Rotation vertical shaft ascending and descending ultrahard cutter powerful grinding machine and application method

A technology for vertical shafts and cutting tools, which is applied in the direction of grinding bed, manufacturing tools, grinding slides, etc. It can solve the problems that it is difficult to meet the processing requirements at the same time, achieve a wide range of processing objects, flexible operation, and meet the requirements of sharpening processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

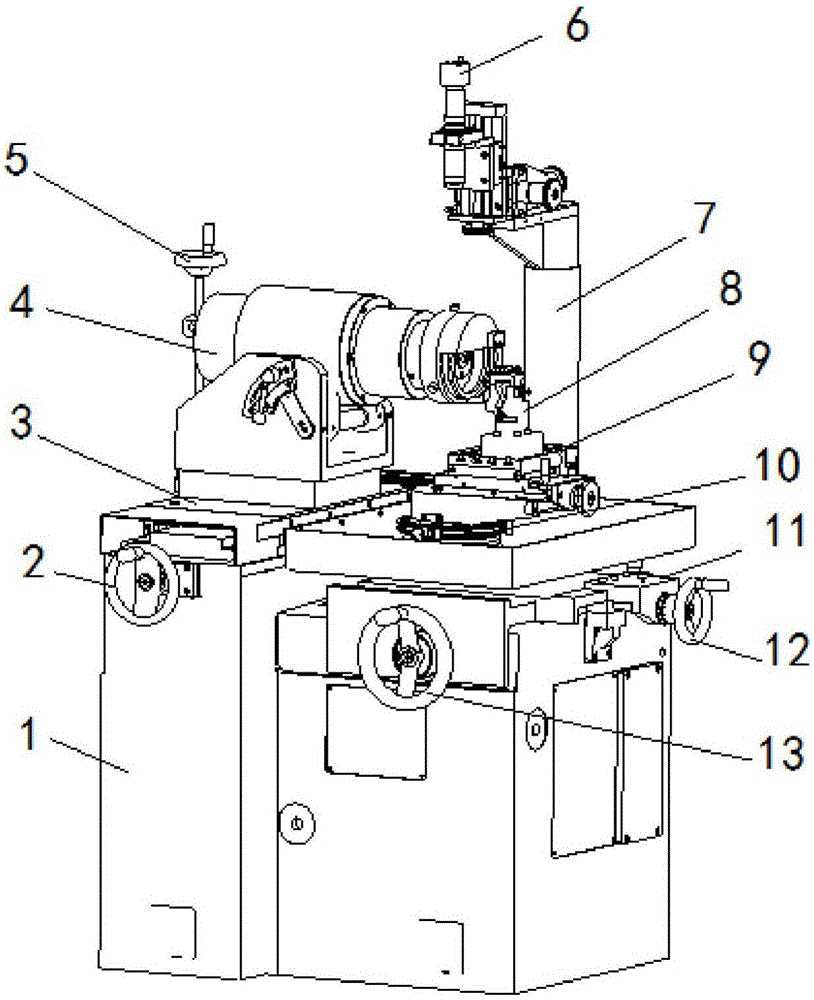

[0054] refer to figure 1 , a powerful grinding machine for superhard tools with a vertical axis that can be lifted, its main mechanism includes: a bed part 1, a grinding wheel spindle translation part 3, a grinding wheel spindle part 4, a CCD online monitoring part 6, a tool holder part 8, and a workbench part 9 , Rotating vertical shaft part 10, feed carriage part 11, etc.

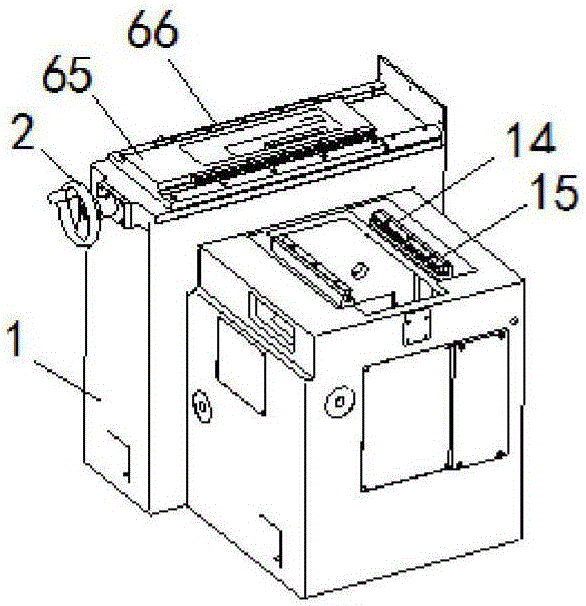

[0055] refer to figure 2 , the bed components include a bed 1, a moving hand wheel 2 for the grinding wheel spindle, a fixed seat 65, a translational rolling guide 66 for the grinding wheel spindle, a fixed bar 14, and a moving rolling guide 15 for the carriage. Rotating the grinding wheel main shaft to move the handwheel 2 can drive the screw pair to rotate, and realize the positioning and movement of the grinding wheel main shaft translational parts along the rolling guide rail.

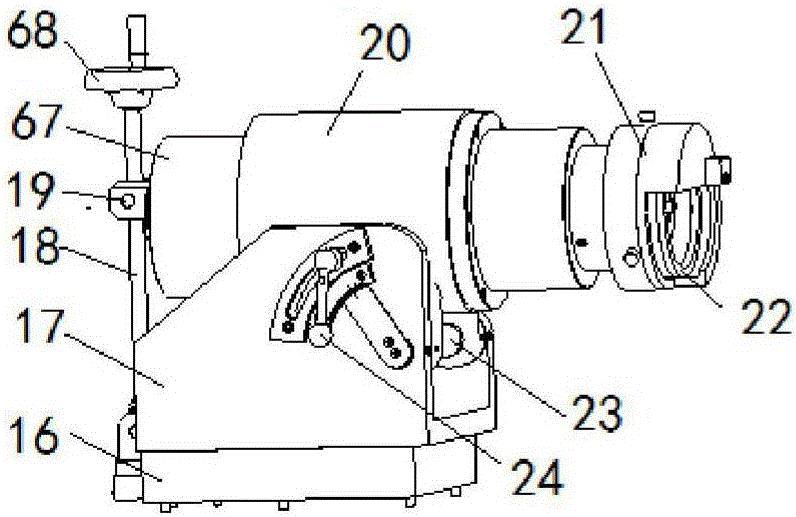

[0056] refer to image 3 , the grinding wheel spindle components include a base 16, a U-shaped frame 17, an adjusting sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com