Novel discard shearing device of aluminum profile extruding machine

A shearing device and extruder technology, applied in the field of aluminum profile extrusion press equipment, can solve the problems of affecting the shearing accuracy, damage the extrusion die, affecting the flatness of the shearing surface of the extruded profile, etc. Cutting accuracy, strong application performance, and the effect of improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

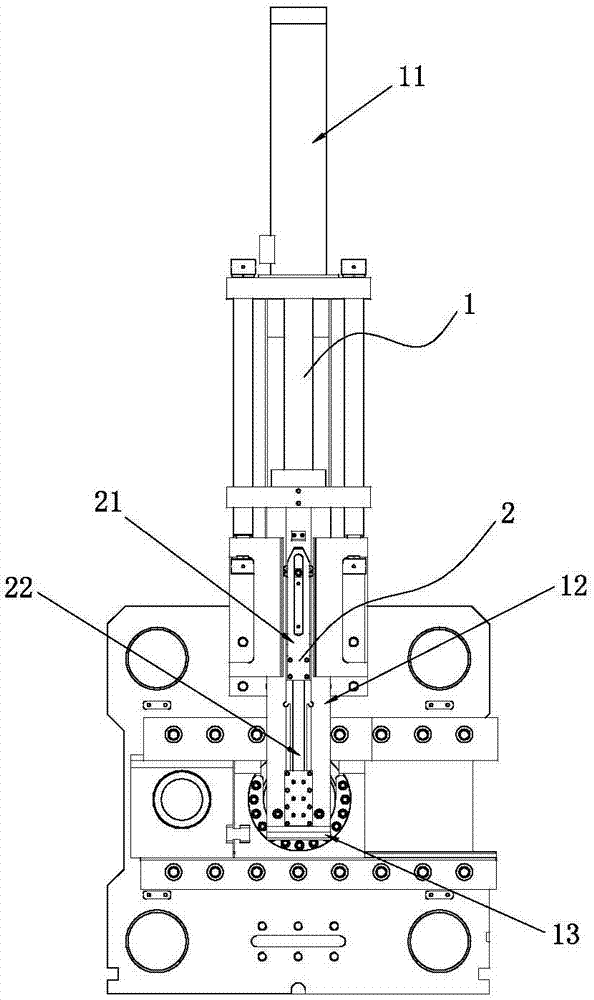

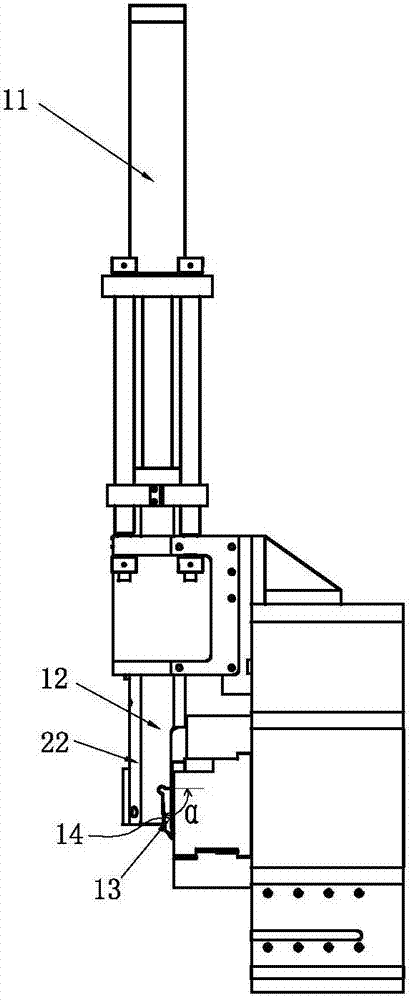

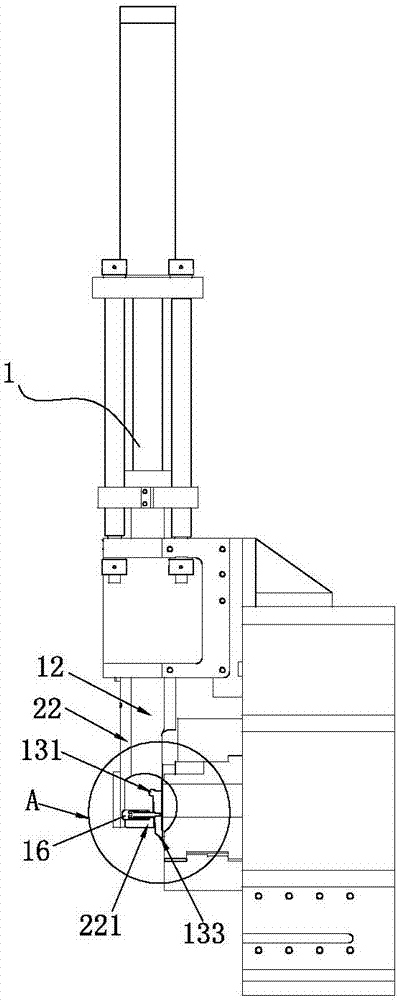

[0026] refer to Figure 1 to Figure 5 The new excess shearing device of the aluminum extrusion machine shown includes a shearing mechanism 1 and a pressing mechanism 2. The shearing mechanism 1 is composed of a shearing telescopic cylinder 11, a shearing rod 12 and a shearing knife 13. , the shearing knife 13 is oscillatingly installed on the bottom of the shearing rod 12, located at the entrance 3 of the extrusion die of the extruder, driven by the shearing telescopic cylinder 11 to move up and down for shearing, and the shearing knife 13 is provided with a The return mechanism 5, the return mechanism 5 makes the shearing mechanism 1 cut, the shearing knife 13 closes to the extrusion die entrance 3 and cuts downward, after the cutting, the shearing knife 13 automatically leaves the extrusion die Inlet 3, so that the gap 4 is formed between the shear knife 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com