Flat-layer locking device for elevator

A technology for locking devices and elevators, which is applied in the field of elevators, can solve the problems that the locking rollers cannot be accurately aligned with the locking bayonets, there are many hinged structures and bending parts, and the locking function fails, so as to improve the balance of the carrier, Low manufacturing cost and space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

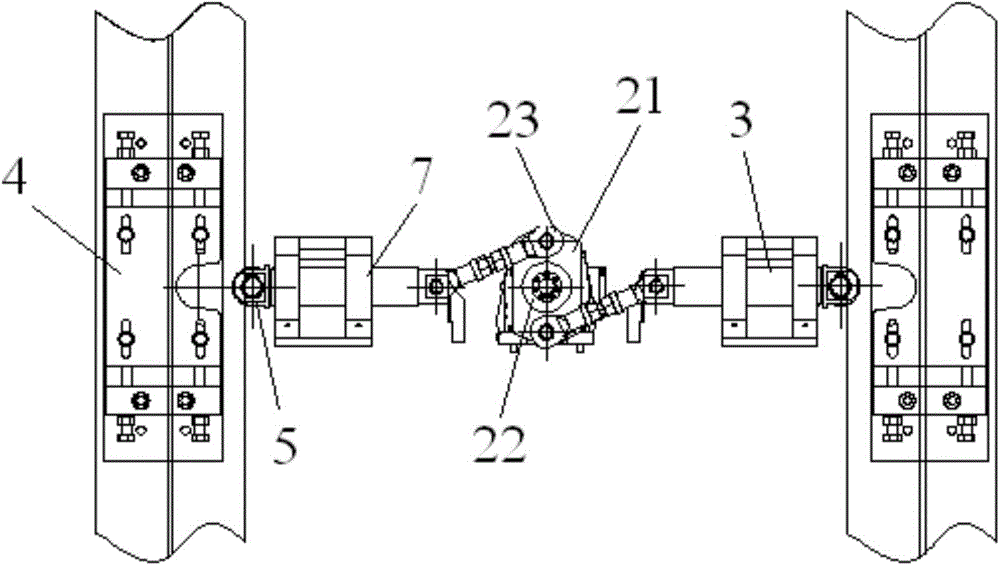

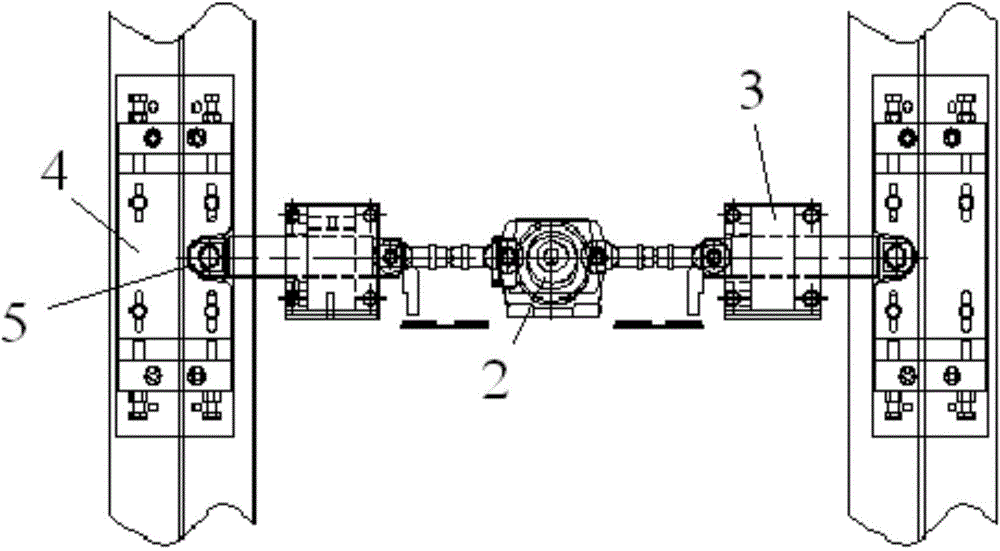

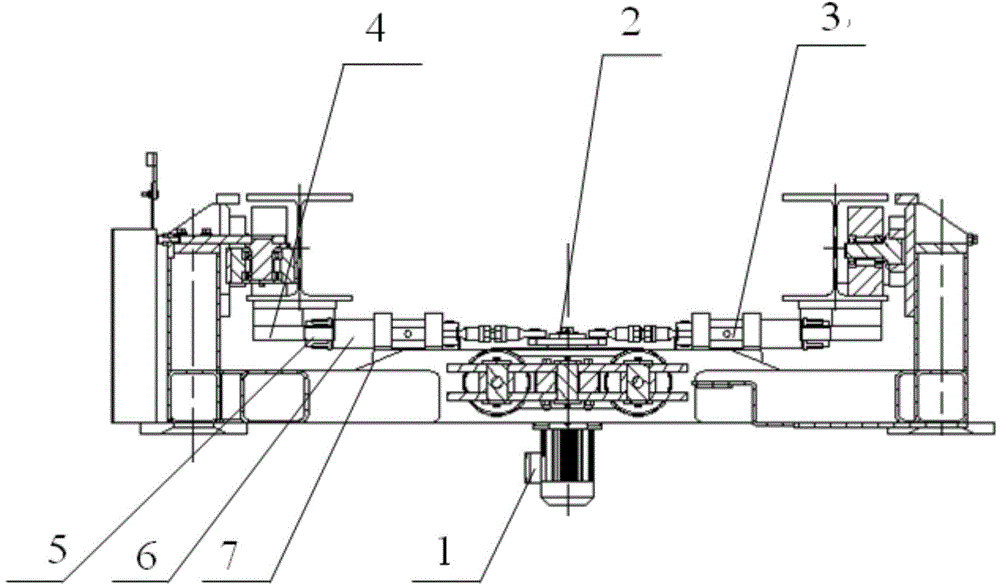

[0027] The leveling locking device of the elevator of the present invention includes a locking motor 1 , a rotating mechanism 2 , a slotted plate 4 , a guide bearing 5 , a connecting rod 6 and a proximity switch 7 . Among them, the locking motor 1 is fixed on the frame of the elevator trolley; the rotating mechanism 2 includes a support plate 21, an expansion sleeve 22, and a pull rod 23. Axle tension connection, pull rod 23 is provided with two, is respectively fixed on support plate 21 two ends, the other end of two pull rods 23 connects connecting rod 6 through a rotating bearing, and is provided with a limit its axial movement on connecting rod 6 The connecting rod fixing block 3, the connecting rod fixing block 3 is fixed on the frame of the lift trolley, when the pull rod 23 rotates, the connecting rod 6 connected to it through the rotating bearing moves horizontally through the connecting rod fixing block 3; the connecting rod 6 is connected to the guide bearing 5 The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com