PE diaphragm processing device for automobile starting battery and use method of PE diaphragm processing device

A technology for starting and processing an automobile, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of reducing the number of windings, unable to adjust the tension, and increasing the volume of windings, and achieves improved processing efficiency, convenient use, Practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

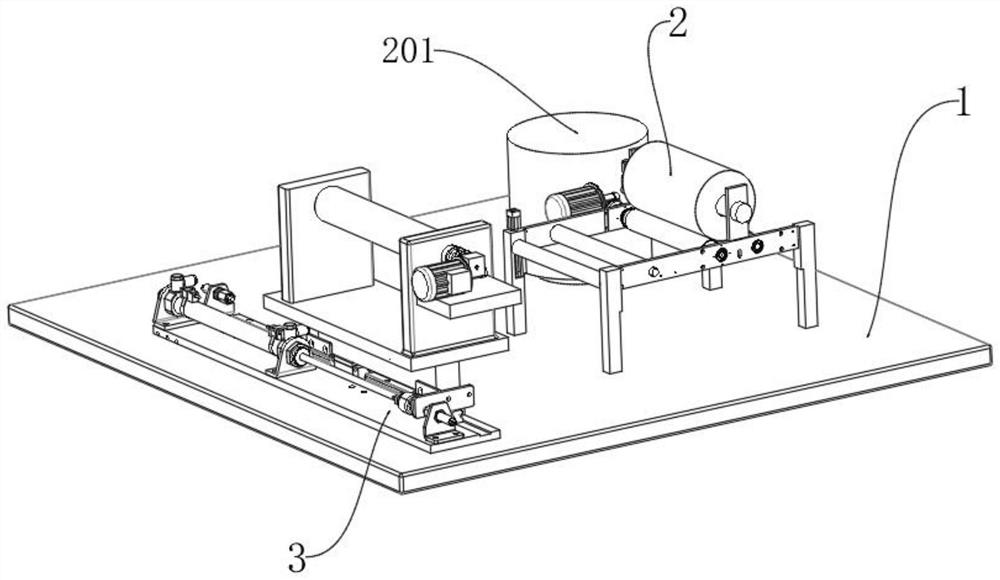

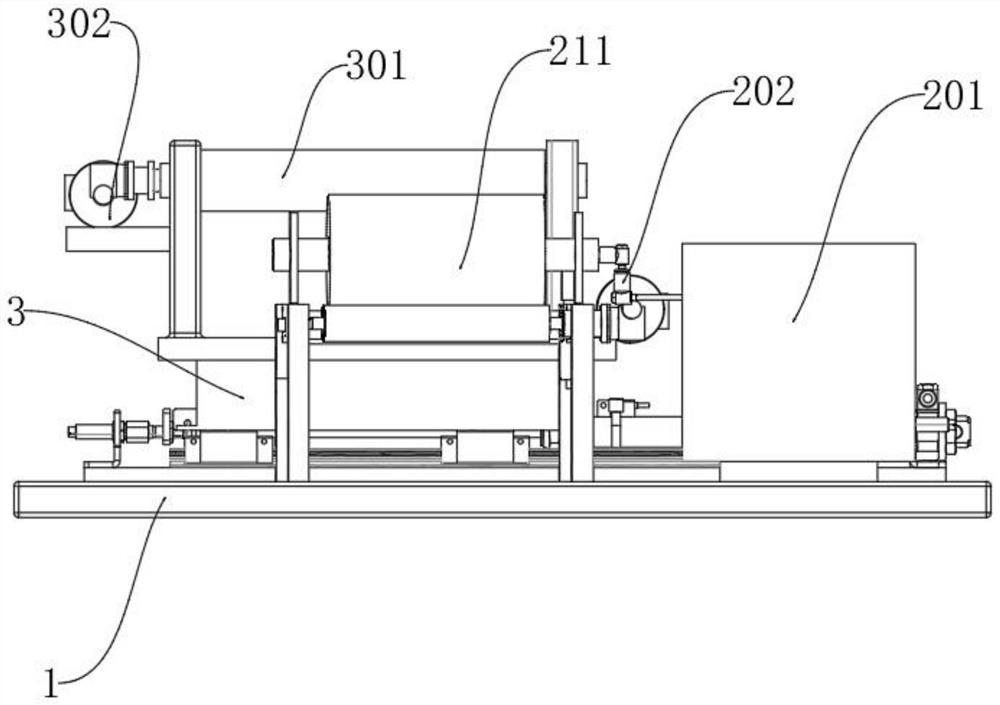

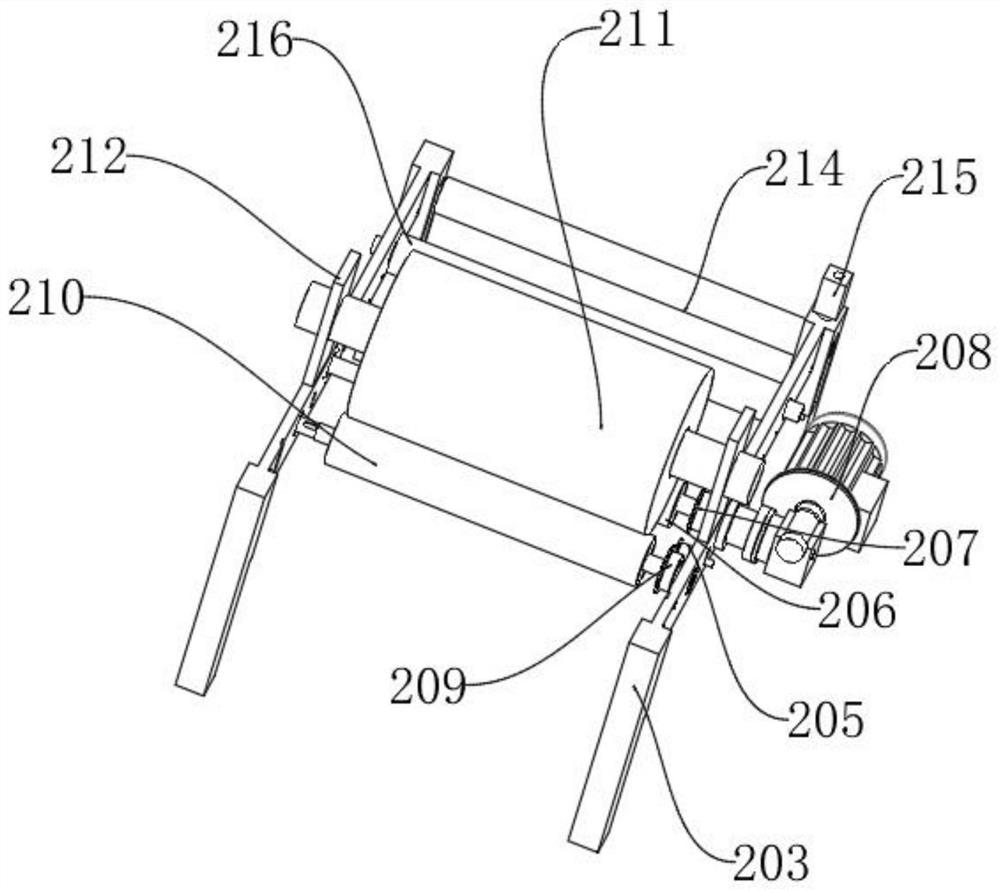

[0029] Such as Figure 1-Figure 5 As shown, a PE diaphragm processing device for automobile starting batteries of the present invention includes a base 1, a sizing assembly 2 for shaping the PE diaphragm is installed on one side above the base 1, and a sizing assembly 2 is installed on the other side of the sizing assembly 2. The rewinding assembly 3 for rewinding the PE diaphragm, the shaping assembly 2 includes a side support plate 203, a cooling roller 211 and a first speed reducer 208, the number of the side support plates 203 is two, and above the side support plates 203 are installed Cooling roll mounting plate 212, and cooling roll 212 is installed in the inside of cooling roll mounting plate 211 in rotation, and side support plate 203 inner side is installed with the second lamination roll 210, the first lamination roll 206 and take-up roll 204 sequentially, si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com