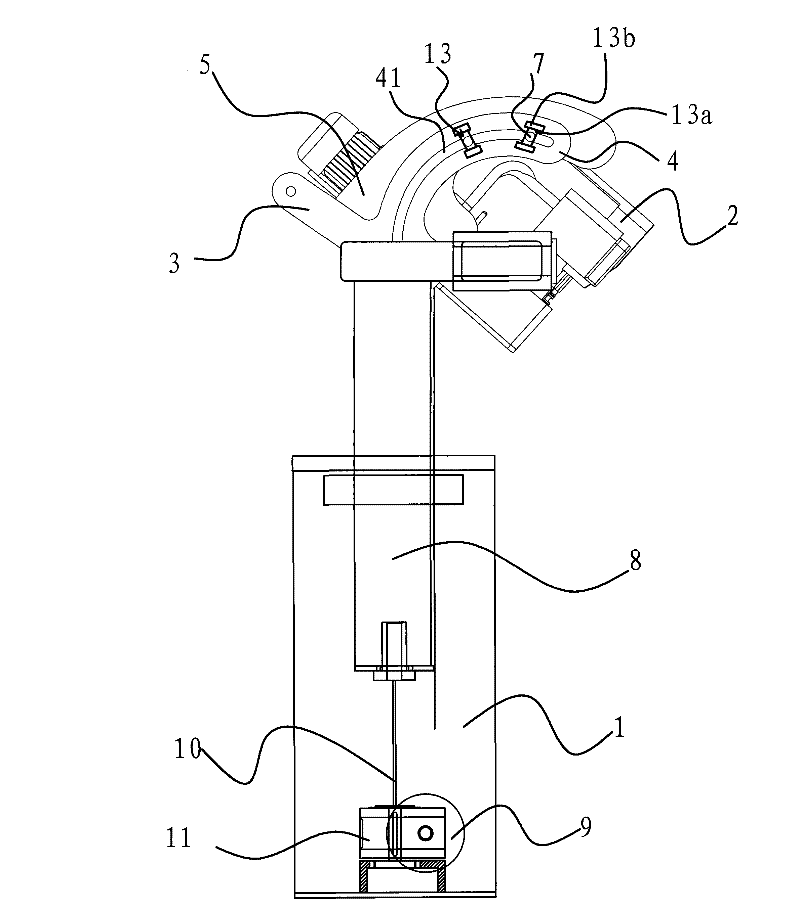

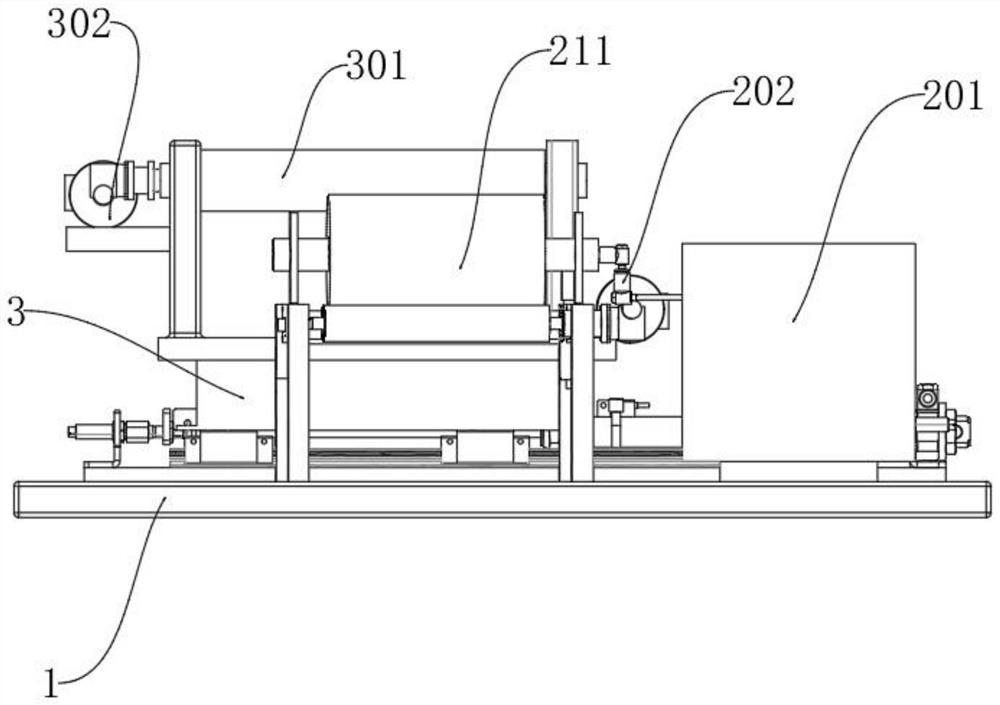

Rotating lifting device

ActiveCN107552261AEasy to controlRealize automatic swingMovable spraying apparatusEngineeringMechanical engineering

The invention relates to a rotating lifting device which comprises a fixed bracket, a servo motor, a hand wheel, a moving mechanism, a lifting mechanism and a working disc of a mounting tool, whereinthe servo motor, the hand wheel, the moving mechanism and the lifting mechanism are mounted on the fixed bracket; the servo motor is connected with the moving mechanism and drives one moving block onthe moving mechanism to move left and right; the moving block is connected with a lifting moving block on the lifting mechanism through a swing rod and drives the lifting moving block to rotate; the hand wheel is connected with the lifting mechanism and drives one of lifting blocks to move; a working rotary disc is fixedly connected with a lifting rotary block; the working rotary disc is coaxiallyand rotatably connected with the lifting block; and the servo motor and / or the hand wheel are / is operated to realize rotation and / or lifting movement of the working rotary disc. The rotating liftingdevice can be used for mounting a water spraying device and enables the water spraying device to rotate according to a specific sine curve.

Owner:SHANGHAI UNIV

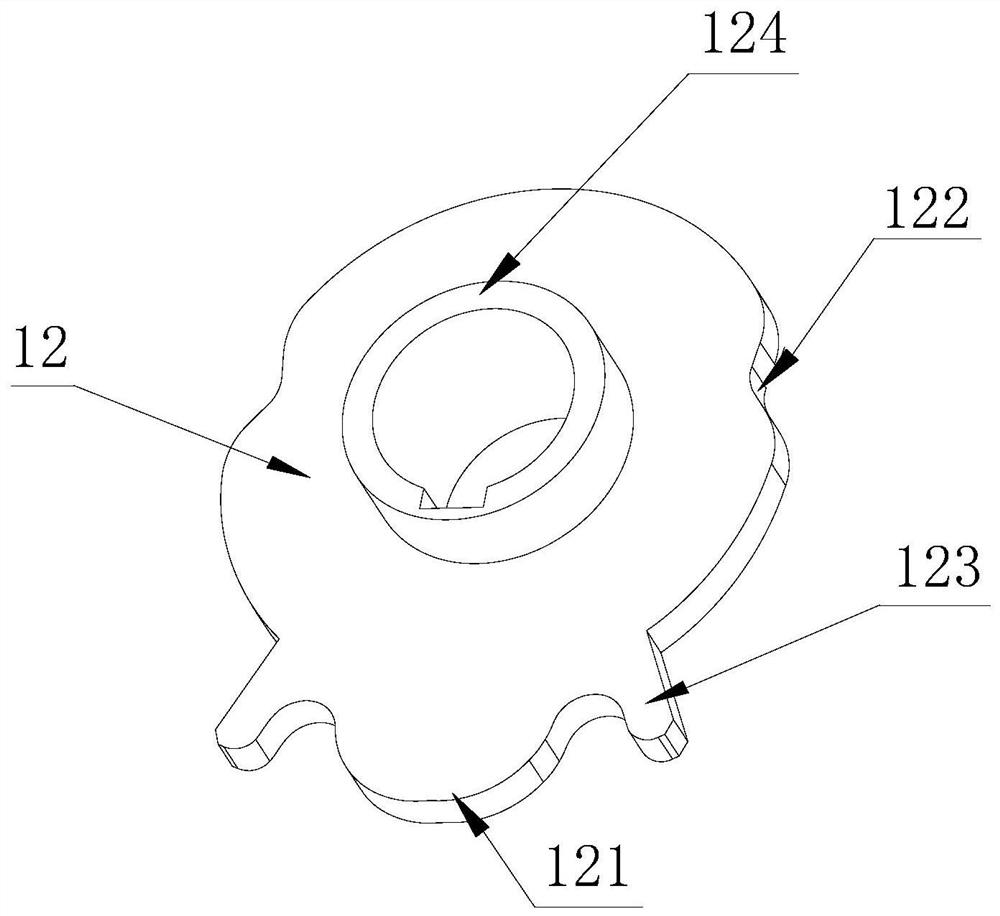

Flat-layer locking device for elevator

The invention relates to a flat-layer locking device for an elevator. The device comprises a locking motor (1), a rotating mechanism (2), clamping groove boards (4), guide bearings (5), connecting rods (6) and proximity switches (7). The locking motor (1) is fixed on a frame of an elevator trolley. The center of the rotating mechanism (2) is connected with the locking motor (1). The two sides of the rotating mechanism (2) are each connected with the corresponding guide bearing (5) through one connecting rod (6). Each clamping groove board (4) is fixed on a stand column. Each clamping groove board (4) is provided with a clamping groove. Each proximity switch (7) is arranged on the corresponding connecting rod (6) and is in signal connection with the locking motor (1). When the elevator moves vertically to arrive at a preset position, the proximity switches (7) output signals, the locking motor (1) operates, and the rotating mechanism (2) pulls the connecting rods (6) so as to push the guide bearings (5) to be locked into the clamping grooves; on the contrary, the guide bearings (5) are released. Compared with the prior art, the device has the advantages of being simple in structure, high in reliability and good in balance.

Owner:SHANGHAI FULANGDE MACHINERY EQUIP

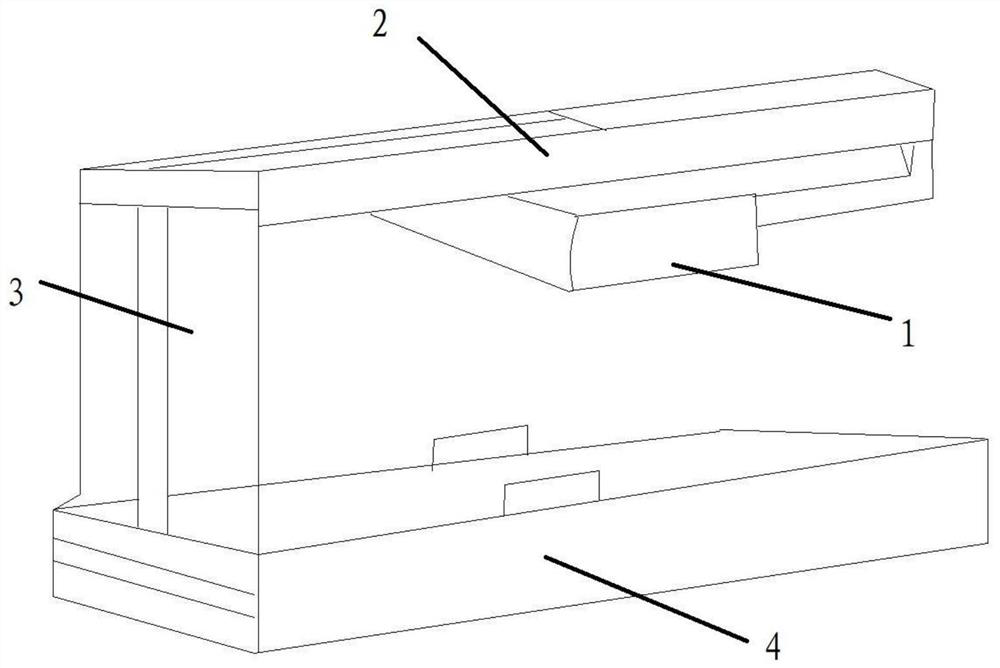

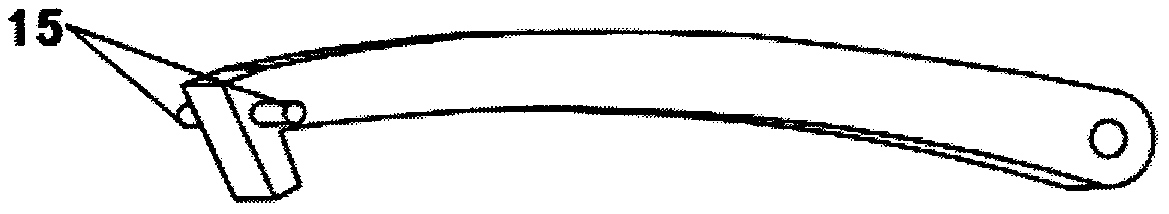

Novel discard shearing device of aluminum profile extruding machine

The invention relates to a novel discard shearing device of an aluminum profile extruding machine. The novel discard shearing device comprises a shearing mechanism and a discard striking mechanism. The shearing mechanism is composed of a shearing telescopic cylinder, a shearing rod and a shear knife. The shear knife is installed at the bottom of the shearing rod in a swinging manner, is located at the position of an extrusion mold inlet of the extruding machine and is driven by the shearing telescopic cylinder to move up and down to conduct shearing. The shear knife is provided with a return mechanism. The discard striking mechanism is composed of a discard striking telescopic cylinder and a material push rod. The discard striking mechanism is installed on the shearing rod. After shearing is completed, the discard striking telescopic cylinder drives the material push rod downwards. A telescopic cylinder for secondarily driving the material push rod is formed by the discard striking telescopic cylinder on the shearing rod. When the novel discard shearing device is applied, it can be completed avoided that the shear knife of the shearing device can be pulled to a shearing face or an extrusion mold when retracted (returned), and in this way, flatness of the shearing face of an extruded profile can be effectively improved, the shearing precision can be improved and it can be avoided that the extrusion mold is damaged.

Owner:FOSHAN NANHAI MINGSHENG MACHINE MFR

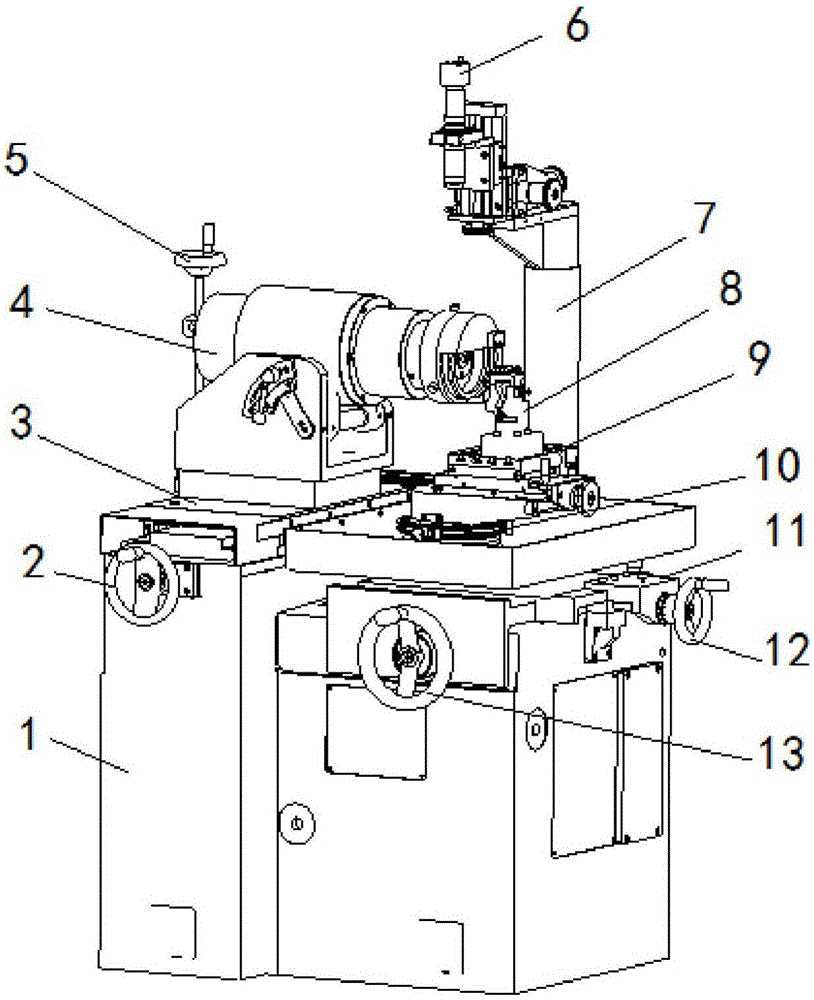

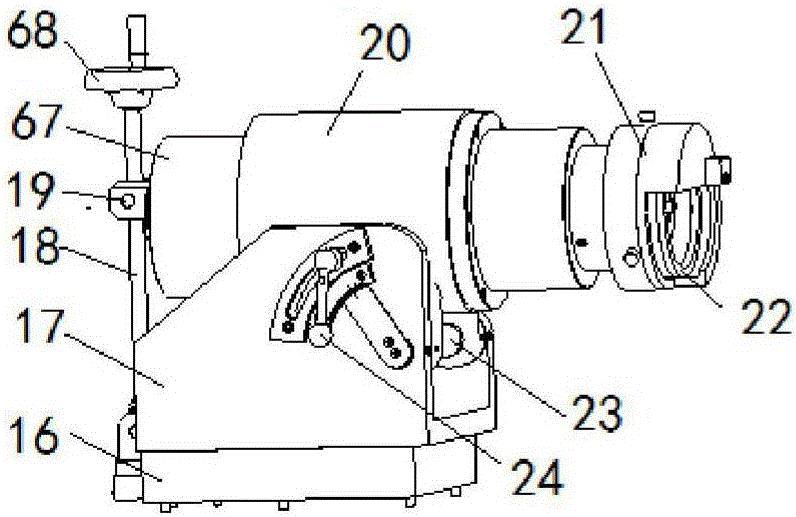

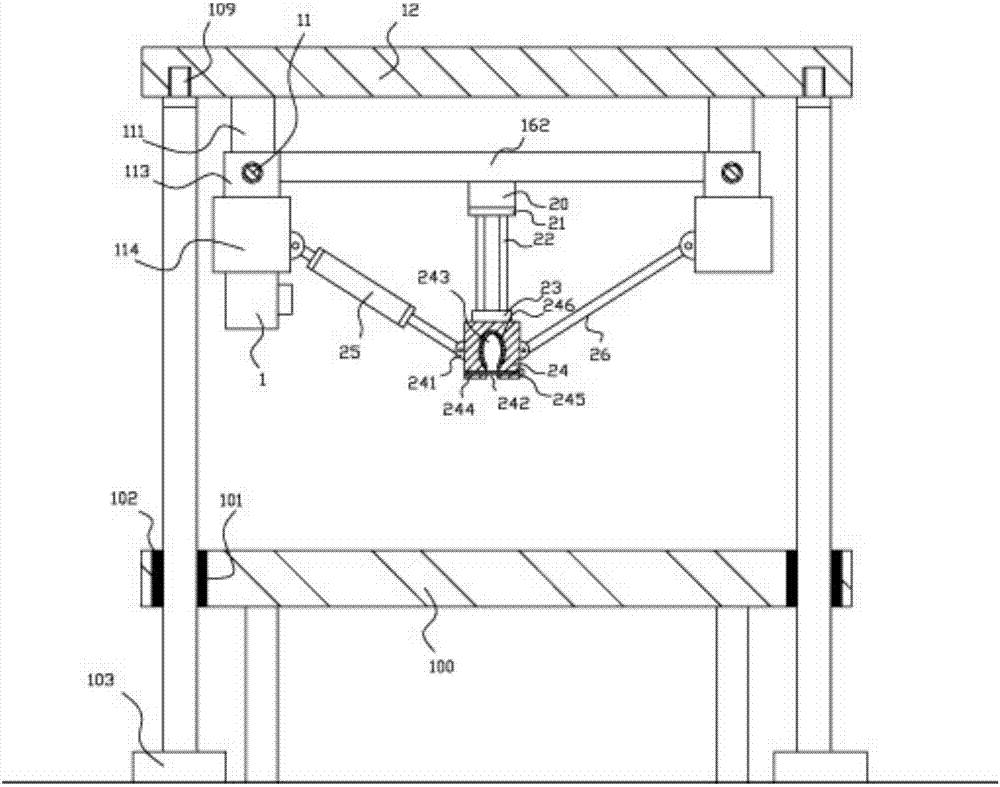

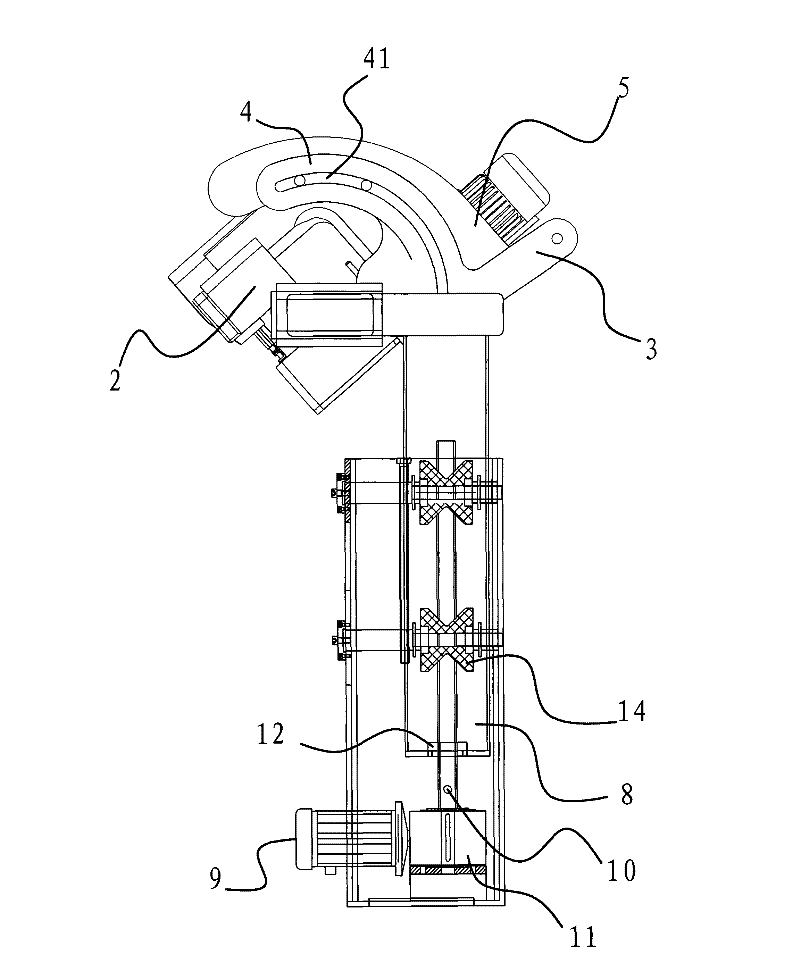

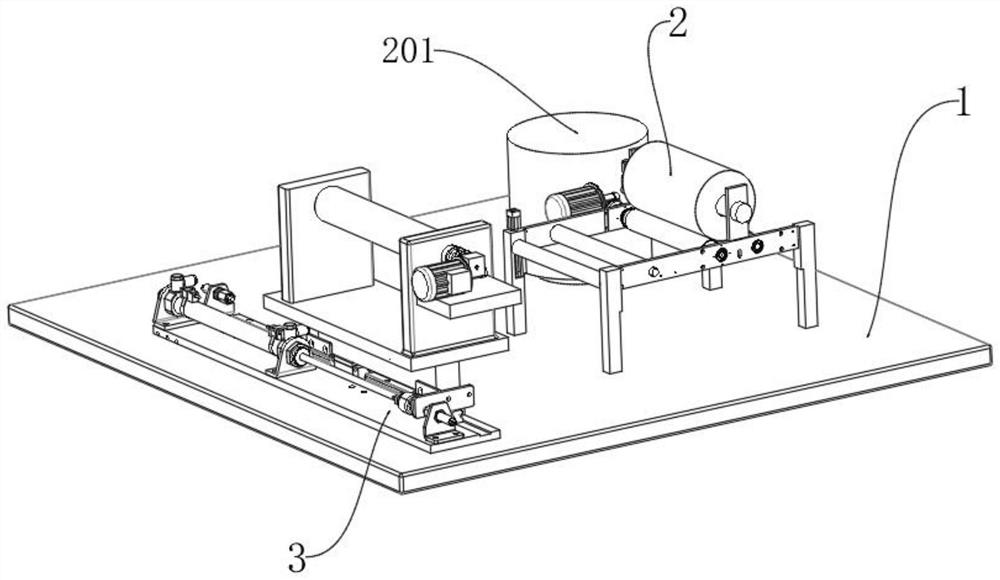

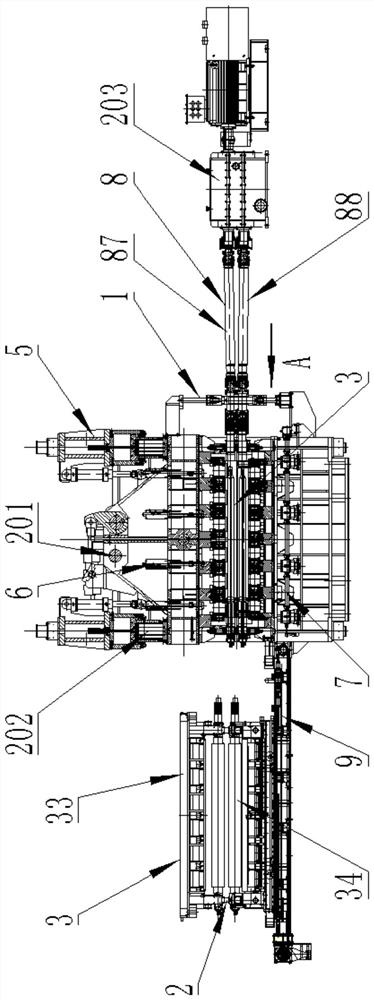

Rotation vertical shaft ascending and descending ultrahard cutter powerful grinding machine and application method

ActiveCN106695466ARealize automatic swingAdjust swingGrinding carriagesGrinding drivesBoron nitrideGrinding wheel

The invention discloses a rotation vertical shaft ascending and descending ultrahard cutter powerful grinding machine and an application method, and belongs to the technical field of tool edge grinding machining of diamond, cubic boron nitride and other ultrahard materials. The grinding machine is composed of a lathe bed component, a grinding wheel spindle translation component, a grinding wheel spindle component, a CCD online monitoring component, a tool rest component, a workbench component, a rotation vertical shaft component, a feed carriage component and the like. The lathe bed component comprises a main bed body, a grinding wheel spindle moving hand wheel, a fixing base, a grinding wheel spindle translation rolling guide rail, a fixing strip and a tool feed carriage moving rolling guide rail. The grinding wheel spindle moving hand wheel is rotated to drive a lead screw pair to rotate, and the grinding wheel spindle translation component conducts positioning movement along the rolling guide rail. The rotation vertical shaft ascending and descending ultrahard cutter powerful grinding machine has the beneficial effect that a vertical shaft can ascend and descend; and compared with ordinary grinding machines, the rotation vertical shaft ascending and descending ultrahard cutter powerful grinding machine has the beneficial effects that operation is flexible, the machined object range is wide, and functions are complete; and the rotation vertical shaft ascending and descending ultrahard cutter powerful grinding machine is matched with various special clamps, and the requirement for edge grinding machining of various ultrahard tools can be met.

Owner:北京市电加工研究所有限公司 +1

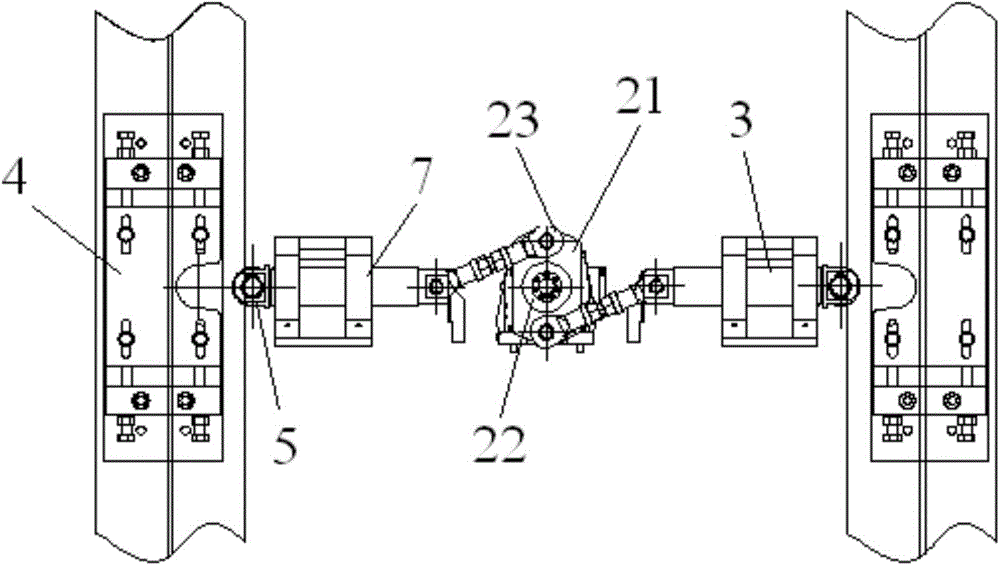

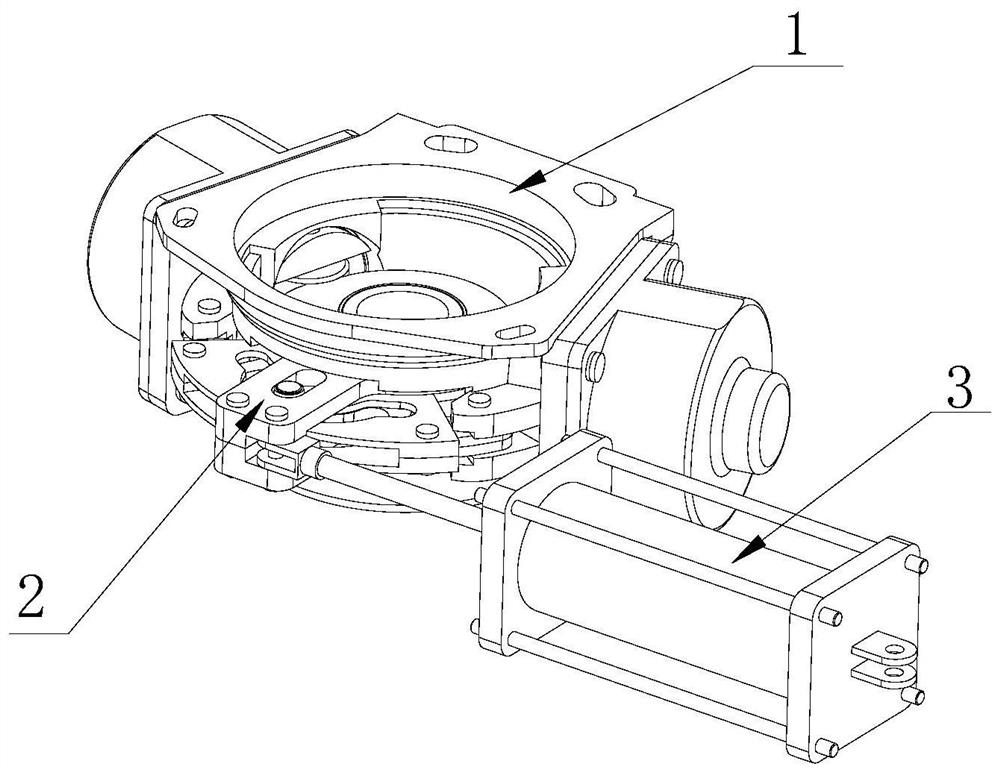

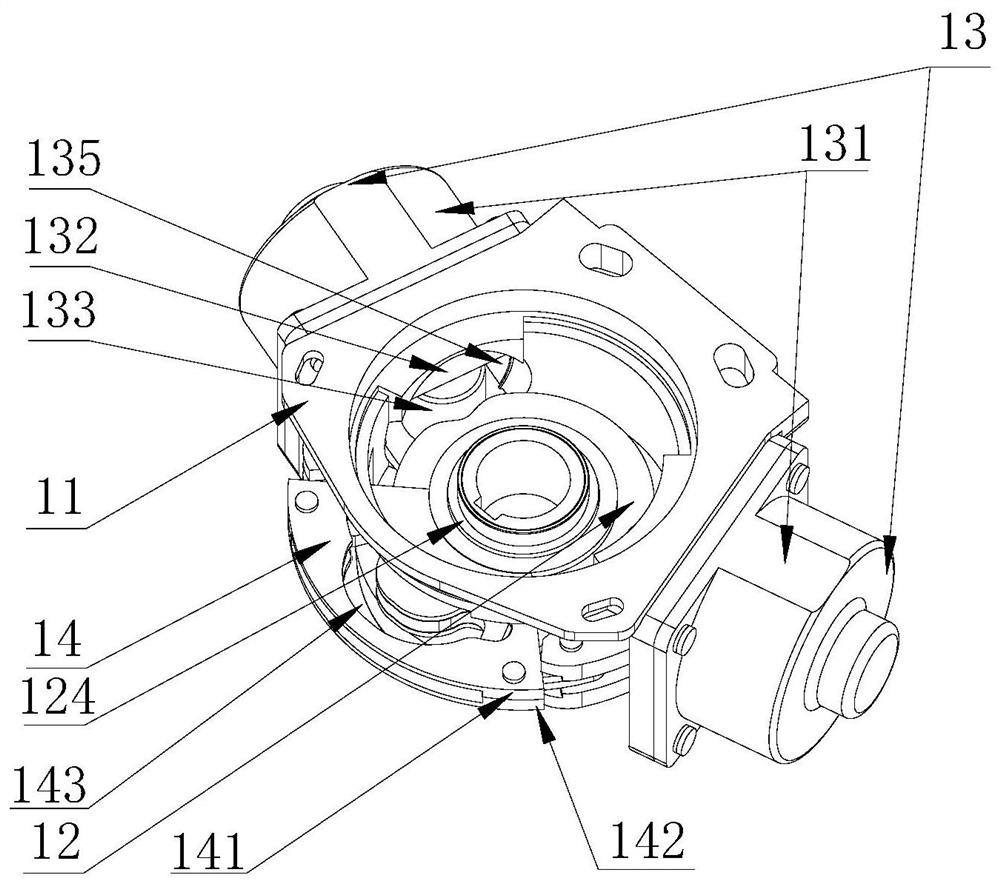

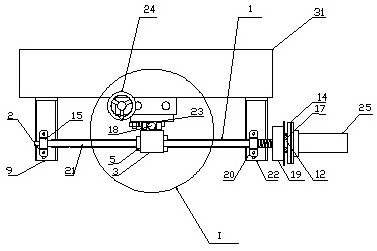

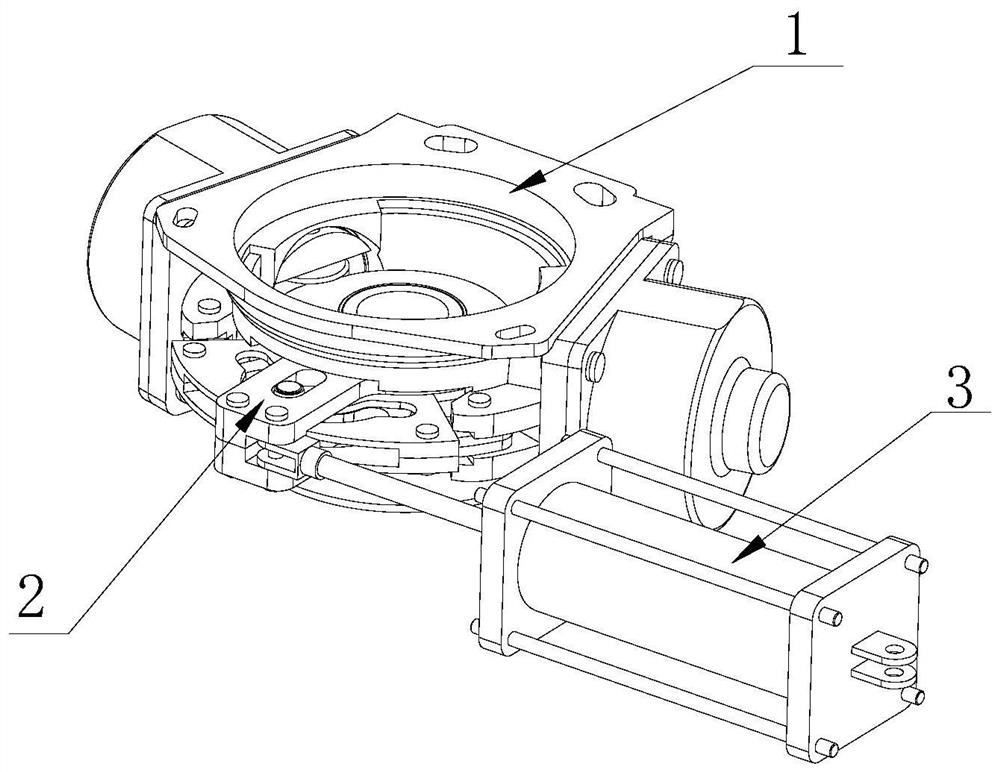

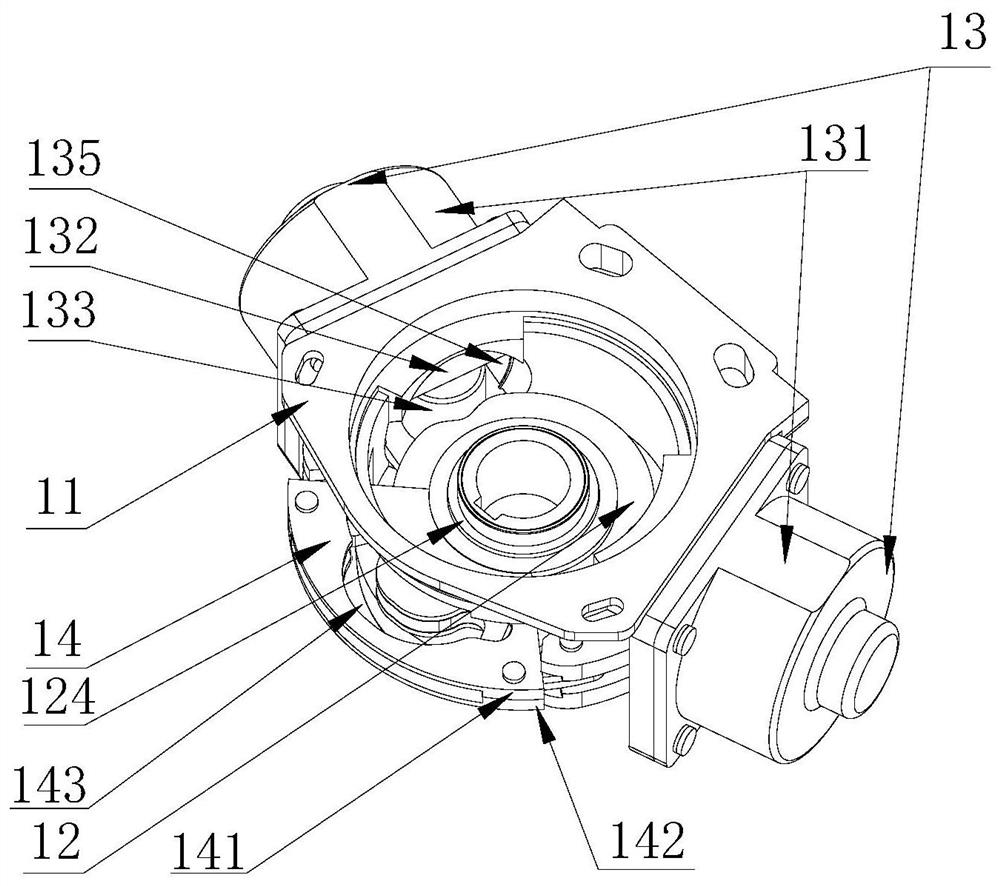

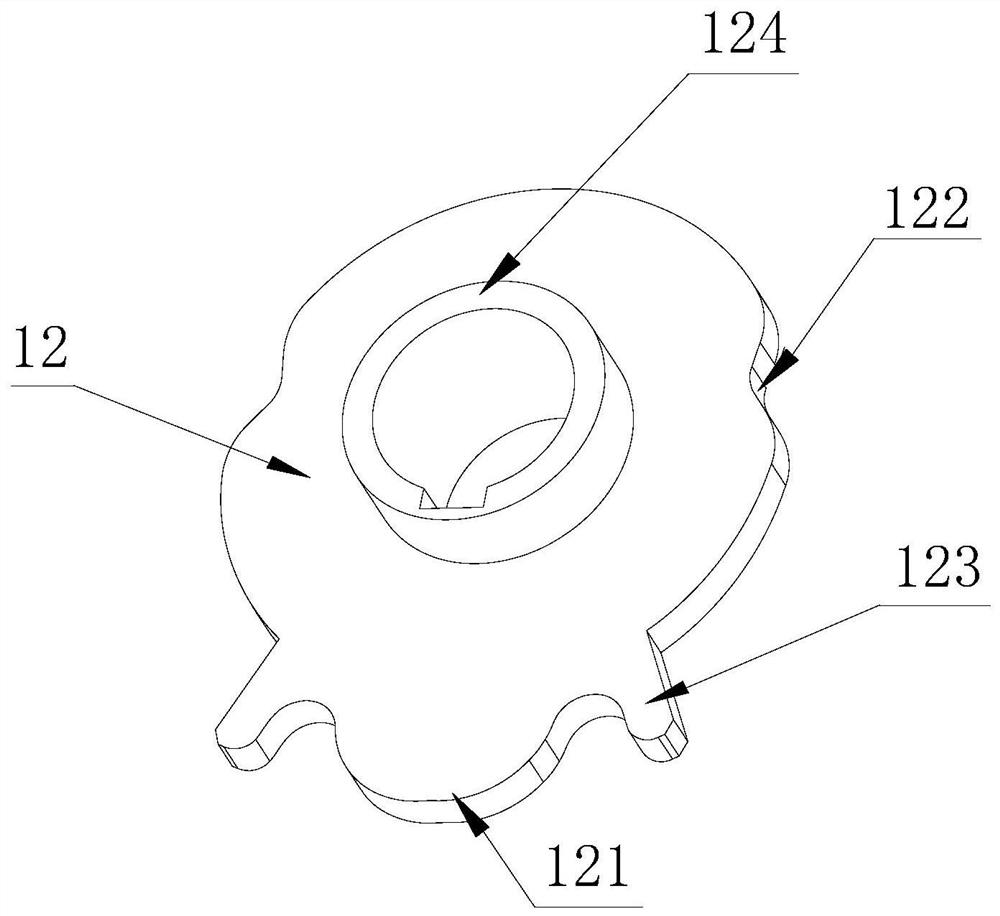

Active corner driving device and rotary car coupler

ActiveCN112977530AReduce loadAvoid the problem of overloadingRailway coupling accessoriesDrive shaftEngineering

The invention provides an active corner driving device and a rotary car coupler. The device comprises a centering mechanism, the centering mechanism comprises a shell assembly, a centering disc and a piston assembly, the centering disc is arranged in the shell assembly in a pivoted mode, the piston assembly abuts against the circumferential wall of the centering disc, a sleeve, a protrusion, a notch and a cam are arranged on the centering disc, and the protrusion and the notch are symmetrically arranged on the two sides of the cam; the guide plate assembly is connected with the shell assembly and the sleeve and provided with an arc-shaped guide groove matched with the cam and the protrusion, and the protrusion is arranged in the arc-shaped guide groove; the driving mechanism is pivotally mounted in the shell assembly and comprises a cam plate assembly provided with a strip-shaped groove and a driving shaft assembly mounted in the strip-shaped groove; and the power assembly is connected with the driving mechanism. The power assembly pushes the cam plate assembly to rotate and extrude the piston assembly, the driving shaft assembly moves along the guide groove, and when the driving shaft assembly moves to make contact with the protrusion, the driving shaft assembly continues to move to push the centering disc to rotate. The centering disc is connected with a mechanical structure, and automatic rotation of the mechanical structure can be achieved.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST +1

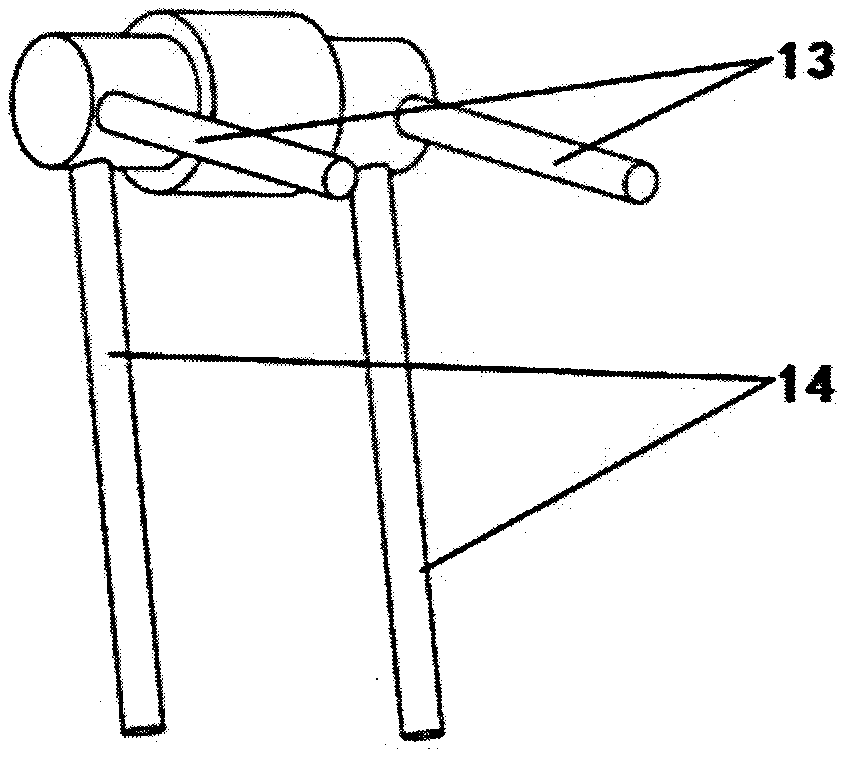

Swing mechanism of child automatic swing bed

The invention discloses a swing mechanism of a child automatic swing bed, which comprises an arc swing plate arranged at the bottom of a bed head. A lever is arranged on the swing plate by a hinge pin. One end of the lever is in contact with the ground. The other end of the lever is connected with a push-and-pull mechanism which is driven by a motor to ensure the lever to rotate back and forth around the hinge pin. The swing mechanism of the child automatic swing bed has reasonable structure, can be used for realizing automatic swing, has reliable working performance, stably works and uniformly swings.

Owner:徐李华

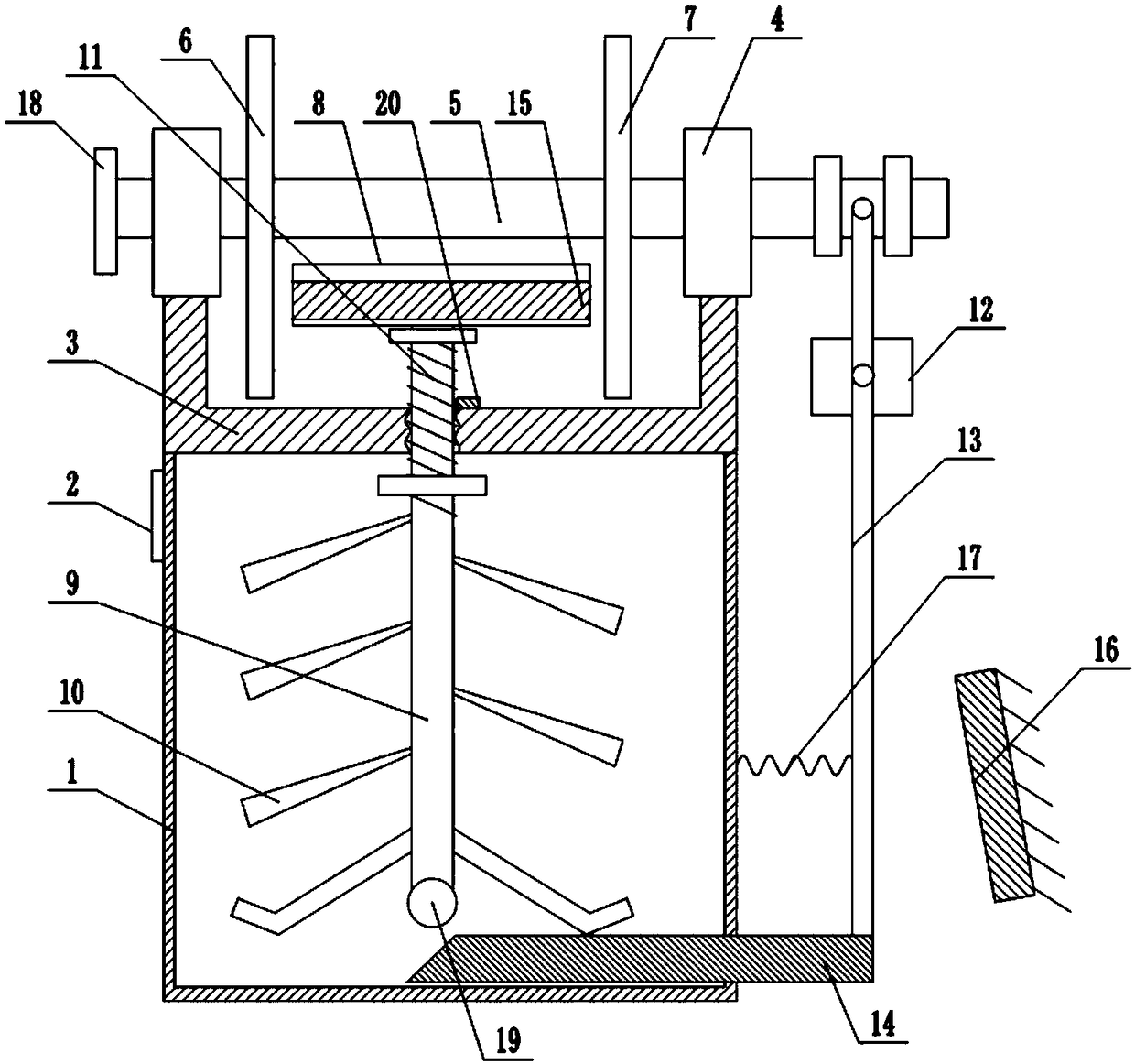

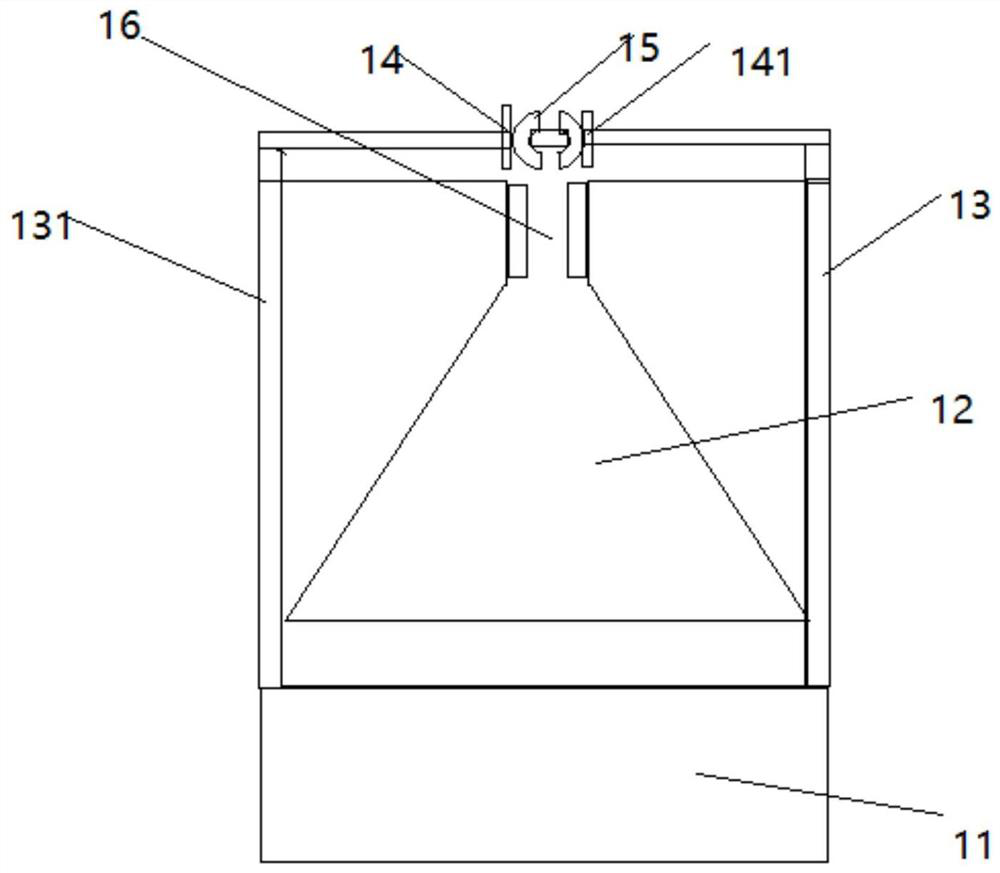

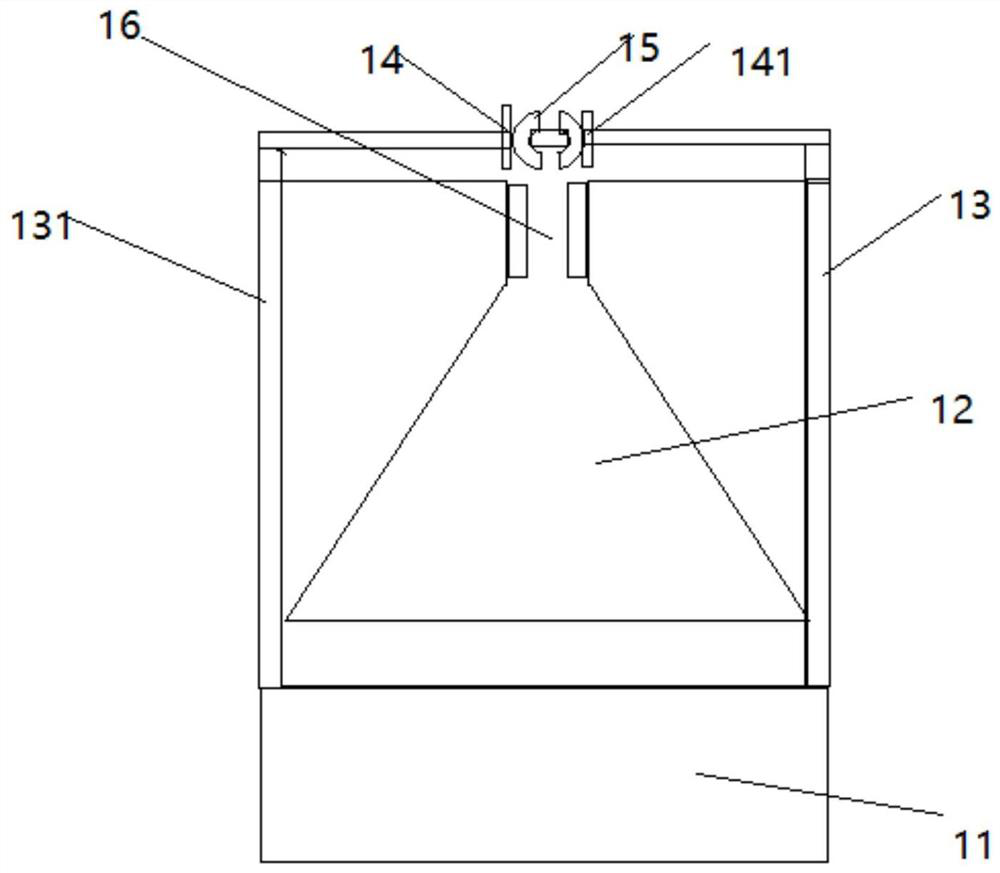

Organic fertilizer processing device

InactiveCN108794094ARealize automatic swingHigh degree of automationShaking/oscillating/vibrating mixersTransportation and packagingEngineeringOrganic fertilizer

The invention relates to an organic fertilizer processing device which comprises a stirring bucket, wherein a support plate is fixedly connected with the top of the stirring bucket; support platformsare fixedly connected with both ends of the support plate; through holes are formed in the two support platforms; driving shafts are connected to the interiors of the through holes; a first driving disc and a second driving disc parallel to each other are fixedly connected with the driving shafts coaxially; a stirring disc is arranged between the first driving disc and the second driving disc; thestirring disc is radially perpendicular to the first driving disc and the second driving disc; the stirring disc is intermittently propped against the first driving disc and the second driving disc;a stirring shaft is coaxially and fixedly connected with the bottom of the stirring disc; the bottom of the stirring shaft penetrates through the support plate and extends into a stirring bucket; stirring blades are hinged with the stirring shaft axially; a screw rod section is arranged at the top of the stirring shaft; the screw rod section is in threaded connection with the support plate; the driving shaft is connected with a direction change mechanism. By adopting the device, materials at different heights inside the stirring bucket can be stirred in different directions.

Owner:仁怀市泓熙养殖专业合作社

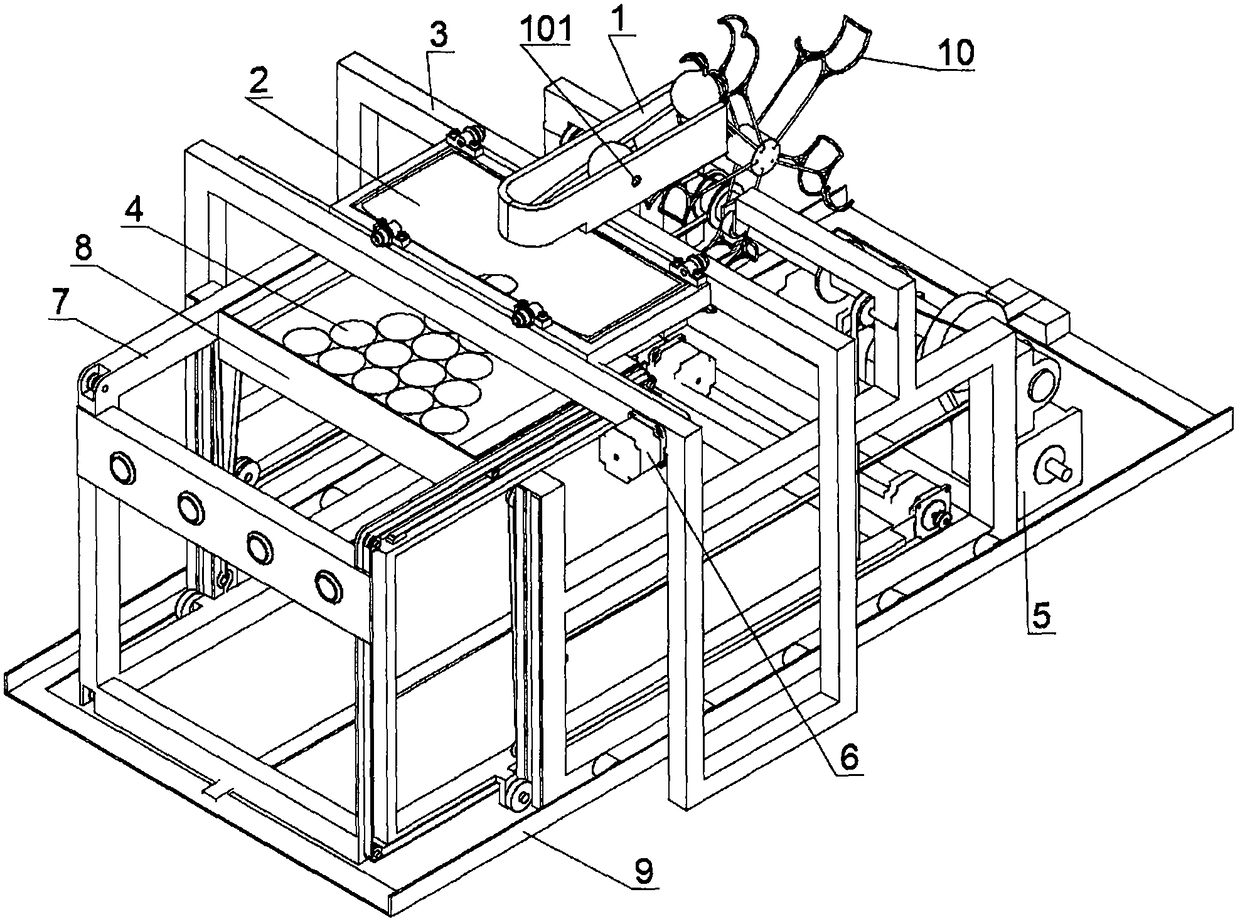

Automatic arranging device for billiard balls

InactiveCN108654073AHigh degree of automationRealize automatic swingBilliardsColor recognitionBilliard ball

The invention discloses an automatic arranging device for billiard balls. The device comprises a module recognition table, a billiard leaking hopper, a billiard pushing frame, transverse rails, longitudinal rails and a control unit. The control unit receives recognition signals of color recognition modules at positions for the billiard balls, the serial numbers of the billiard balls are determinedafter the signals are processed, the positions where the billiard balls are supposed to be located are determined, then a command is sent to a motor to drive the billiard leaking hopper and the billiard pushing frame to move relatively in the transverse direction and the longitudinal direction, a billiard outlet of the billiard leaking hopper corresponds to one specific position hole of a billiard groove in the billiard pushing frame, an electromagnetic pushing rod is controlled to extend out, the billiard balls fall into the one specific position hole of the billiard groove in the billiard pushing frame from the billiard leaking hopper, and then the billiard balls are automatically recognized and arranged. According to the structure, colors of the billiard balls are recognized, the positions are determined, the billiard balls are automatically arranged, in this way, the automation degree of a billiard game is increased, the billiard balls are arranged accurately and rapidly, and using is convenient and rapid.

Owner:丁希文

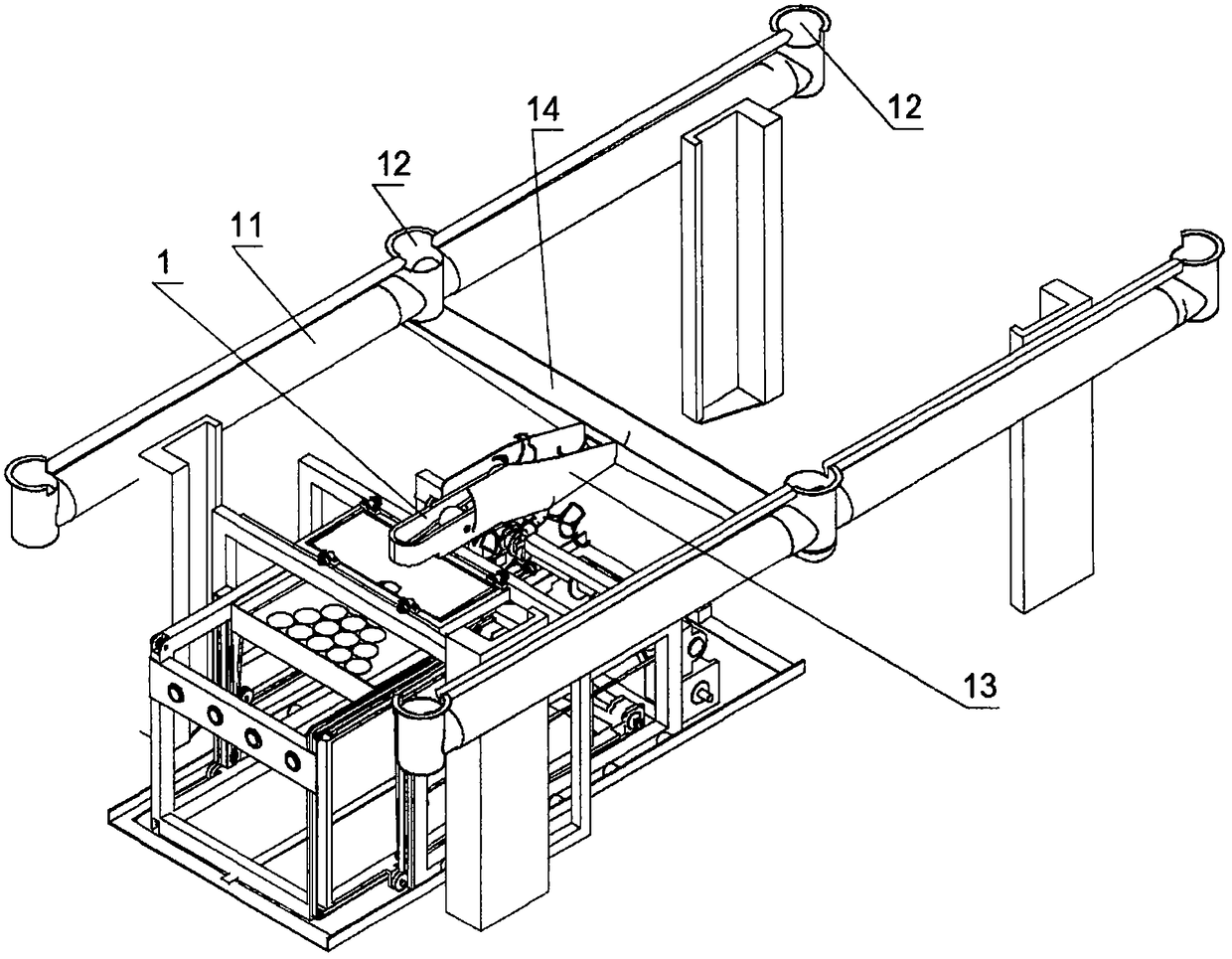

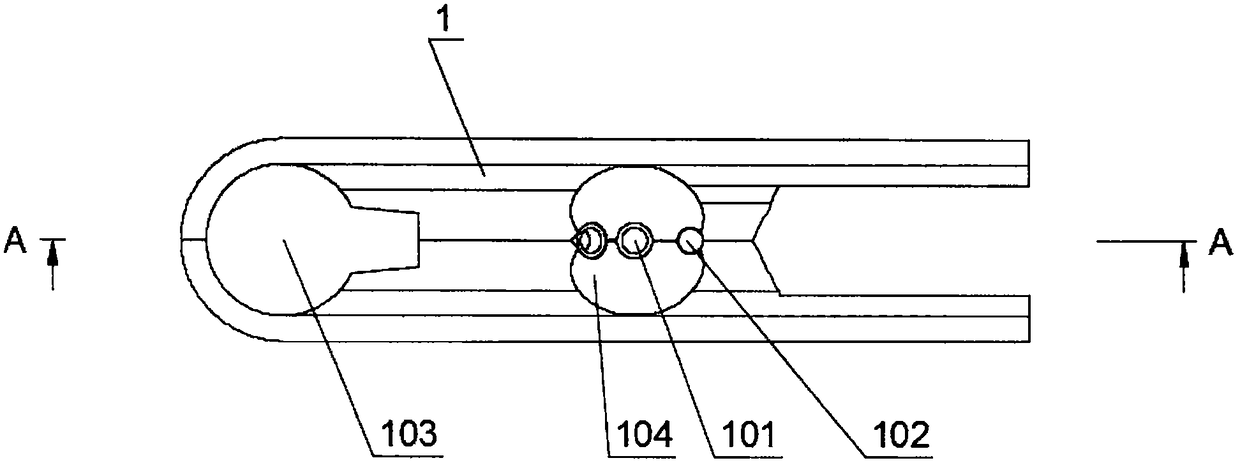

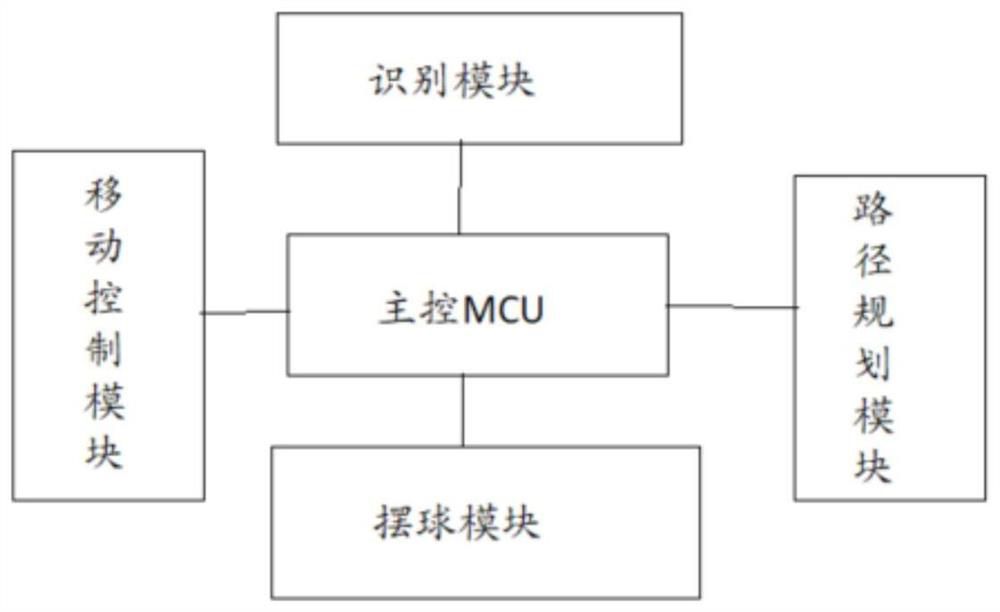

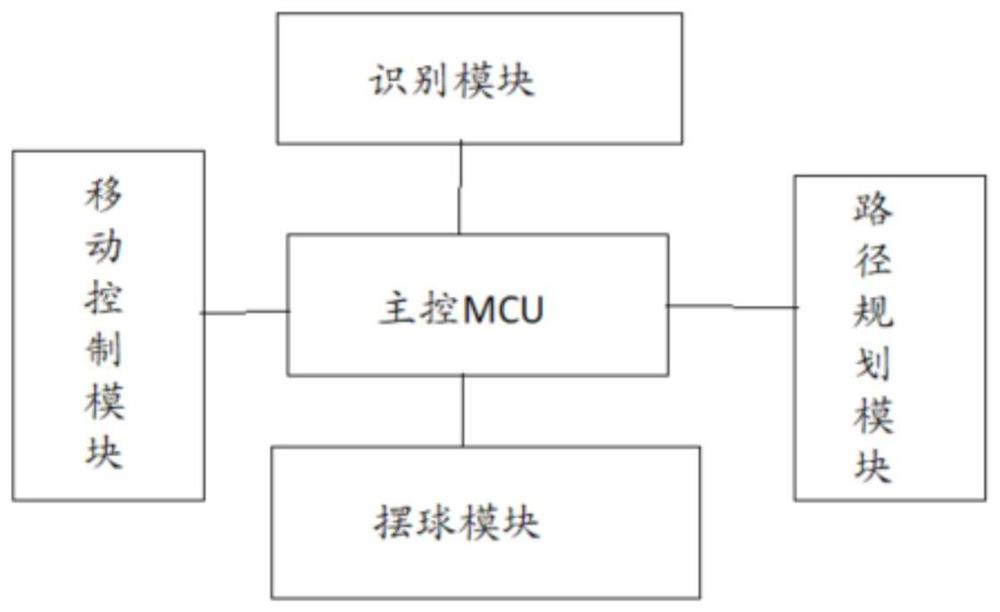

Automatic billiard placing robot capable of identifying billiard numbers

ActiveCN112692836ARealize automatic swingEasy to controlProgramme-controlled manipulatorPath planMovement control

The invention provides an automatic billiard placing robot capable of identifying billiard numbers. The automatic billiard placing robot comprises an identification module, a billiard placing module, a moving control module, a path planning module and a main control MCU, wherein the identification module is used for shooting high-definition pictures on a billiard table and identifying the number of each billiard in the high-definition pictures; the billiard placing module is used for placing the billiards on the billiard table according to a received billiard placing instruction; the billiard placing instruction comprises a user real-time input instruction and a default billiard placing instruction; the moving control module is used for controlling the movement and the movement direction of a billiard placing device; the movement direction comprises a front-back direction, a left-right direction and an up-down direction; the path planning module is used for generating a billiard placing path planning instruction according to the high-definition pictures and the billiard placing instruction and sending the billiard placing path planning instruction to the billiard placing module and the moving control module; and the main control MCU is used for controlling the identification module, the billiard placing module, the moving control module and the path planning module to carry out automatic billiard placing.

Owner:深圳市瑞驰文体科技发展有限公司

Position adjustable in-bed leg swing mechanism for medical rehabilitation

InactiveCN107213000ARealize automatic swingEasy to fixChiropractic devicesNursing bedsEngineeringAutomatic testing

The invention discloses a position-adjustable bed leg swing mechanism for medical rehabilitation. Fixed on the ground, the top of the support rod is hinged with connecting studs, and the connecting studs are screwed on the bottom surface of the top plate. There are front and rear adjustment screws on the left and right sides of the top plate, and the two ends of the front and rear adjustment screws are hinged on the corresponding upper connection blocks. Above, the bottom surface of the main moving block is fixed with the lower moving block, the transverse connecting beam is fixed on the two main moving blocks, and the middle bottom surface of the transverse connecting beam is fixed with the main connecting block. It can be installed on the bed body through the support rod sleeve, which is easy to install and disassemble. At the same time, the position of the elastic leg fixing block can automatically move back and forth, which is convenient for different people's legs to be placed and fixed, and it runs through the swing cylinder. It can realize the automatic swing of the legs, so as to realize the swing exercises of the legs, which is very convenient.

Owner:FOSHAN XUNYUAN MEDICAL EQUIP CO LTD

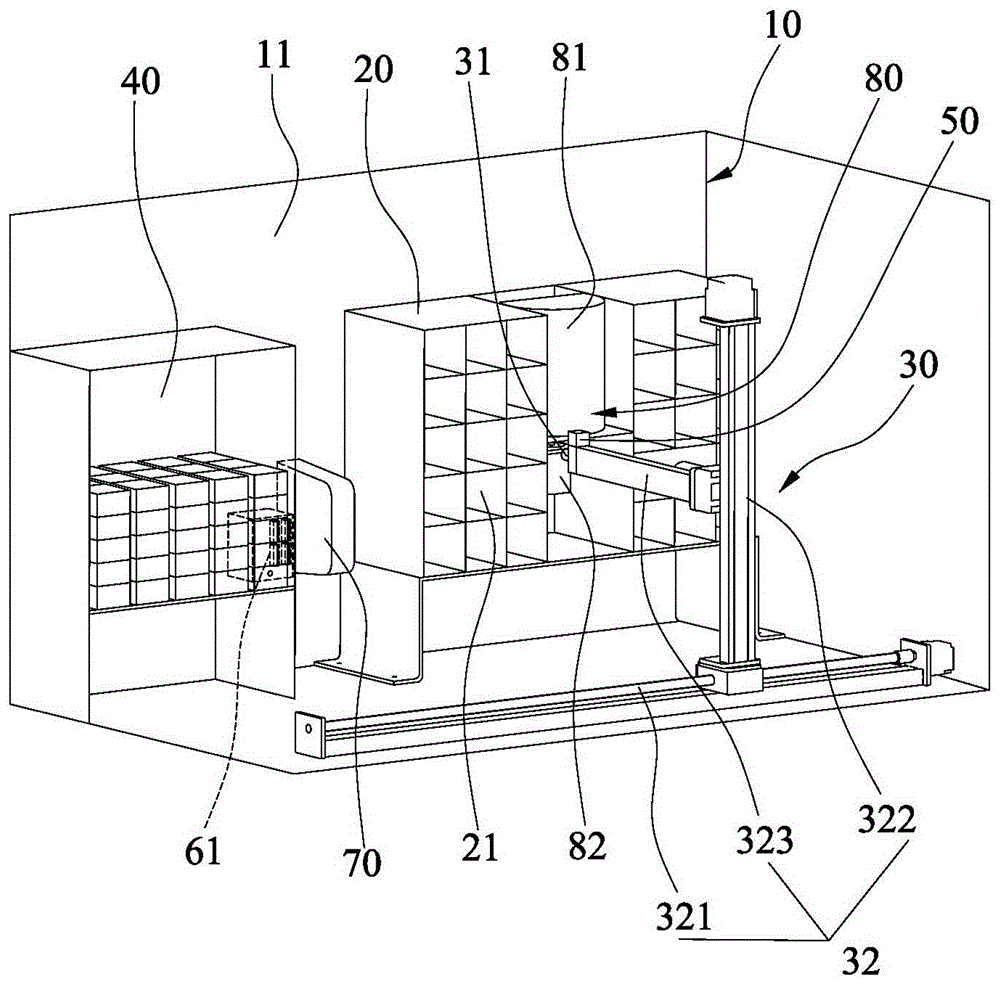

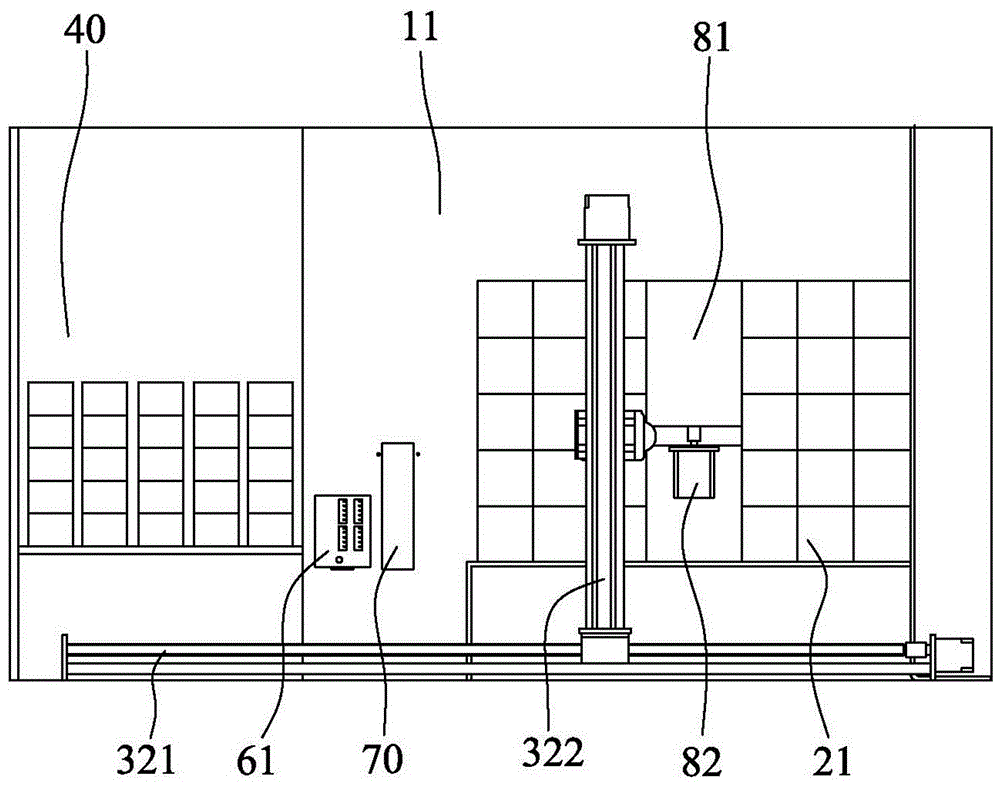

A cake vending machine and its control method

InactiveCN104599399BShorten the timeEnsure hygieneCoin-freed apparatus detailsApparatus for dispensing discrete articlesControl systemThree-dimensional space

The invention discloses a cake vending machine and a control method thereof. The vending machine comprises a housing, a storage compartment, a movable system, a stacking compartment, a recognizer and a control system; the movable system comprises a picking mechanism capable of taking or storing a cake box and a movable mechanism capable of driving the picking mechanism to move in a three-dimensional space; the recognizer is arranged above the picking mechanism and used for acquiring color or image information of different cake boxes of different types and transmitting the information to the control system; the control system comprises a controller, an operating interface and a storage device for storing the position information of each cake, the color information or image information of the cake box. By adopting the vending machine, not only can the automatic selling of the cake be realized and convenience be brought to the consumer, but also the automatic arrangement of the cake can be realized by utilizing the recognizer, the time for arranging the cake can be reduced, and convenience can be brought to merchants.

Owner:XIAMEN UNIV OF TECH

Electric rocking chair

The invention relates to the technical field of baby products and particularly discloses an electric rocking chair, comprising: a motor, wherein an output shaft of the motor rotates in reciprocating manner when the electric rocking chair operates, and reciprocating rotation includes a positive rotation and a reverse rotation; a rotating block which is driven by a driving shaft of the motor to rotate around its axis in reciprocating manner; a chair frame, wherein the bottom of the chair frame is releasably connected with the rotating block. The electric rocking chair can be rocked by electricity so that manpower is saved.

Owner:DONGGUAN CROWN SHIN BABY APPLIANCES

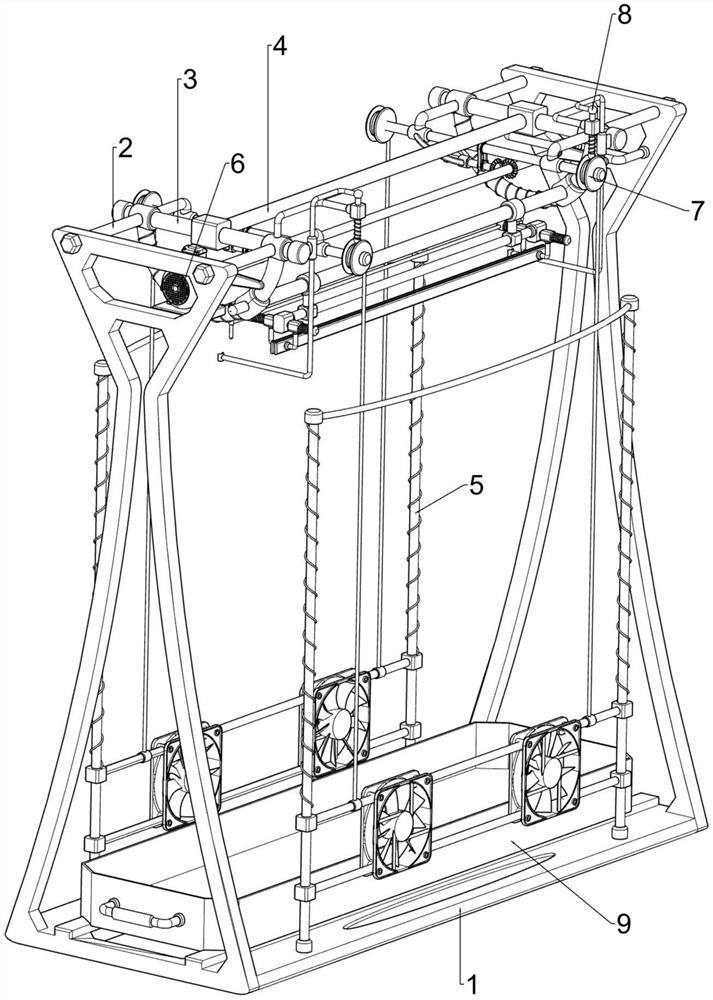

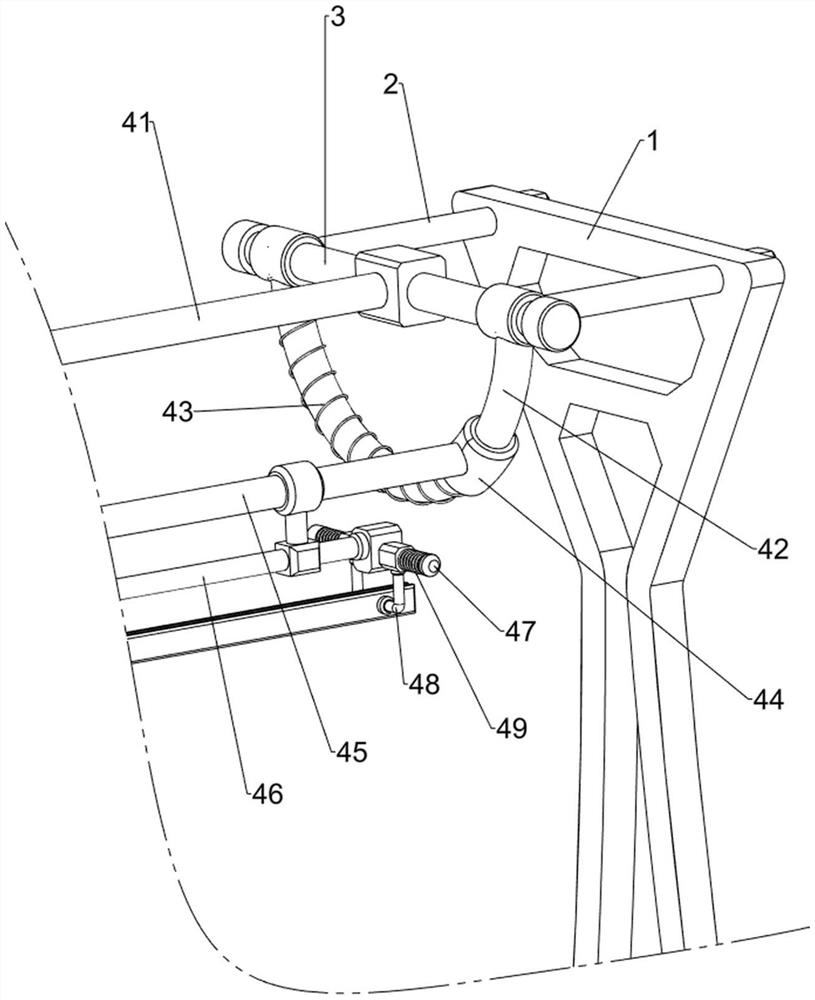

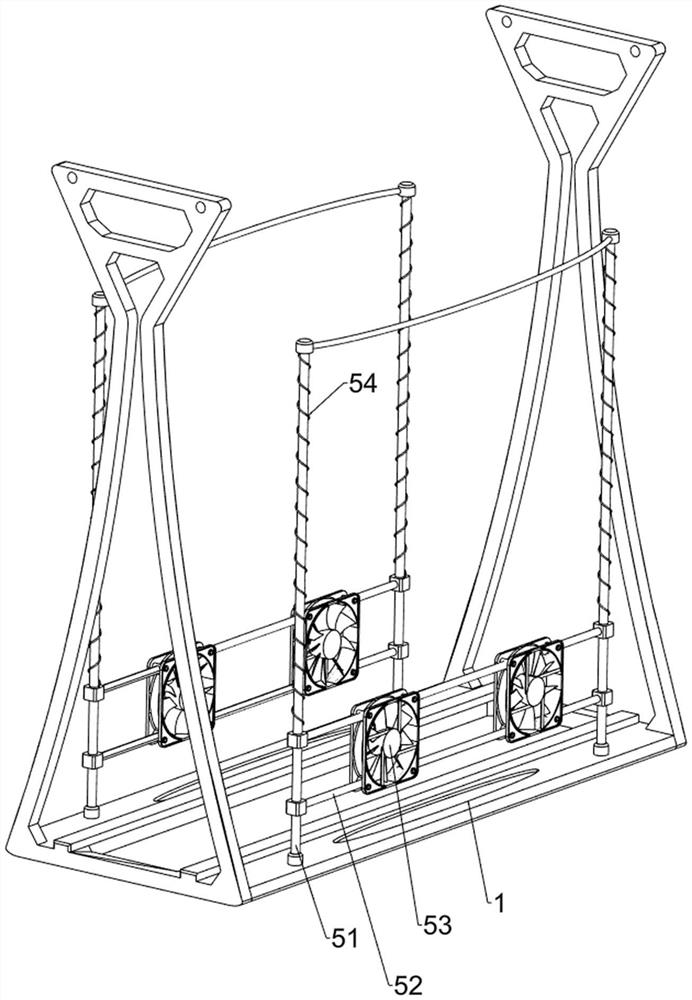

Swing type blow-drying device for clothing wrinkles for clothing production

ActiveCN112481964AAchieve clampingAchieve blow dryTextiles and paperLaundry driersMechanical engineeringIndustrial engineering

The invention relates to a blow-drying device, in particular to a swing type blow-drying device for clothing wrinkles for clothing production. The swing type blow-drying device for the clothing wrinkles for clothing production can automatically clamp and loosen clothing and enable all positions of the clothing to be blown by wind. The swing type blow-drying device for the clothing wrinkles for clothing production comprises a base, supporting columns, a swinging mechanism and a drying mechanism, wherein first supports are symmetrically arranged on the two sides of the base; the supporting columns are arranged between every two adjacent first supports; the swinging mechanism is arranged between the supporting columns; and the drying mechanism is arranged on the base. The clothing is clampedthrough the swinging mechanism, then the clothing can be thrown away by moving the swinging mechanism, and then the clothing is blow-dried under the cooperation of the drying mechanism.

Owner:江西美硕实业有限公司

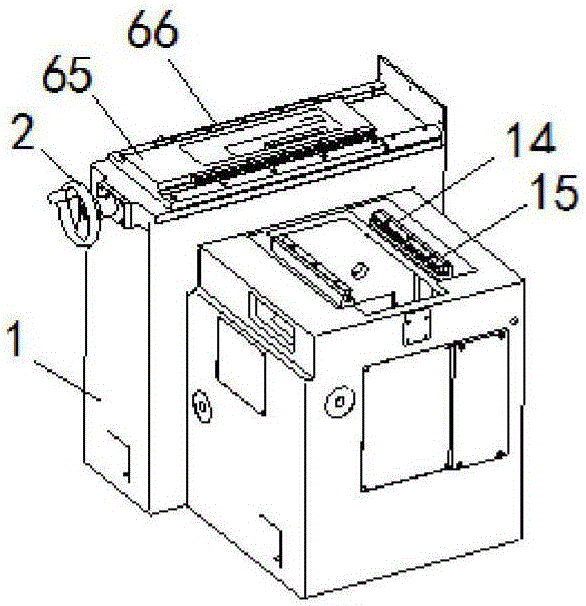

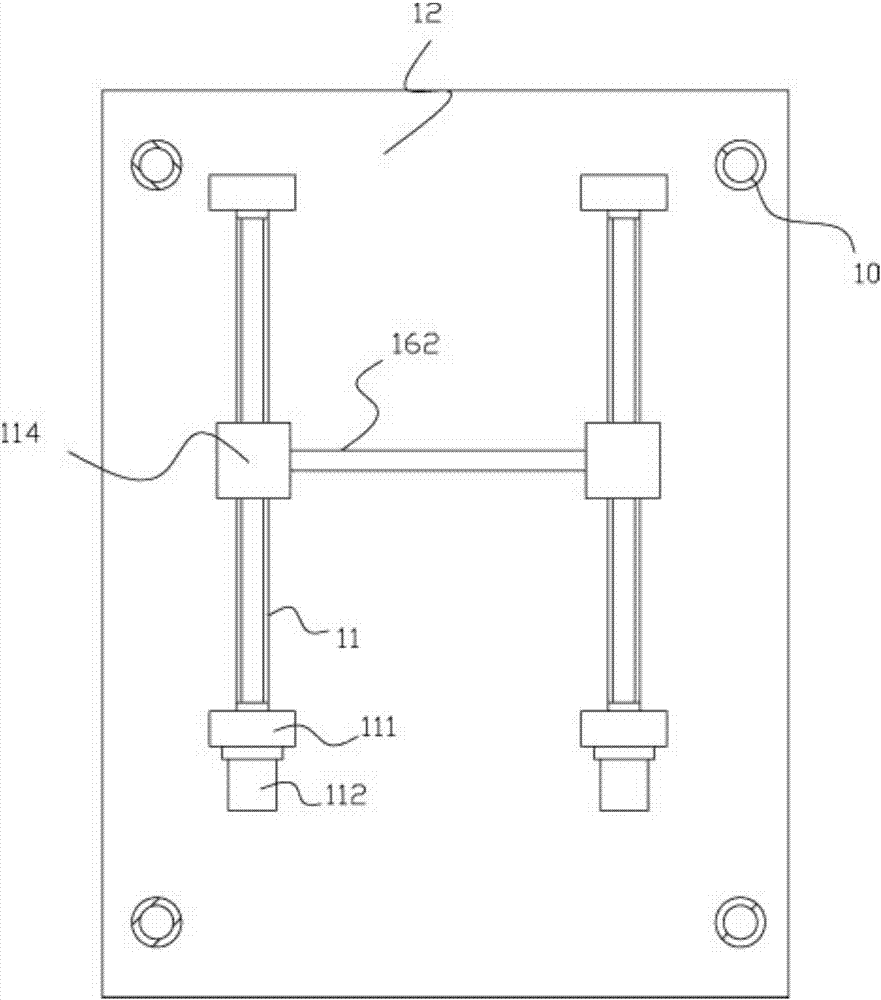

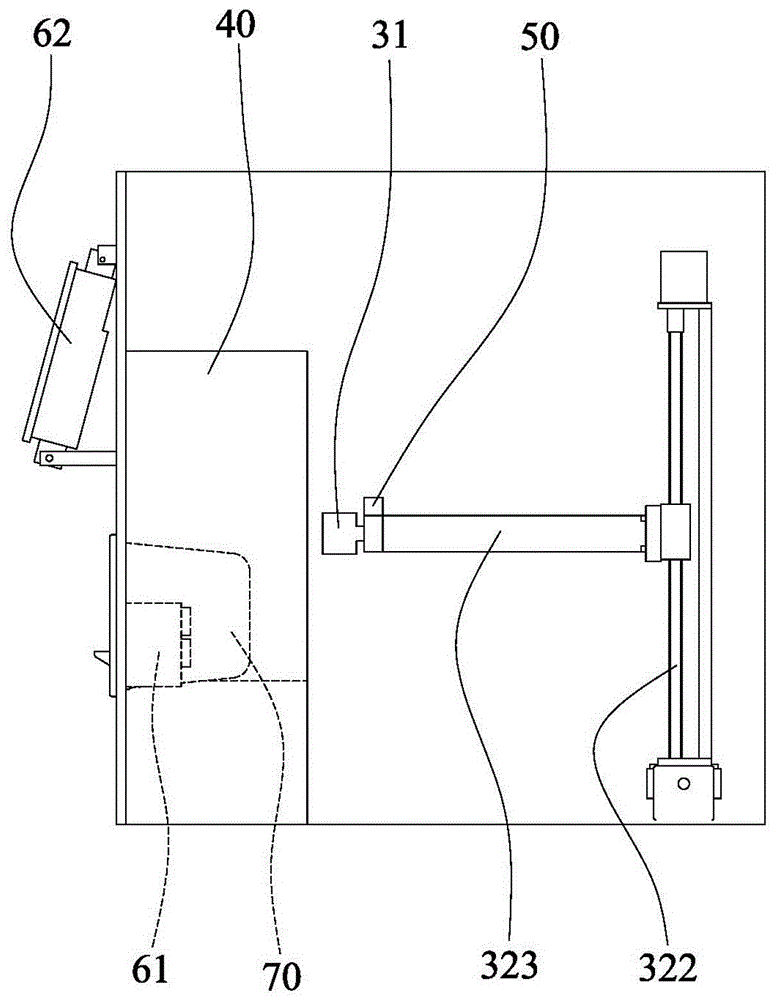

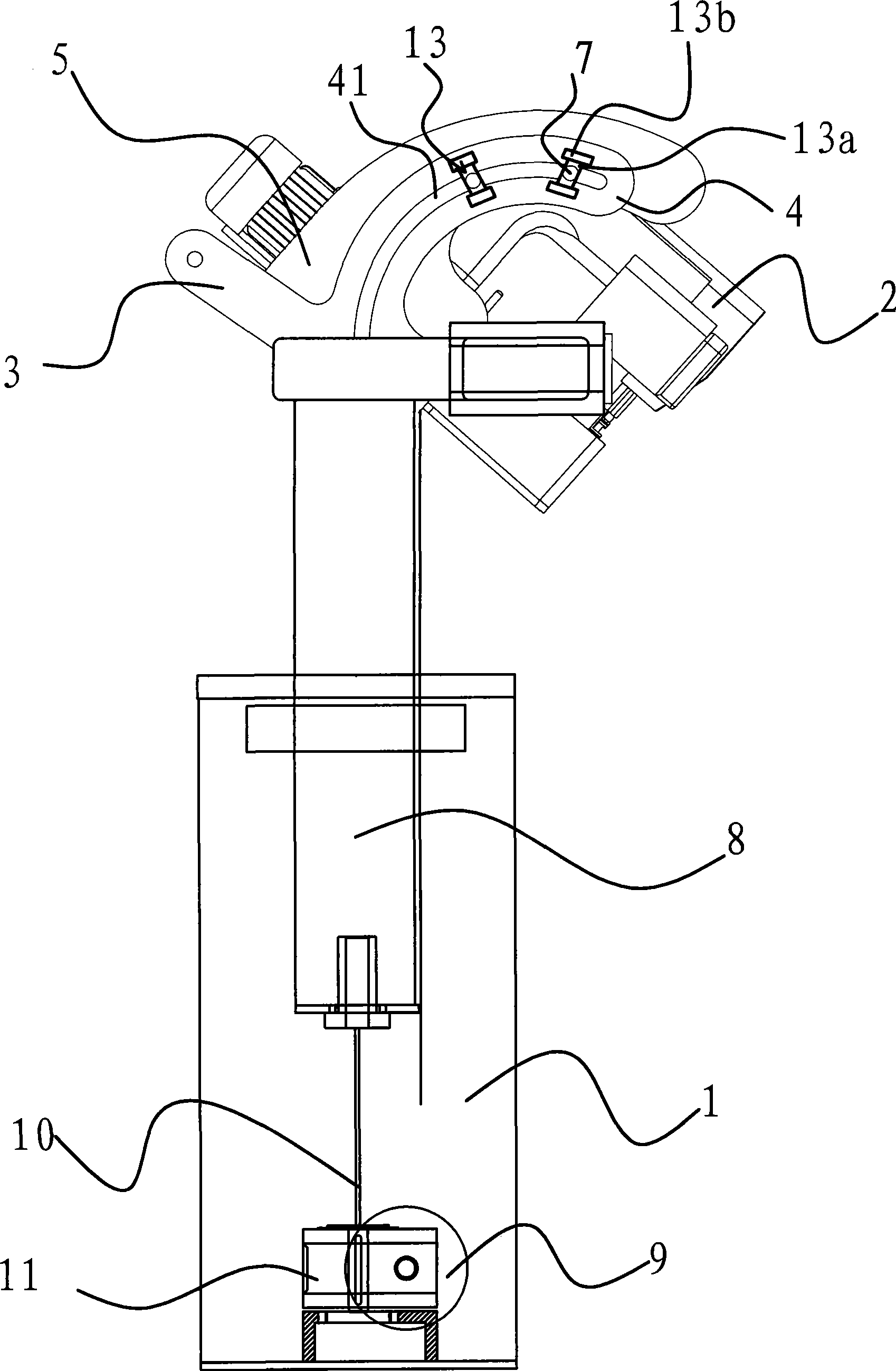

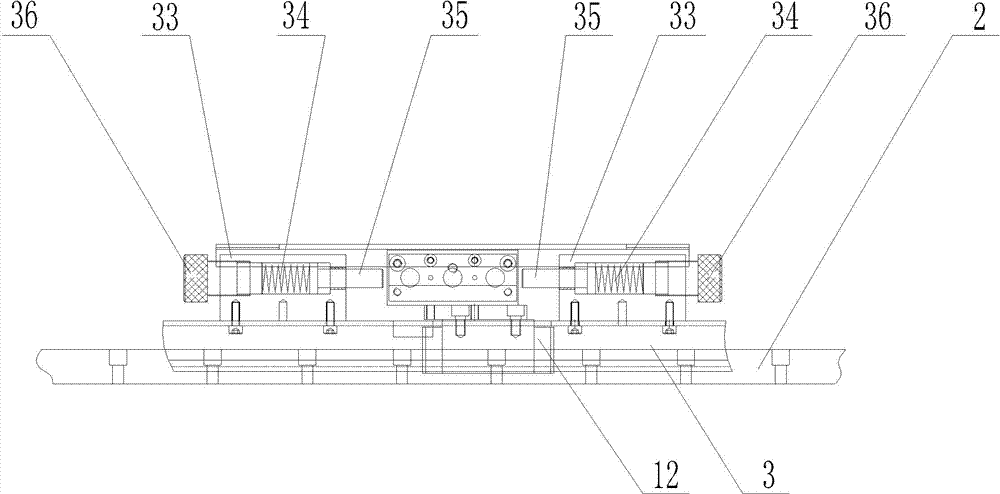

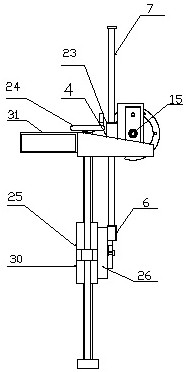

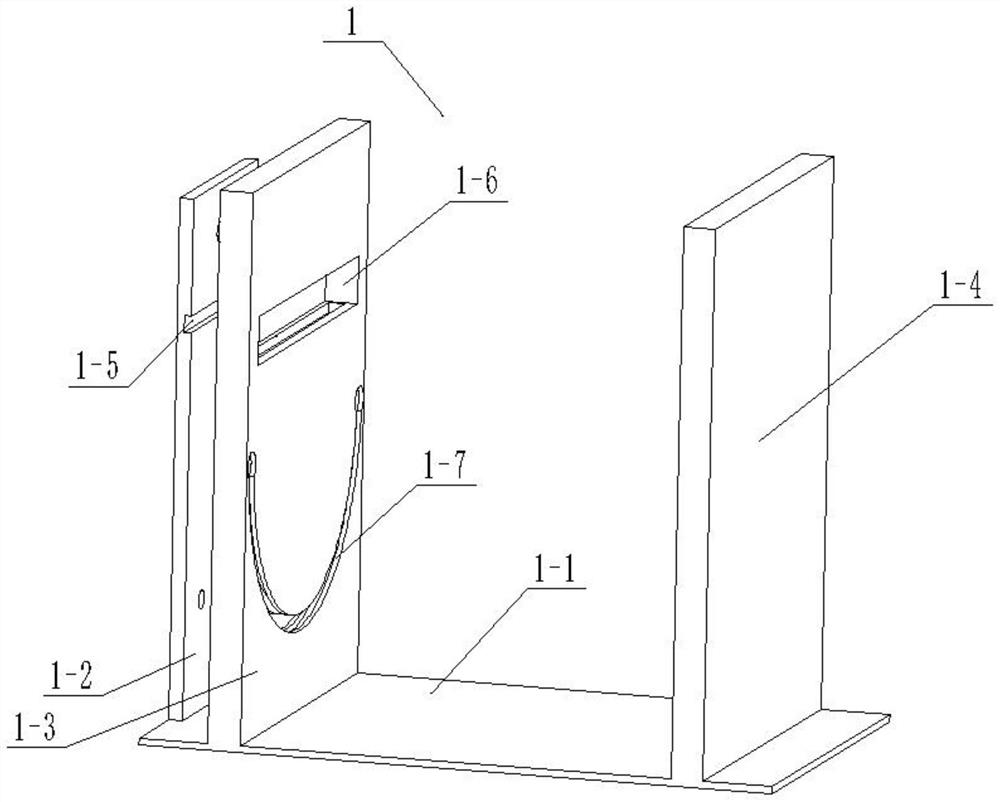

Adjusting device of tape edge sewing head for mattress

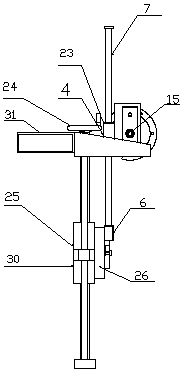

InactiveCN101476215ARealize automatic swingSimple structureUpholstery manufactureSewing-machine elementsInstabilityMechanical engineering

The invention provides a mattress surrounding edge machine sewing head adjusting device, which belongs to the mechanical technology field, and solves the problems of per swinging accuracy and lifting instability existing in current mattress surrounding edge machine sewing head adjusting devices. The mattress surrounding edge machine sewing head adjusting device comprises a base and a sewing head; a movable seat board is disposed on the base; a elevating system is disposed between the movable seat board and the base for lifting the movable seat board; an adjusting plate with an arced guiding through hole is fixed on the movable seat board; a connection seat is disposed on one side of the adjusting plate; the sewing head is fixed on the connection seat; and a swing mechanism is disposed between the movable seat board and the connection seat fro pushing the connection seat to slide along the guiding through hole. The invention achieves the advantages of reasonable design, swinging accuracy, elevating stability and high practicability.

Owner:ZHEJIANG SHENDU OPTOELECTRONICS TECH

Cradle bed for baby

The invention discloses a cradle bed for a baby. The cradle bed comprises a bed body, a mattress is arranged on the bed body, legs are arranged below the bed body, a ball is arranged in the middle below the bed body, the ball is hemispherical, a swing arm is arranged below the ball, springs are arranged around the bed body, four springs are available, a support frame is arranged below the ball, acontrol circuit board and a Bluetooth system are arranged inside the support frame, four stabilizing brackets are further arranged below the bed body, and support bed legs are arranged inside the springs. For the cradle bed, the ball is arranged, the automatic swing can be realized through the swing arm, the swing speed of the swing arm can be adjusted, when shaking is not needed, the stabilizingbrackets can be inserted into the support frame, then the bed body can be stabilized, the application range is wide, meanwhile, bed sides are arranged around the bed body, interaction toys are arranged on the bed sides, so that the entertainment property is strong, the bed sides also can protect the baby in the bed body, then the use is more stable and safer, in addition, with the Bluetooth system, the connection with a mobile phone can be realized, so that the cradle bed can be remotely controlled.

Owner:宁波思洞工业设计有限公司

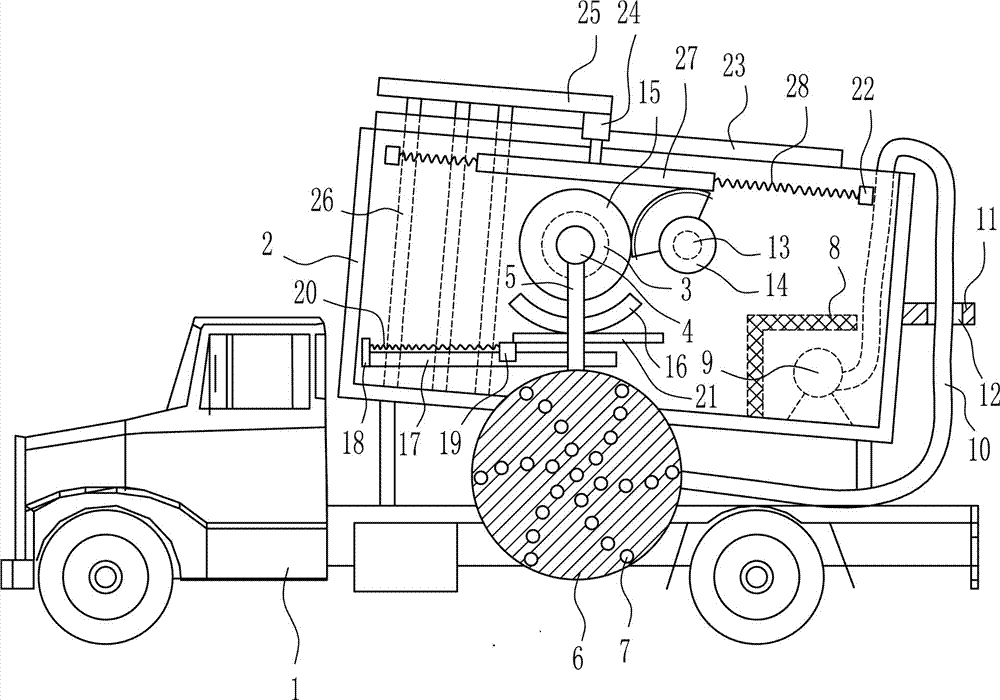

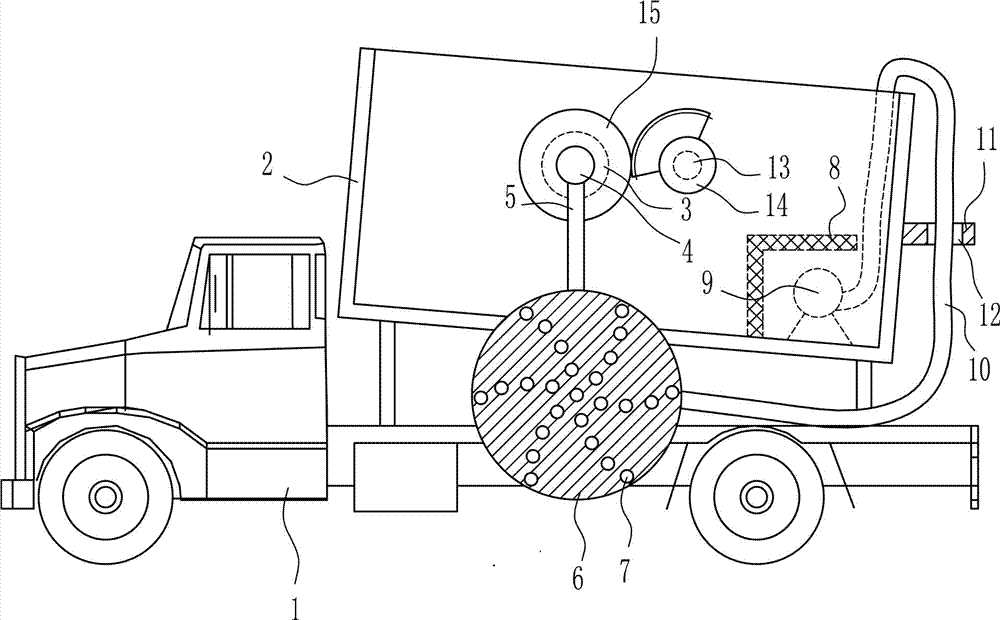

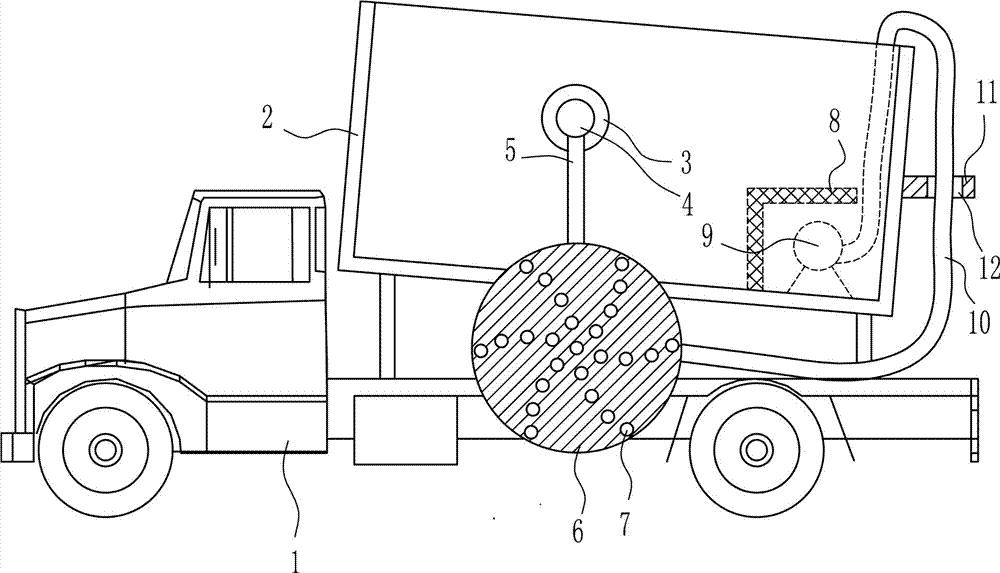

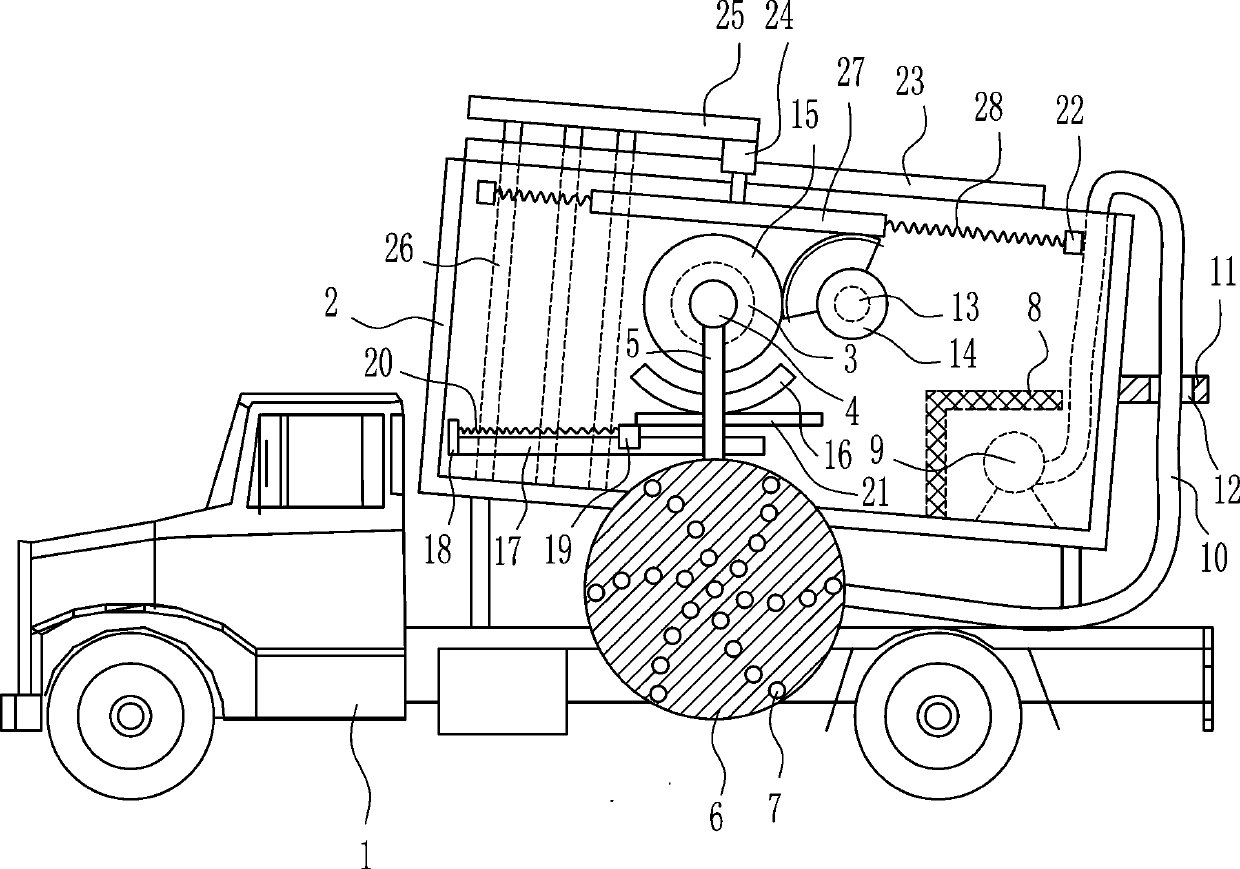

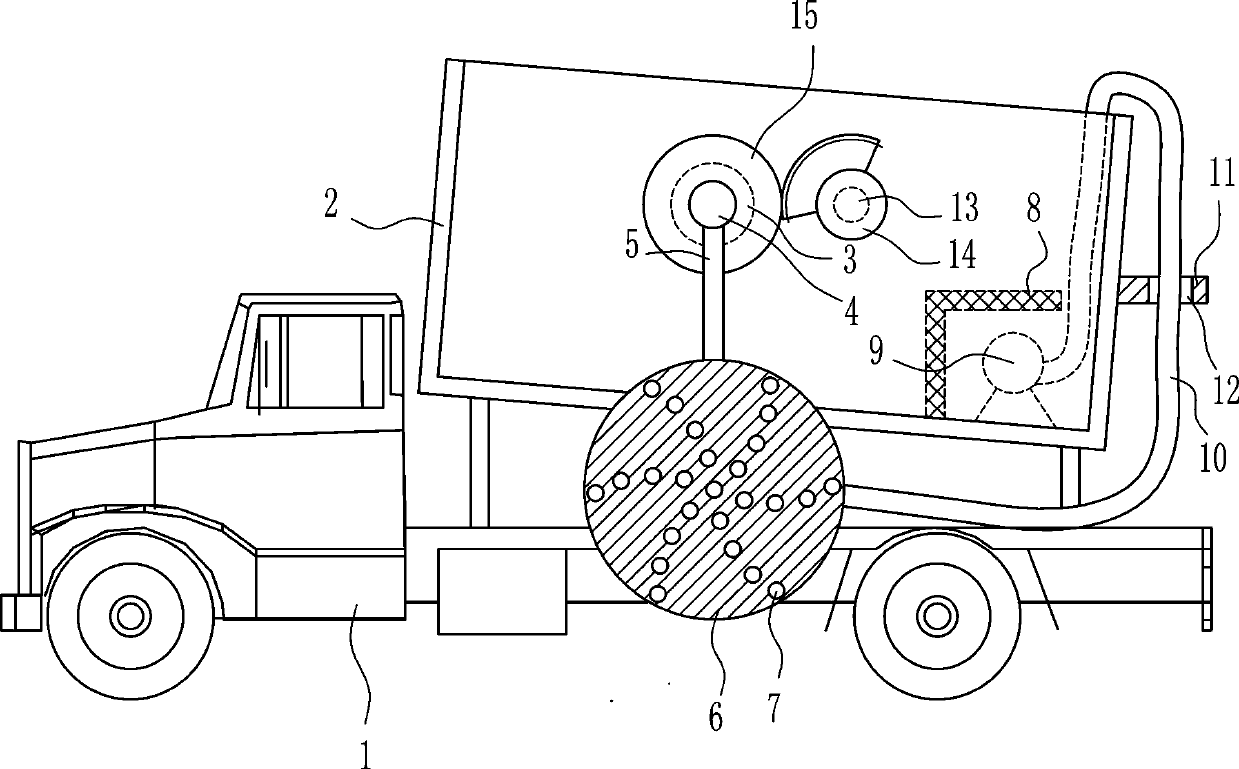

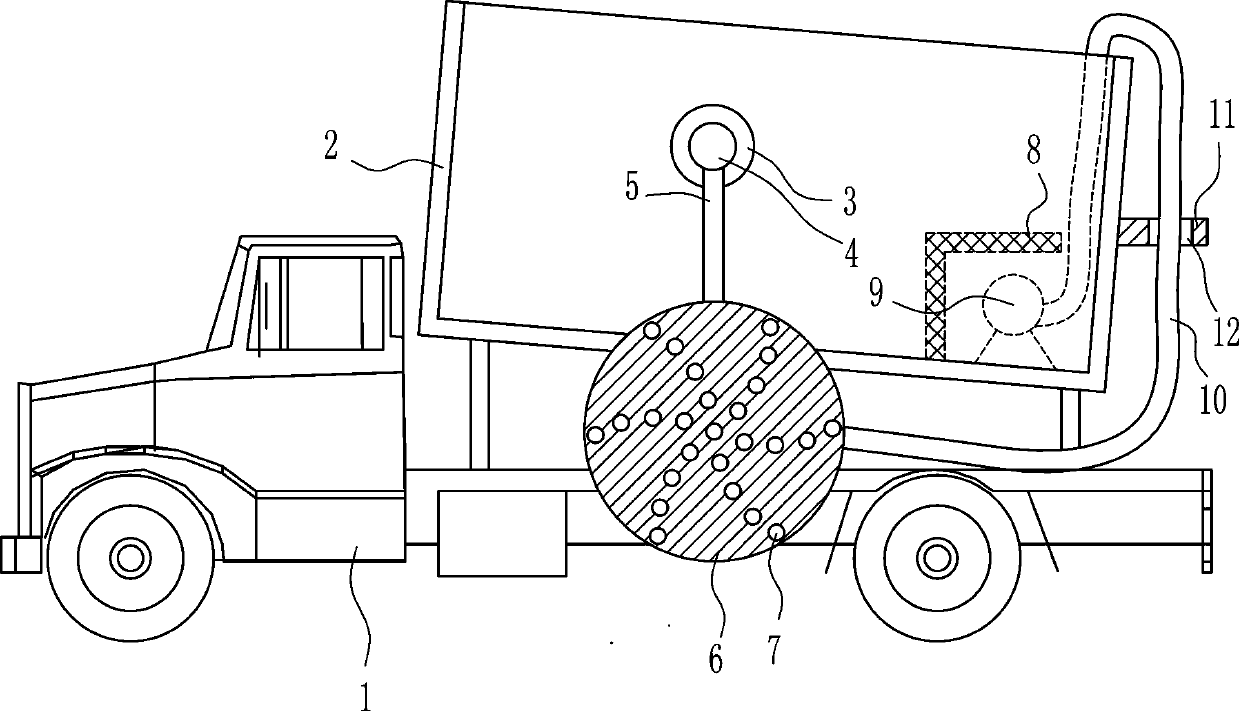

Dedusting agent oscillating type spraying vehicle for tunnel construction

ActiveCN108005709ARealize automatic swingExpand the range of dust removalDust removalFire preventionTunnel constructionAgricultural engineering

The invention relates to a dedusting agent spraying vehicle for tunnel construction, in particular to a dedusting agent oscillating type spraying vehicle for tunnel construction. The dedusting agent oscillating type spraying vehicle for tunnel construction can automatically change the spraying angle of a dedusting agent, and manpower does not need to be relied on for spraying. The dedusting agentoscillating type spraying vehicle for tunnel construction comprises a spraying vehicle body, a storage box, a bearing seat, a first rotating rod, a second rotating rod, a hollow plate and the like. The storage box is connected to the top of the spraying vehicle body, the bearing seat is connected to the middle of the front wall of the storage box, the first rotating rod is connected with the bearing seat, and the second rotating rod is connected with the front end of the first rotating rod. The dedusting agent oscillating type spraying vehicle achieves the effects that the spraying angle of the dedusting agent can be automatically changed, and the manpower does not need to be relied on for spraying, and by arranging the spraying vehicle body, the storage box, the bearing seat and the like,the dedusting agent can be sprayed out from multiple directions.

Owner:倡创(上海)咨询管理事务所

Automatic rocking chair

InactiveCN105361531ARealize automatic swingReduce manufacturing costChildren furnitureEngineeringSupport surface

The invention discloses an automatic rocking chair, which comprises a rocking chair main body, wherein a driving device, for driving the rocking chair main body to swing, is arranged on the rocking chair main body; the driving device comprises a hollow shell; an electromagnet is arranged inside the shell; an ejector rod, which can extend out of the shell or shrink into the shell, is connected to the lower part of an iron core of the electromagnet; an opening, where the ejector rod can move in and out, is formed in the sidewall of the shell; and meanwhile, a monitoring device, which is used for monitoring the swing amplitude of the rocking chair main body, is additionally arranged inside the shell. According to the automatic rocking chair disclosed by the invention, the ejector rod, driven by the electromagnet, extends out of the shell and is propped against a supporting surface, so that the rocking chair main body is driven to swing; when the electromagnet is repeatedly electrified discontinuously, the ejector rod repeatedly moves in and out of the shell and is propped against the supporting surface, so that the rocking chair main body repeatedly swings; therefore, a purpose that the rocking chair automatically swings is achieved; and through the structures above, the automatic rocking chair is beneficial for simplifying the structure of the driving device and is convenient for production and processing, and the production cost of the rocking chair is reduced.

Owner:中山涛美远东日用制品有限公司

Energy-saving automatic cradle

The invention discloses an energy-saving automatic cradle. The energy-saving automatic cradle comprises a cradle body, a first gear, a first gear shaft, a second gear, a second gear shaft, a plane spring, a gear claw, a clamp, a reciprocating angle piece, a gear bracket and a second bracket; the first gear and the plane spring are in splined connection with the first gear shaft, and the second gear and the gear claw are in splined connection with the second gear shaft; the first gear shaft is installed on the lower middle portion of the gear bracket, the second gear shaft is installed at the proper position of the upper middle portion of the gear bracket, and the first gear is engaged with the second gear. The clamp and the reciprocating angle piece are installed on the two sides of the top of the gear bracket respectively, the front end of the clamp makes contact with the gear claw, a pair of short rods of the reciprocating angle piece can make contact with ears of the clamp, and a pair of long rods of the reciprocating angle piece can make contact with ears of the gear claw. One end of the reciprocating angle piece is welded to a cradle rocker, and the other end of the cradle rocker is installed on the top of the second bracket. The swing of the cradle can be realized without consuming electric energy, so that the cradle is energy-saving and environment-friendly.

Owner:GUANGXI UNIV

An automatic ball-swinging robot capable of recognizing billiard ball numbers

ActiveCN112692836BRealize automatic swingEasy to controlProgramme-controlled manipulatorClassical mechanicsEngineering

The present invention provides an automatic ball-swinging robot capable of identifying billiard ball numbers, including a recognition module: used to take high-definition pictures on a billiard table, and to identify the number of each billiard ball in the high-definition picture; a ball-swinging module: used to Receive the ball swing instruction, and place the billiard balls on the billiard table; wherein, the swing ball instruction includes the user's real-time input instruction and the default swing ball instruction movement control module: used to control the movement and movement direction of the ball swing device; wherein, the The direction of motion includes the front-to-back direction, the left-right direction and the up-down direction; the path planning module: used to generate a swing ball path planning instruction according to the high-definition picture and the swing ball instruction, and send the swing ball path planning instruction to the swing ball Module and mobile control module; main control MCU: control the identification module, ball swing module, mobile control module, and path planning module to automatically swing the ball.

Owner:深圳市瑞驰文体科技发展有限公司

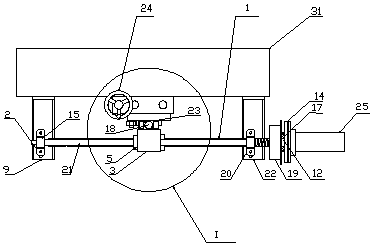

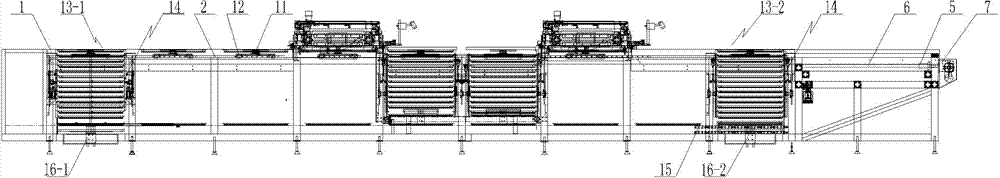

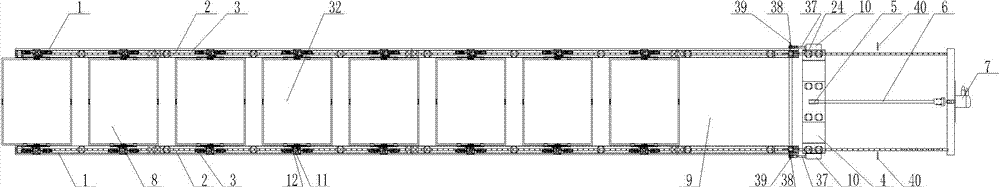

Cycle conveying device for bedplate

InactiveCN102765588ARealize automatic swingFast shippingMechanical conveyorsProduction lineEngineering

The invention provides a cycle conveying device for a bedplate, which ensures the continuously cyclic and automatic conveyance of the bedplate on a plurality of continuous stations and has high automaticity meeting the requirement of a high-efficiency multistation automatic print production line and high bedplate conveying speed, thereby enhancing the printing efficiency and greatly reducing labor intensity. The cycle conveying device for the bedplate comprises a rack, wherein long sliding tracks are respectively arranged on both sides of the rack; the sliding tracks are respectively provided with a carriage which is connected with a sliding plate; the sliding plates are connected with the sliding tracks through sliding blocks of the sliding plates and connected with a rolling screw through a rolling nut; the rolling screw is connected with a servo motor; the rack is provided with a plurality of working stations and one transition station; and the carriages are provided with bedplate clamping cylinders respectively corresponding to the working stations. The cycle conveying device for the bedplate is characterized in that vertical conveying stations are respectively arranged on both ends of the rack and respectively provided with a bedplate vertical conveying device, and the lower ends of the vertical conveying stations on both ends are respectively provided with a conveying belt.

Owner:陆新田 +1

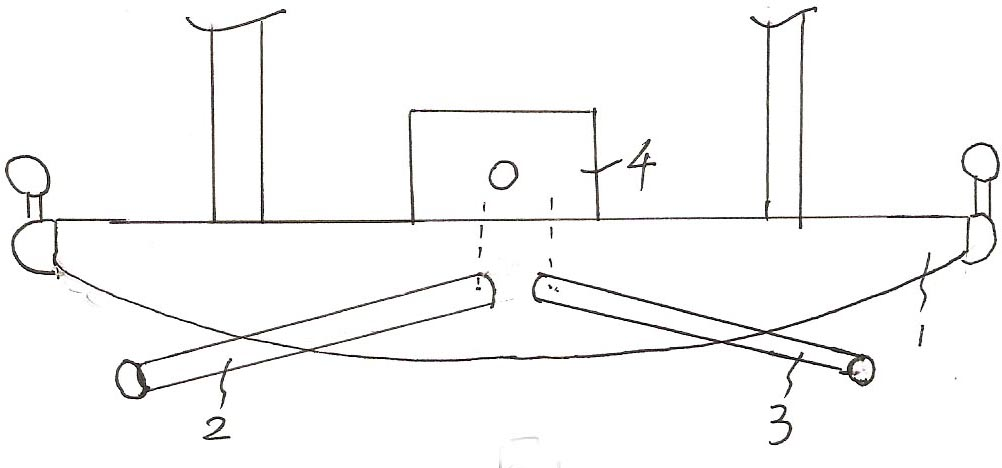

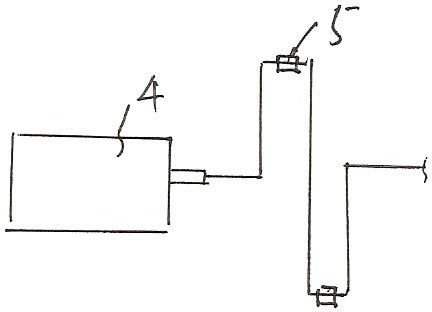

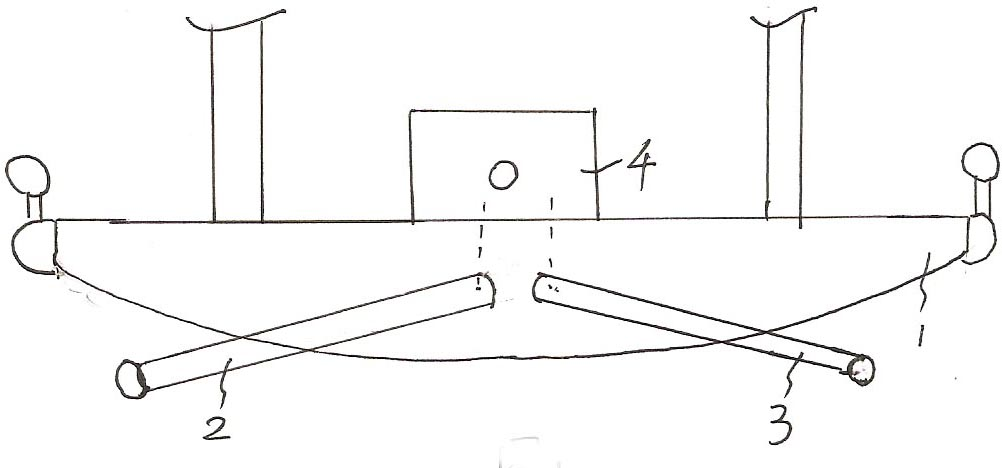

A rotating lifting device

The invention relates to a rotary lifting device. Consists of fixed brackets, a servo motor, a hand wheel, a moving mechanism, a lifting mechanism and a work plate for mounting tools. The servo motor, hand wheel, moving mechanism and lifting mechanism are installed on the fixed bracket; the servo motor is connected to the moving mechanism and drives a moving block on the mechanism to move left and right, and the moving block is connected to the lifting mechanism through a swing rod One of the lifting moving blocks, and drives it to rotate; the hand wheel is connected to the lifting mechanism and drives one of the lifting blocks to move up and down; the working turntable is fixedly connected to the lifting rotating block, and the working turntable and the lifting block rotate coaxially Connection; operating the servo motor and / or the hand wheel can realize the rotation and / or lifting movement of the working turntable. It can be used to install sprinklers to rotate according to a specific sinusoidal curve.

Owner:SHANGHAI UNIV

Adjusting device of tape edge sewing head for mattress

InactiveCN101476215BRealize automatic swingSimple structureUpholstery manufactureSewing-machine elementsInstabilityEngineering

The invention provides a mattress surrounding edge machine sewing head adjusting device, which belongs to the mechanical technology field, and solves the problems of per swinging accuracy and lifting instability existing in current mattress surrounding edge machine sewing head adjusting devices. The mattress surrounding edge machine sewing head adjusting device comprises a base and a sewing head;a movable seat board is disposed on the base; a elevating system is disposed between the movable seat board and the base for lifting the movable seat board; an adjusting plate with an arced guiding through hole is fixed on the movable seat board; a connection seat is disposed on one side of the adjusting plate; the sewing head is fixed on the connection seat; and a swing mechanism is disposed between the movable seat board and the connection seat fro pushing the connection seat to slide along the guiding through hole. The invention achieves the advantages of reasonable design, swinging accuracy, elevating stability and high practicability.

Owner:ZHEJIANG SHENDU OPTOELECTRONICS TECH

Active corner drive and swivel coupler

ActiveCN112977530BReduce loadAvoid the problem of overloadingRailway coupling accessoriesDrive shaftEngineering

The invention provides an active angle driving device and a rotating coupler. The device includes a centering mechanism, which includes a housing assembly, a centering plate pivotally arranged in the shell assembly and a piston assembly pressing against the surrounding wall of the centering plate, and the centering plate is provided with a sleeve, a protrusion, The notch and the cam, the protrusion and the notch are symmetrically arranged on both sides of the cam; the guide plate assembly is connected with the shell component and the sleeve, and is provided with an arc-shaped guide groove matching the cam and the protrusion, and the protrusion Placed in the arc-shaped guide groove; a pivotally installed drive mechanism in the housing assembly, which includes a cam plate assembly provided with a bar-shaped groove and a drive shaft assembly installed in the bar-shaped groove; and connected with the drive mechanism Power components. The power assembly pushes the cam plate assembly to rotate and extrudes the piston assembly, and the drive shaft assembly moves along the guide groove. When it moves to contact with the protrusion, the centering disc is driven to rotate by continuing to move. The centering disc is connected with the mechanical structure, which can realize the automatic rotation of the mechanical structure.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST +1

Baby hammock with adjustable swing range

The invention discloses a swing-amplitude-adjustable baby hammock which comprises a base, a transmission adjusting structure, a driving structure, a driven structure, a baby hammock body, a protectionstructure and two driving sliders. The swing-amplitude-adjustable baby hammock has the advantages that a baby bed can be automatically swung, a baby is comforted to fall asleep, the baby hammock relieves burden of an adult for soothing the baby to fall asleep, swing amplitude can be adjusted according to actual situations such as age and body weight of a baby, so that sleep of the baby is more comfortable, the transmission adjusting structure is fixedly connected at the left end of the base, left ends of the two driving sliders are slidably connected on the base, the right ends of the two driving sliders are fixedly connected with the driving structure, the transmission adjusting structure is slidably connected in the two driving sliders, the driving structure is slidably connected on thebase, the right end of the driving structure is hinged to the baby hammock, the right end of the baby hammock is hinged to the driven structure, the driven structure is slidably connected on the base, and the protection structure is inserted into the left end of the base.

Owner:章雪霞

PE diaphragm processing device for automobile starting battery and use method of PE diaphragm processing device

PendingCN114497889ASmall diameterIncrease the number ofCell component detailsWebs handlingAutomotive engineeringElectrical battery

The invention discloses a PE diaphragm processing device for an automobile starting battery and a using method thereof.The PE diaphragm processing device for the automobile starting battery comprises a base, and a shaping assembly used for shaping a PE diaphragm is installed on one side of the upper portion of the base; and the other side of the shaping assembly is provided with a rolling assembly for rolling the shaped PE diaphragm. By installing the shaping assembly and the winding assembly, the PE diaphragm subjected to thermoplastic extrusion can be rapidly cooled and shaped through the shaping assembly, meanwhile, the PE diaphragm is output after being shaped and shrunk through the winding assembly, the tension of the PE diaphragm can be adjusted in time in the shrinking process, meanwhile, automatic swing of a winding roller can be achieved, and the production efficiency is improved. According to the device, a convex strip-shaped structure of a PE diaphragm product is staggered, the winding diameter is greatly reduced, the winding number is increased, the device is convenient and fast to use, easy to operate and high in practicability, and meanwhile the machining efficiency is greatly improved.

Owner:江苏神力电源科技有限公司

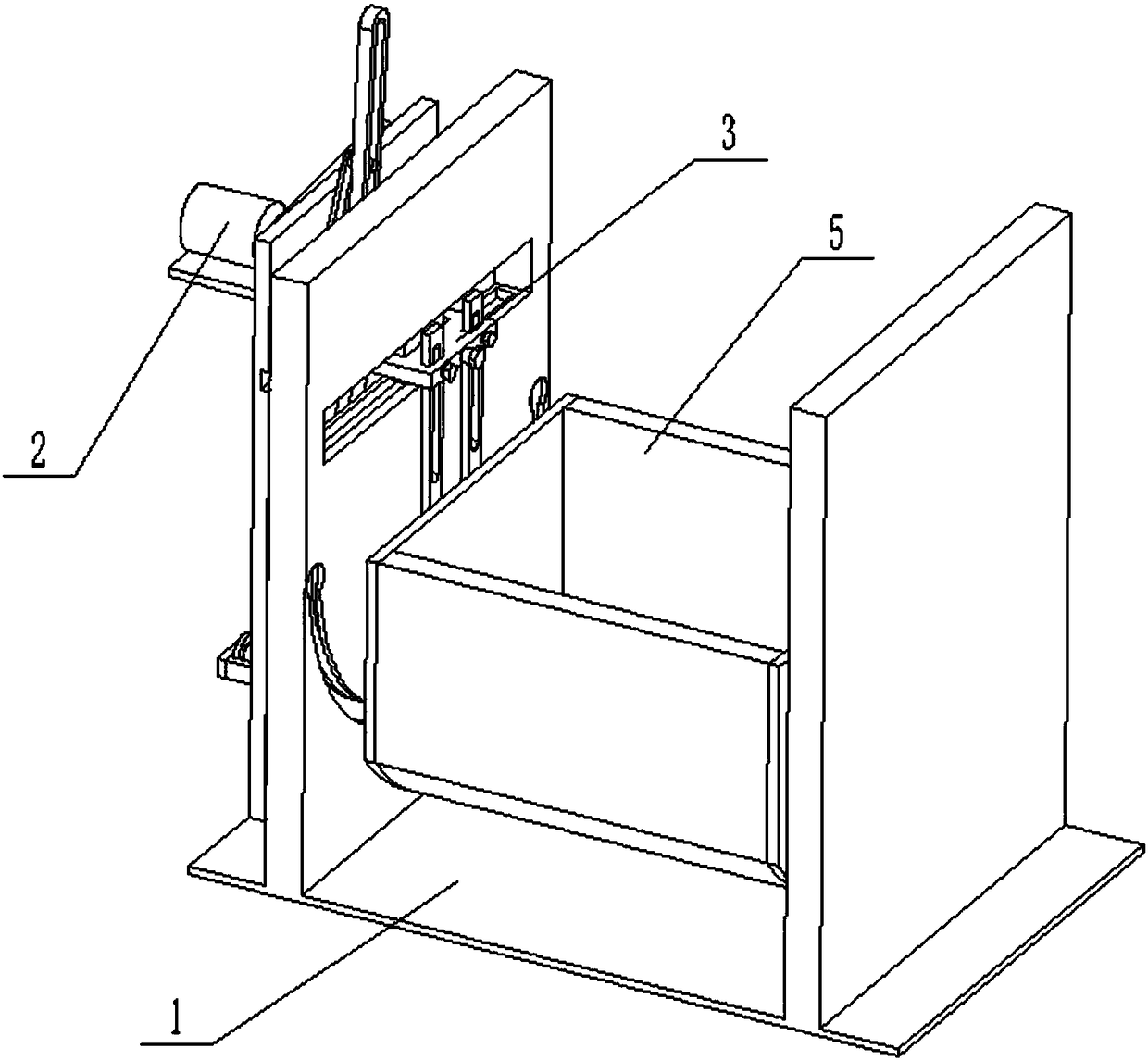

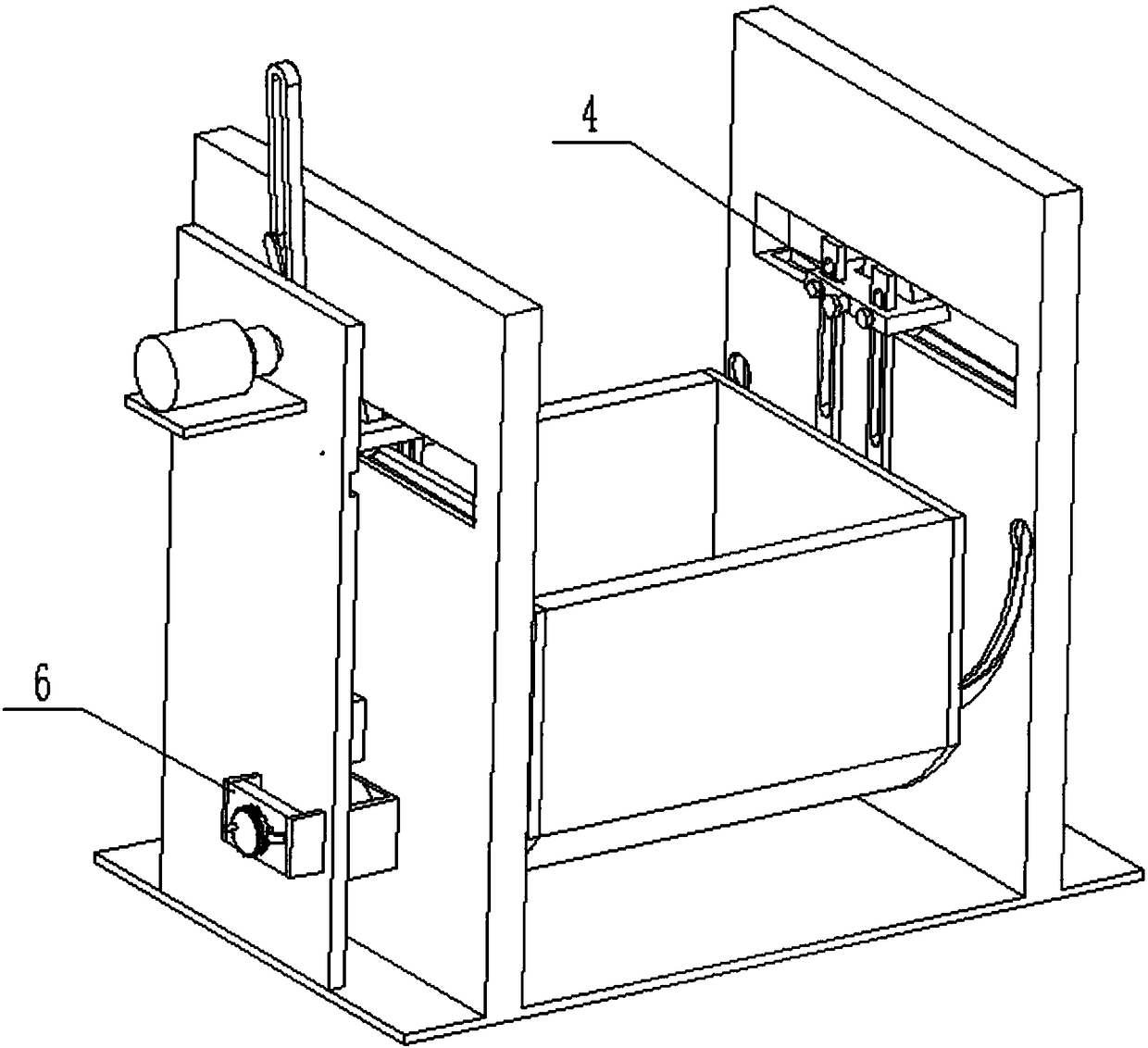

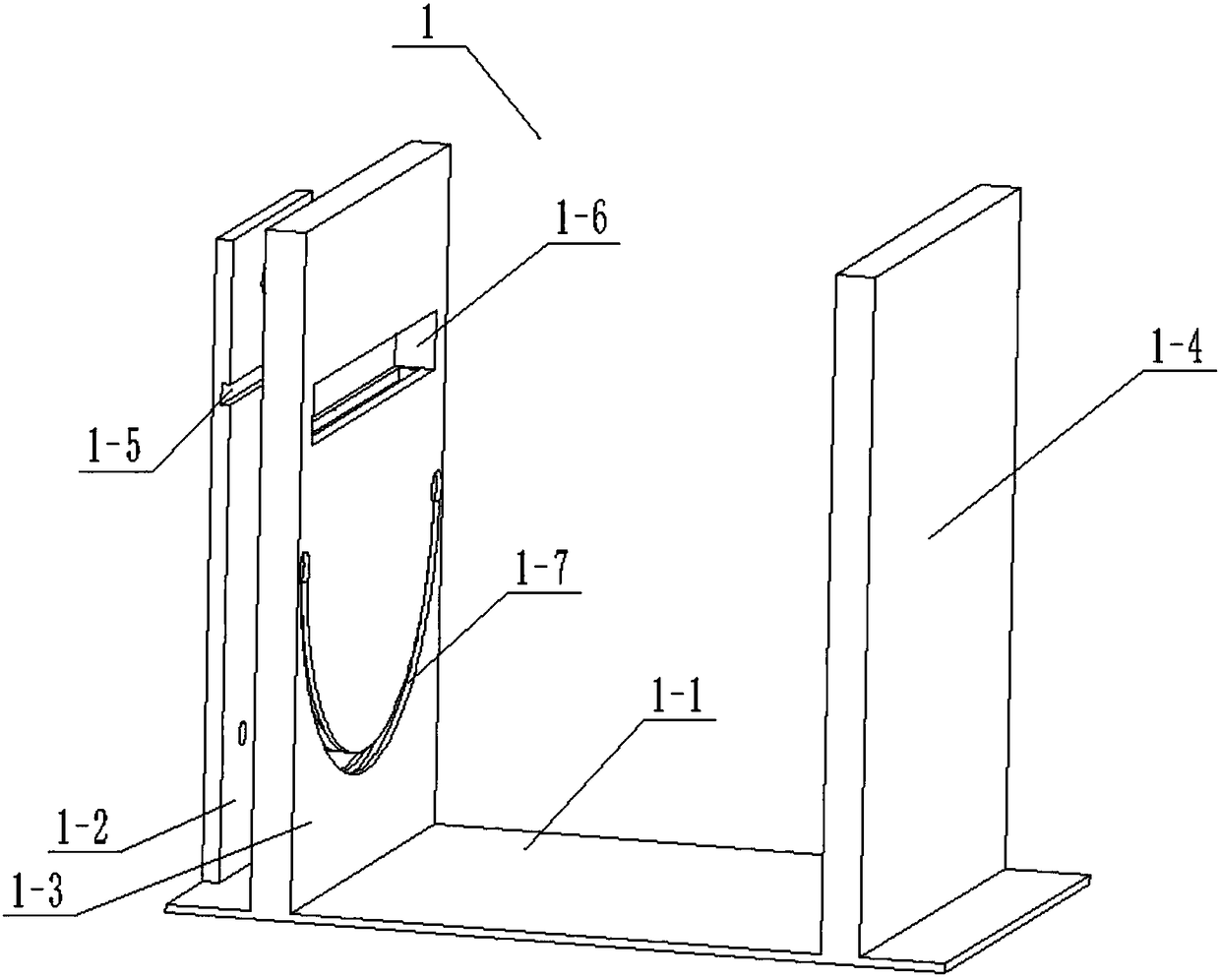

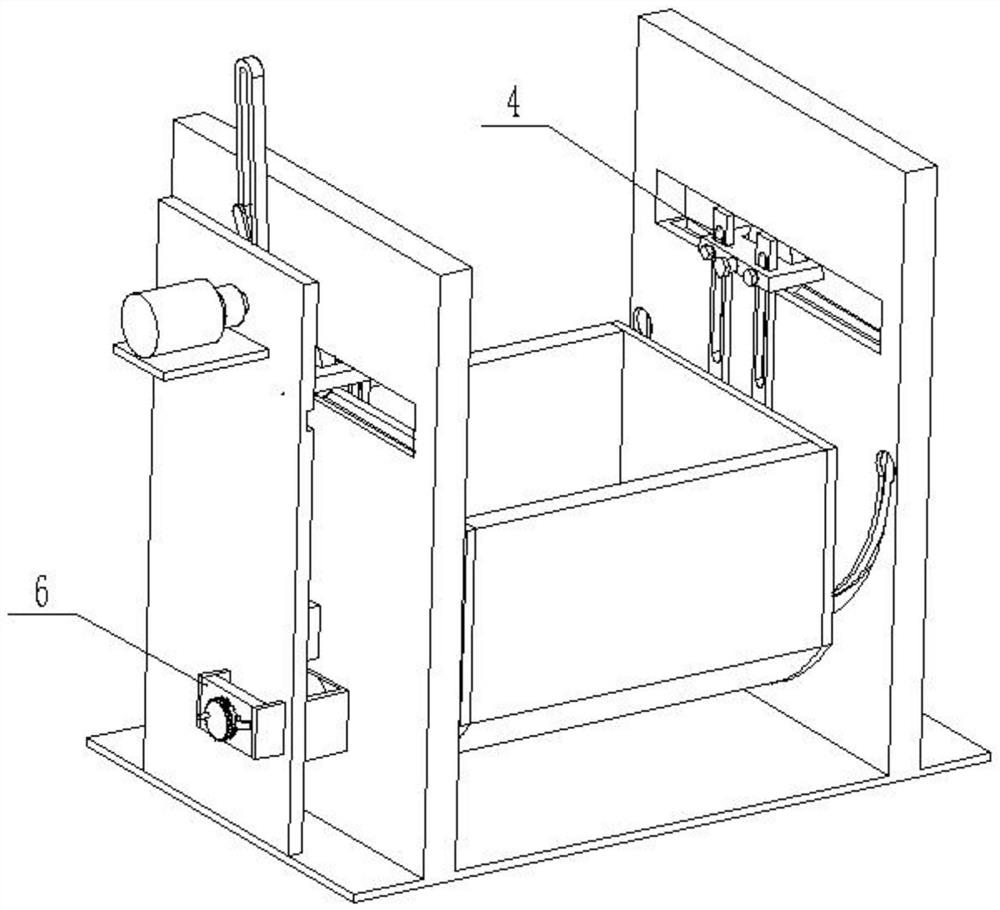

Bearing type cradle bed and control method for bearing type cradle bed

The invention relates to a bearing type cradle bed and a control method for the bearing type cradle bed, and the bearing type cradle bed comprises a bed frame which comprises a left support and a right support which are symmetrically arranged, and a connecting assembly for connecting the left support and the right support; a lifting mechanism which is arranged between the left support and the right support and is connected with the connecting assembly; and a cradle which is provided with a left convex eave and a right convex eave and is placed on the lifting mechanism. When the cradle is located at the preset lowest position, the left convex eave and the right convex eave of the cradle are in lap joint with the left support and the right support respectively, so that the left support and the right support can prevent the cradle from swinging left and right on the lifting mechanism; when the cradle is located at the preset highest position, the left convex eave and the right convex eaveof the cradle are located above the left support and the right support respectively, and the left support and the right support can allow the cradle to swing left and right on the lifting mechanism.Therefore, the bearing type cradle bed can at least prevent the cradle from rolling over.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI +1

A dust agent swing type spraying vehicle for tunnel construction

ActiveCN108005709BExpand the range of dust removalAchieve precipitationDust removalFire preventionAgricultural engineeringTruck

Owner:倡创(上海)咨询管理事务所

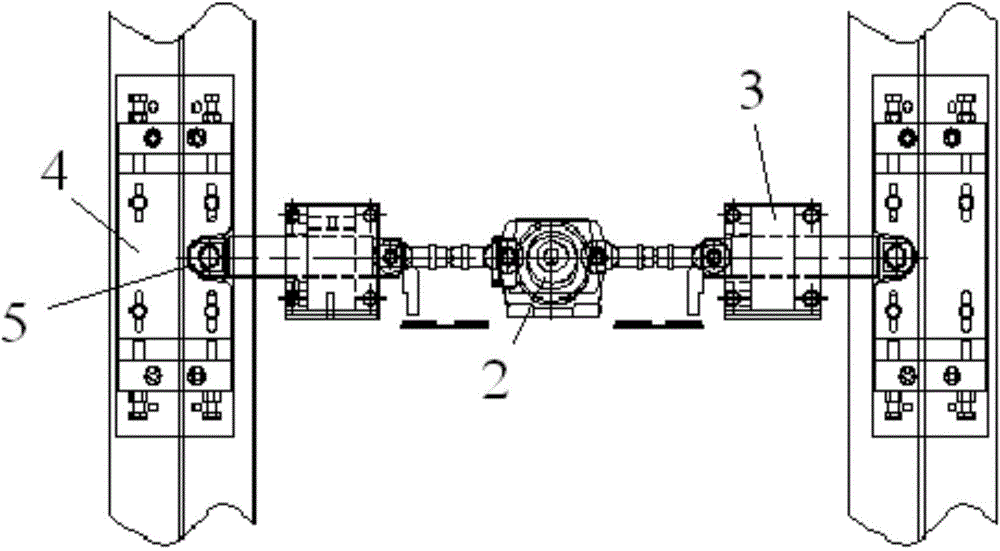

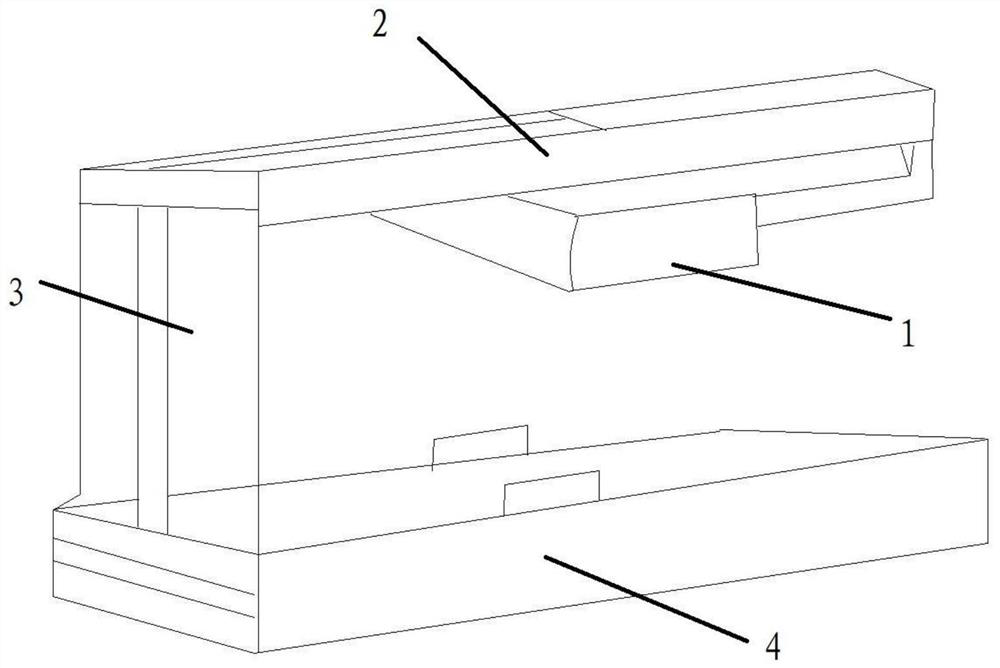

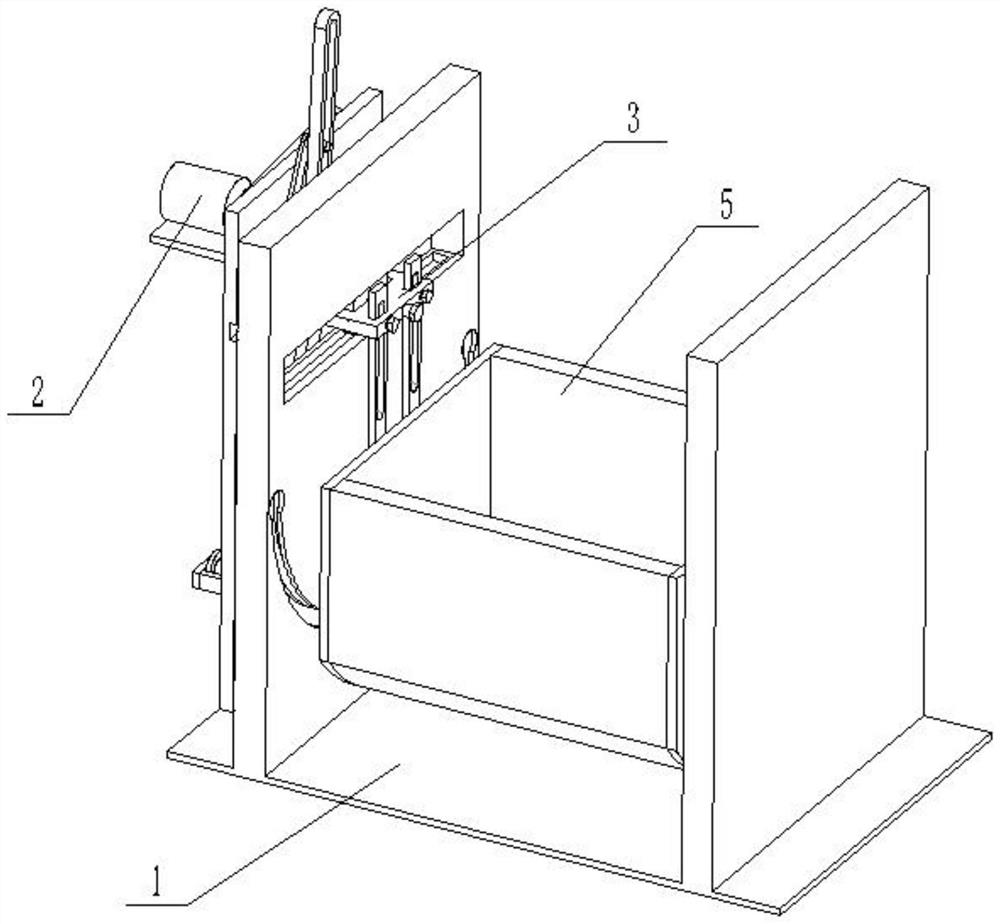

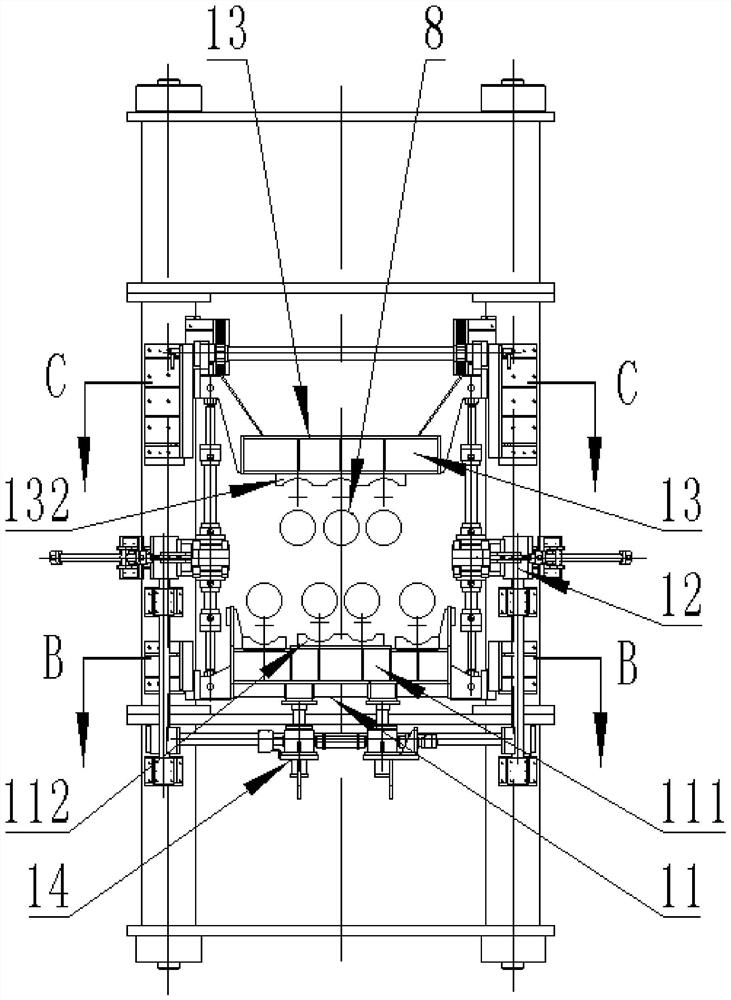

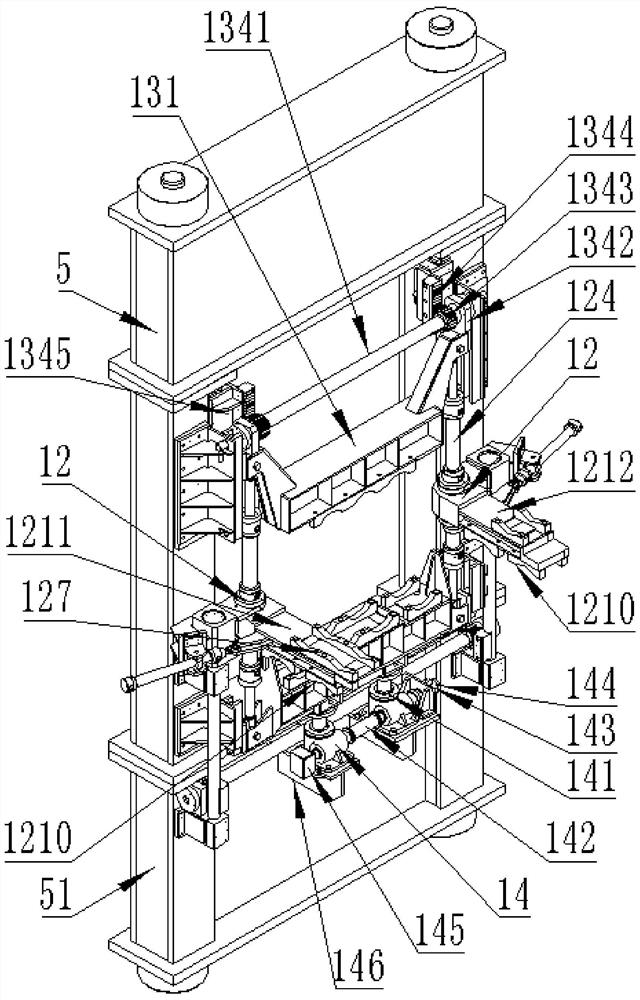

Efficient roll changing system of wide and thick plate straightener

The invention discloses an efficient roll changing system of a wide and thick plate straightener. The system comprises a memorial archway (5), a roll changing driving device (9), a main transmission connecting shaft (8) and a connecting shaft adjusting mechanism (1), a roll system device (3) is arranged in the memorial archway (5) and comprises straightening rolls (31), the roll changing driving device (9) is located on the operation side of the memorial archway (5), the main transmission connecting shaft (8) and the connecting shaft adjusting mechanism (1) are located on the transmission sideof the memorial archway (5), one end of the main transmission connecting shaft (8) is connected with one ends of the straightening rolls (31), the other end of the main transmission connecting shaft(8) is connected with a driving mechanism, and the connecting shaft adjusting mechanism (1) can adjust the position of one end of the main transmission connecting shaft (8) in the vertical direction.The efficient roll changing system of the wide and thick plate straightener has the advantages of fast roll changing rhythm, stable process, safety, reliability, high automation degree and the like.

Owner:CERI TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com