Cycle conveying device for bedplate

A cycle conveying and platen technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as low degree of automation, inability to adapt to high-efficiency multi-station automatic printing production lines, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

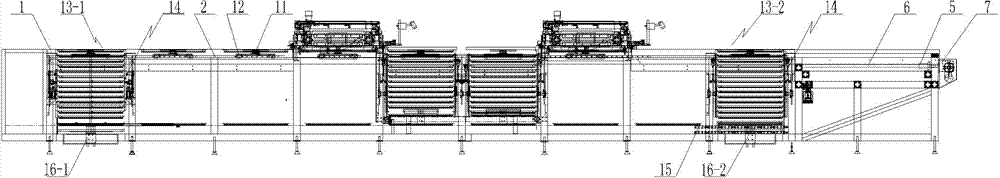

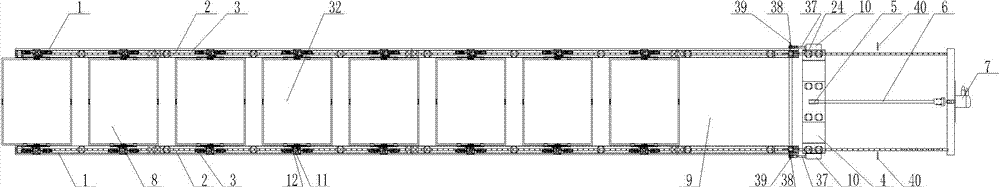

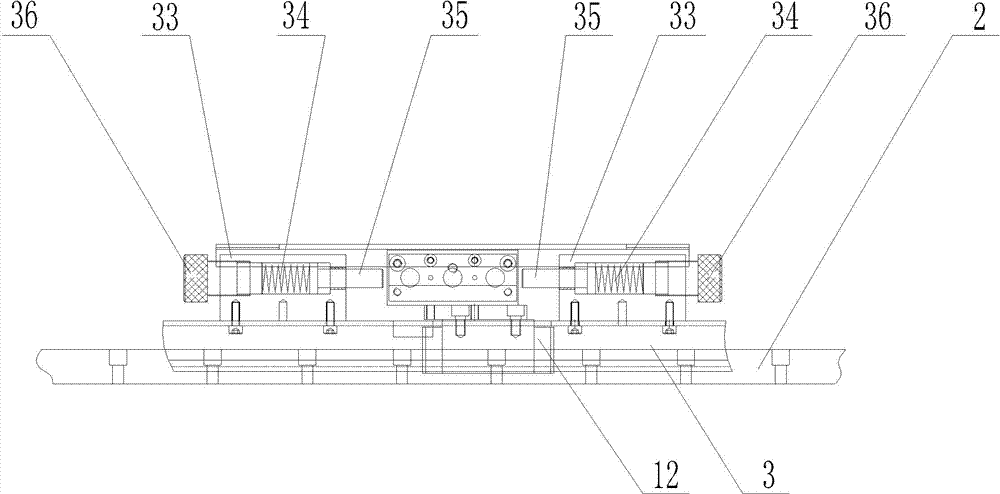

[0013] See figure 1 , figure 2 , image 3 , a platen circulation conveying device, which includes a frame 1, the two sides of the frame 1 are respectively provided with full-length slide rails 2, the slide rails 2 are respectively provided with drag plates 3, and the slide plates 4 are connected by slide blocks 24 The slide rail and the two sides of the slide plate 4 are respectively fixed with compensation cylinders 10, the carriage 3 is connected to the slide plate 4 through the compensation cylinder piston rod 37, the slide plate 4 is connected to the rolling screw 6 through the rolling nut 5, the rolling screw 6 is connected to the servo motor 7, and the frame A plurality of working stations 8 and a transition station 9 are provided. The corresponding working stations 8 on the carriage 3 are provided with table clamping cylinders 11 respectively, and the table clamping cylinders 11 are fixed on the slide block 12. Connect the slide rail 2, the two ends of the frame are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com