Patents

Literature

47results about How to "Precise swing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

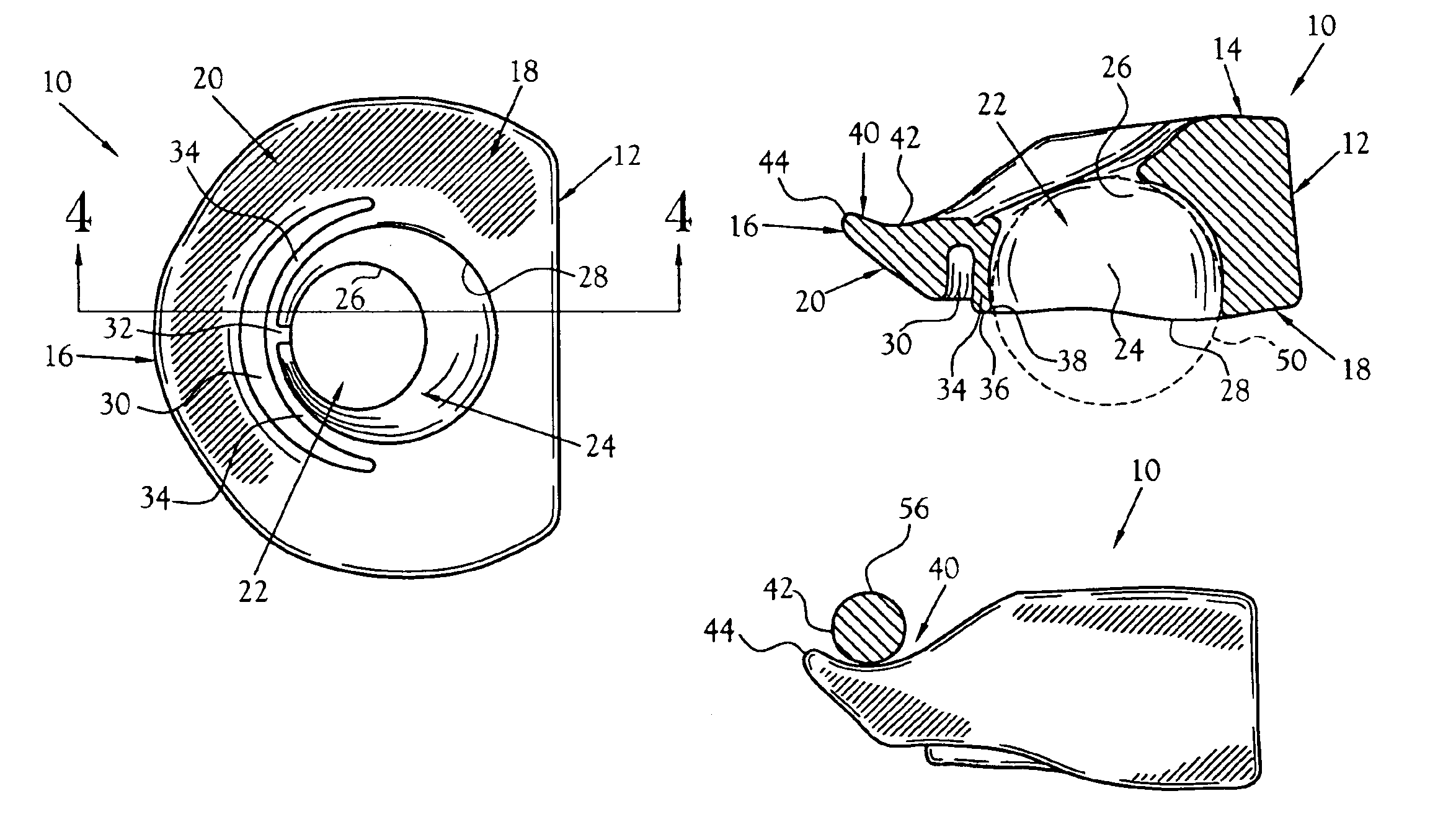

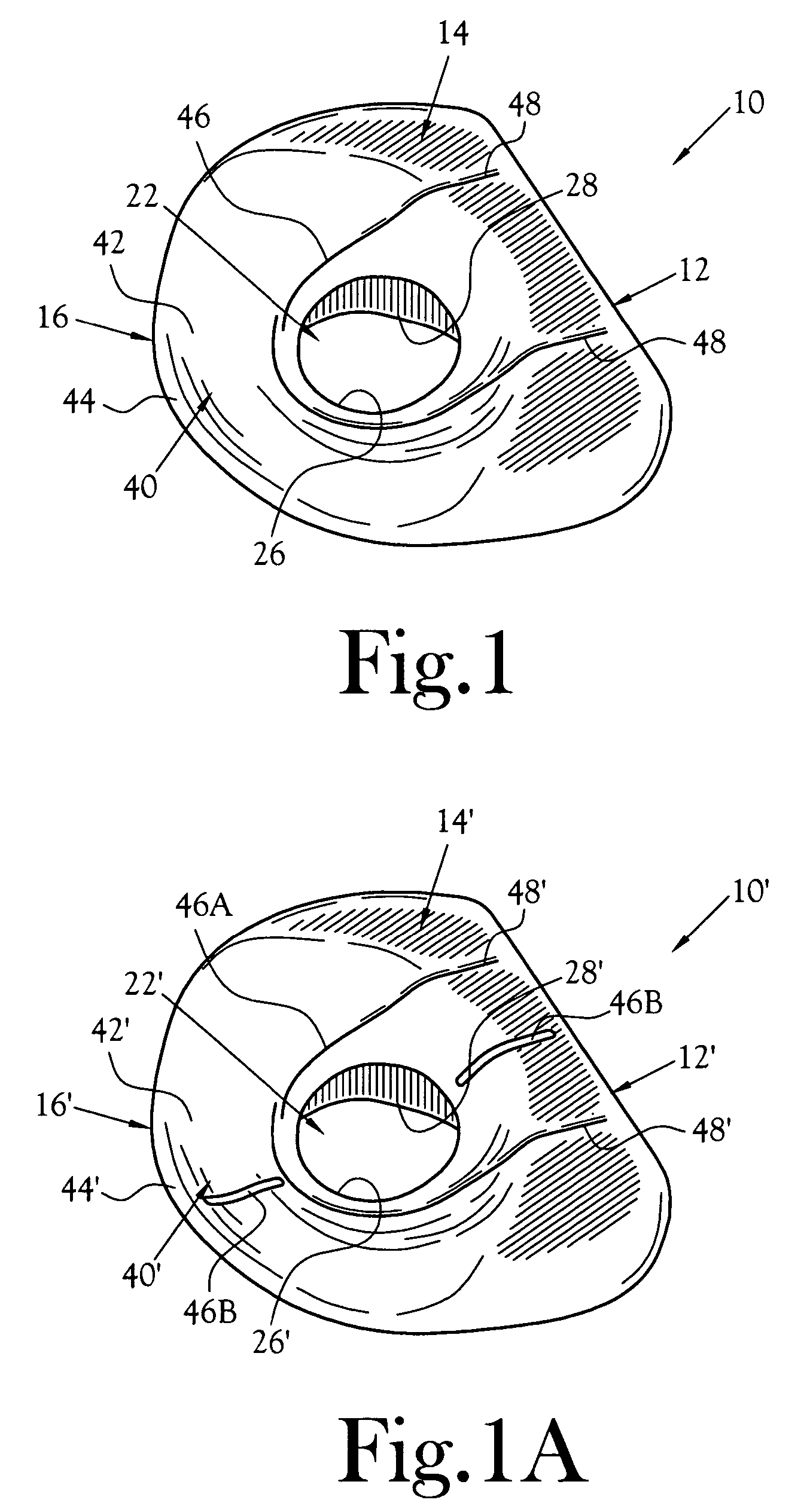

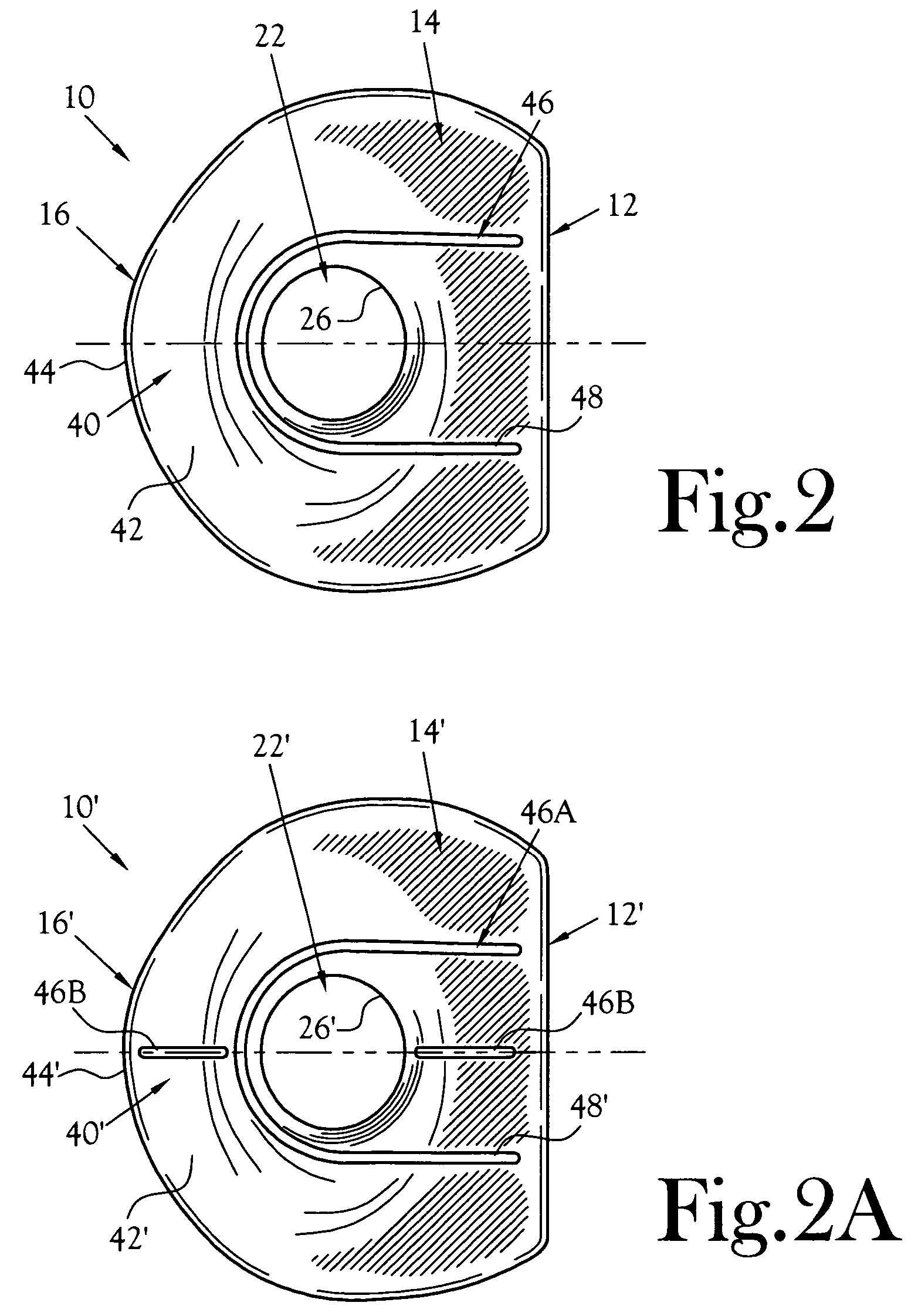

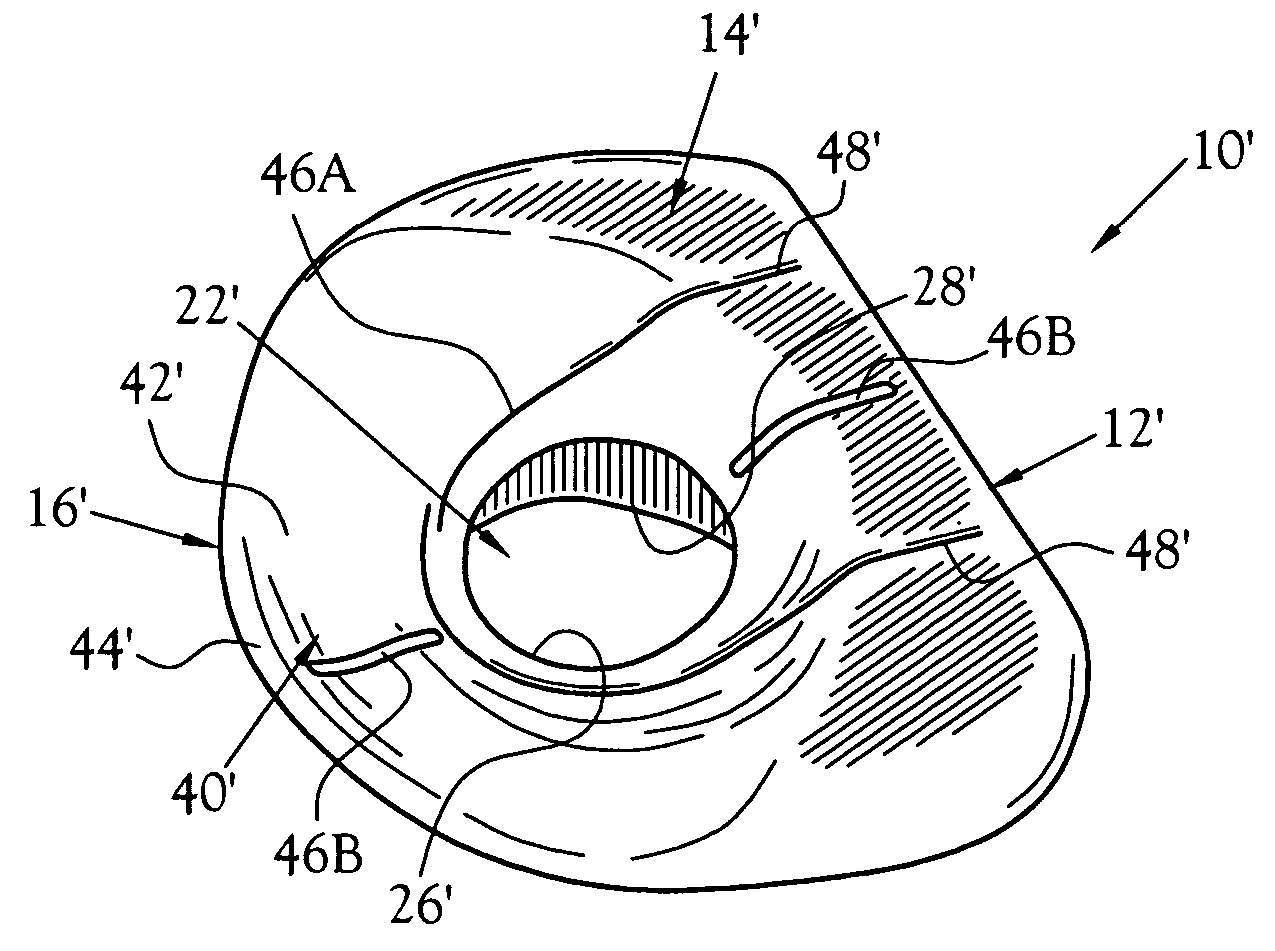

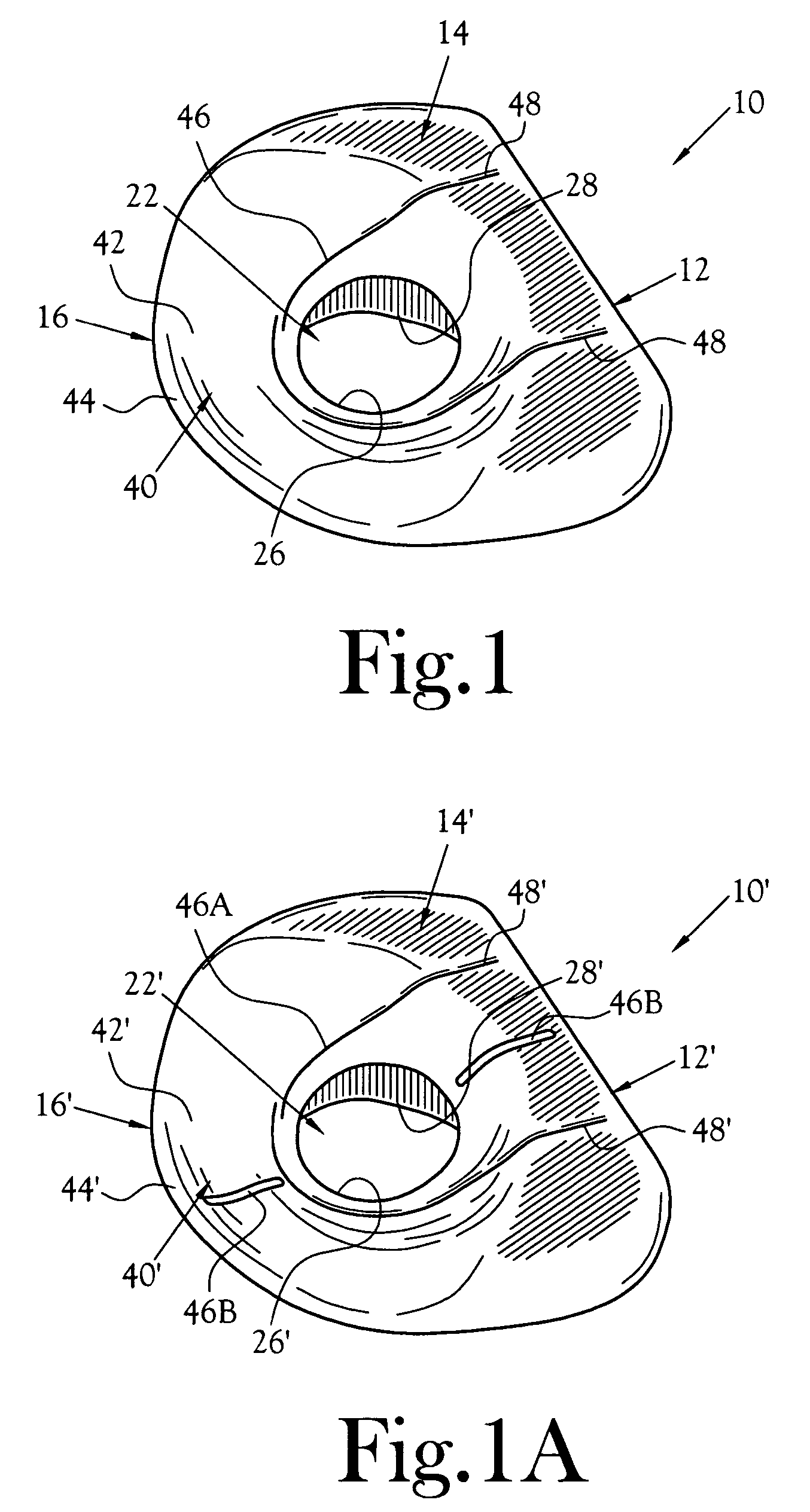

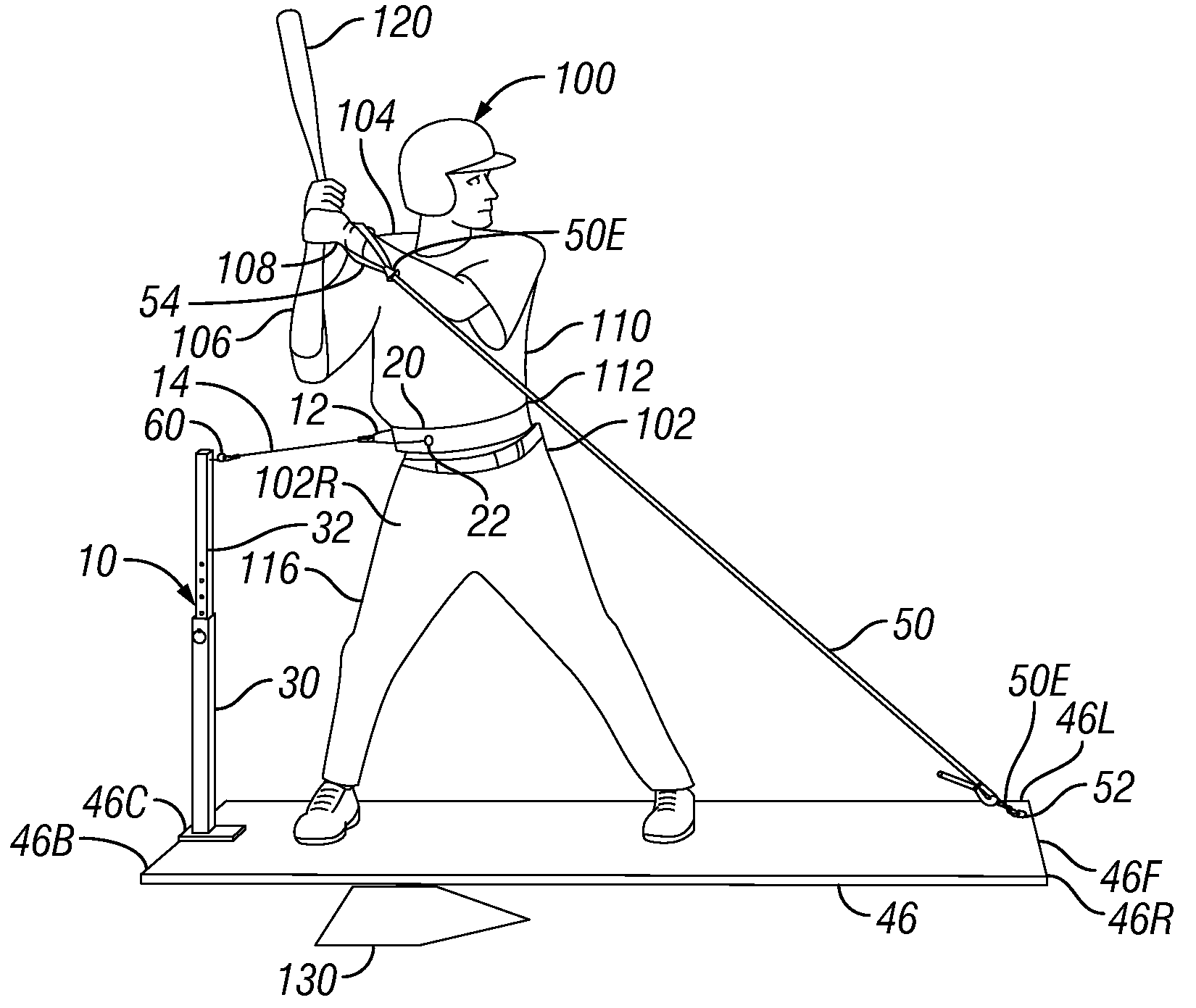

Golf ball putter, retriever and retainer

A golf putter, ball retriever and retainer configured to retrieve and hold a golf ball. The putter defines a substantially symmetrical configuration from heel to toe. The ball retriever and retainer is defined by a spherical recess formed in the sole of the putter and an opening defined on the top surface thereof. The spherical recess is further defined by an opening on the sole of the putter, the sole opening defining a diameter slightly less than the diameter of a conventional golf ball. In order to receive a golf ball into the ball retriever and retainer, at least one resilient tab is defined in the sole to enlarge the sole opening. The top surface of the putter defines a shaft retriever proximate the trailing edge for engaging a golf club shaft or flag for lifting the same from the ground.

Owner:MPH GOLF

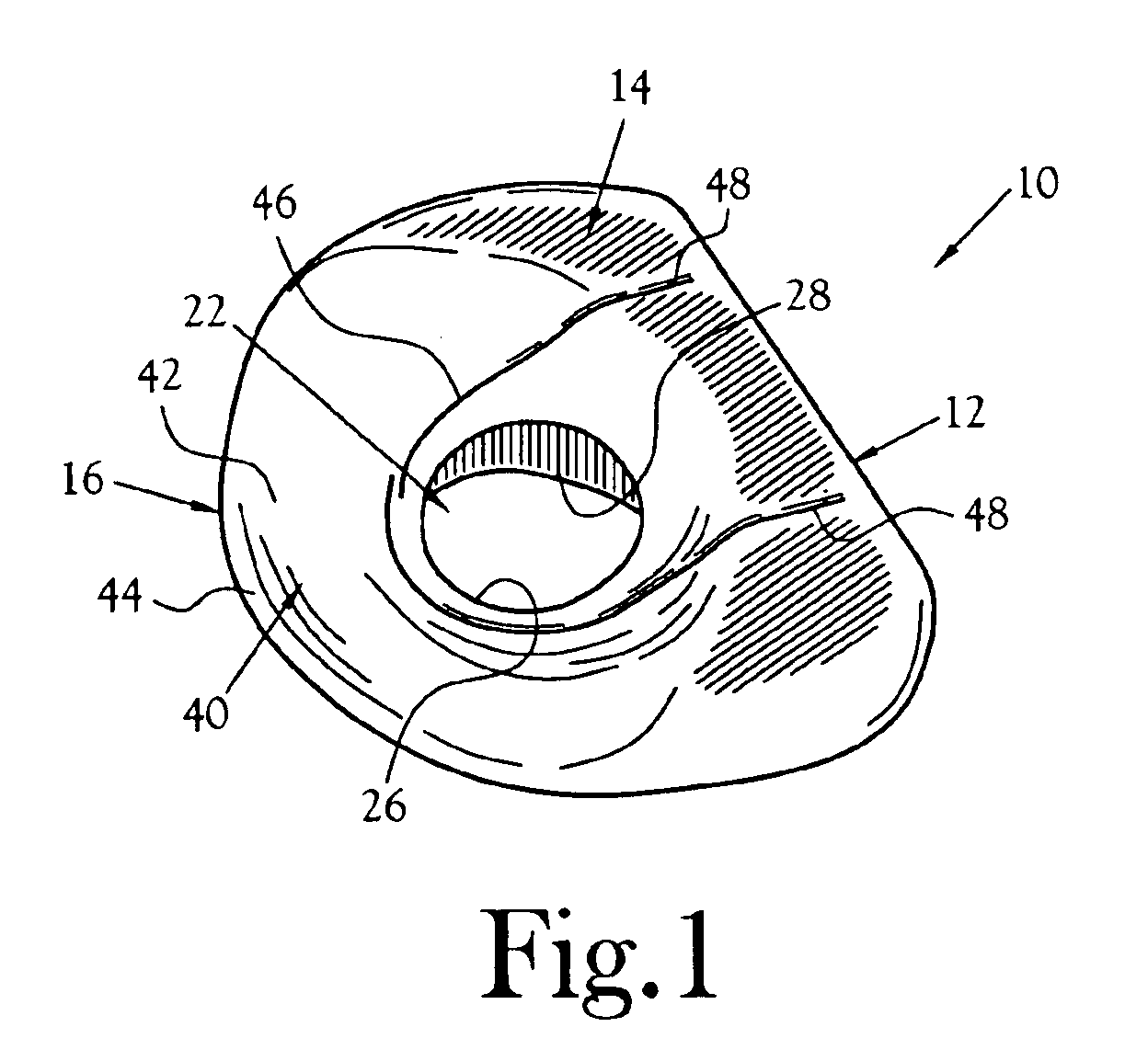

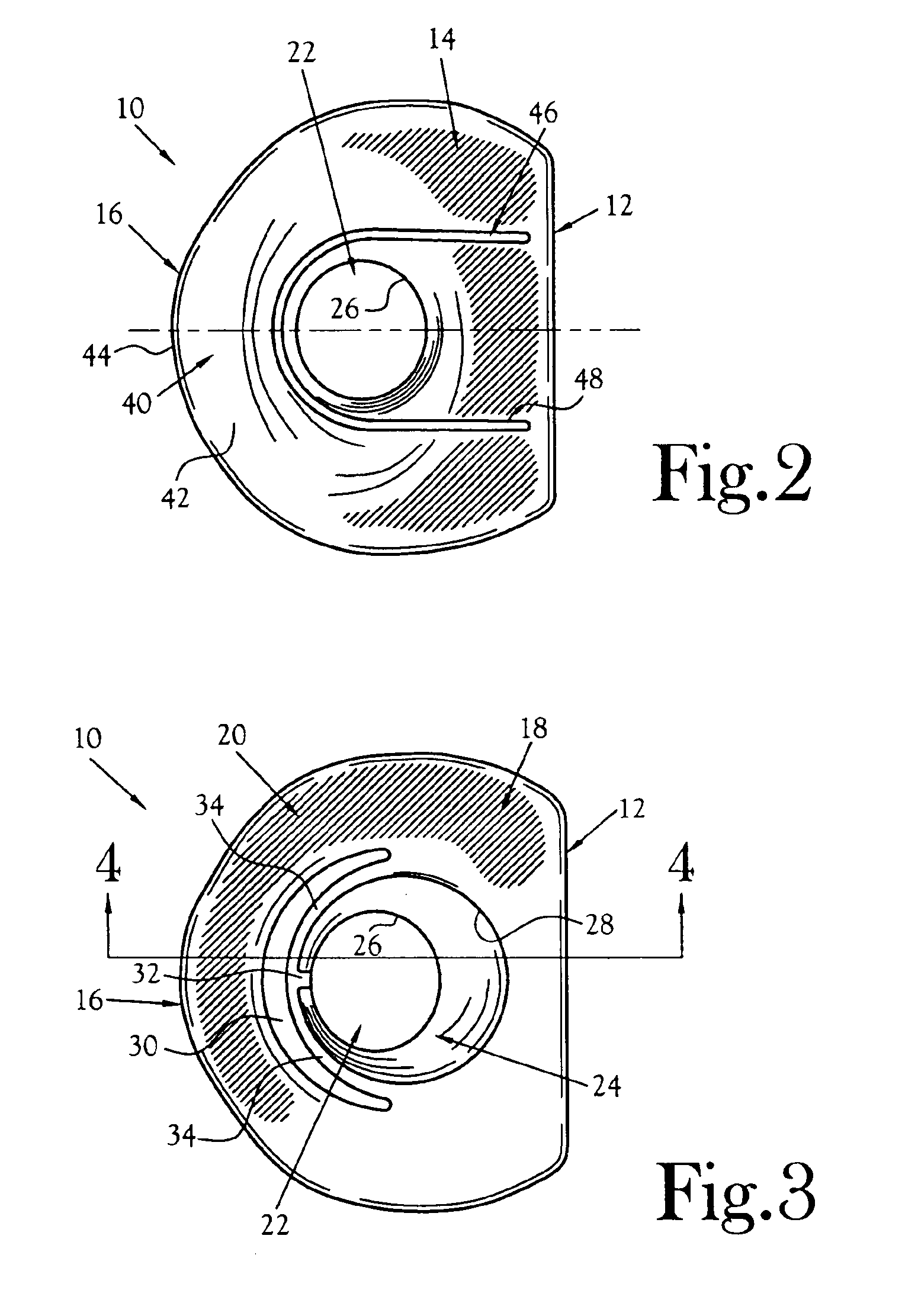

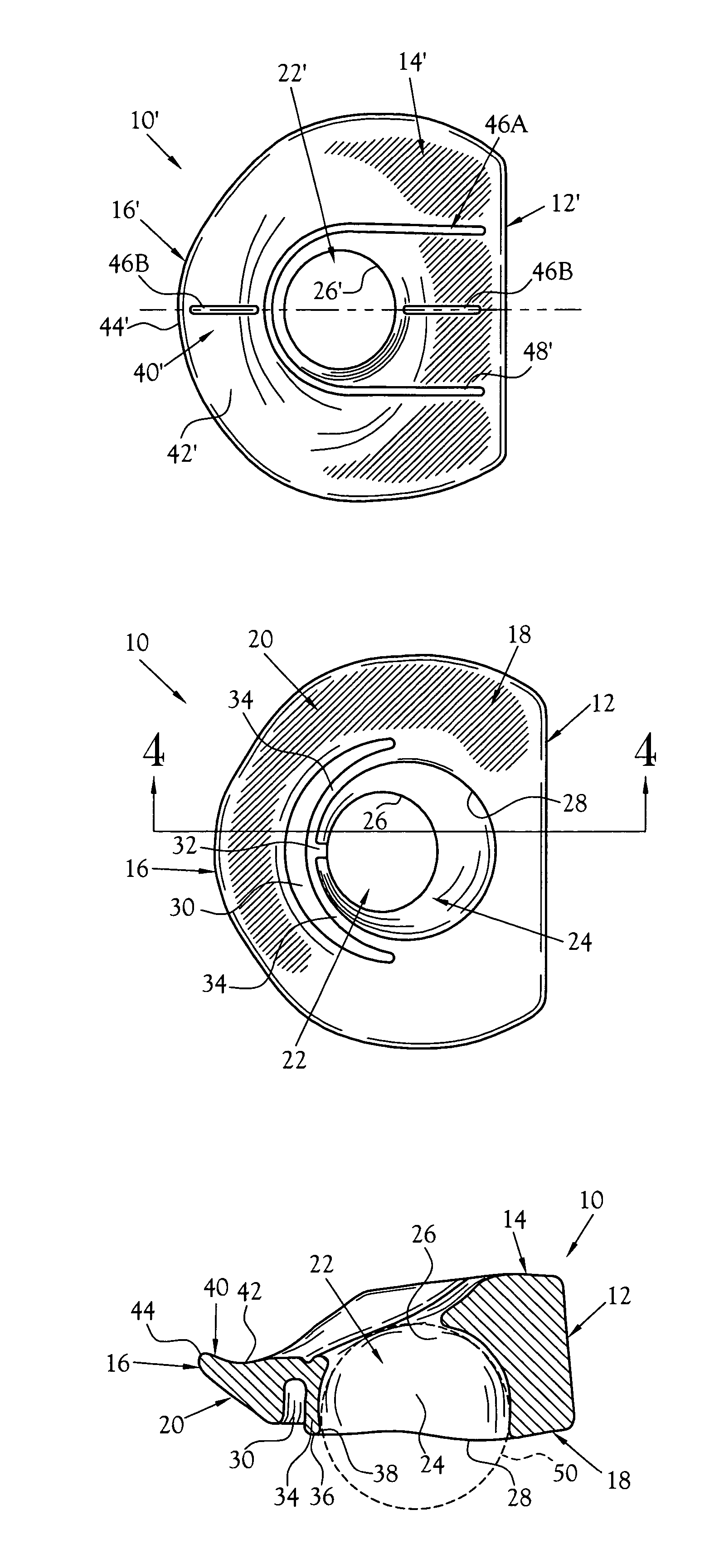

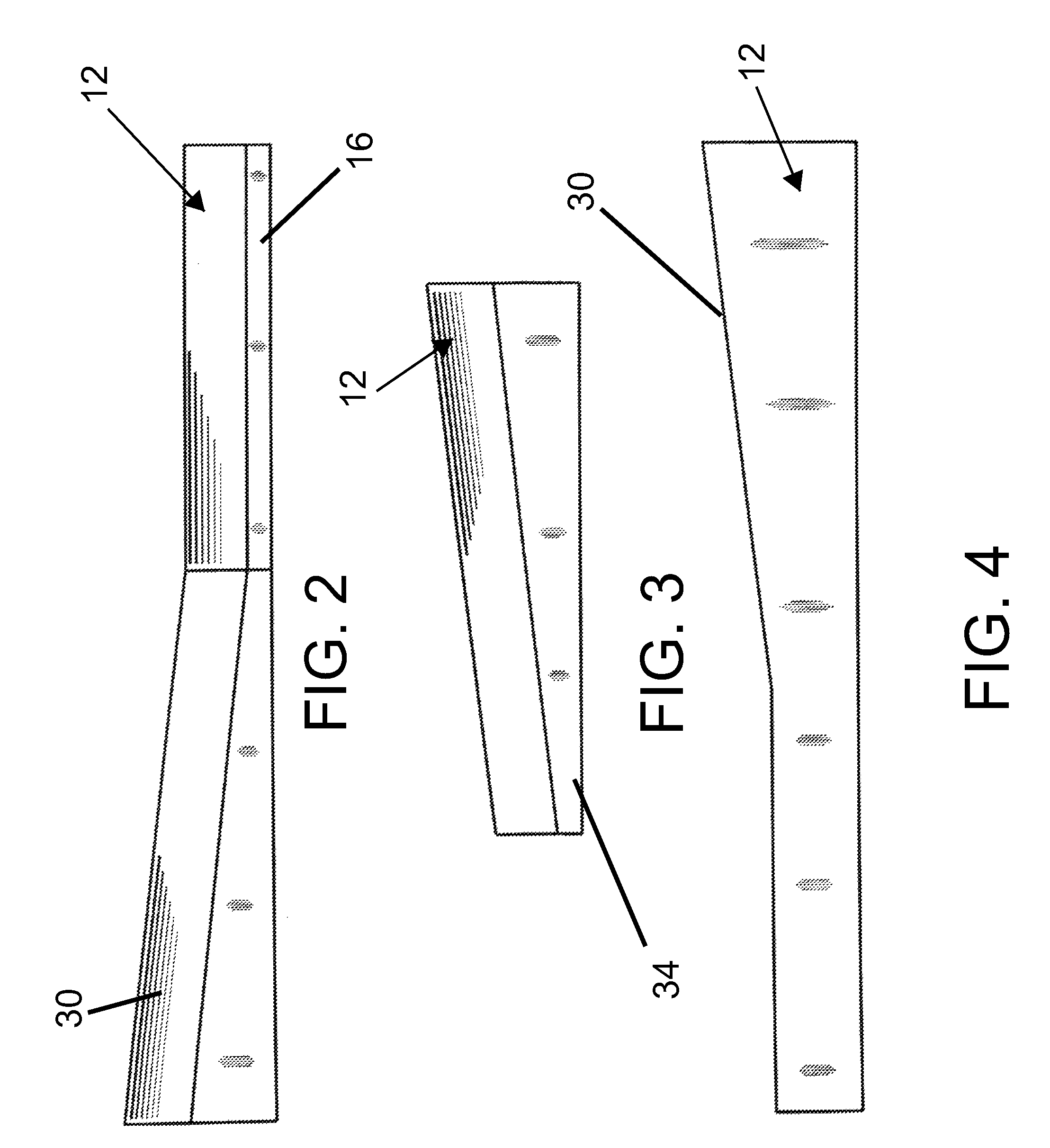

Golf ball putter including golf ball alignment indicia

A golf putter, ball retriever and retainer configured to retrieve and hold a golf ball. The putter defines a substantially symmetrical configuration from heel to toe. The ball retriever and retainer is defined by a spherical recess formed in the sole of the putter and an opening defined on the top surface thereof. At least one resilient tab is defined in the sole to enlarge the sole opening. Ball alignment indicia are disposed on the top surface of the golf putter head, the ball alignment indicia defining at least a C-shaped configuration, whereby a ball is visually aligned between said first and second ends to center the ball on said striking face. The ball alignment indicia may further include at least one line segment disposed coincidentally to the initial direction of travel of the golf ball.

Owner:MPH GOLF

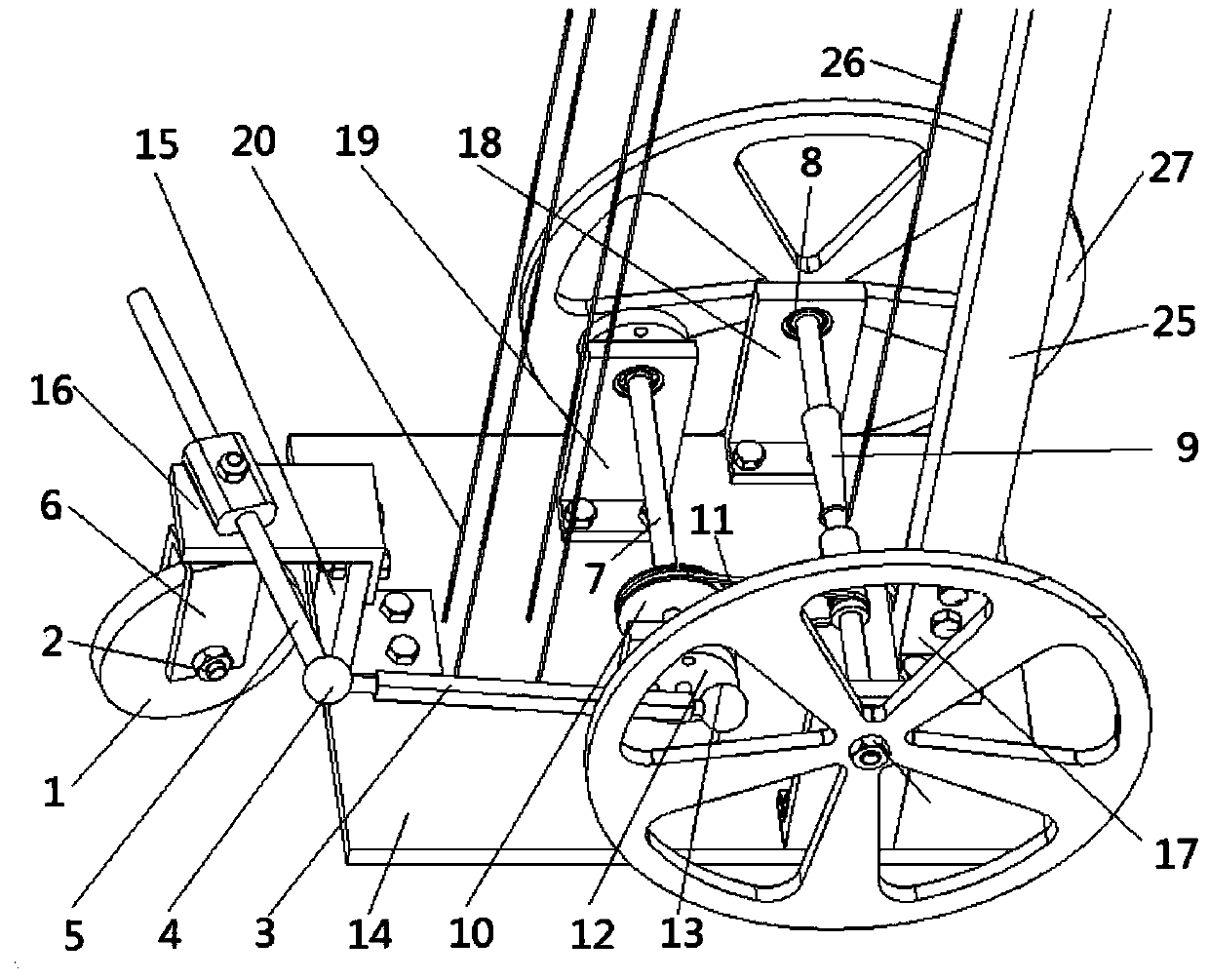

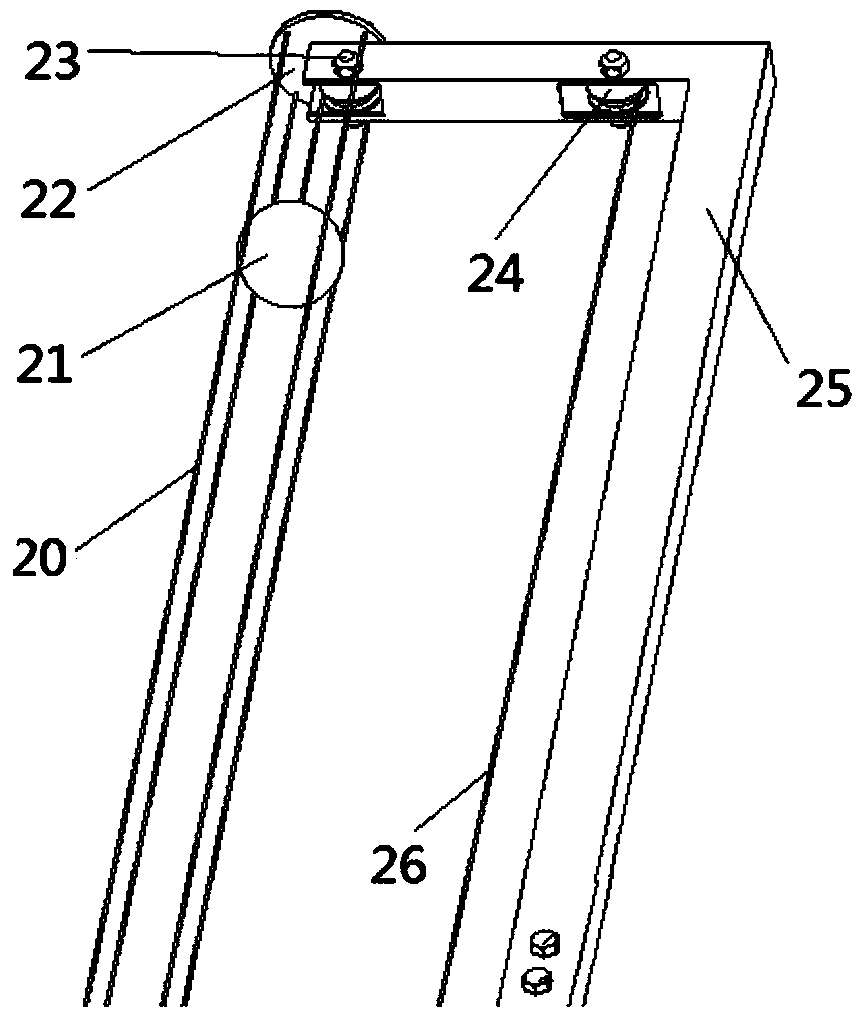

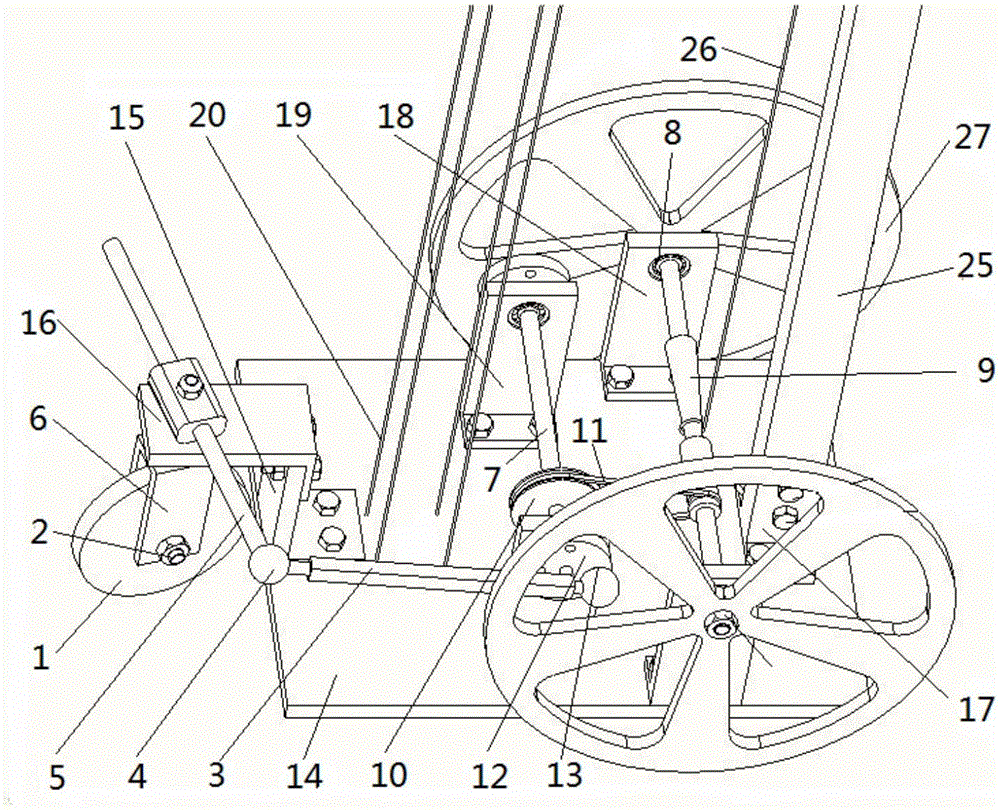

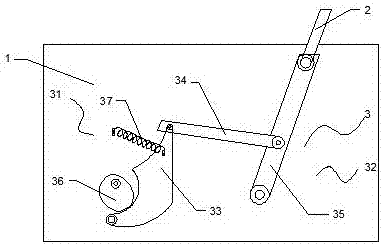

Carbon-free self-propelled trolley with reversing function

InactiveCN103463812AAchieve steeringEasy to understandEducational modelsRemote-control toysDrive wheelMechanical energy

The invention discloses a carbon-free self-propelled trolley with a reversing function. A four-connecting-rod mechanism and a joint bearing part are used to accurately control swing of a guide wheel fork so as to realize turning of a guide wheel, small torque and abrasion and accurate swing are achieved. Four rail rods are used to limit swing of a counter weight, so that tilting of the trolley during turning and coming up and down a slope can be avoided effectively. The carbon-free self-propelled trolley is driven to move by converting gravitational potential energy into kinetic energy, no fuel or electric energy is needed, no greenhouse effect gases such as carbon dioxide are emitted, and the carbon-free self-propelled trolley is low-carbon, environmental friendly, and simple to use. An operator can reverse a trolley drive wheel to hang a heavy object, namely converting mechanical energy into gravitational potential energy. The carbon-free self-propelled trolley can be used as physics demonstration experiment equipment for primary schools and middle schools, and students are allowed to better understand experiment energy conversion and application through specific instances.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

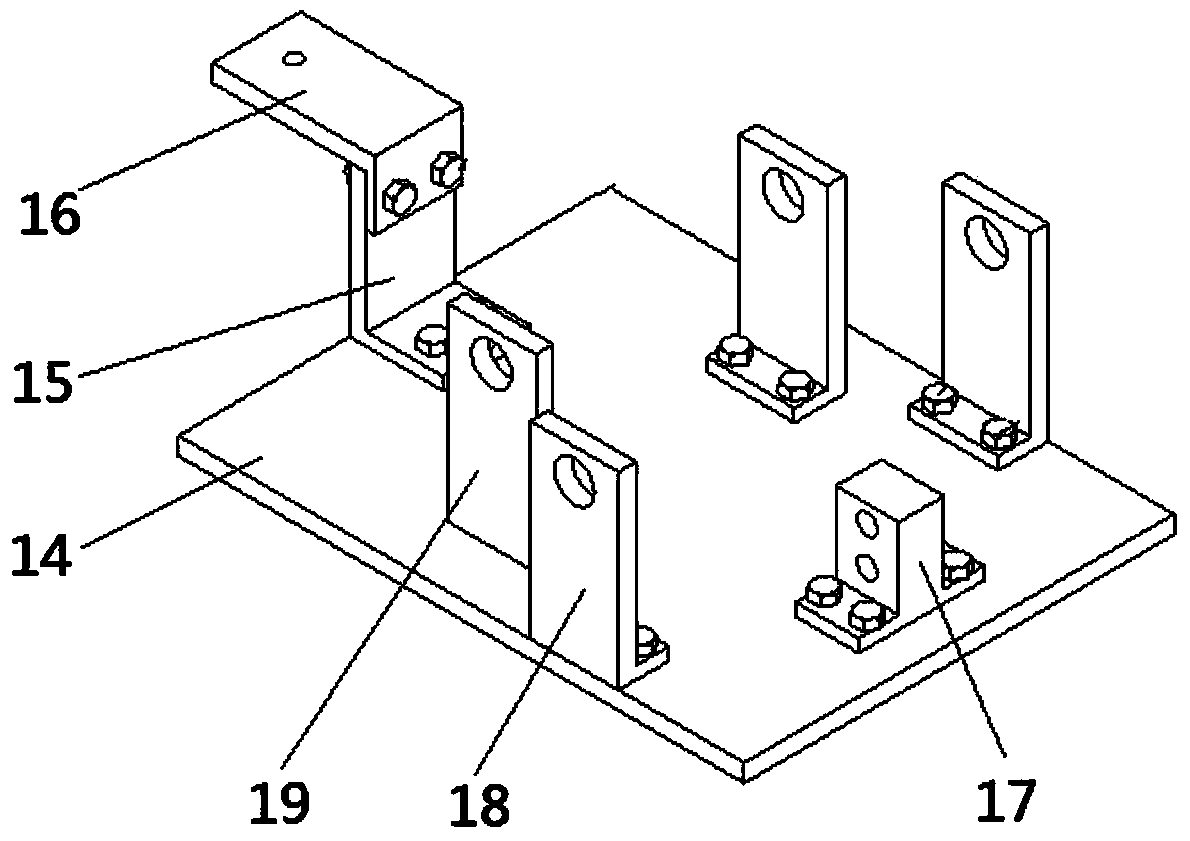

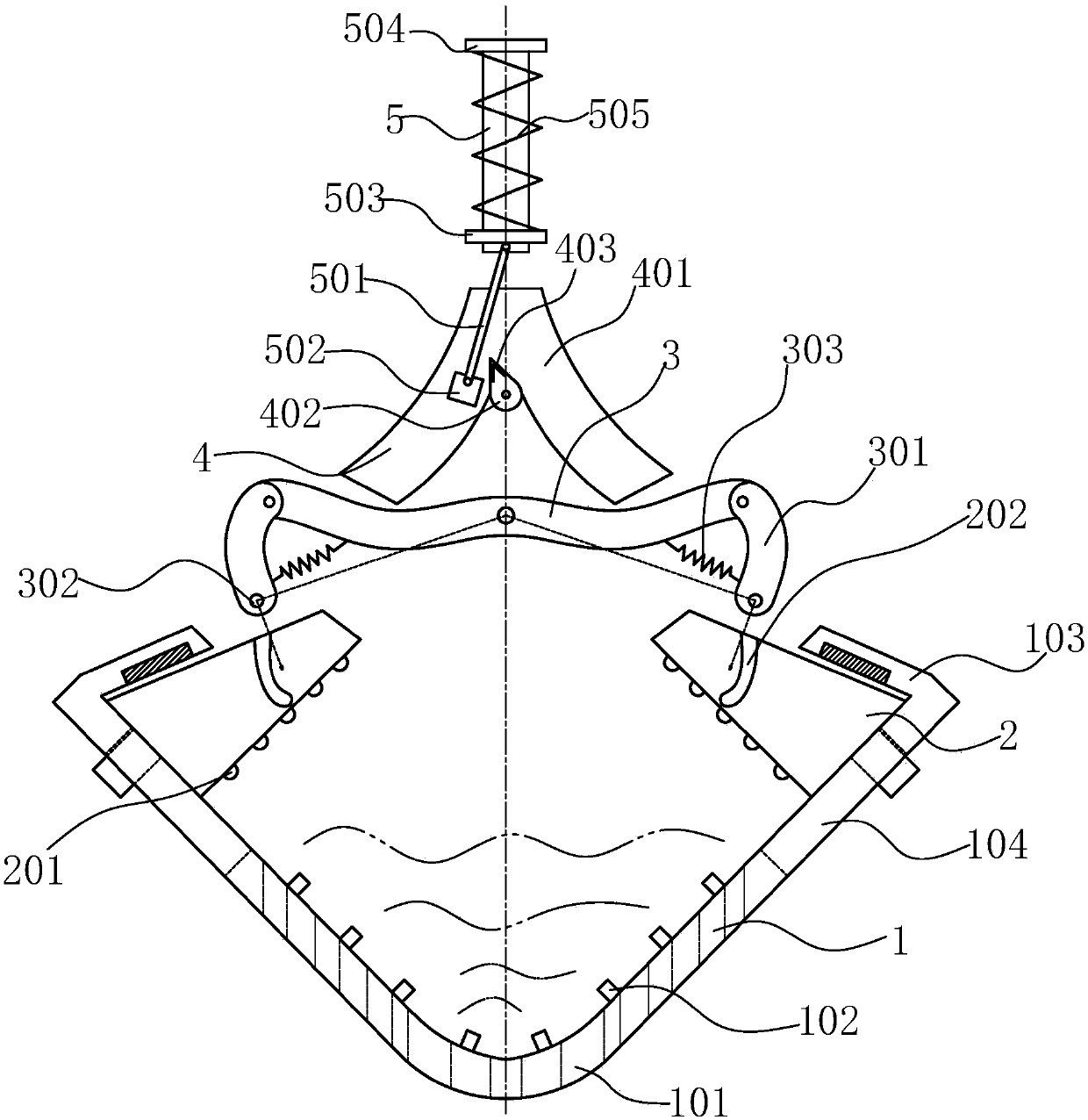

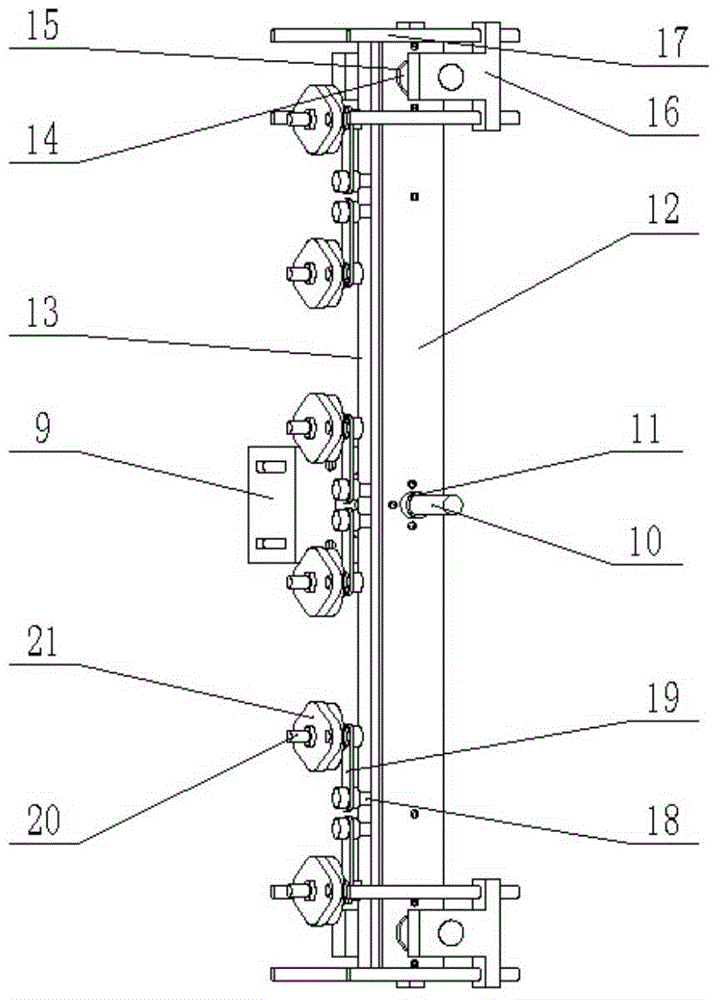

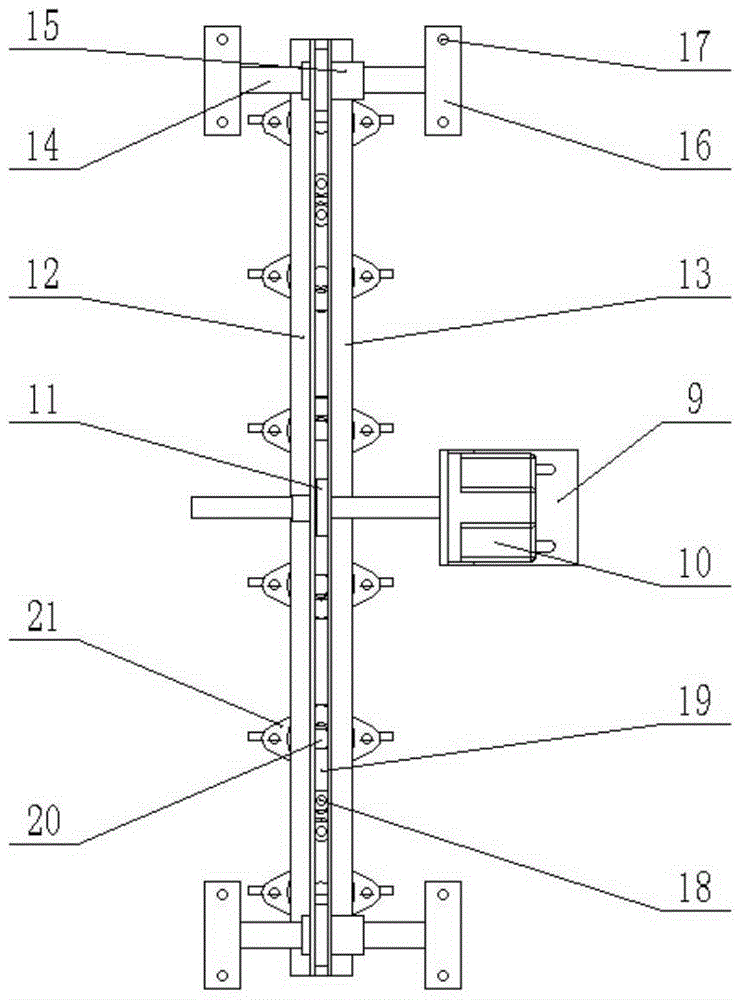

Gait rehabilitation training device

InactiveCN106539668AAchieve trainingAchieve correctionGymnastic exercisingChiropractic devicesGait trainingEngineering

The invention discloses a gait rehabilitation training device, and belongs to the technical field of medical instruments. The gait rehabilitation training device is characterized by comprising a bearing mechanism (1) and a gait training mechanism (2); the bearing mechanism (1) includes a bearing frame for fixing a body of a user, and a driving mechanism for driving the bearing frame to walk; the gait training mechanism (2) includes mechanical legs arranged on two sides and a power mechanism; each of the mechanical legs includes a thigh rod (16), a calf rod (19) and a pedal (20); the upper end of the calf rod (19) is rotationally connected with the thigh rod (16), and the lower end is rotationally connected with the pedal (20); the upper end of the thigh rod (16) is rotationally connected with the power mechanism; and the power mechanism is connected with the thigh rod (16), the calf rod (19) and the pedal (20) at the same time. The gait rehabilitation training device can really stimulate hemiplegic extensor to move, stimulates active selection control of patients, and achieves greater help on clinical application.

Owner:刘建英

Golf ball putter including golf ball alignment indicia

A golf putter, ball retriever and retainer configured to retrieve and hold a golf ball. The putter defines a substantially symmetrical configuration from heel to toe. The ball retriever and retainer is defined by a spherical recess formed in the sole of the putter and an opening defined on the top surface thereof. At least one resilient tab is defined in the sole to enlarge the sole opening. Ball alignment indicia are disposed on the top surface of the golf putter head, the ball alignment indicia defining at least a C-shaped configuration, whereby a ball is visually aligned between said first and second ends to center the ball on said striking face. The ball alignment indicia may further include at least one line segment disposed coincidentally to the initial direction of travel of the golf ball.

Owner:MPH GOLF

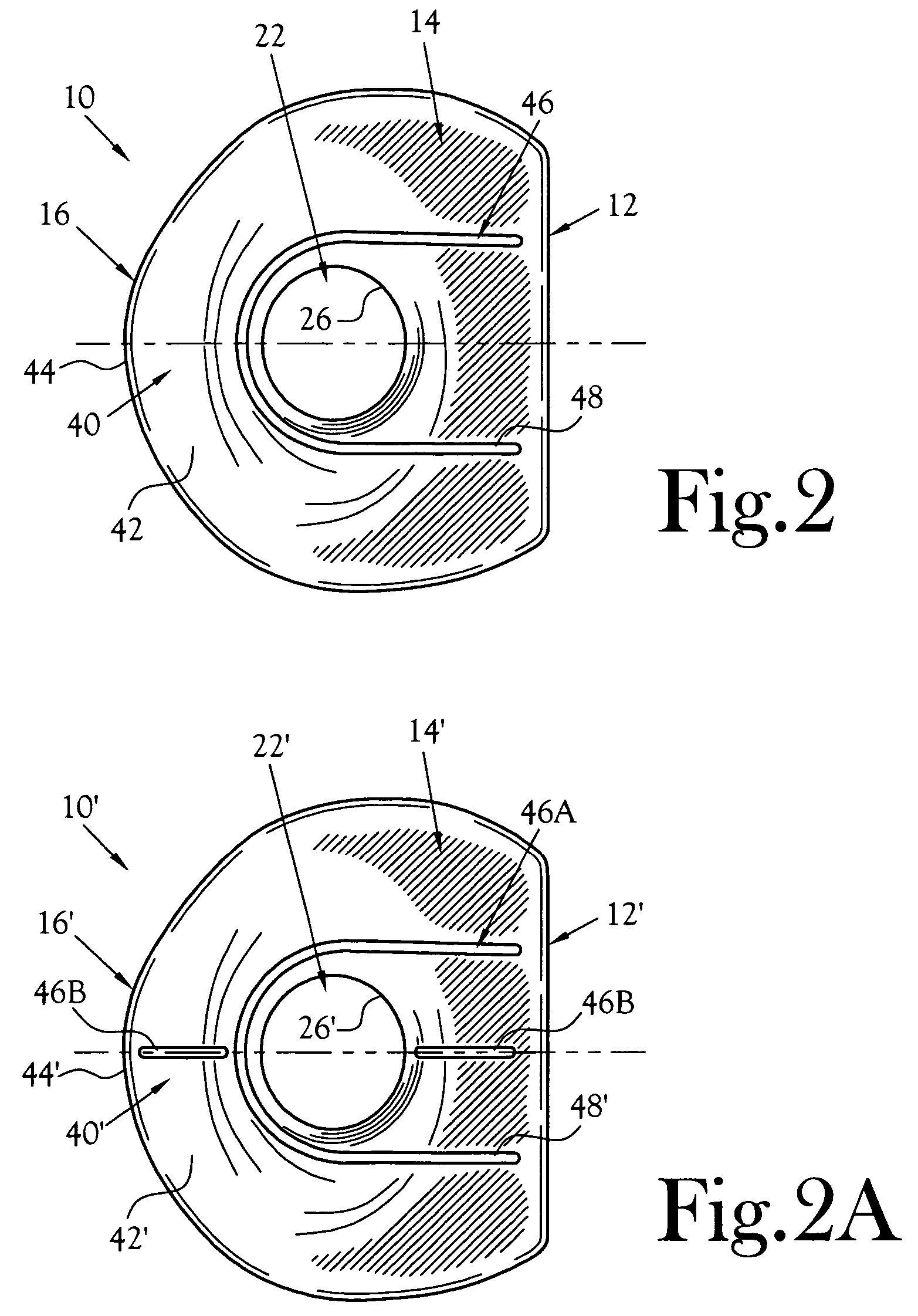

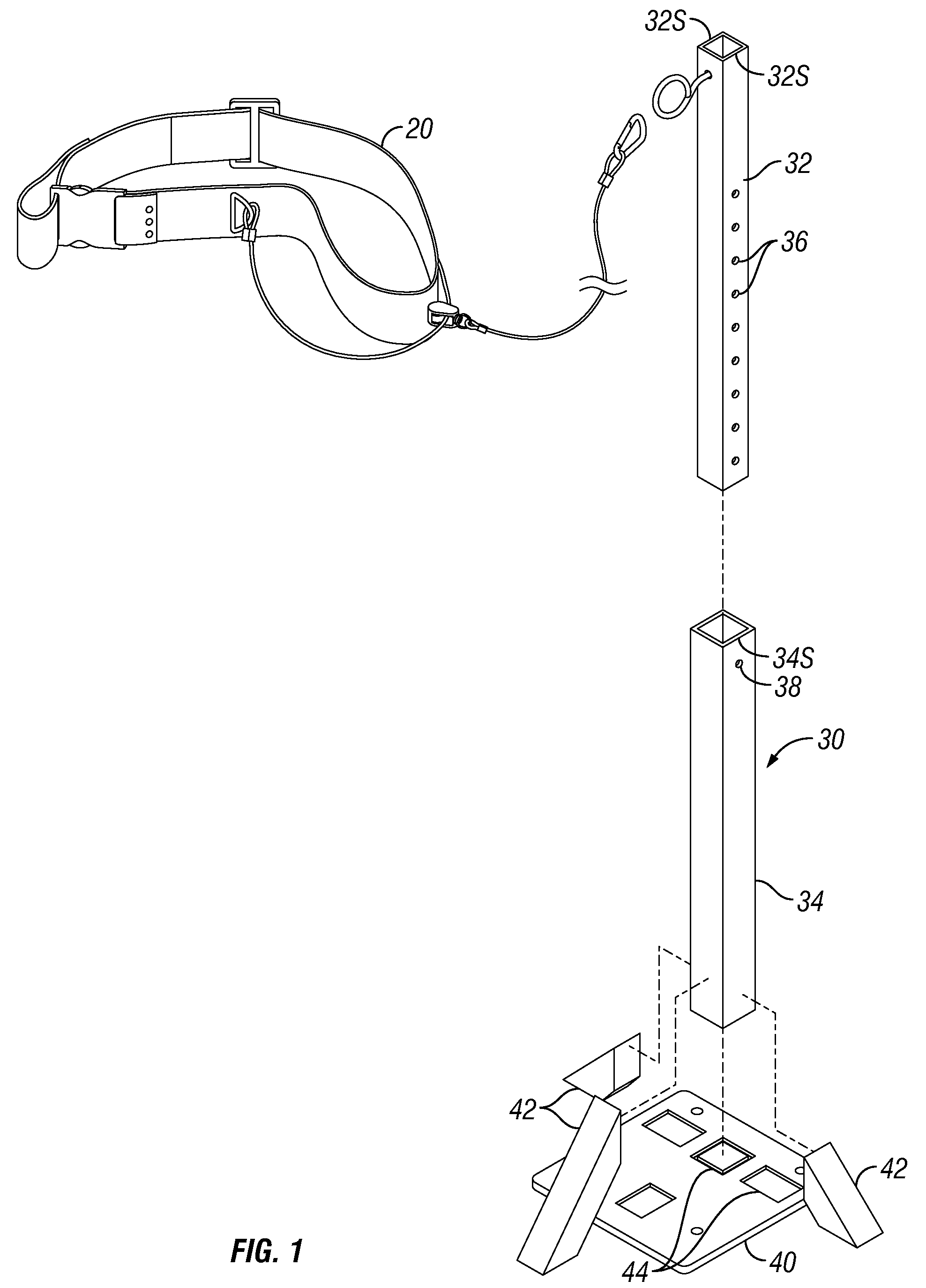

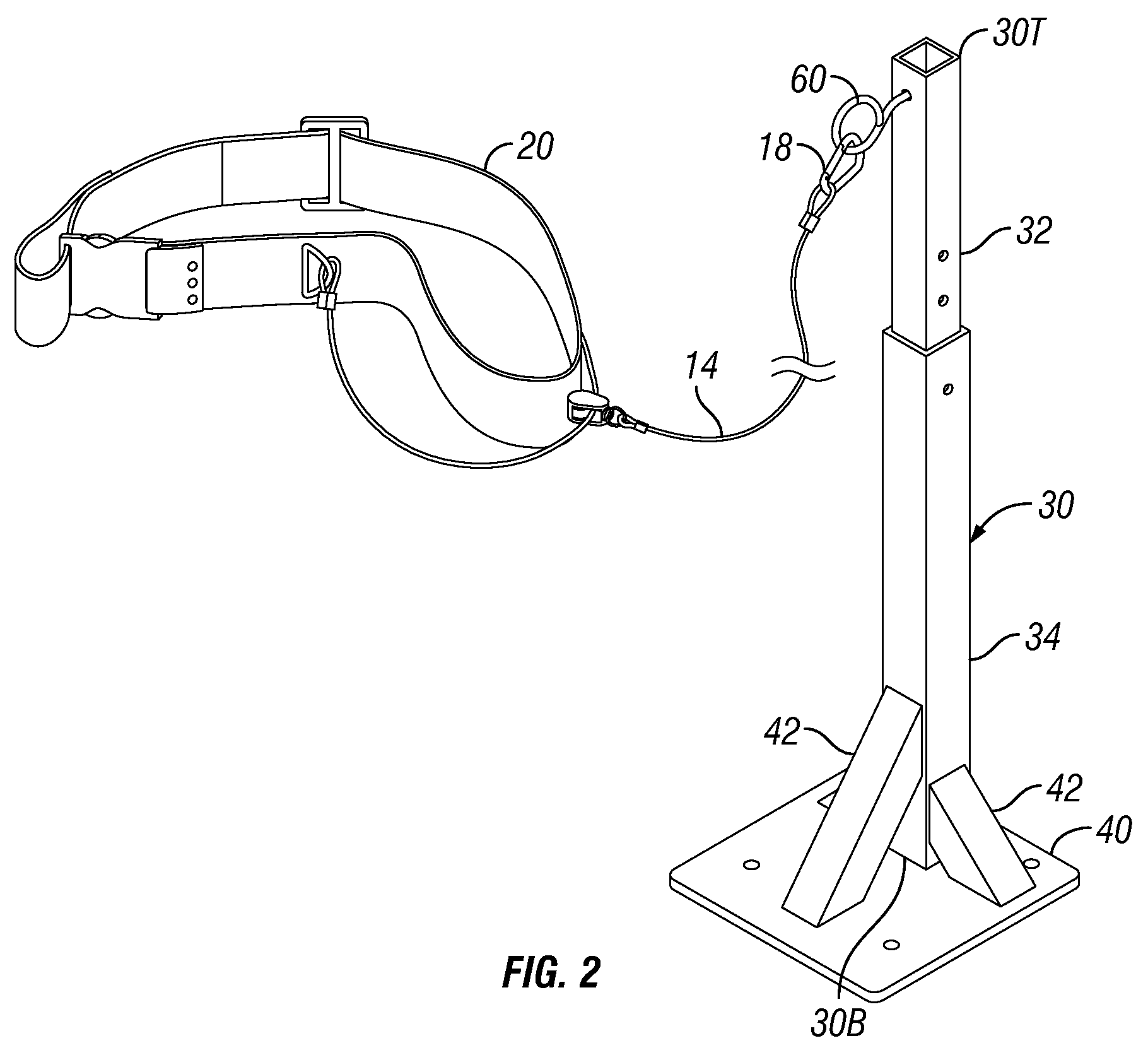

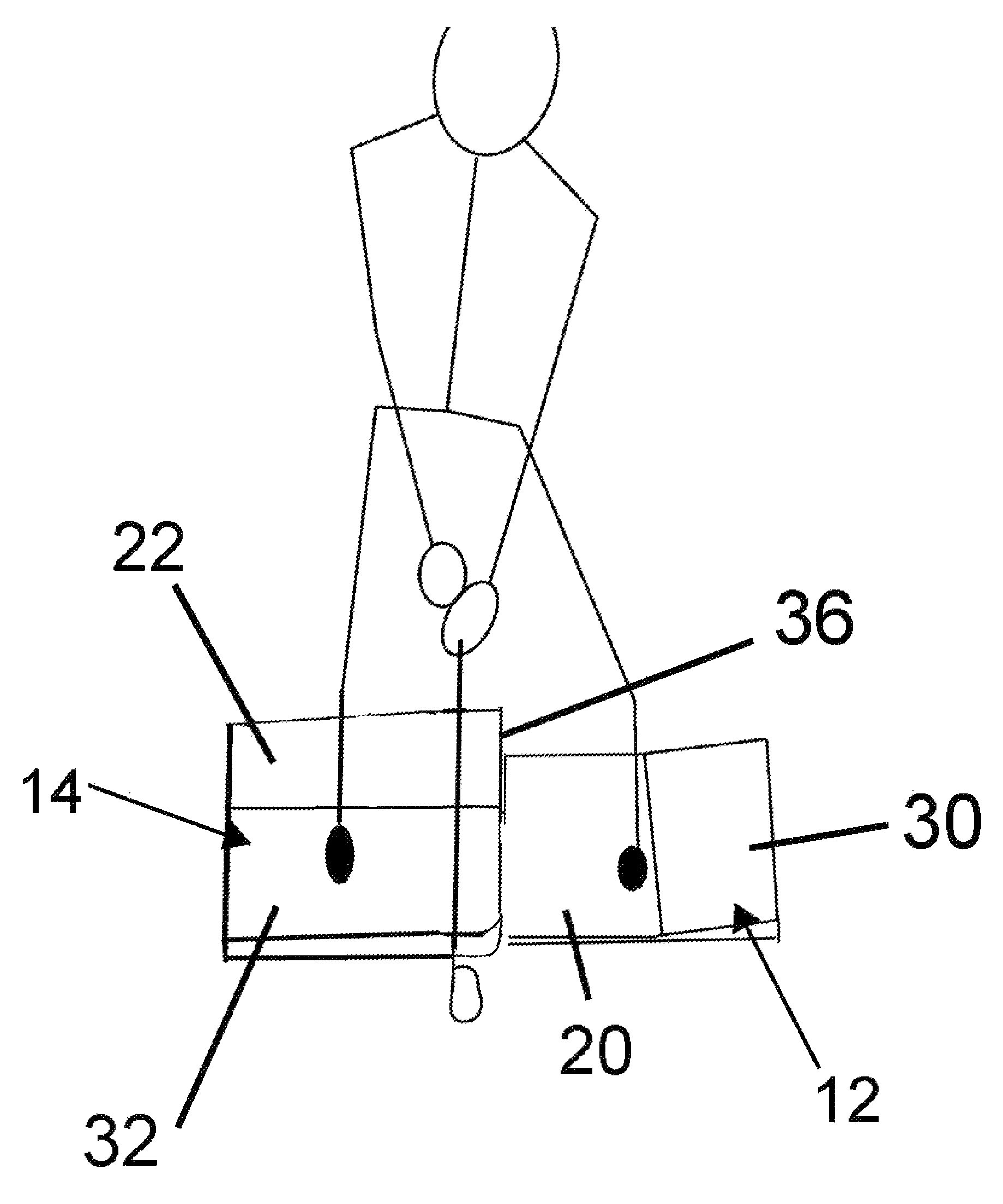

Batter training apparatus and method

InactiveUS8512171B1Precise rotationAvoid relative motionSpace saving gamesMicrochiropteraBiomechanics

A batter training apparatus and method for training batters to attain optimal biomechanics for most effectively hitting a ball, with a proper rotation of a batter's hips and proper follow through with a batter's arms, wrists and shoulders. The training apparatus includes a belt worn over the hips that has a cable extending behind and between the hips. A tether connects the belt to a support post, preventing forward motion of the batter's body, but allowing and conditioning the hips to rotate. The support post sits at the rear of a platform that is about the size of a batter's box. An elastic cord connected to a forward arm and attached to the front of the platform, pulls a batter's wrists, arms and shoulders forward during proper follow through, conditioning the batter to swing the bat efficiently.

Owner:MINOTTI DAVID

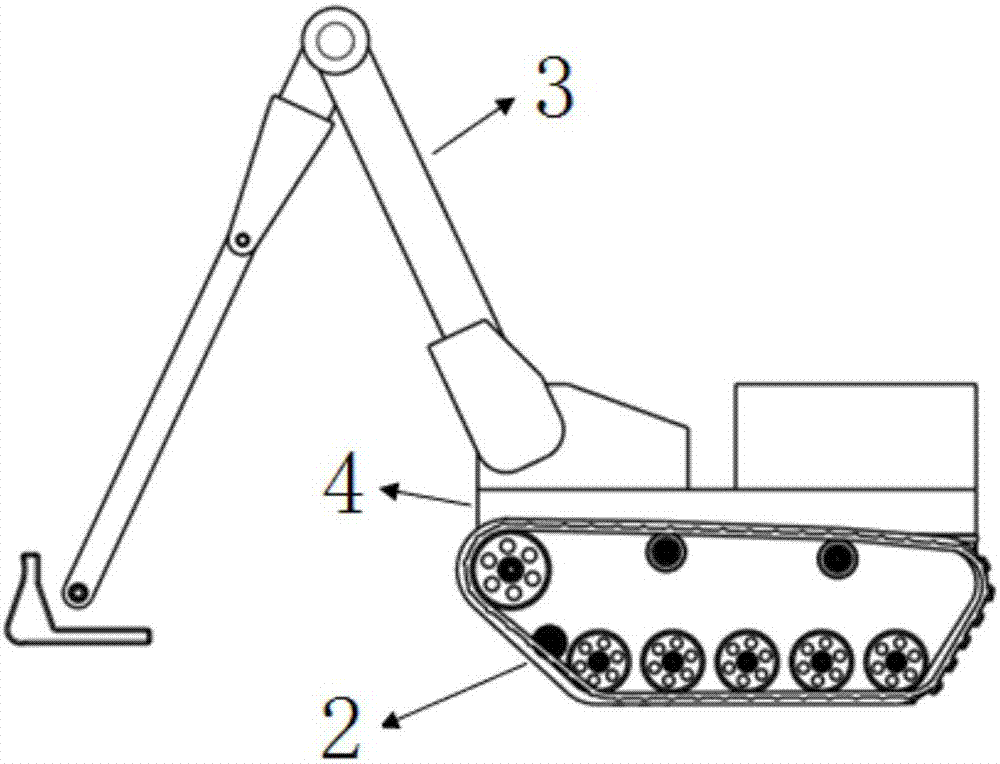

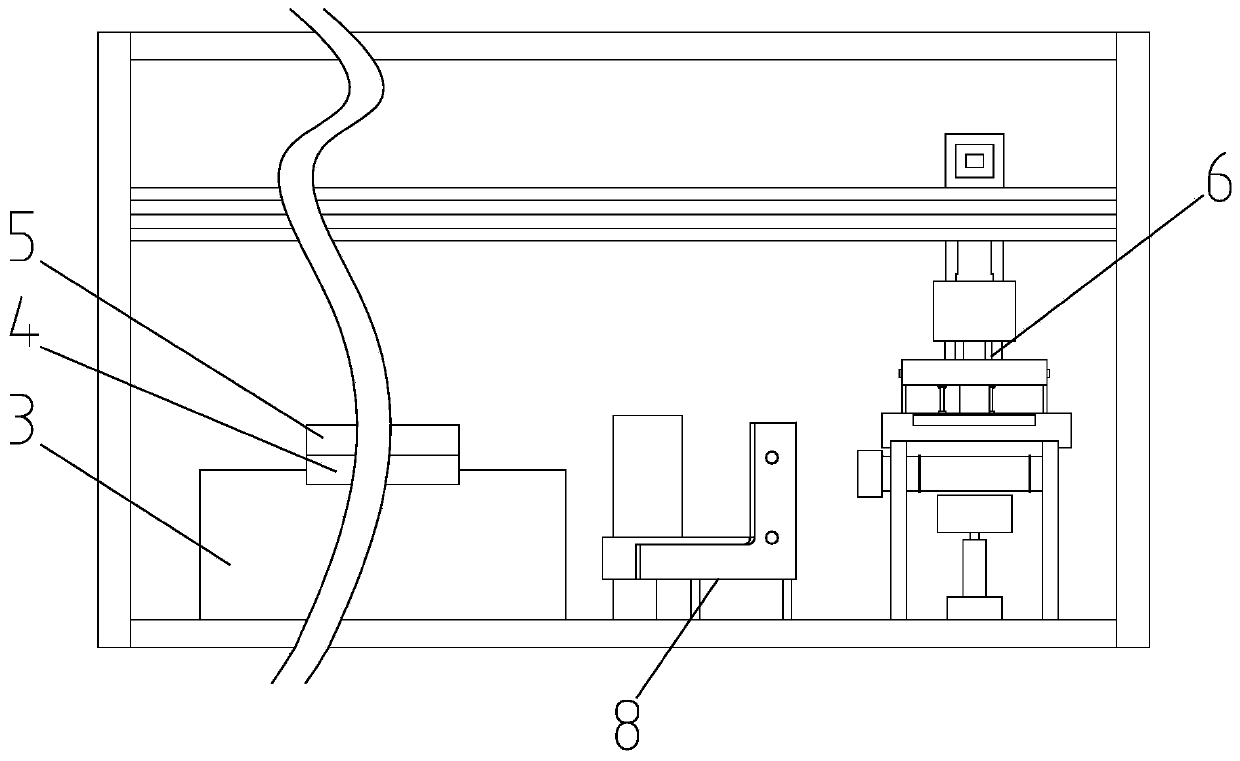

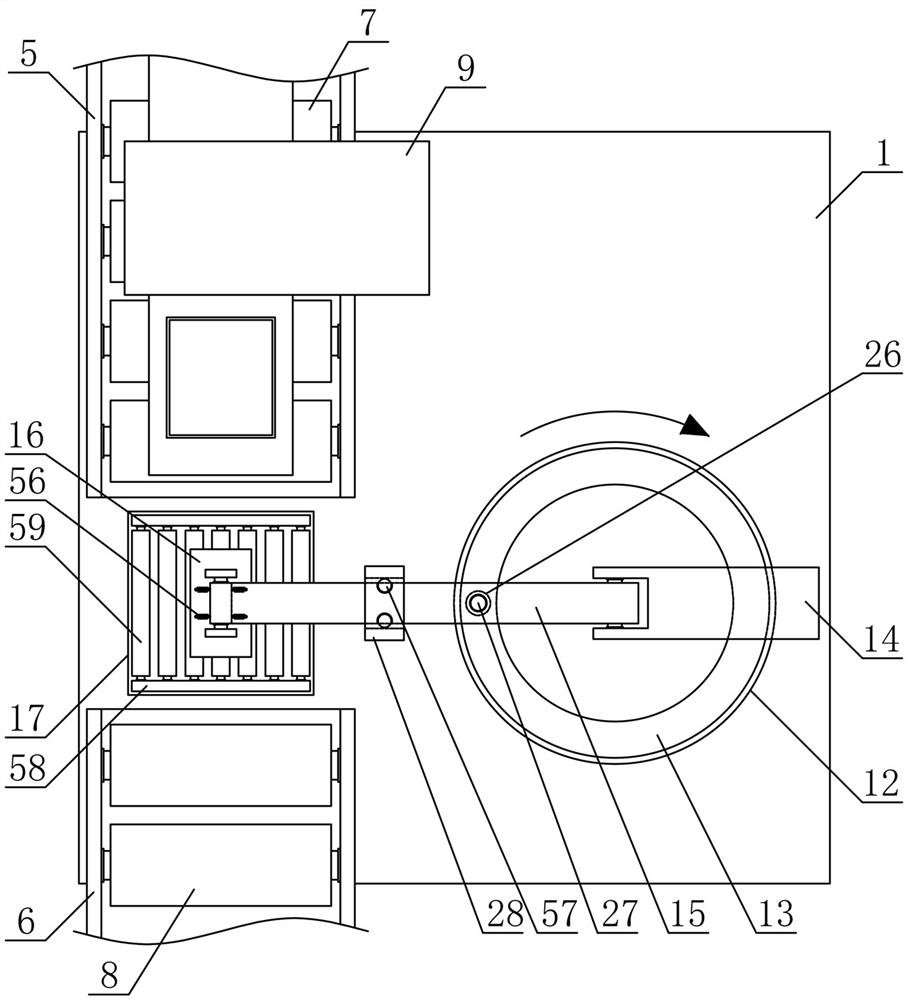

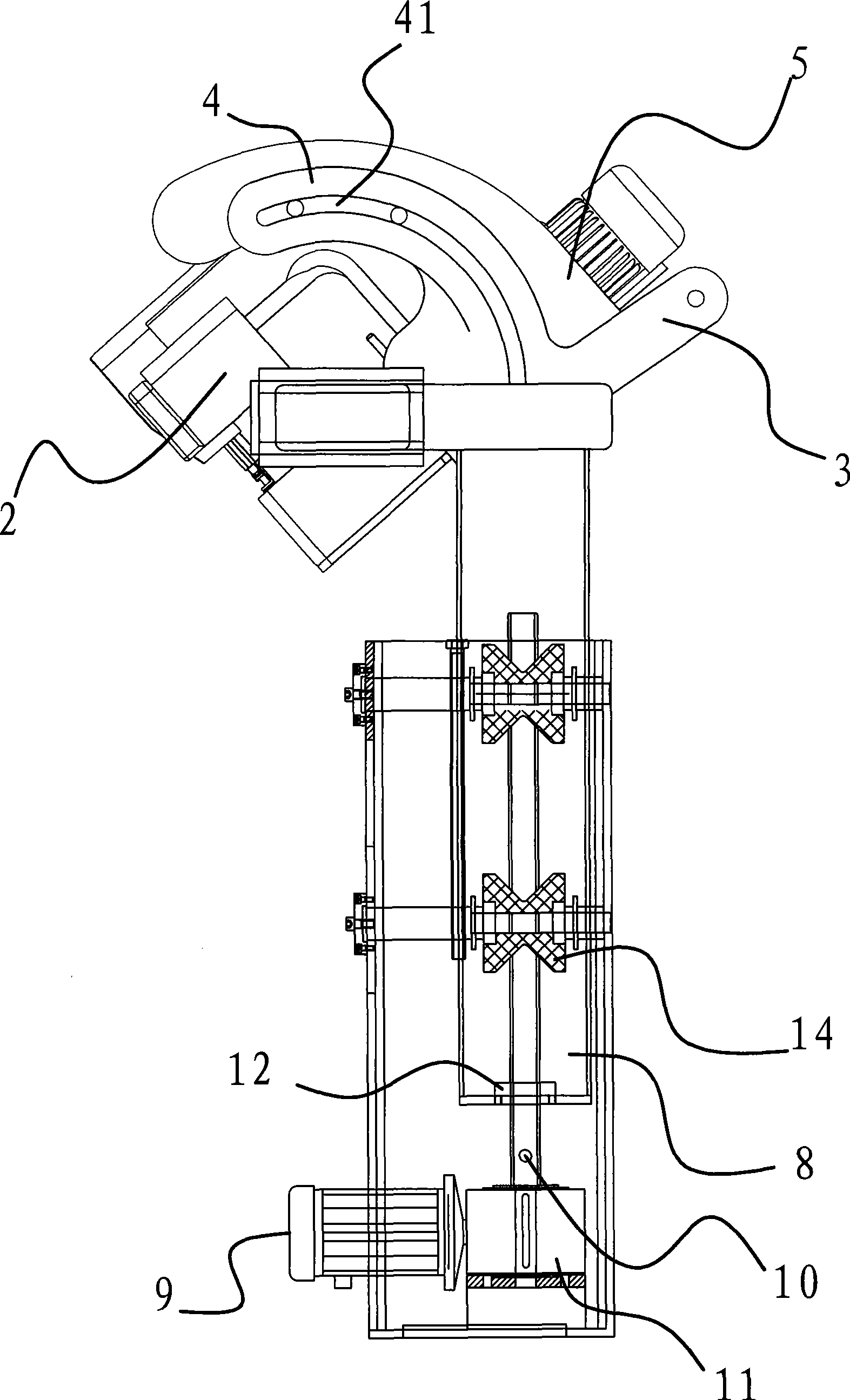

Multifunctional heading machine

InactiveCN104612200AImprove crushing effectImprove work efficiencySoil-shifting machines/dredgersTunnelsVertical planeManufacturing technology

The invention belongs to the technical field of design and manufacturing of mining machinery, and particularly relates to a multifunctional heading machine. The multifunctional heading machine comprises a heading machine main body (1), a walking mechanism (2) arranged below the heading machine main body (1), a power device arranged in the middle of the heading machine main body (1) and a conveying mechanism, and is characterized in that a movable arm (5) capable of swinging in the horizontal plane and the vertical plane is arranged in front of the heading machine main body (1); a crushing head (4) which is provided with a crushing hard layer and is used for conveying crushed materials into the conveying mechanism is mounted on the movable arm (5). The multifunctional heading machine disclosed by the invention is wide in application range, high in working efficiency, low in energy consumption and multi-purpose and integrates a crushing machine, a loading machine and a bulldozer.

Owner:ZIBO HAILUN MACHINERY MFG

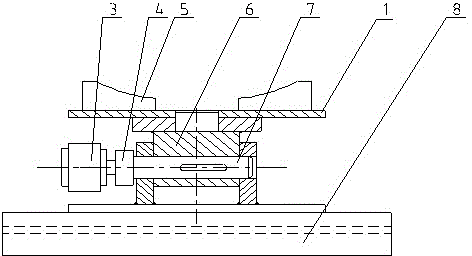

Yarn tension control mechanism of warp knitting machine

The invention discloses a yarn tension control mechanism of a warp knitting machine, which comprises a tension seat, a tension rod, a yarn-through rod, a driving gear, a driven gear and a servo motor, wherein the tension rod and the yarn-through rod are mounted on the tension seat; the driven gear is mounted on the tension rod; tension springs of certain number are equidistantly mounted in the same direction on the tension rod; yarn guide caps are clamped by the tail-end openings of the tension springs; a flange of the servo motor is fixed on the tension seat through a bolt; the driving gear is arranged on an output shaft of the servo motor; the driving gear is meshed with the driven gear; when the servo motor rotates back and forth under the control of the set program, the driving gear rotates along with the servo motor and the driven gear is driven to rotate; the rotation of the driven gear drives the tension rod and the yarn guide caps of the tension springs to rotate; and the control program controls the motor to rotate back and forth according to the rotation speed of a main shaft of the wrap knitting machine to cooperate with the looping motion of the warp knitting machine so as to control the tightness of the yarn tension. The uniformity of the yarn tension is guaranteed, thus the knitting of the warp knitting machine is smooth, the quality of the grey cloth is good, and the production efficiency is high.

Owner:FUJIAN XIN GANG TEXTILE MACHINERY

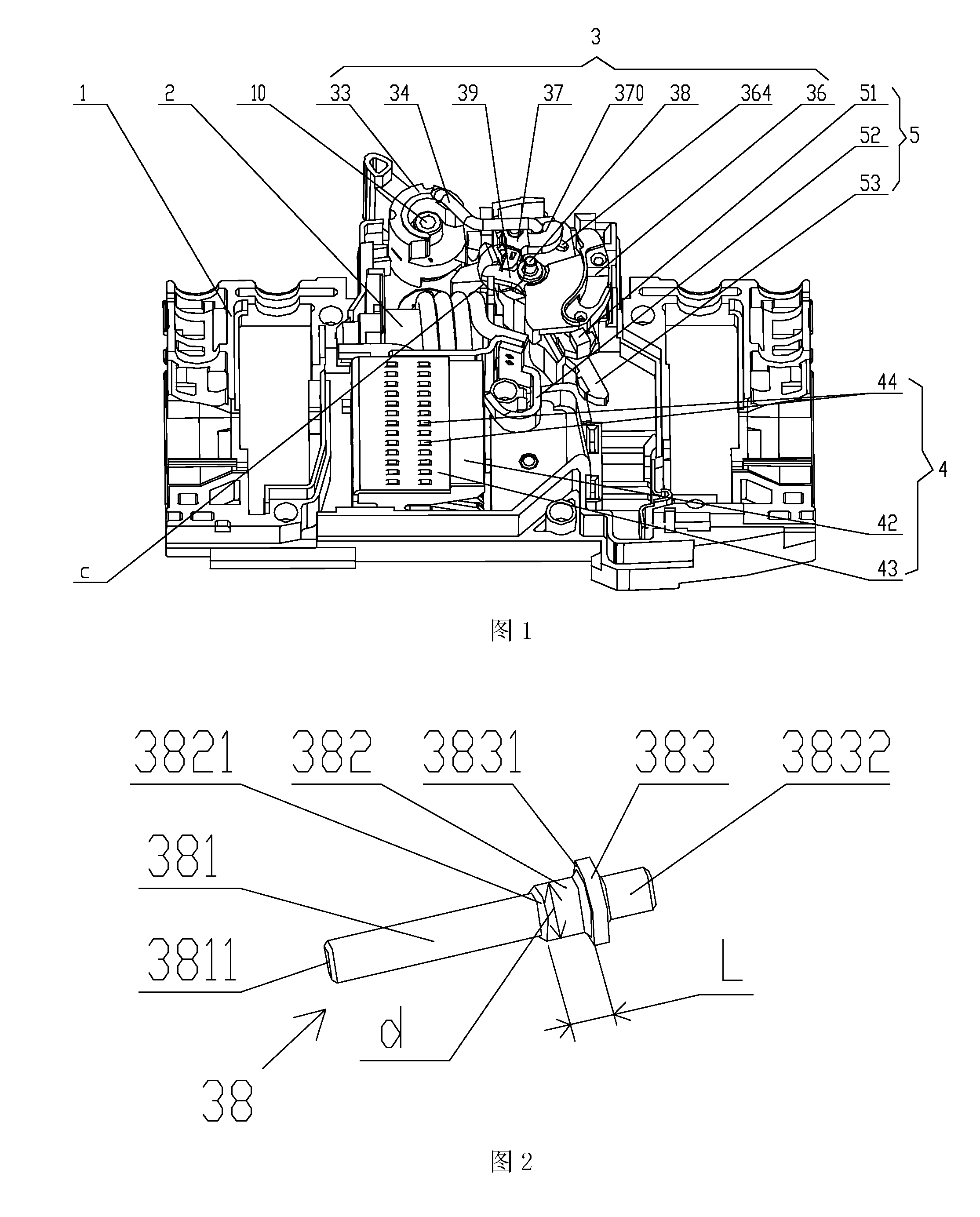

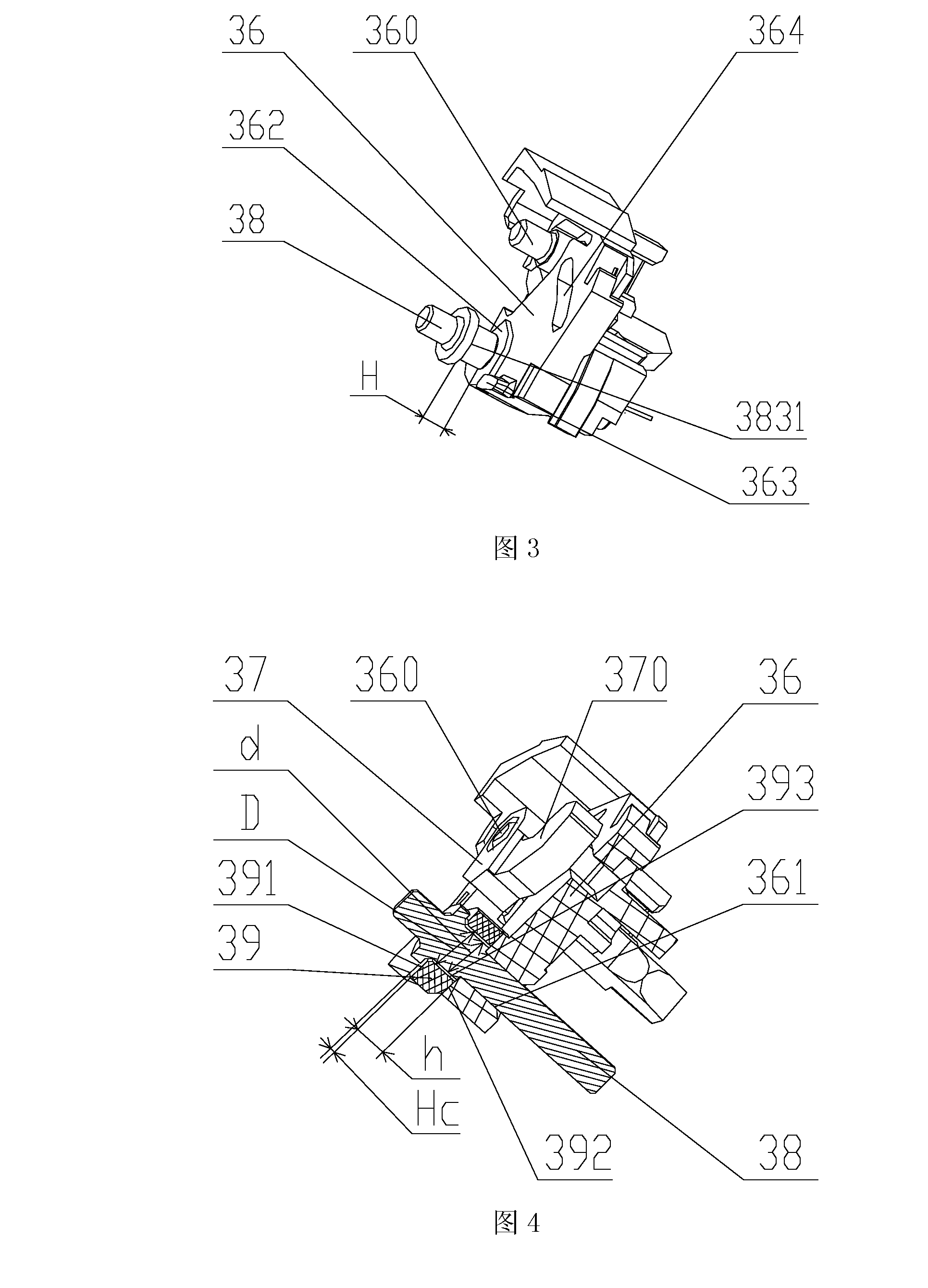

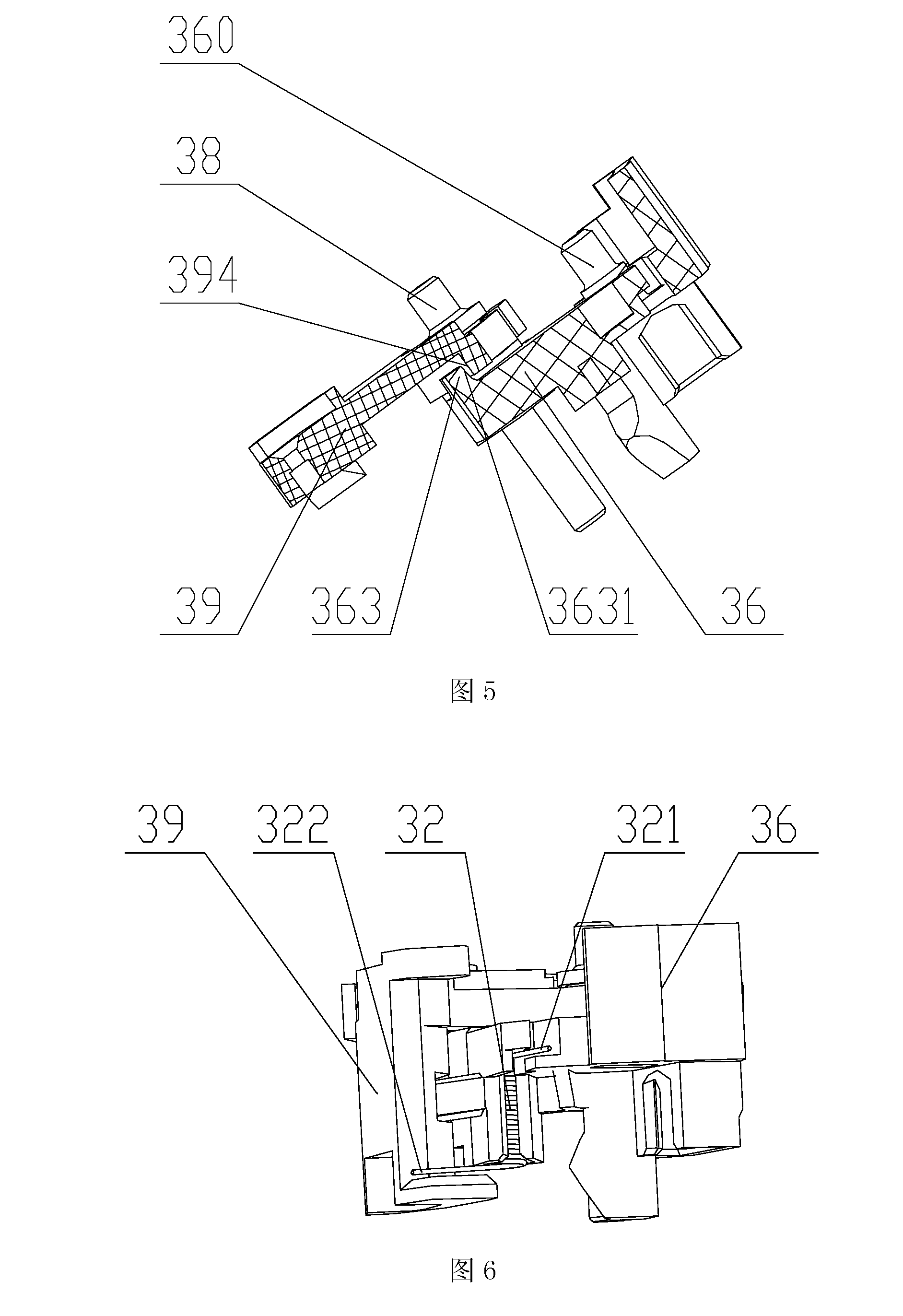

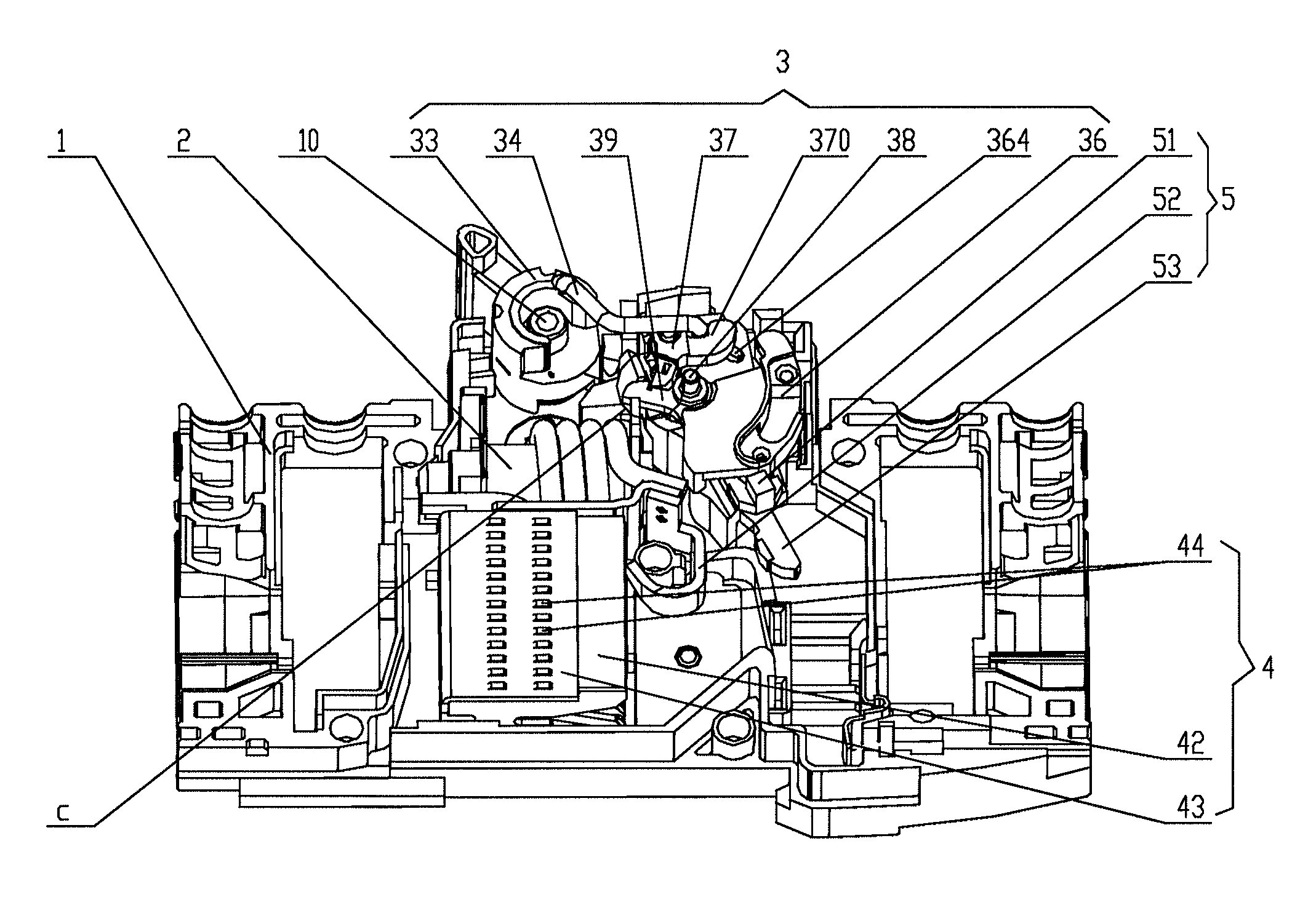

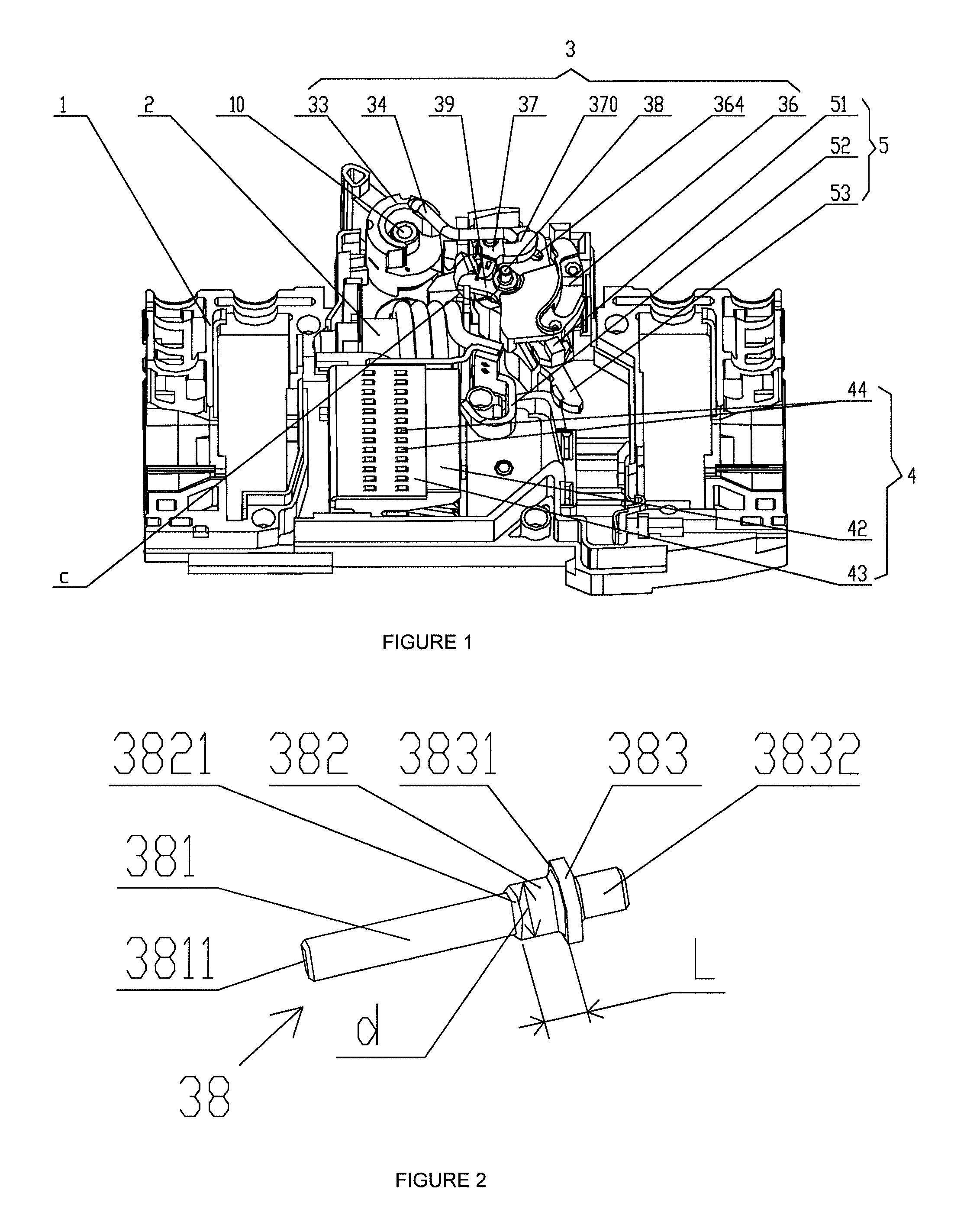

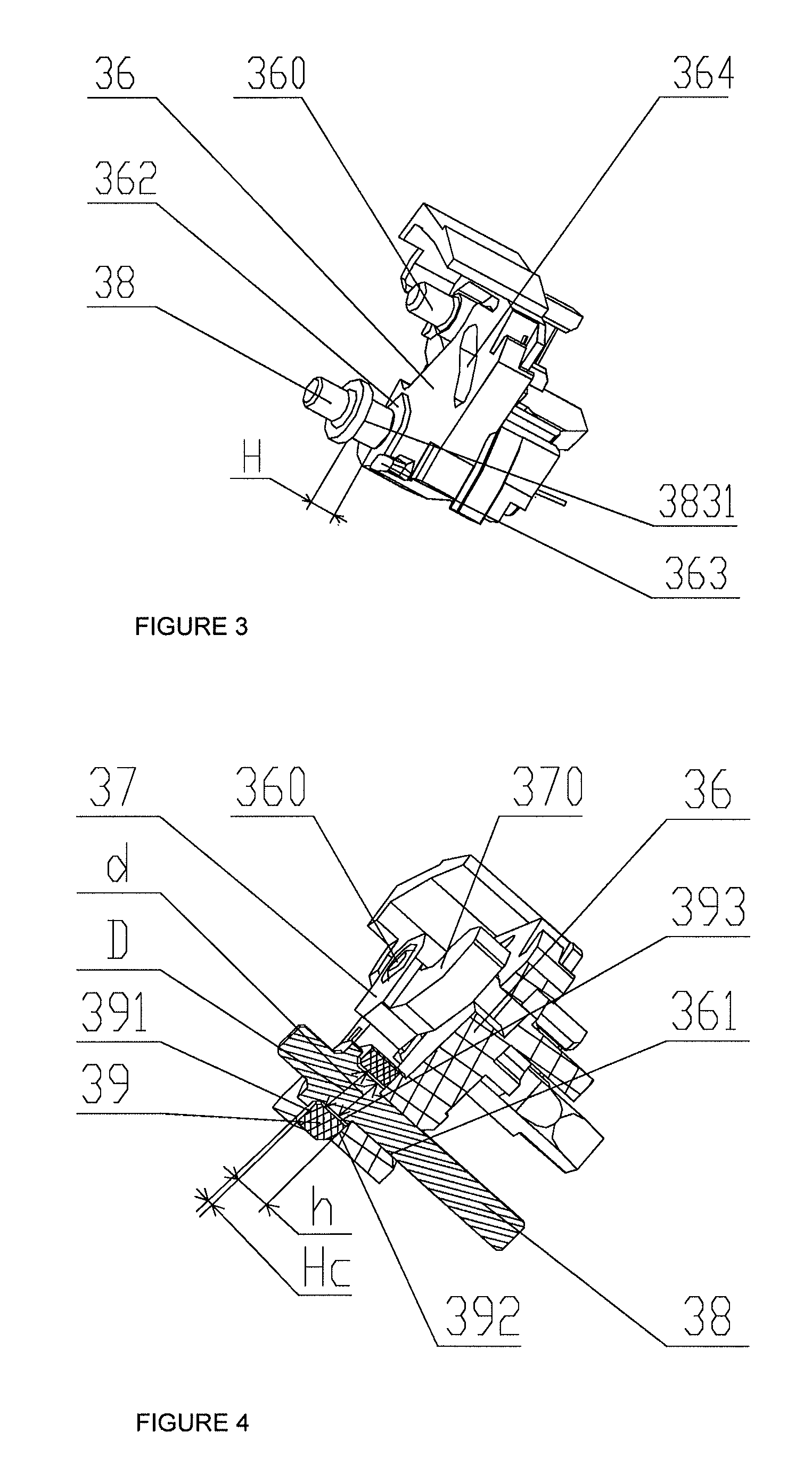

Minitype breaker with high stability

ActiveUS20150255228A1High strengthTripping forceProtective switch detailsEmergency actuatorsEngineeringCircuit breaker

A high-stability miniature circuit breaker includes an operating mechanism, wherein a pivotal shaft of the operating mechanism fixed on a shell includes a first shaft section, a second shaft section and a shaft shoulder; the diameter of the second shaft section is larger than that of the first shaft section, and the diameter of the shaft shoulder is larger than that of the second shaft section. A lever is installed on the first shaft section through a first shaft hole in a pivoting way and used for limiting the axial position of a protruding mesa relative to the pivotal shaft through contact fit between the protruding mesa disposed on the lever and a thrust surface on the second shaft section. A latch assembly is installed on the second shaft section through a second shaft hole in a pivoting way; a first end face fitted with a support surface on the shaft shoulder is disposed at one end of the second shaft hole; and a second end face fitted with the protruding mesa is disposed at the other end of the second shaft hole. A first hasp fitted with a second hasp of the latch assembly is disposed on a connecting rod, the connecting rod is engaged with each other with the latch assembly in the first and second hasp contact and withhold state, and the latch assembly controls a drive rod and the lever not to move relatively; the connecting rod is separated from the latch assembly when the first and second hasps are separated and unbuckled, and the latch assembly is separated from the drive rod, so that the drive rod can slide along a groove of the lever.

Owner:SHANGHAI NOARK ELECTRIC

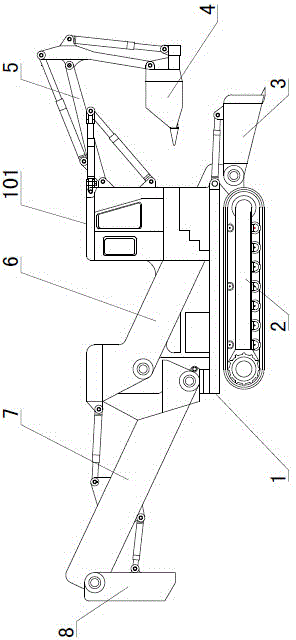

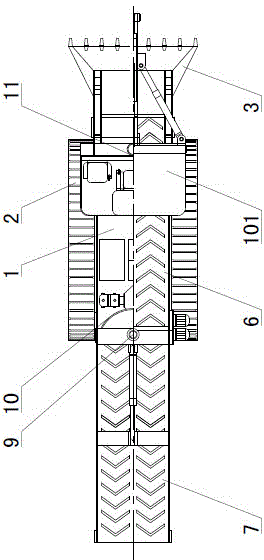

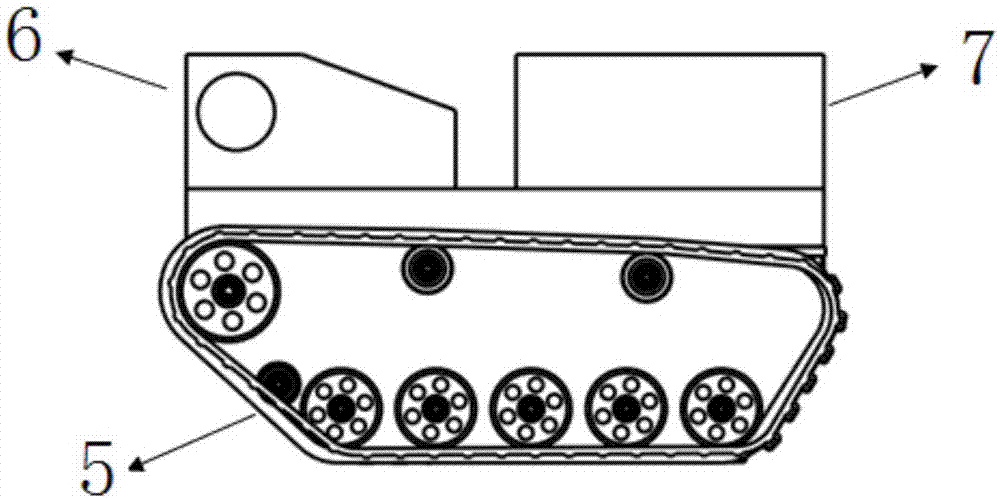

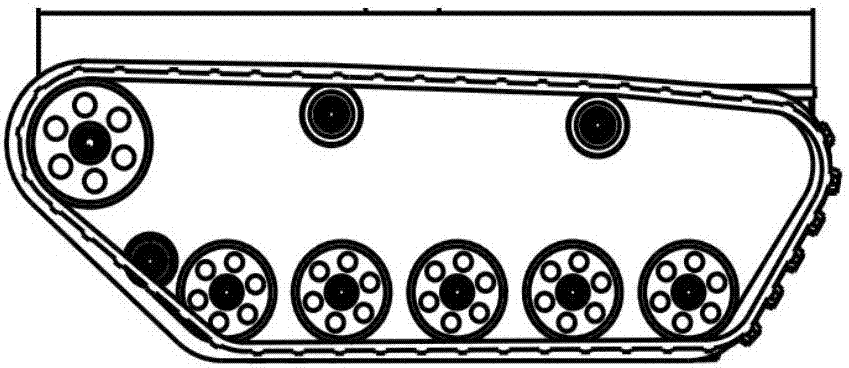

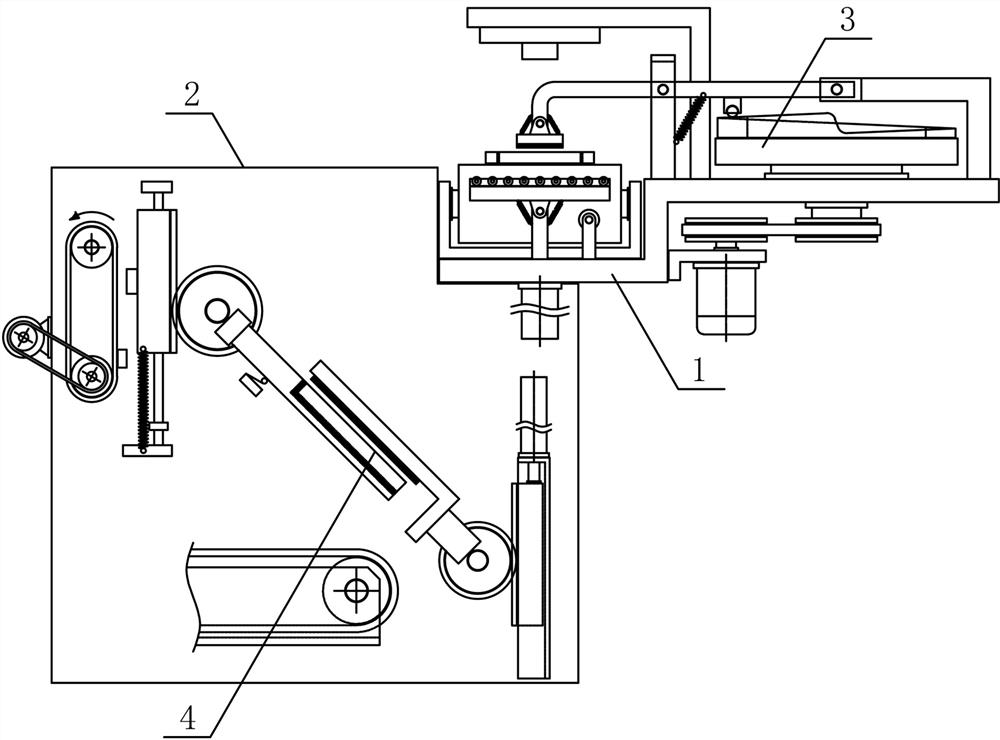

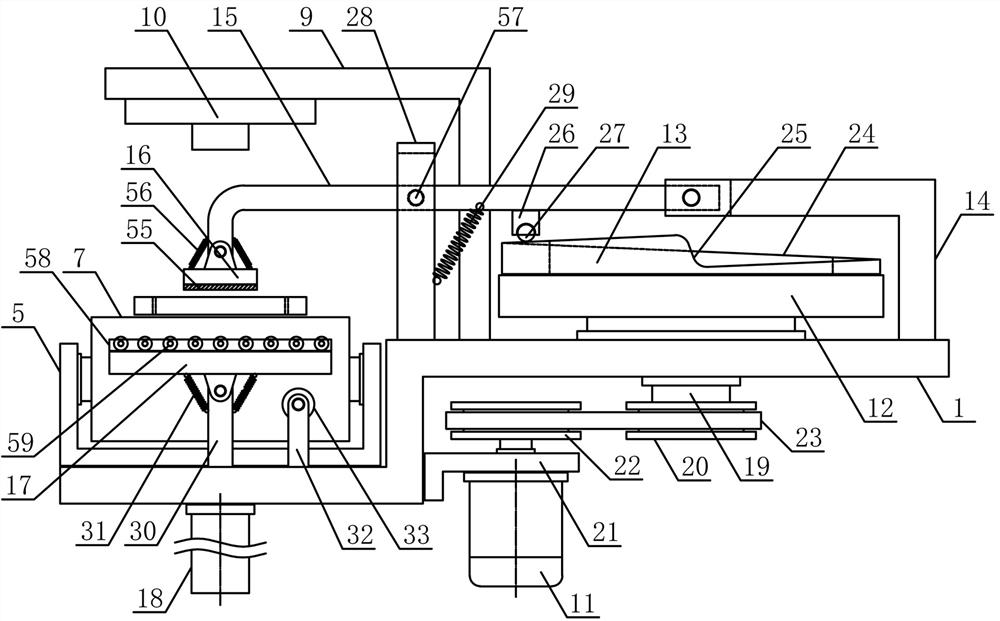

Autonomous type mine detection robot system and mine detection method

InactiveCN107328308AReasonable path planningImprove operational efficiencyDefence devicesPosition/course control in two dimensionsRobotic systemsControl system

The invention discloses an autonomous type mine detection robot system and a mine detection method. The autonomous type mine detection robot system comprises a vehicle body. A moving chassis system 2, a mechanical arm detection system 3 and a coating system 4 are arranged on the vehicle body. The moving chassis system 2 is connected with the mechanical arm detection system 3 and the coating system 4. The moving chassis system 2 comprises a moving platform system 5, a power system 6 and a control system 7. The mechanical arm detection system 3 comprises a mechanical arm movement system 8 and a detection system 9. The power system 6 is installed at the back end of the movement platform system 5, provides the power source for the whole device and is used as a counter weight. The control system 7 is connected with the power system 6 and the detection system 9. The detection system 9 is arranged at the front end of the mechanical arm movement system 8. The autonomous type mine detection robot system can intelligently, accurately and efficiently detect and mark mine points of a mine area in a non-destructive manner, and therefore the safe and reliable guarantee is provided for follow-up mine removal. The autonomous type mine detection robot system conducts mine detection and marking and is long in service life.

Owner:上海圭目机器人有限公司

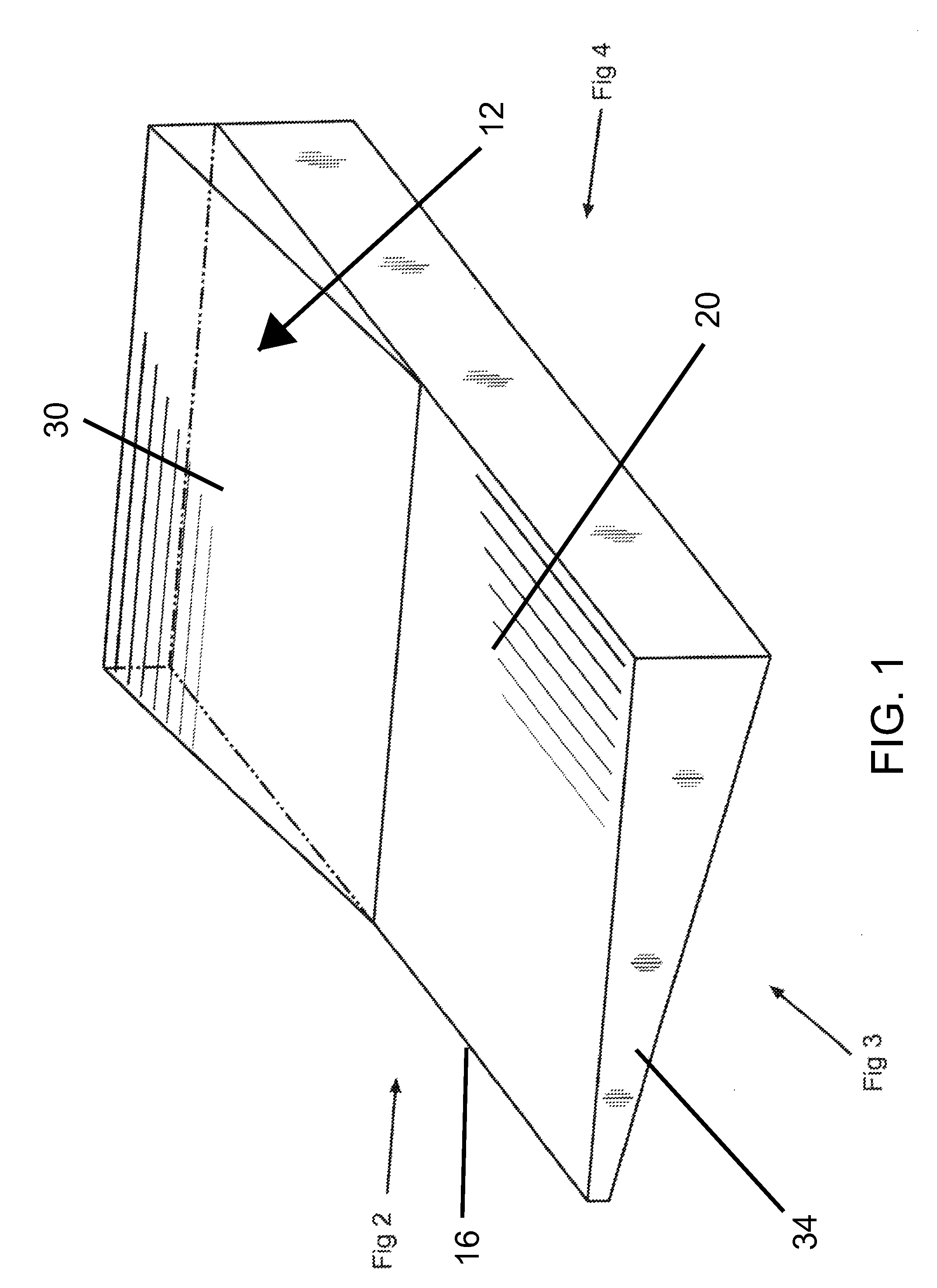

Golf teaching device

InactiveUS7901304B1Precise swingGolfers improve their stance and swingGolfing accessoriesEngineeringGolf Ball

The training device is made in two pieces that are mirror image of each other. In the first embodiment which is used to improve an individual's general swing the two pieces are laid together such that the two inclines form a valley. To use the device one steps on the inclines and places his feet approximately shoulder length apart in parallel with the valley. One then takes up a stance to swing. As he practices swinging the golf club he noticed how his body feels with the weight on the insides of his feet. By him standing on the inclines he will keep his feet, hips, shoulders in the proper position for a correct swing.

Owner:MOORE RANDY L

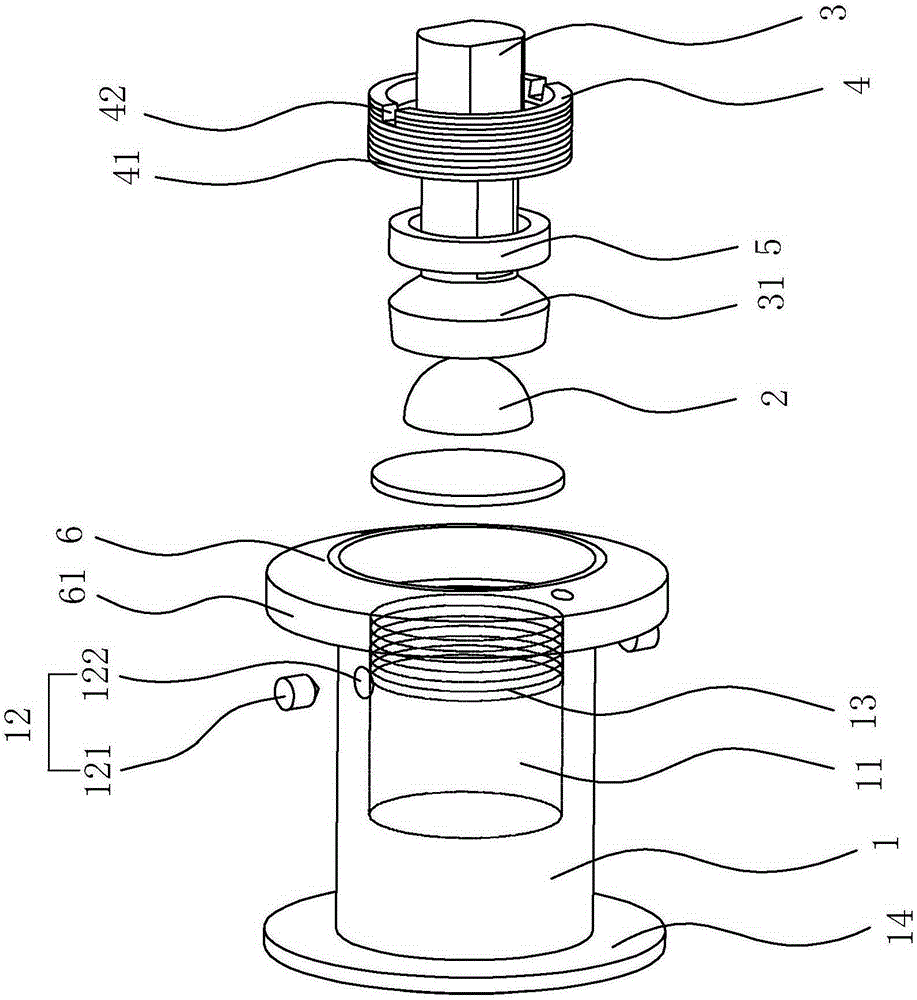

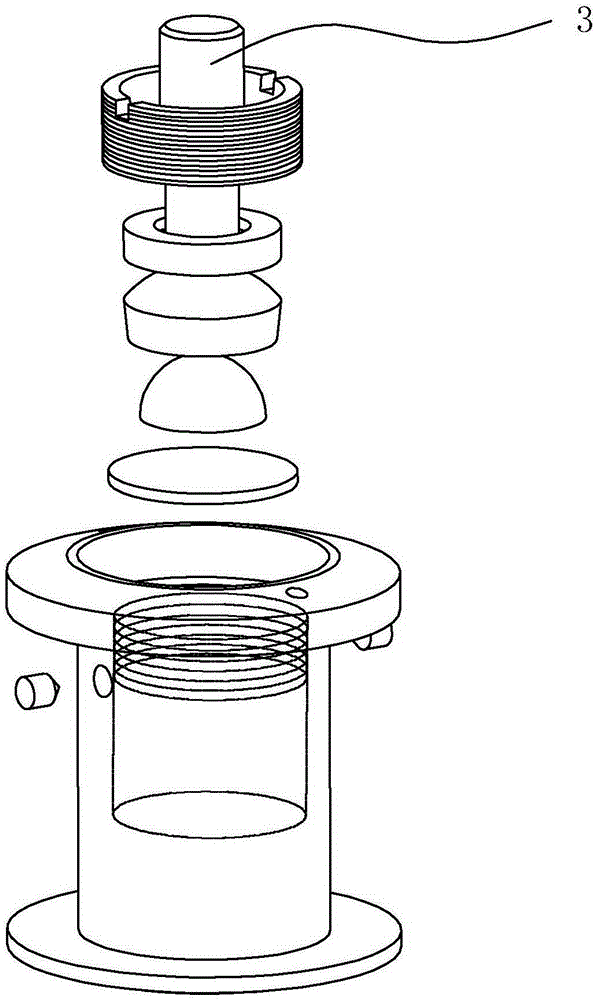

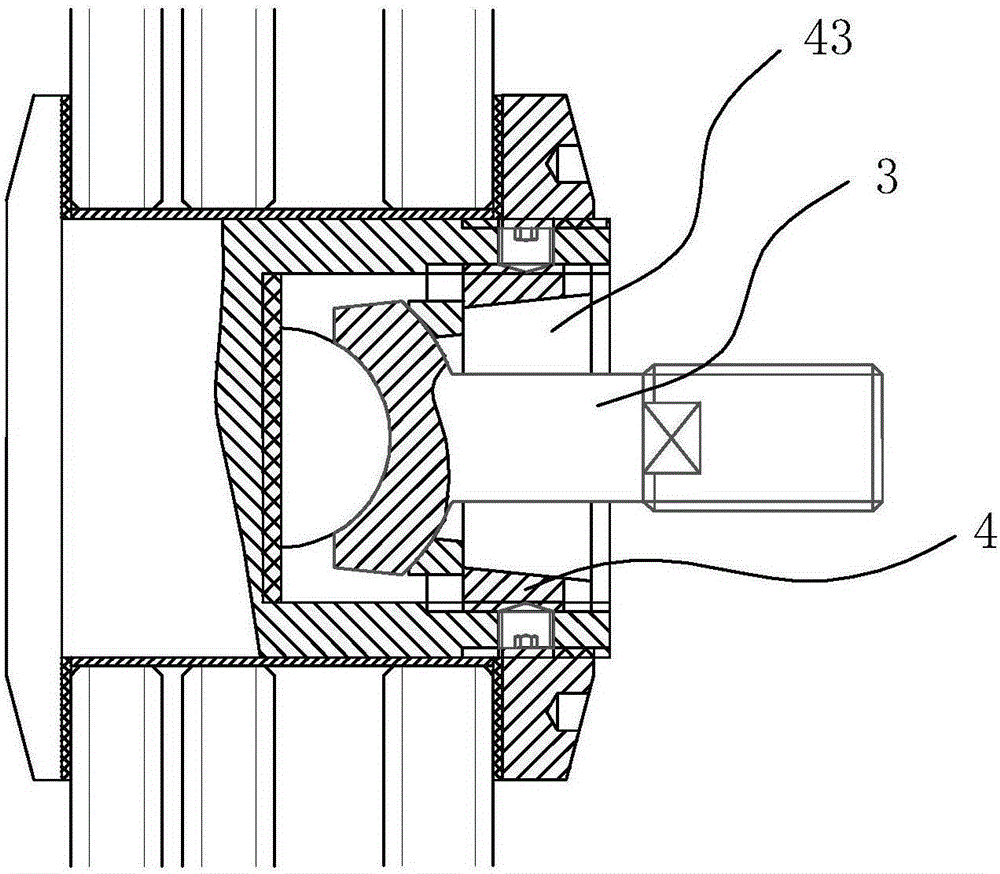

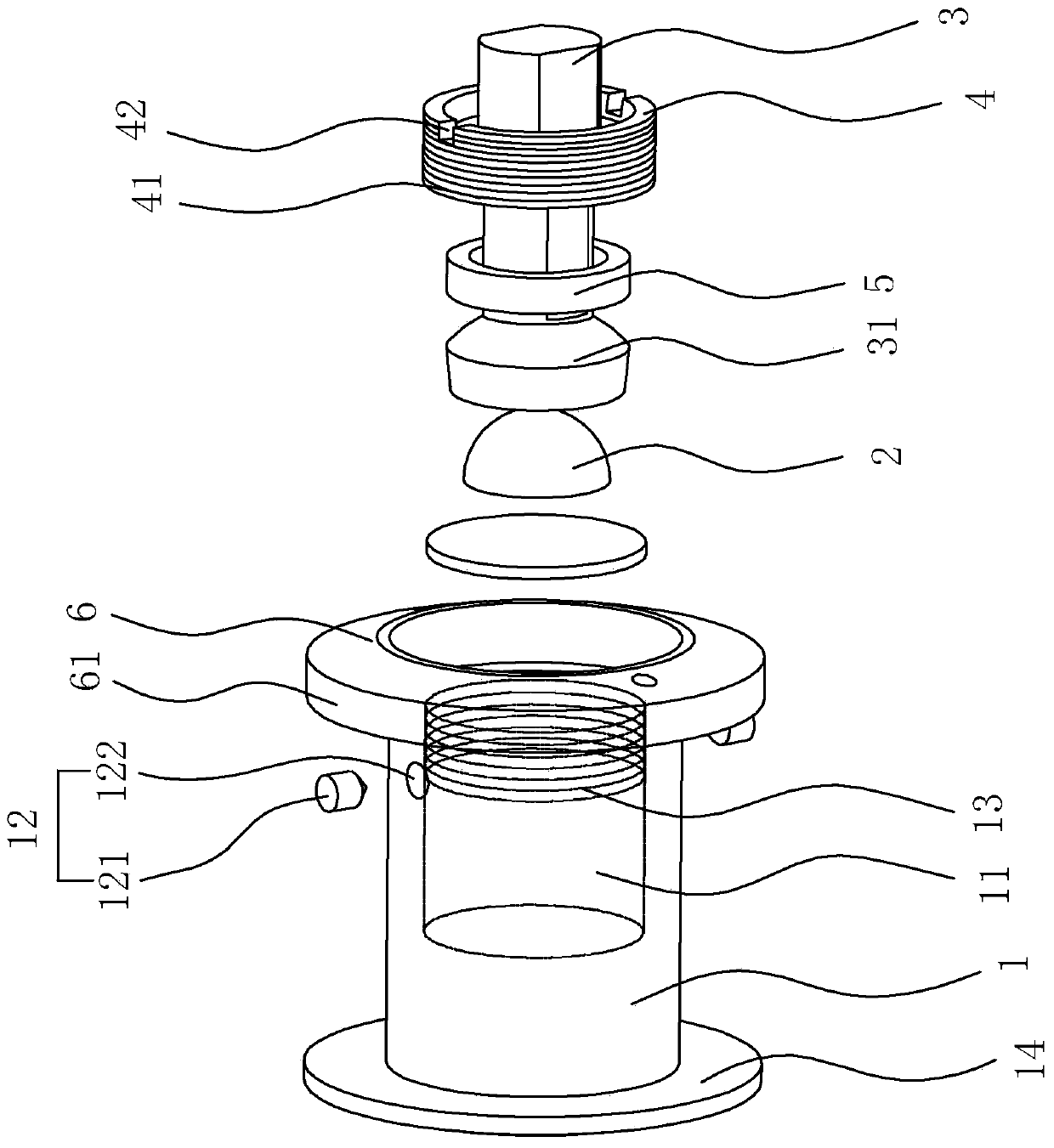

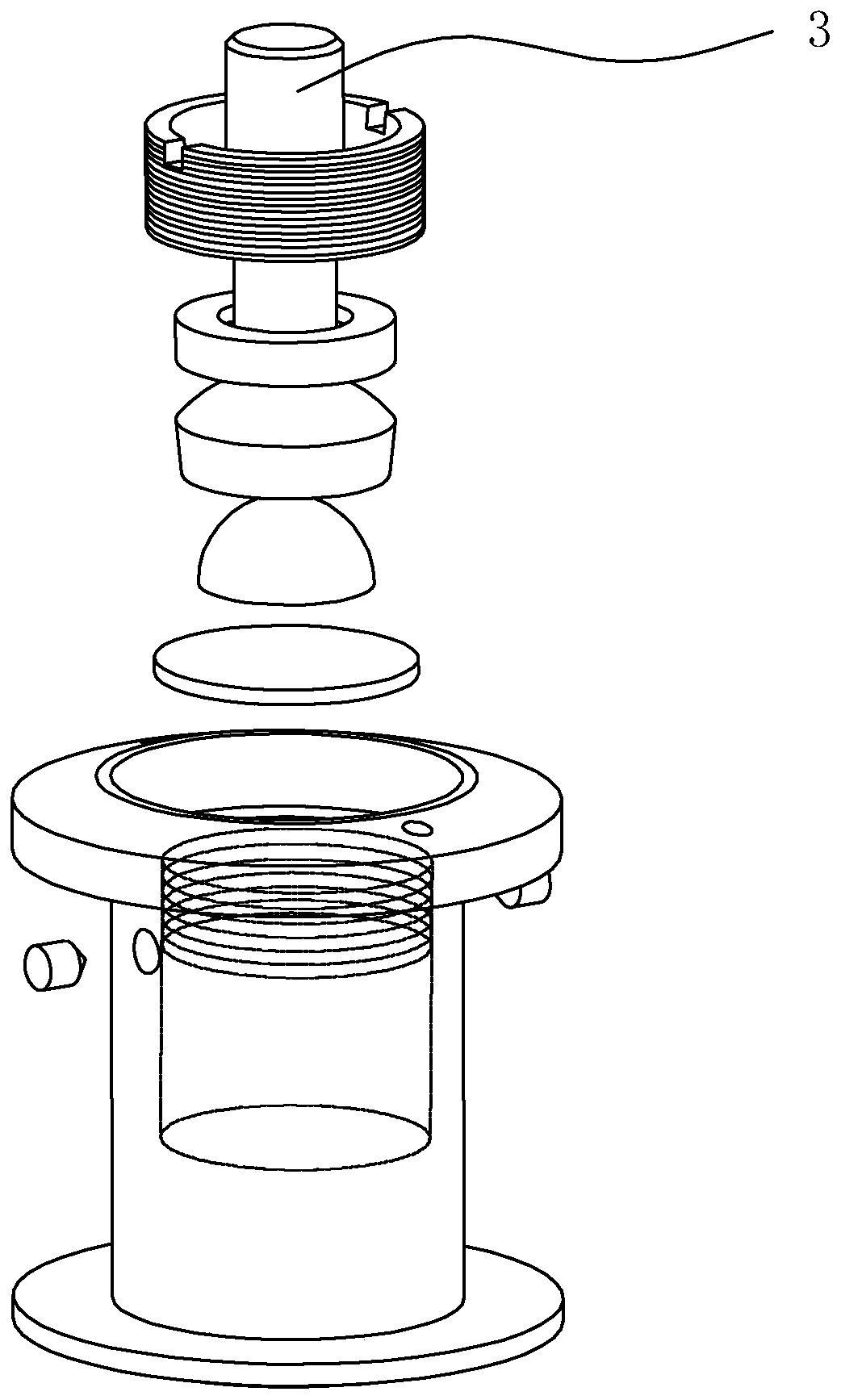

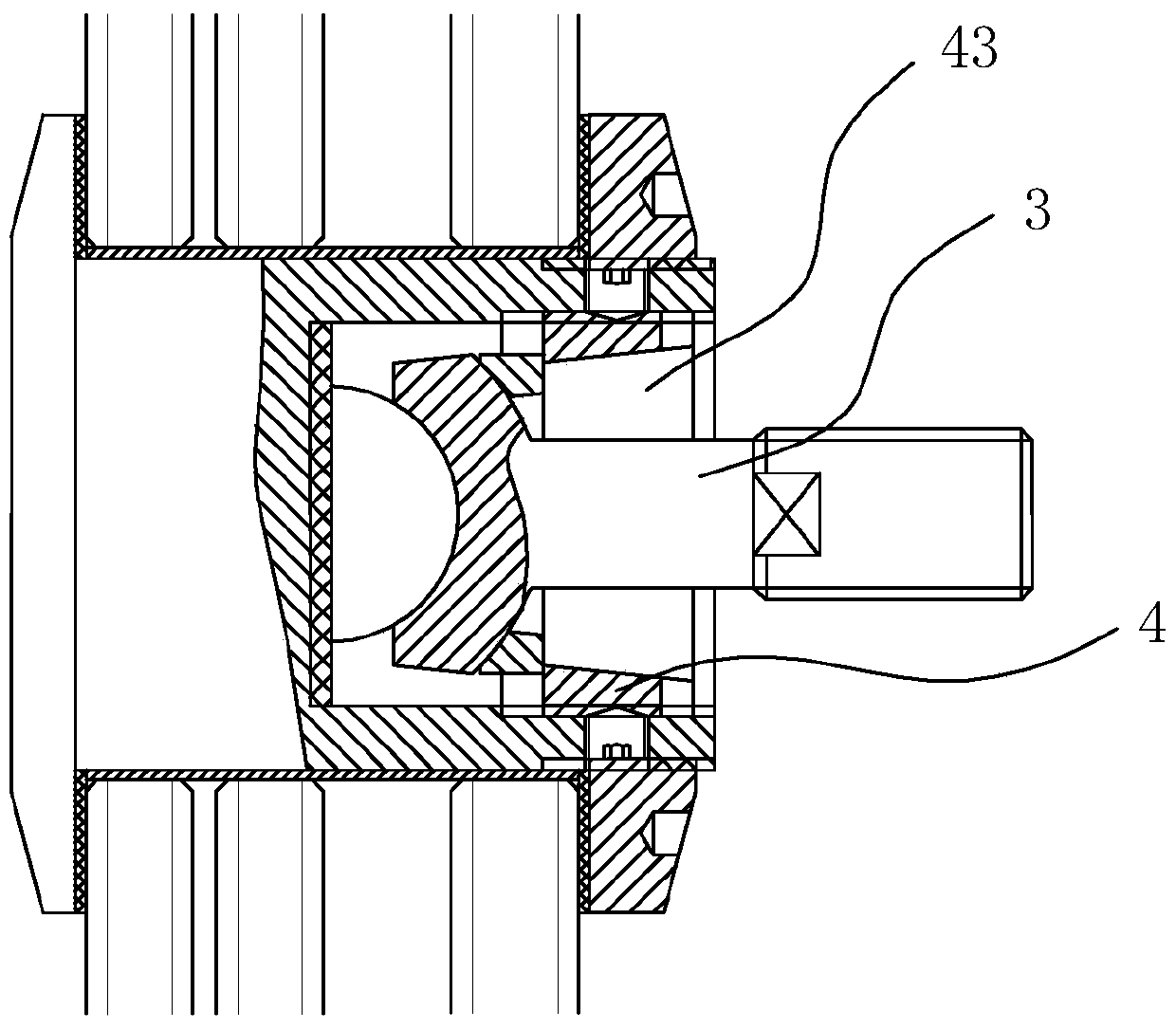

Rope-structure connection adjuster

The invention discloses a rope-structure connection adjuster, comprising a base. The base is provided with a cavity. Inside the cavity, arranged are an adjusting ball connected slidably to the bottom of the cavity, an adjusting screw rotating around the adjusting ball, a nut fixed to the base, and a bushing connected slidably to an end face of the nut. The head of the adjusting screw is provided with a spherical adjusting portion. The nut pushes sequentially the bushing and the spherical adjusting portion to the adjusting ball. The adjusting screw sequentially penetrates and radially movably connected to the bushing and the nut. A bottom end of the spherical adjusting portion is provided with an inner spherical face. The inner spherical face matches with the surface of the adjusting ball. Through the rotation of the adjusting screw around the adjusting ball, the movement of the adjusting screw and adjusting ball in the cavity and a combined manner of both, the positions of the base and adjusting screw can be adjusted according to their stress conditions. The rope-structure connection adjuster is reasonable in design, the problem that a rope-structure glass curtain wall has large deformation can be solved, and this adjuster is worthy of popularization and application in the market.

Owner:SHENZHEN SANXIN FACADE ENG

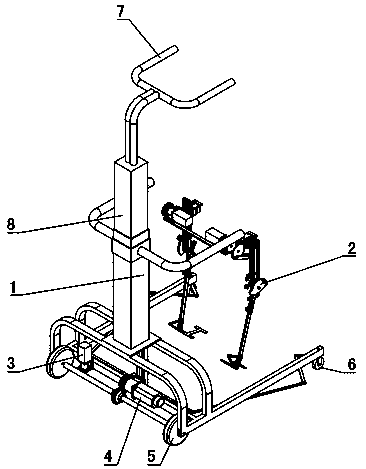

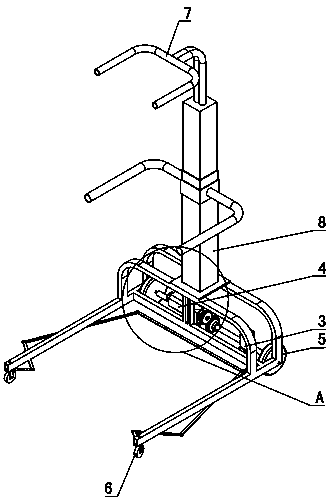

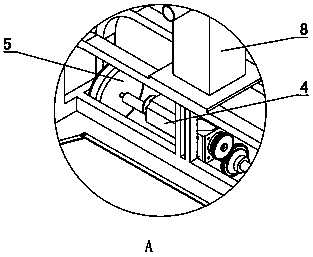

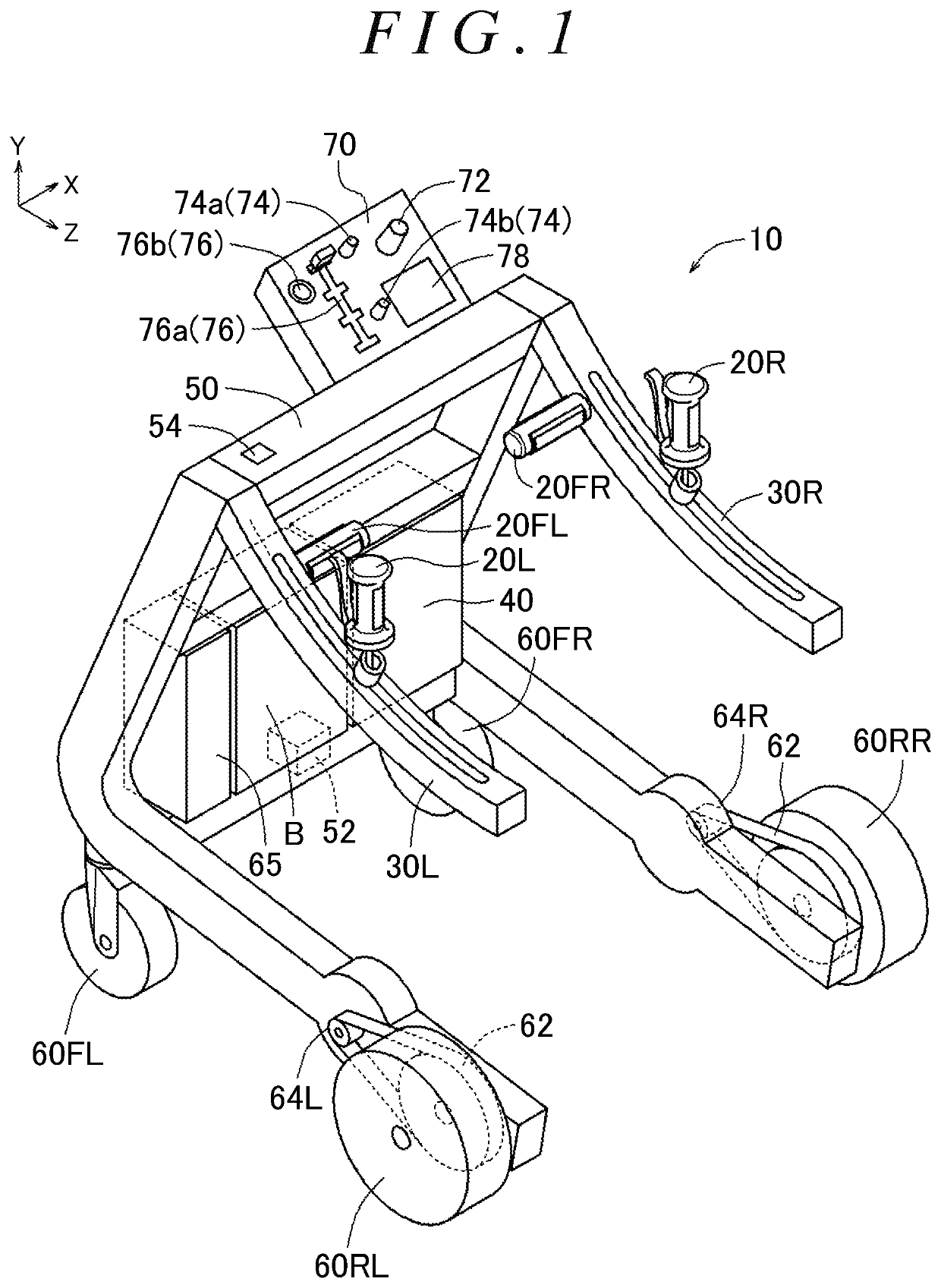

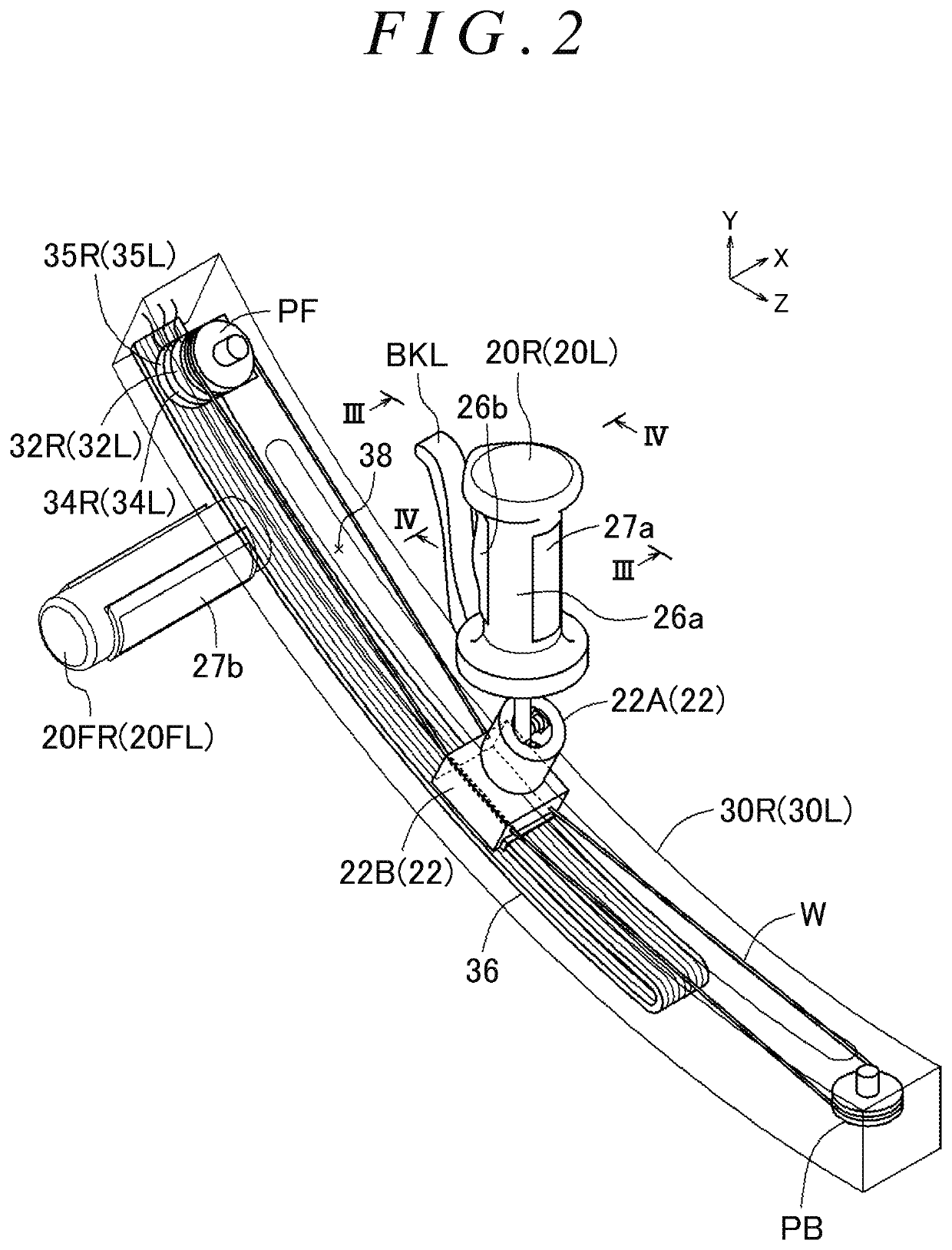

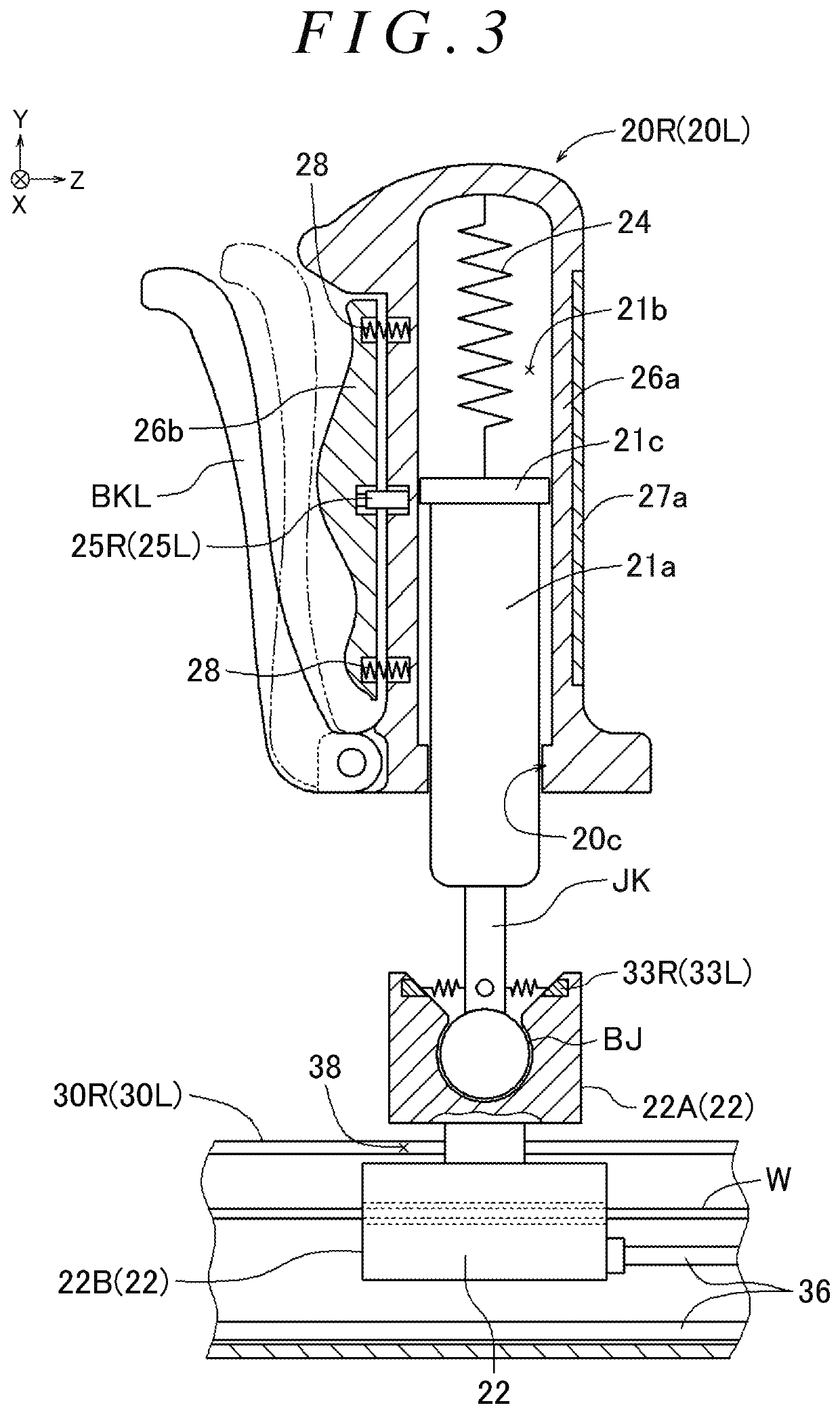

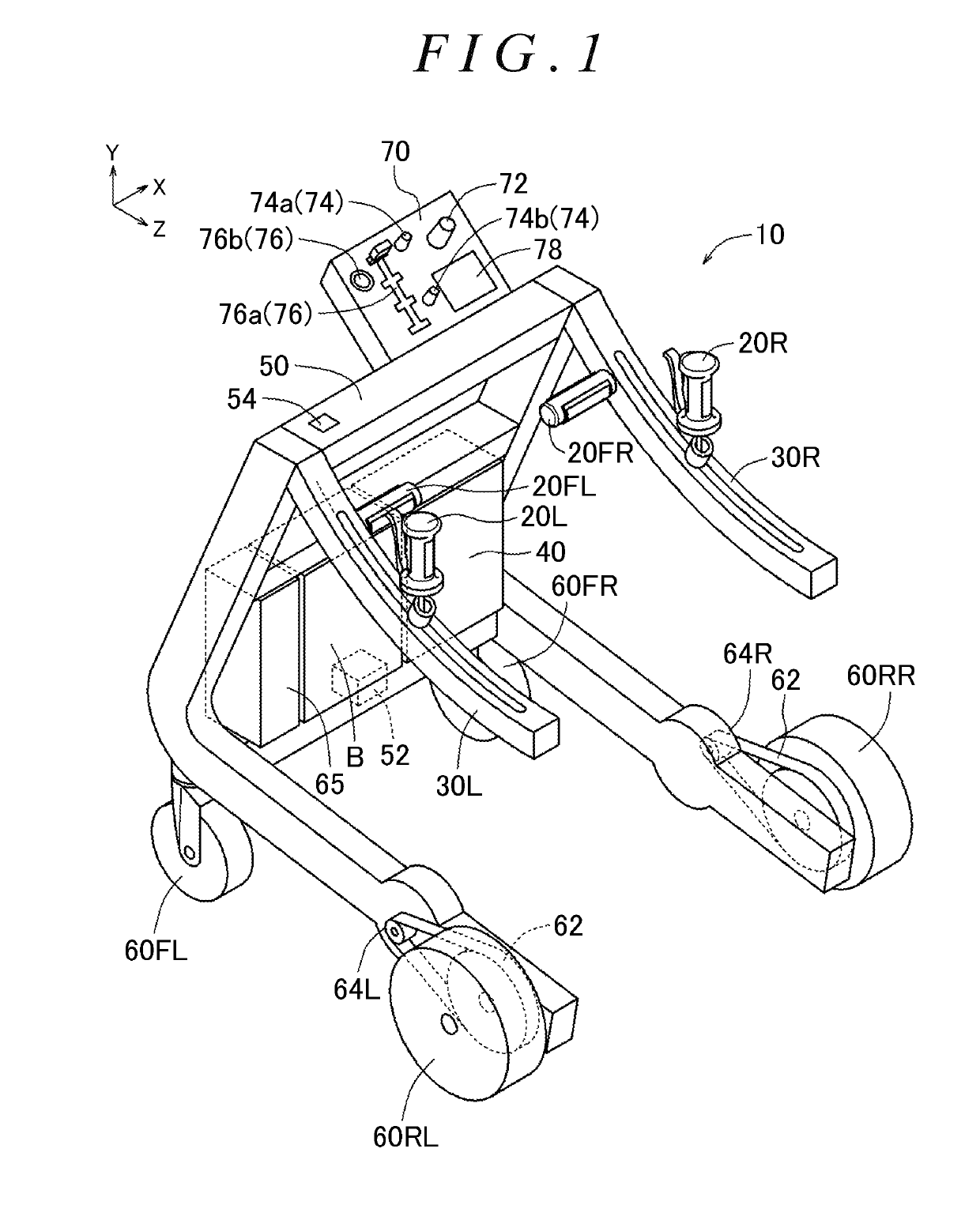

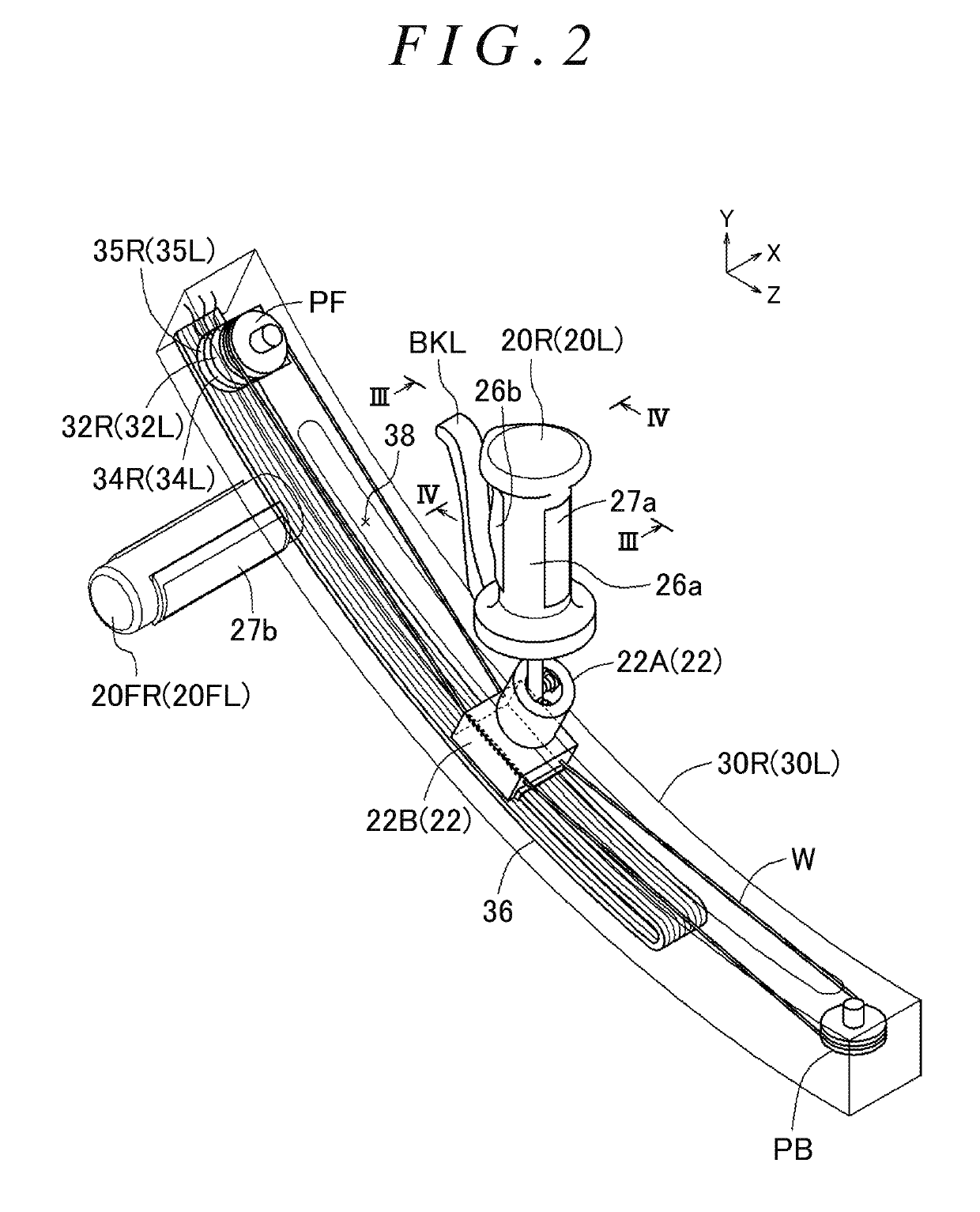

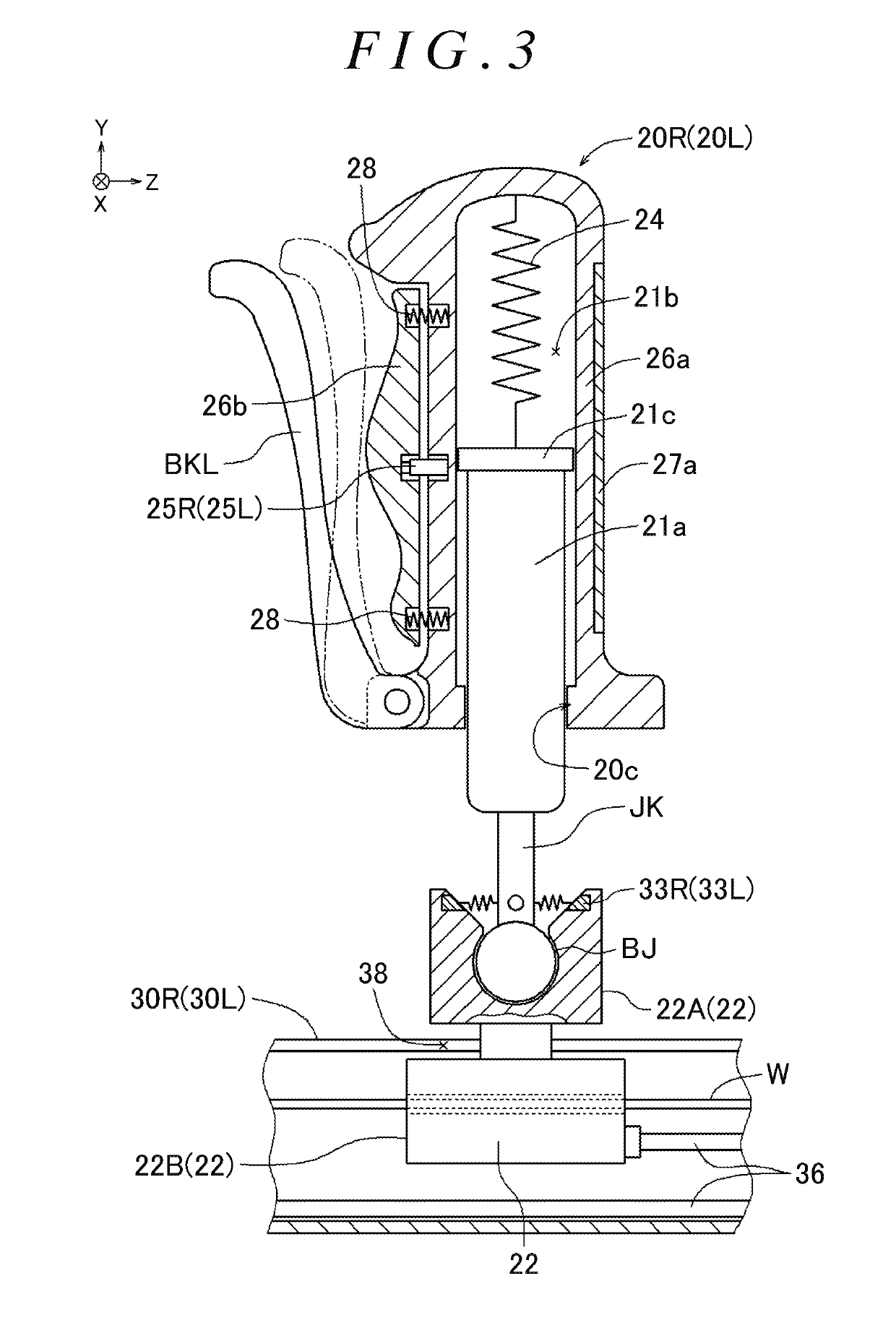

Walking assist device

ActiveUS11452662B2Precise swingQuality improvementDiagnosticsChiropractic devicesSimulationControl engineering

A walking assist device has a frame, a plurality of wheels, drive units, a battery, and a drive control unit that controls the drive units. The walking assist device also has: a pair of right and left movable handles that are grasped by a user and movable back and forth with respect to the frame in accordance with arm swing performed during walk of the user; handle guide units provided on the frame to guide the movable handles in a movable range that matches the arm swing performed during walk of the user; and a grasp portion state detection unit that detects the state of the movable handles. The drive control unit controls the travel speed of the walking assist device by controlling the drive units on the basis of the state of the movable handles which is detected using the grasp portion state detection unit.

Owner:JTEKT CORP

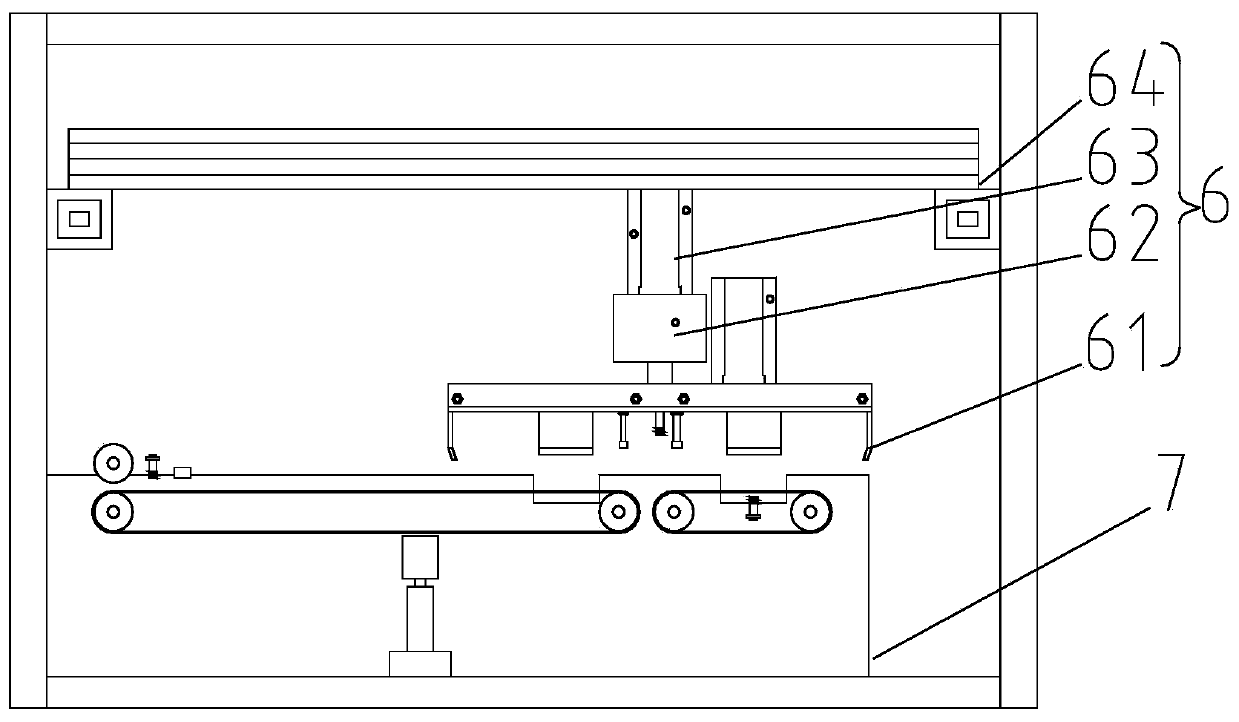

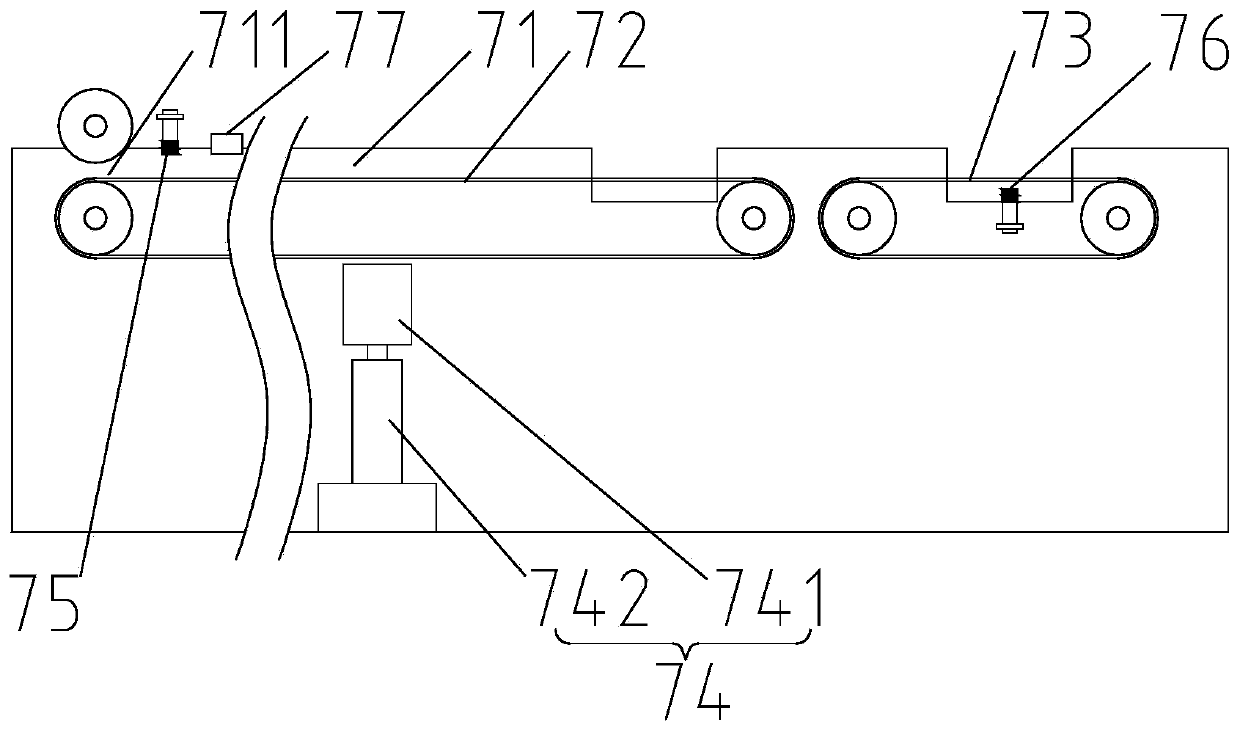

Automatic sheet arranging machine for packaging sheet materials

PendingCN110610882ASmooth nestingAvoid squeezingSemiconductor/solid-state device manufacturingConveyor partsEngineeringSemiconductor

The invention relates to the field of semiconductor processing equipment, in particular to an automatic sheet arrangement machine for packaging sheet materials, which comprises a controller, a workbench, a clamping bottom frame, a clamping top frame, a material moving device and a conveying device. The conveying device comprises a fixing support, a conveying belt, a material supporting belt, a blocking mechanism, a first photoelectric switch and a second photoelectric switch. According to the conveying device of the automatic sheet arranging machine, through mutual cooperation of the conveyingbelt, the material supporting belt and the controller, packaging sheet materials in the previous procedure can be moved to a feeding area of the material moving device instead of manual work, and themanual participation rate is reduced; and meanwhile, under the action of the blocking air cylinder, the first photoelectric switch and the second photoelectric switch, the subsequently-entering packaging sheet materials are prevented from entering a feeding area of the conveying device to be mutually extruded with the previous packaging sheet material, and smooth discharging of the automatic sheet arranging machine is guaranteed.

Owner:广东协铖微电子科技有限公司

Walking assist device

ActiveUS20190262217A1Precise swingQuality improvementDiagnosticsChiropractic devicesEngineeringControl unit

A walking assist device has a frame, a plurality of wheels, drive units, a battery, and a drive control unit that controls the drive units. The walking assist device also has: a pair of right and left movable handles that are grasped by a user and movable back and forth with respect to the frame in accordance with arm swing performed during walk of the user; handle guide units provided on the frame to guide the movable handles in a movable range that matches the arm swing performed during walk of the user; and a grasp portion state detection unit that detects the state of the movable handles. The drive control unit controls the travel speed of the walking assist device by controlling the drive units on the basis of the state of the movable handles which is detected using the grasp portion state detection unit.

Owner:JTEKT CORP

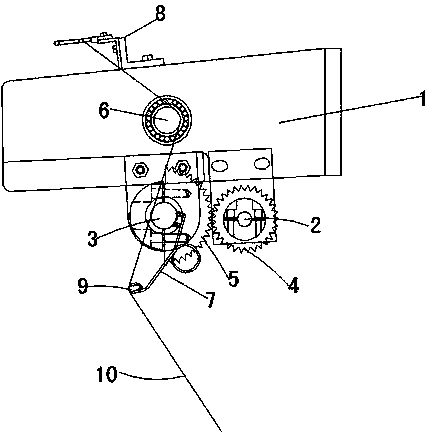

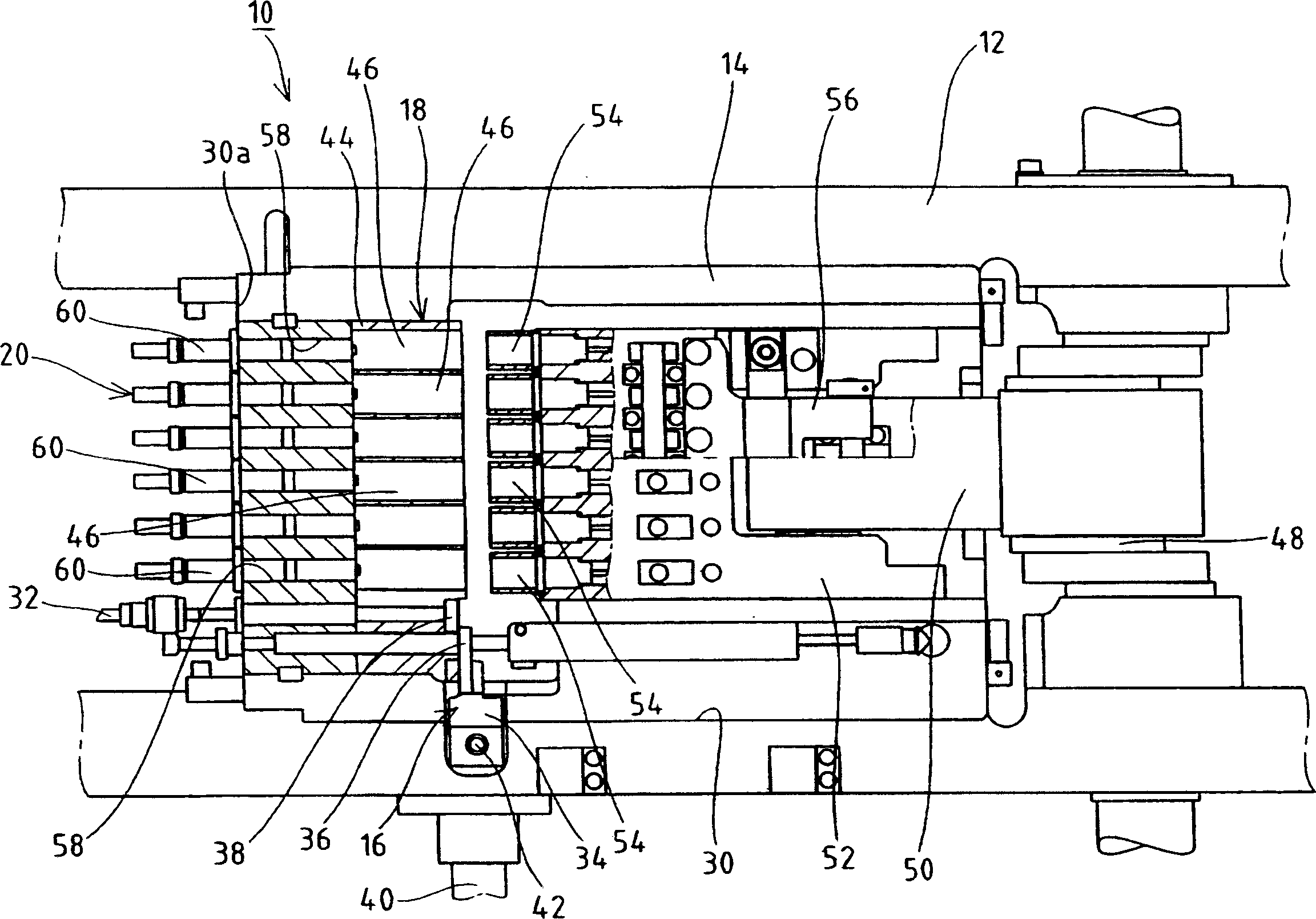

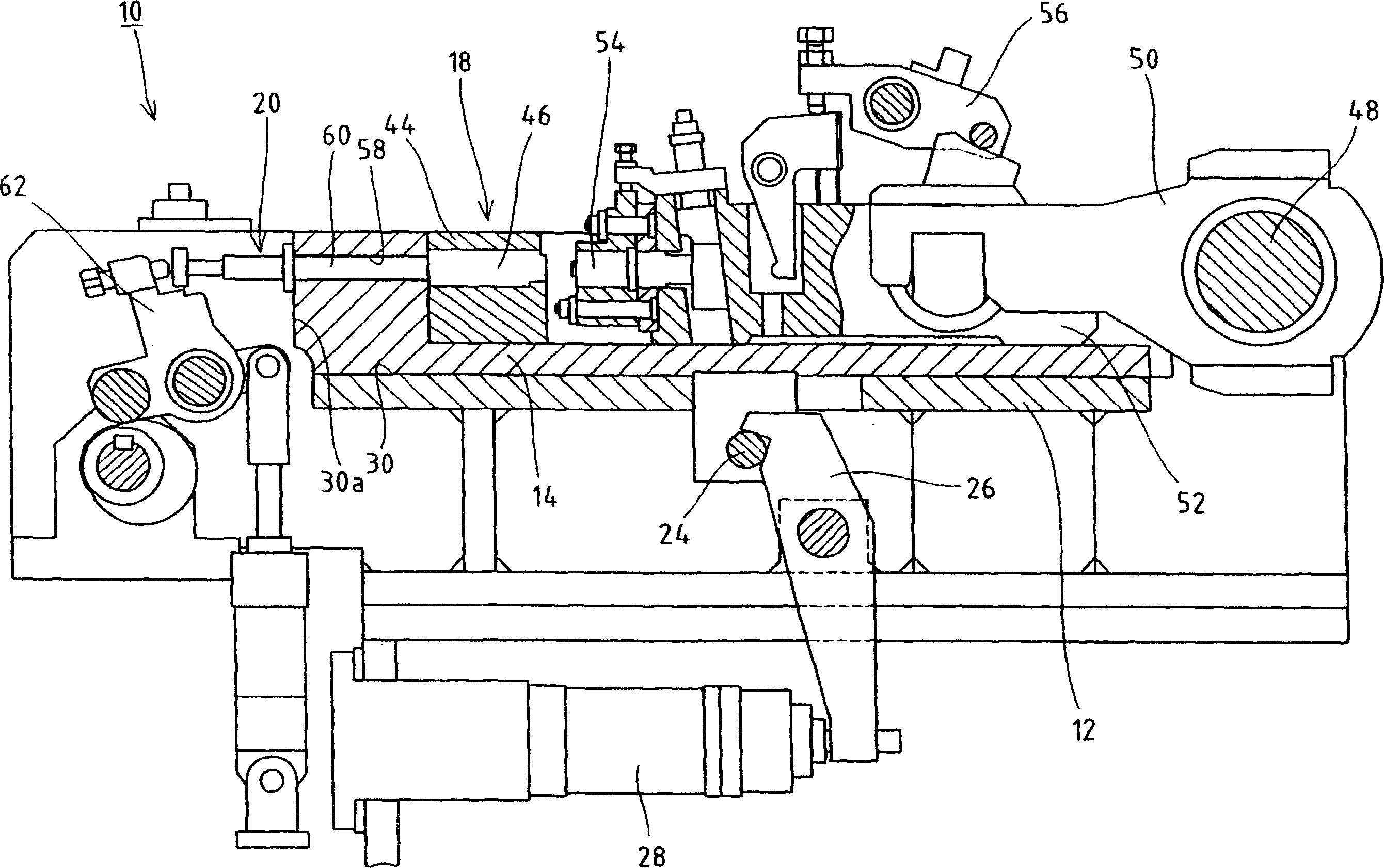

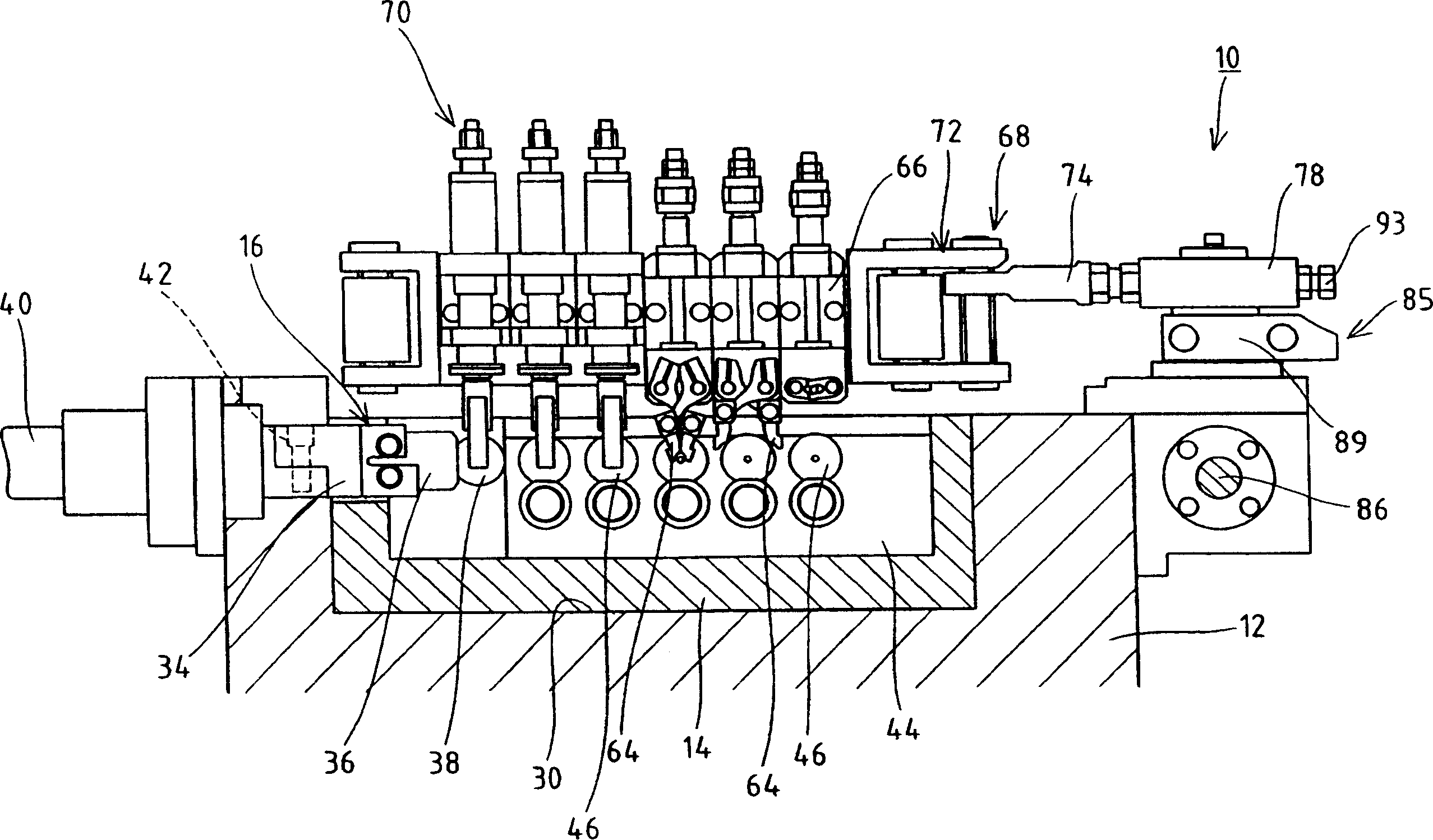

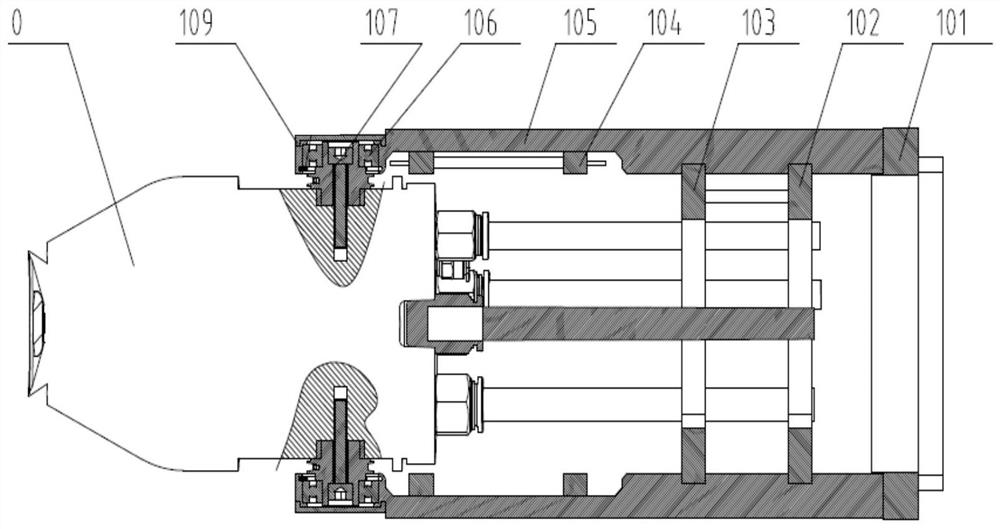

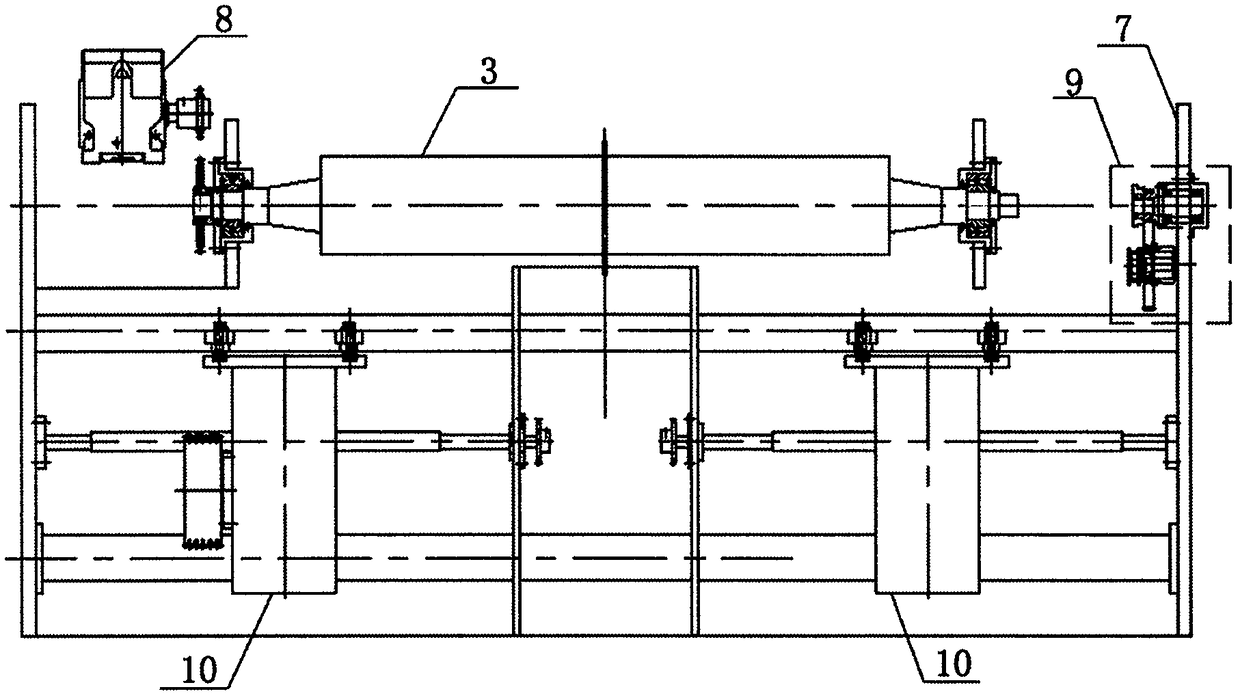

Multistage heading machine

ActiveCN1913989APrecise swingReduce installation errorsTool carrier control devicesForging/hammering/pressing machinesDrive shaftEngineering

The invention provides a multistage heading machine capable of manufacturing micro parts without producing defective transportation and defective molding by swinging the chuck of a carrying means at an accurate stroke. A drive mechanism (85) operating a swing mechanism is disposed on a first drive shaft (88) forwardly and reversely rotated by the forward and backward movements of a drive rod (86) so that an operating member (89) can be rotated integrally with each other. An eccentric shaft (90) is disposed in the operating member (89) eccentrically from the first drive shaft (88), and the eccentric shaft (90) is swung in an arc shape as the first drive shaft (88) is rotated in the forward and reverse directions. The connection member (78) of the swing mechanism is connected to a sleeve (91) fitted onto the eccentric shaft (90), and the chuck swings between adjacent dies according to the swing movement of the eccentric shaft (90). Since a separate distance (L) between the axis (C5) of the first drive shaft (88) and the center (C4) of a through-hole (78a) in the connection member (78) is changed by rotating the eccentric shaft (90), the swing stroke of the chuck can be adjusted.

Owner:DAIDO MACHINERY

Minitype breaker with high stability

ActiveUS9589743B2Reduced stabilitySimple structureEmergency actuatorsContact driving mechanismsEngineeringCircuit breaker

A high-stability miniature circuit breaker has a pivotal shaft having a first section, a second section and a shoulder. The diameter of the second section is larger than the first section. The shoulder diameter is larger than the second section. A pivoting lever on the first section limits the axial position of a protruding mesa relative to the shaft by contact fit between the mesa and a thrust surface on the second section. A pivoting latch is on the second section. A first end face fits to a support surface on the shoulder. A second end face fits to the protruding mesa at the other end. The latch controls a drive rod and the lever. A connecting rod separates from the latch when latch hasps are separated and the latch separates from the drive rod which slides along a groove of the lever.

Owner:SHANGHAI NOARK ELECTRIC

A carbon-free self-propelled trolley with reversing function

InactiveCN103463812BAchieve steeringEasy to understandEducational modelsRemote-control toysDrive wheelMechanical energy

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Working method of metal plate transferring mechanism

InactiveCN112623720AFast and efficient transferConvenient Guided DeliveryConveyorsConveyor partsGear wheelEngineering

The invention discloses a working method of a metal plate transferring mechanism, and belongs to the field of profile machining mechanical equipment. A push plate guide mechanism is horizontally arranged on the upper side of a machining support; a transferring mechanism is vertically arranged on one side of a transferring support; a front conveying support and a rear conveying support are horizontally and fixedly arranged at the two ends of one side of the upper portion of the machining support in the horizontal direction; a laser cutting machine is horizontally and fixedly arranged at the position, on one side of the upper portion of the front conveying support, of the machining support; the push plate guide mechanism is horizontally arranged at the position, on one side of the front conveying support and one side of the rear conveying support, of the machining support; a transferring guide plate is fixedly arranged on one side of a transferring gear in the radial direction of the transferring gear; a transferring belt is horizontally arranged on the upper side of a conveying support; and the transferring guide plate is fixedly arranged on one side of a plate containing gear in the radial direction of the plate containing gear. The mechanism is reasonable in structural design, a metal plate obtained through cutting machining can be rapidly and efficiently transferred, the automation degree is high, and the machining and use needs are met.

Owner:黄明珠

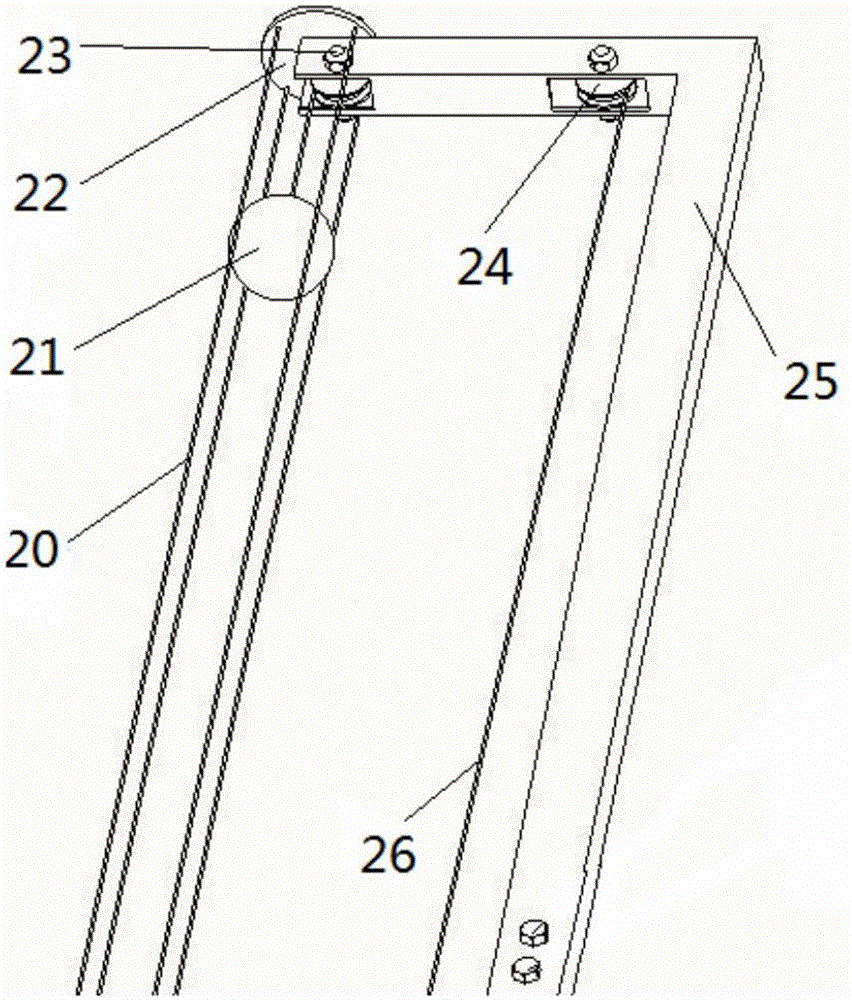

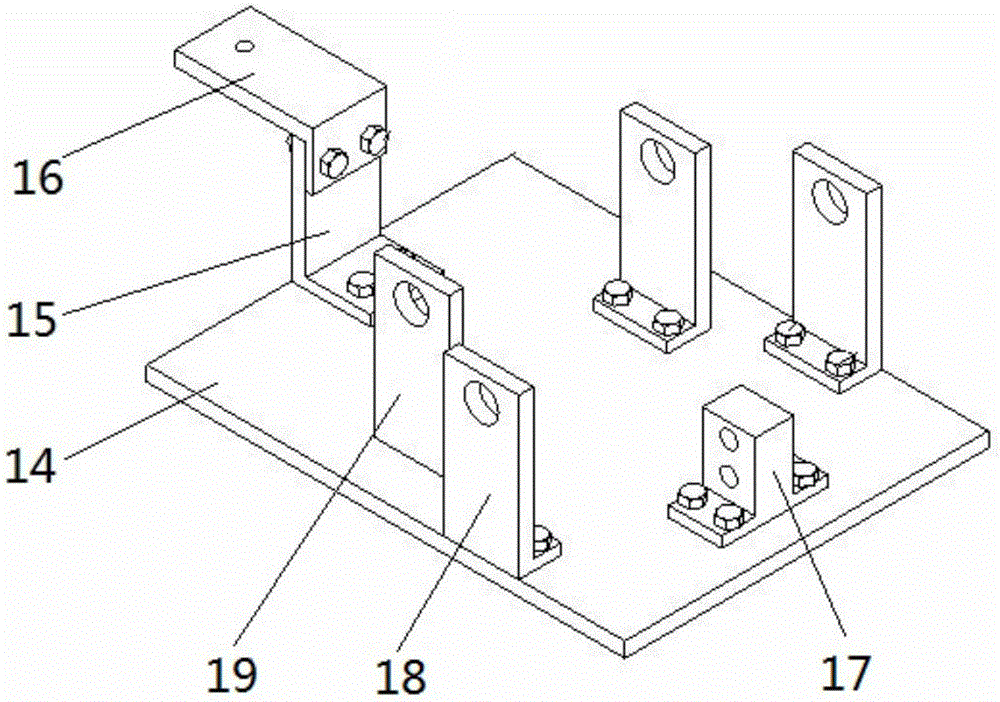

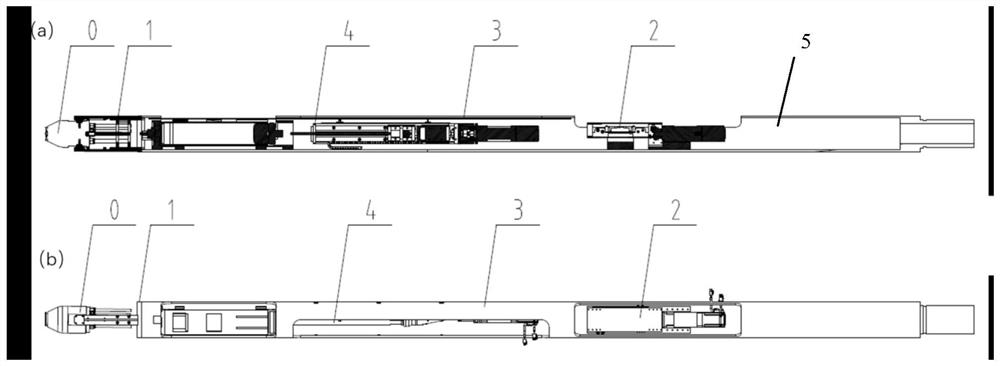

Compact type long-span steel wire rope traction rear-mounted throwing and coating head swinging device

ActiveCN113600431AExpand coating spaceBoth coating quality and efficiency capabilityLiquid surface applicatorsCoatingsWire ropeMaterials science

The invention provides a compact type long-span steel wire rope traction rear-mounted throwing and coating head swinging device. A rotatable and swingable coating head module and a steel wire rope traction group module are arranged at the front end and the rear end of a throwing rod correspondingly, and accurate stretching and retracting of a steel wire rope are controlled through driving of the steel wire rope traction group module so that accurate swinging of a throwing and coating head can be achieved, the coating space of the throwing and coating head is expanded, the throwing and coating head can coat irregular curved surfaces of inner cavities of seal heads with different specifications in engine shells with different lengths and different diameters while the coating quality and the coating efficiency are both considered, and the problems in the prior art are solved.

Owner:HARBIN INST OF TECH +1

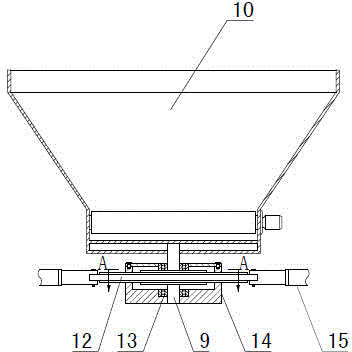

Equipment for recycling and processing construction waste

InactiveCN107159685BLow costReduced service lifeConstruction waste recoverySolid waste disposalFriction effectArchitectural engineering

The invention relates to an operating method of equipment for recycling and treating construction waste, and belongs to the technical field of crushing equipment. The equipment comprises a hopper, wherein the hopper is used for containing construction waste, and two movable jaw plates which are used for crushing the construction waste are respectively installed on both opposite side surfaces of the hopper; an impact power part is arranged above the hopper, a curved pressing plate is hinged to the hopper, and the impact power part alternately acts on both opposite sides of the curved pressing plate, so that the movable jaw plates on the corresponding sides are alternately driven to move on the hopper by the curved pressing plate. According to the operating method, the construction waste istreated in a rubbing mode like washing clothes, the movable jaw plates only have the effects of supplying impact and pushing, and the friction effect between the construction waste is used to the maximum, so that the probability of friction contact between metal of mechanical equipment and the construction waste, especially rebar materials in the construction waste, is avoided, the wear of the mechanical equipment is reduced, the service life of the equipment is prolonged, and the productive maintenance cost is reduced.

Owner:MAANSHAN FULAIYI ENVIRONMENT PROTECTION TECH CO LTD

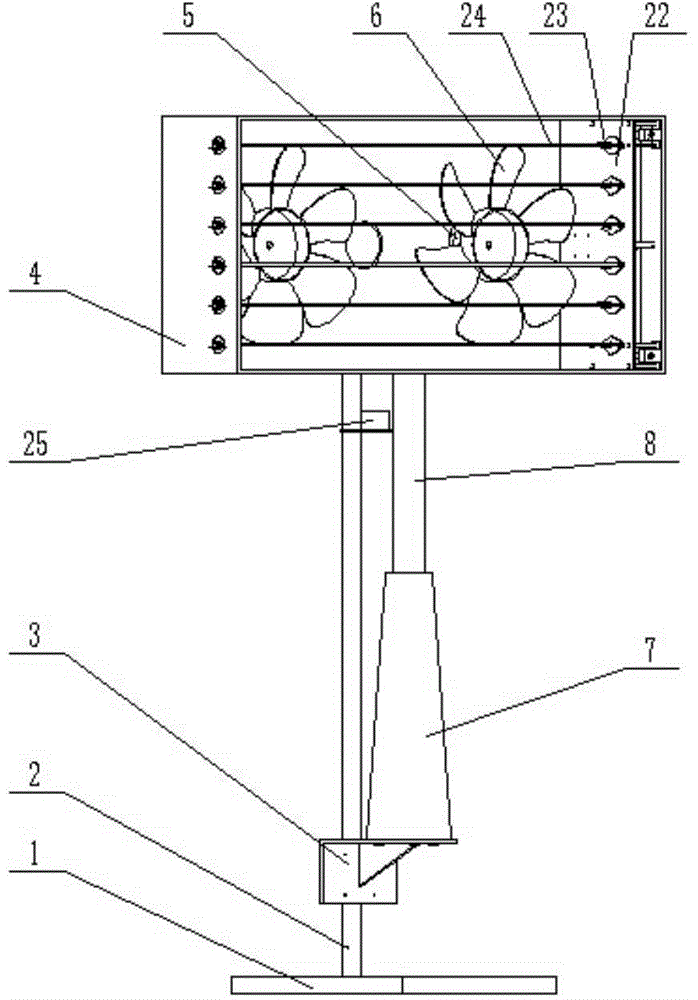

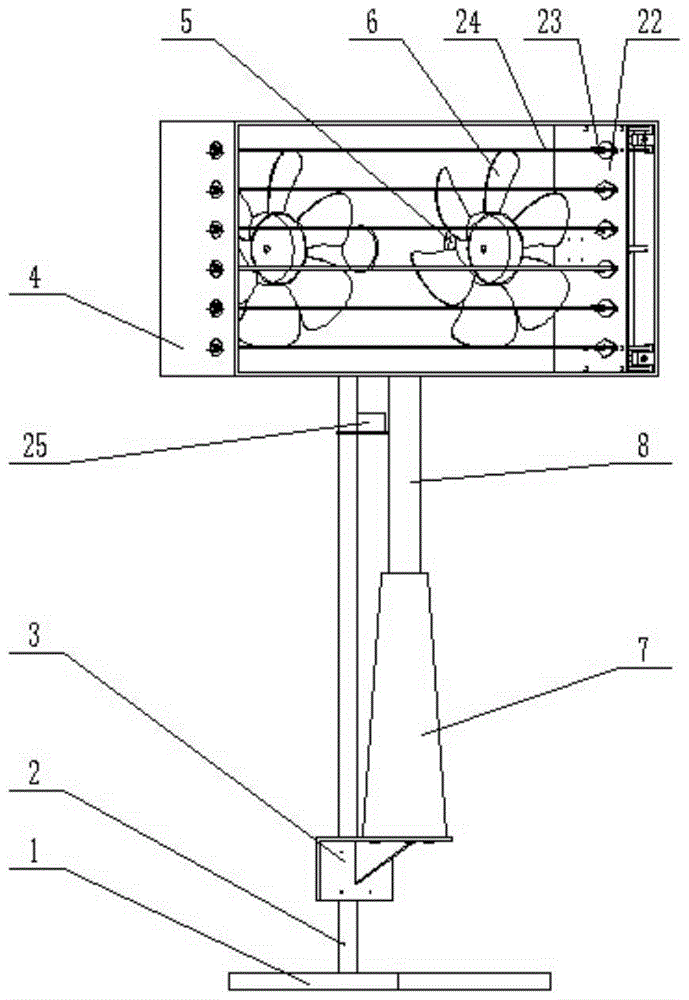

Music fan based on swing blade air changing and control method of music fan based on swing blade air changing

InactiveCN104612988AEasy to controlGood repeatabilityPump componentsPump controlLoop controlElectric machine

The invention relates to a music fan based on swing blade air changing and a control method of the music fan based on swing blade air changing. The music fan comprises a power unit, a supporting unit, a humidification unit, a swing blade driving unit and a control unit; the power unit comprises two fan bodies and is located in the outer shell; the supporting unit comprises a supporting structure and the outer shell; moisture of the humidification unit is led into the outer shell through moisture inlet holes; the swing blade driving unit comprises a front beam, a back beam, a stepping linear lead screw motor, two polish shafts, eight screws, six swing shafts, six fixedly-connected pieces, six rotating shafts, nuts, separating plates, six connecting sheets and six swing blades. An open-loop control linear lead screw motor for converting electric pulse signals into linear displacement is used in the music fan. Under the non-overload condition, the rotating speed and the stopping position of the motor are only determined by the frequency and the pulse number of the pulse signals and are not influenced by load changes; the angular displacement amount is controlled by controlling the number of pulses, and the aim of accurate positioning is accordingly achieved.

Owner:NORTHEASTERN UNIV

Elastic operation switch system

InactiveCN108010793AImprove stabilityStable structureHigh-tension/heavy-dress switchesAir-break switchesCamEngineering

The invention relates to an elastic operation switch system which is characterized in that the system comprises a base plate, a high-voltage switch and an operating mechanism. The operating mechanismis arranged on the base plate. An output end of operating mechanism is connected to the high-voltage switch. According to the system, through the cooperation of an elastic operation cam structure anda dual-rocker mechanism, the accurate swing of the high-voltage switch is achieved. A cam mechanism is powered by an independent stepper motor, and the overall stability performance is improved. The elastic operation cam structure is used in the invention, compared with a general high-voltage switch operation structure, force closure and a more stable structure can be achieved by the structure.

Owner:YANCHENG POWER SUPPLY CO STATE GRID JIANGSU ELECTRIC POWER CO +4

Cable structure barge joint adjustment device

The invention discloses a cable structure barge joint adjusting device, which comprises a base, and the base is provided with a cavity; the cavity is provided with an adjusting sphere slidingly connected to the bottom of the cavity, an adjusting screw rotating around the adjusting sphere, fixed The screw sleeve on the base is slidingly connected to the bushing on the end face of the screw sleeve; the head of the adjusting screw is provided with a spherical adjusting part; the screw sleeve presses the bushing and the spherical adjusting part on the adjusting sphere in turn; The inner spherical surface is provided at the bottom end of the spherical adjusting part; the inner spherical surface matches the surface of the adjusting sphere. The invention adopts the adjustment screw to rotate around the adjustment sphere, the adjustment screw and the adjustment sphere to move in the cavity, and the combination of the first two methods, so that the positions of the base and the adjustment screw can be adjusted according to their own stress conditions. The invention has a reasonable design, can solve the problem of large deformation of the cable-structured glass curtain wall, and can be vigorously popularized and applied to the market.

Owner:SHENZHEN SANXIN FACADE ENG

Warp sizing machine head

ActiveCN109234945AReduce the amount of winding deformationSmall footprintTextile treatment machine arrangementsLiquid/gas/vapor yarns/filaments treatmentYarnEngineering

The invention discloses a warp sizing machine head, comprising a telescopic reed, a length measuring roller, a towing roller, a tension roller, a yarn guiding roller and a live axle. The telescopic reed, the length measuring roller, the towing roller, the tension roller and the yarn guiding roller are all disposed between large wall panels of the head and are on the upper part in the head. The live axle is located on the inner lower part between the large wall panels on both sides. The towing roller is coupled with a reducer and a motor in the large wall panel. A built-in reed swing mechanismis arranged on the upper part of the large wall panel on the right side. The integrated head is in a built-in structure, lengths of a roll surface and a bearing spindle head are reduced, and deformation of winding degree of the towing roller is reduced. Built-in connection transmission of the towing roller, the reducer and motor reduces space occupation, and transmission efficiency loss is small.Transmission of the built-in reed swing mechanism is accurate, and space occupation is small. The transmission mode of a moving box and the motor arrangement form integral transmission and integral moving, thereby reducing the transmission force. The transmission efficiency is improved by about 30%. The warp sizing machine head has simple and reasonable structure, small occupied space, precise transmission and high transmission efficiency.

Owner:盐城华特纺织机械有限公司

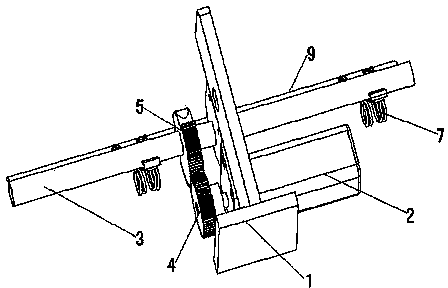

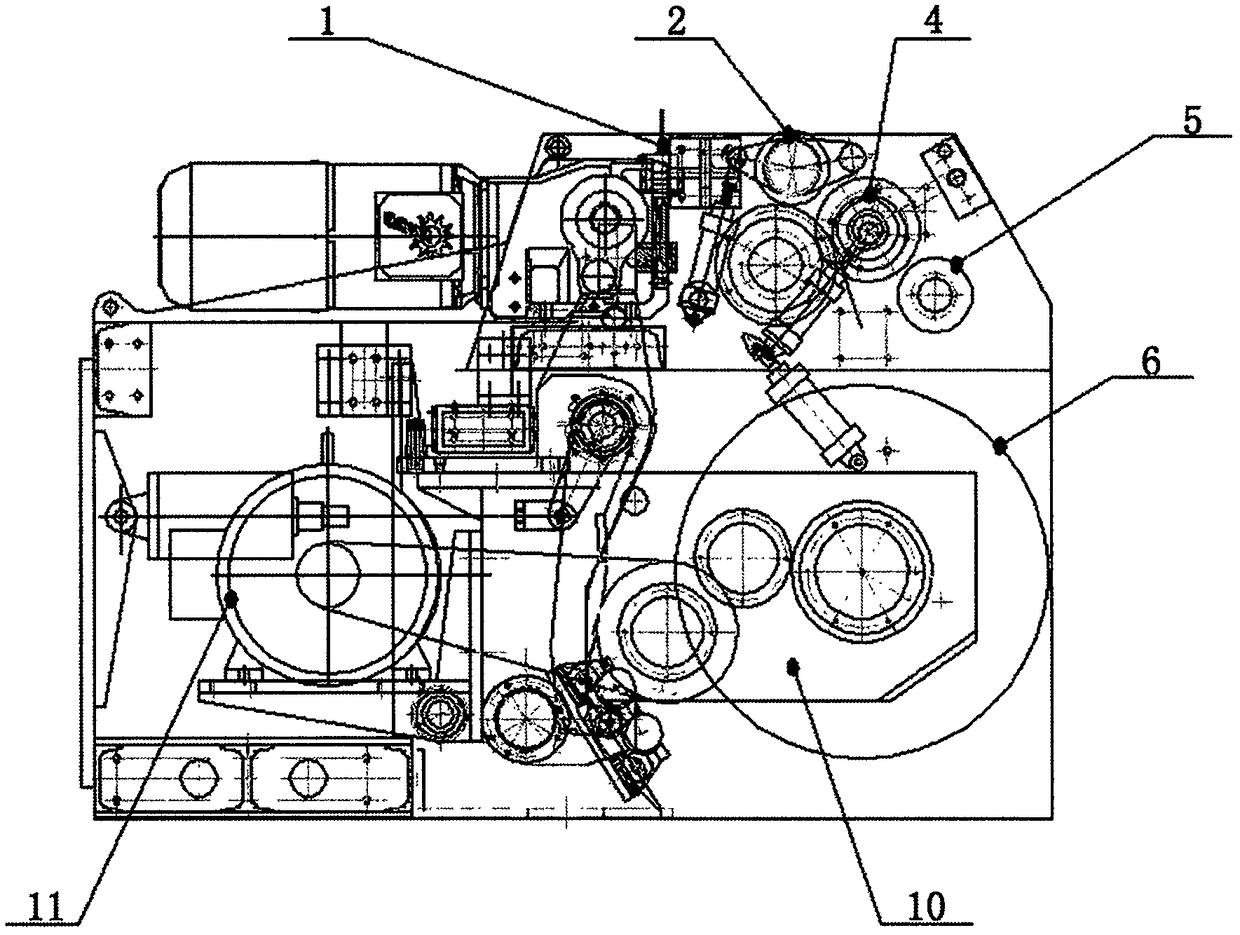

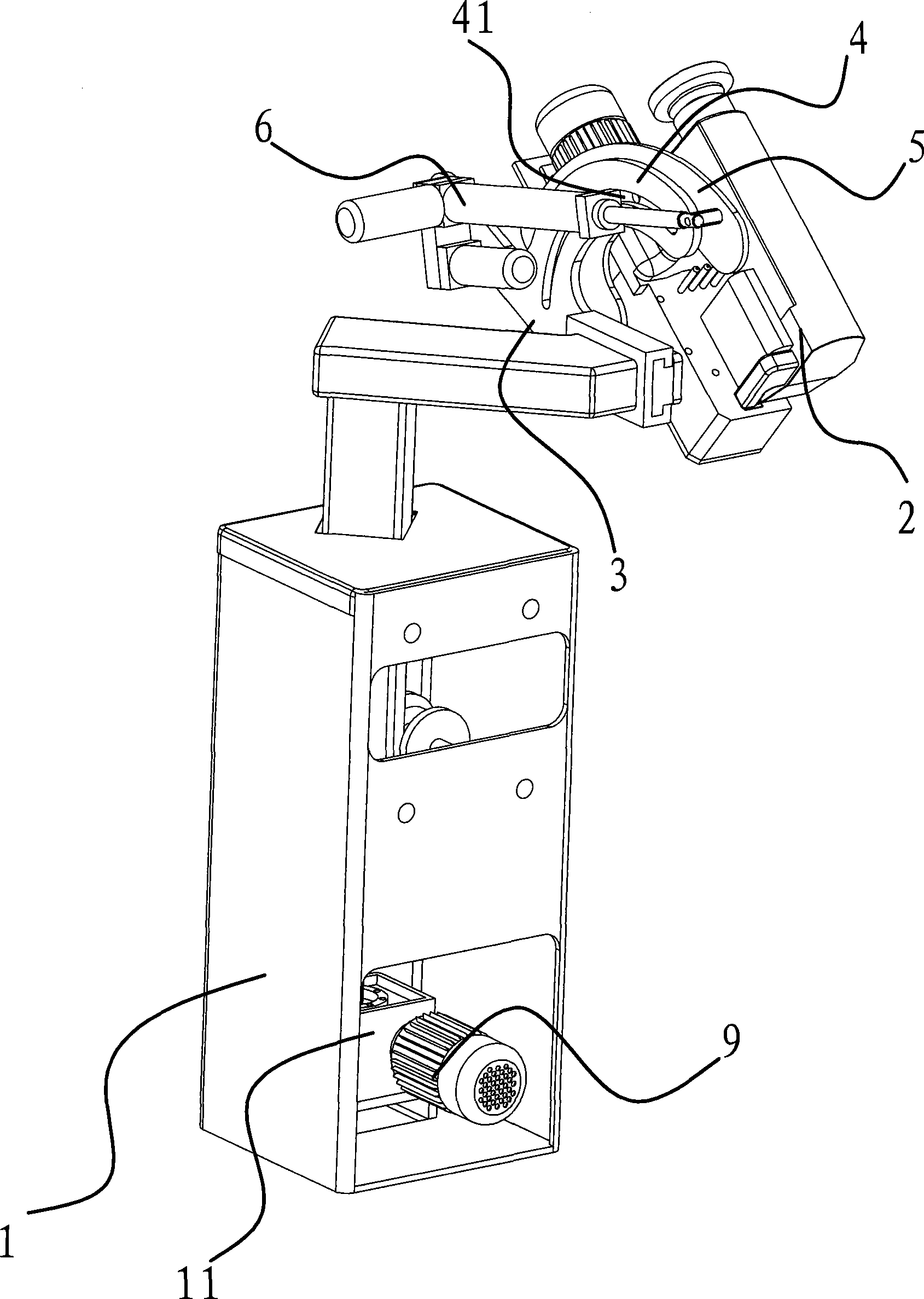

Adjusting device of tape edge sewing head for mattress

InactiveCN101476215ARealize automatic swingSimple structureUpholstery manufactureSewing-machine elementsInstabilityMechanical engineering

The invention provides a mattress surrounding edge machine sewing head adjusting device, which belongs to the mechanical technology field, and solves the problems of per swinging accuracy and lifting instability existing in current mattress surrounding edge machine sewing head adjusting devices. The mattress surrounding edge machine sewing head adjusting device comprises a base and a sewing head; a movable seat board is disposed on the base; a elevating system is disposed between the movable seat board and the base for lifting the movable seat board; an adjusting plate with an arced guiding through hole is fixed on the movable seat board; a connection seat is disposed on one side of the adjusting plate; the sewing head is fixed on the connection seat; and a swing mechanism is disposed between the movable seat board and the connection seat fro pushing the connection seat to slide along the guiding through hole. The invention achieves the advantages of reasonable design, swinging accuracy, elevating stability and high practicability.

Owner:ZHEJIANG SHENDU OPTOELECTRONICS TECH

A music fan and its control method based on swinging leaves to change the wind

InactiveCN104612988BEasy to understandSmooth swingPump componentsPump controlLoop controlOptical axis

A music fan based on swing blade wind change and its control method. The music fan includes a power unit, a support unit, a humidification unit, a swing blade drive unit and a control unit; the power unit includes two fans, and the power unit is located in the casing; the support The unit includes a support structure and a shell; the moisture of the humidification unit is introduced into the shell through the moisture air inlet; the swing leaf drive unit includes: a front beam, a rear beam, a stepper linear screw motor, two optical axes, eight screws, Six swing axes, six fasteners, six rotating shafts, screw nuts, partitions, six connecting pieces, and six swing leaves; the present invention uses an open-loop control linear screw motor that converts electrical pulse signals into linear displacement. . Under non-overload conditions, the motor's speed and stopping position only depend on the frequency and number of pulses of the pulse signal, and are not affected by load changes. The angular displacement is controlled by controlling the number of pulses to achieve accurate positioning. .

Owner:NORTHEASTERN UNIV LIAONING

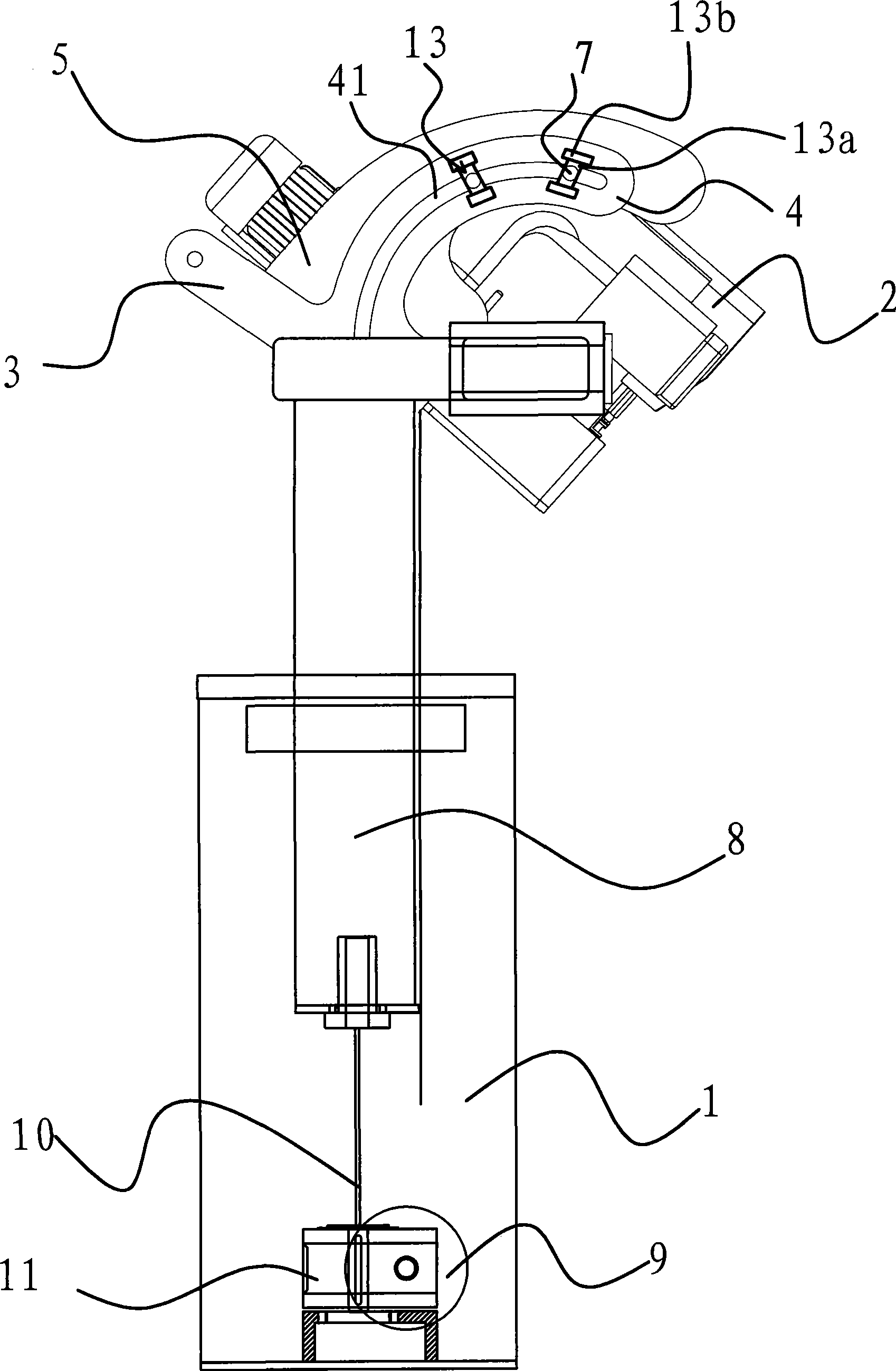

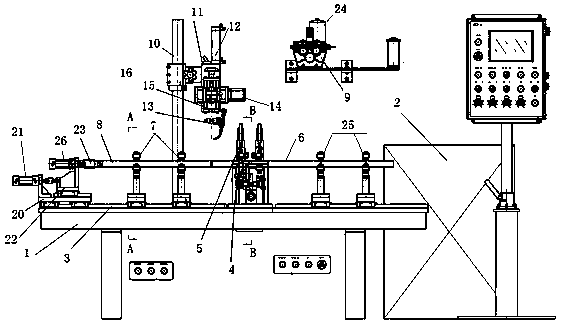

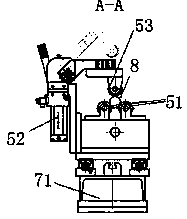

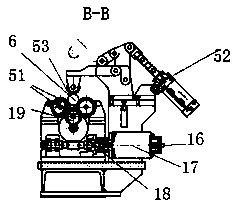

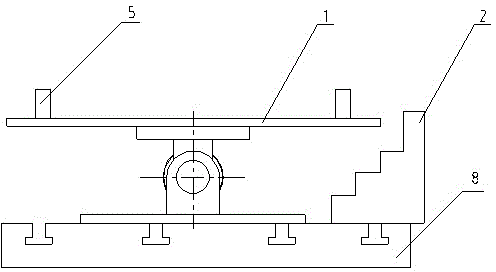

Circular seam welding machine

PendingCN109848512APrecise swingWelding/cutting auxillary devicesArc welding apparatusEngineeringBody positions

The invention discloses a circular seam welding machine. The circular seam welding machine comprises a base and a control cabinet, wherein the base is provided with sliding rails; one end of the sliding rails is connected with a pipe body connecting seat in a sliding mode; the pipe body connecting seat is provided with a pipe body positioning device for positioning the pipe body and a rotating device for driving the pipe body to rotate; a pipe body is arranged on the pipe body positioning device and can rotate relative to the pipe body positioning device; the other end of the sliding rails isconnected with a connecting pipe positioning device and a jacking device in a sliding mode; a connecting pipe is arranged on the connecting pipe positioning device and can rotate relative to the connecting pipe positioning device; the jacking device is fitted with one end, away from the pipe body, of the connecting pipe; the jacking device is used for jacking the other end of the connecting pipe to one end, close to the position, of the pipe body, and a lifting welding device is further included and is connected with an automatic wire feeder; and the welding device comprises a fixing rod, a fixing seat, an air cylinder, a welding gun and a rotating stepping motor, and the fixing seat is connected with the fixing rod. The circular seam welding machine has the advantages of being convenientto use and good in welding effect.

Owner:杭州意盛通力金属制品有限公司

Tire mold pore machining device and method

InactiveCN106141251AAchieve axial swingLarge swing angle rangeBoring/drilling componentsEngineeringMechanical engineering

The invention discloses a tire mold air hole processing device and a processing method. The air hole processing device includes a workbench, a swing plate, an axial swing block of a pattern block, a servo motor, a rotating shaft, and a circumferential swing block of a pattern block. The swing plate is installed on the pattern block. On the block axial swing block, the pattern block axial swing block is connected with the rotating shaft, the rotating shaft is connected with the servo motor transmission, and the pattern block circumferential swing block is installed on the swing plate. The axial swing block and the circumferential swing block of the pattern block are used to realize the swing of the pattern block in the axial direction and the circumferential direction, the swing is flexible, and the normal direction of the air hole position of the pattern block is guaranteed. The swing angle range is large, and the servo The motor controls the axial swing, and the swing angle is precisely adjustable.

Owner:软控联合科技有限公司

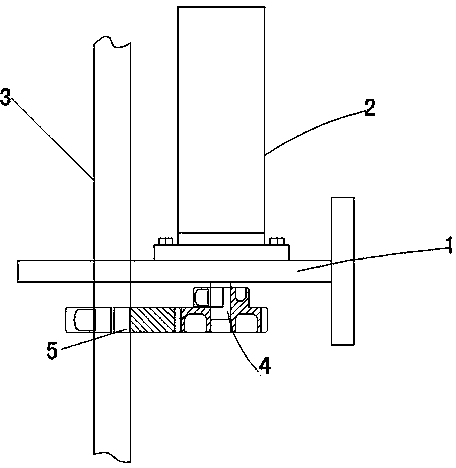

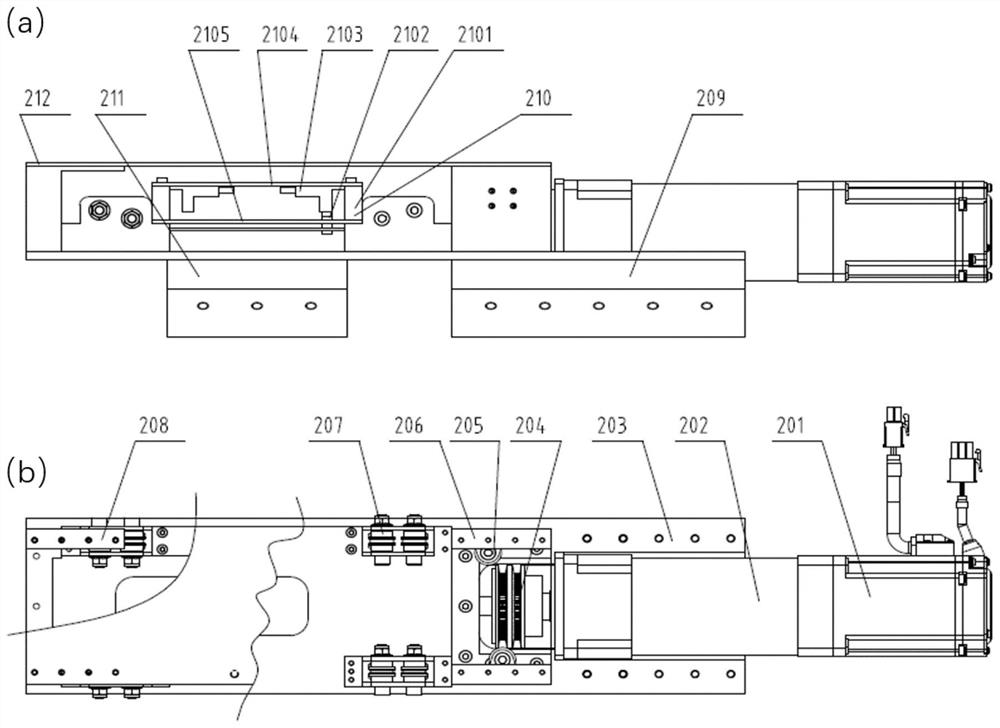

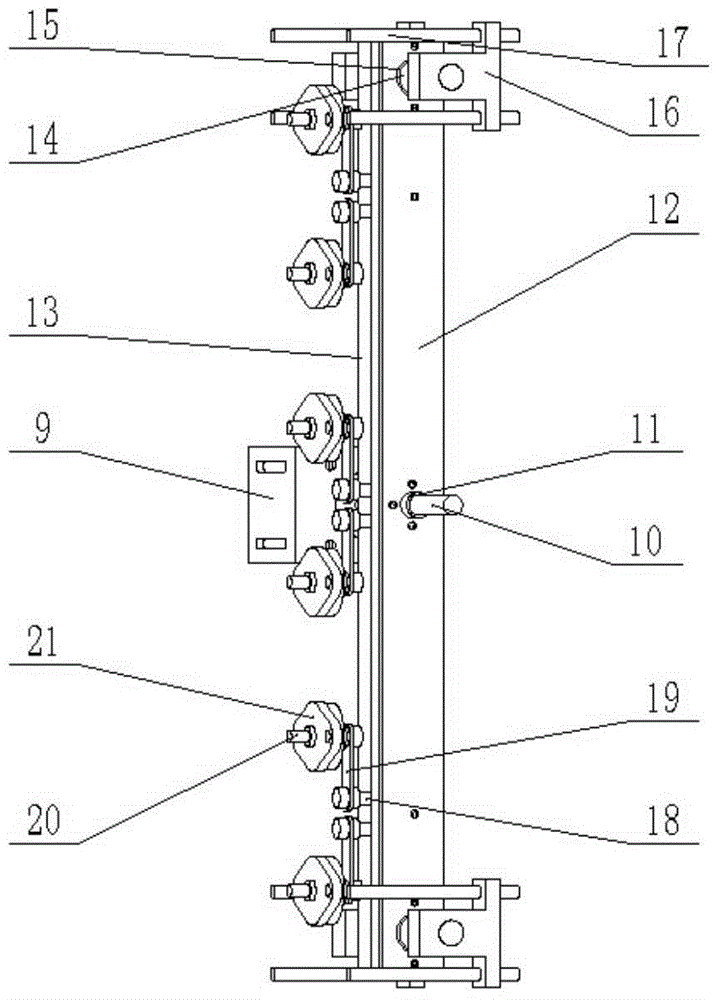

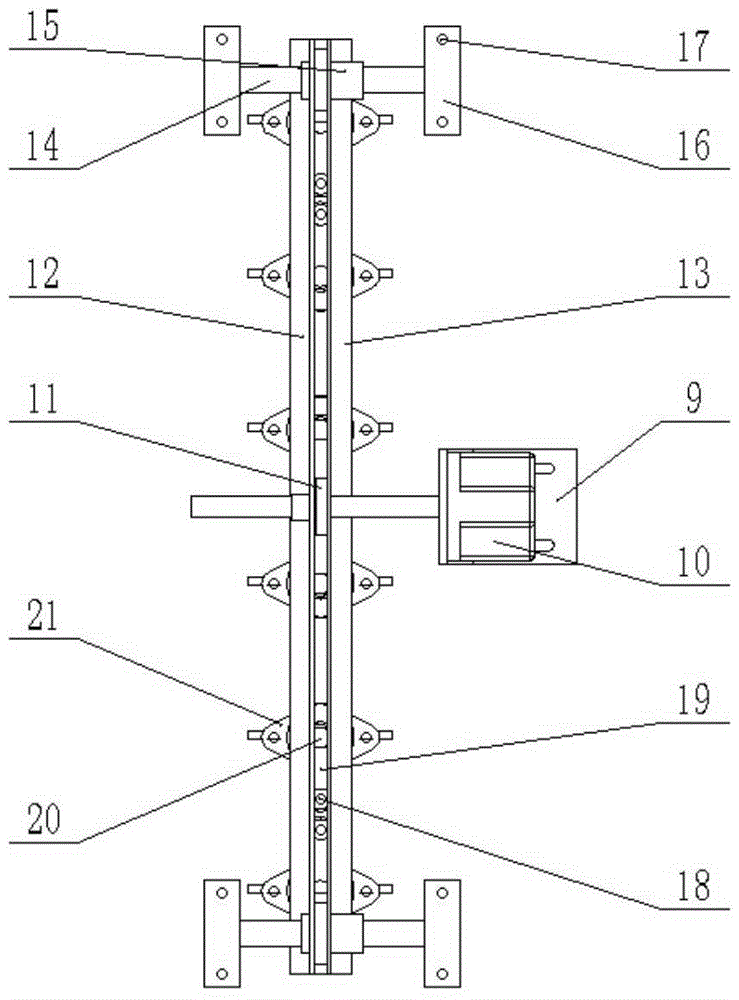

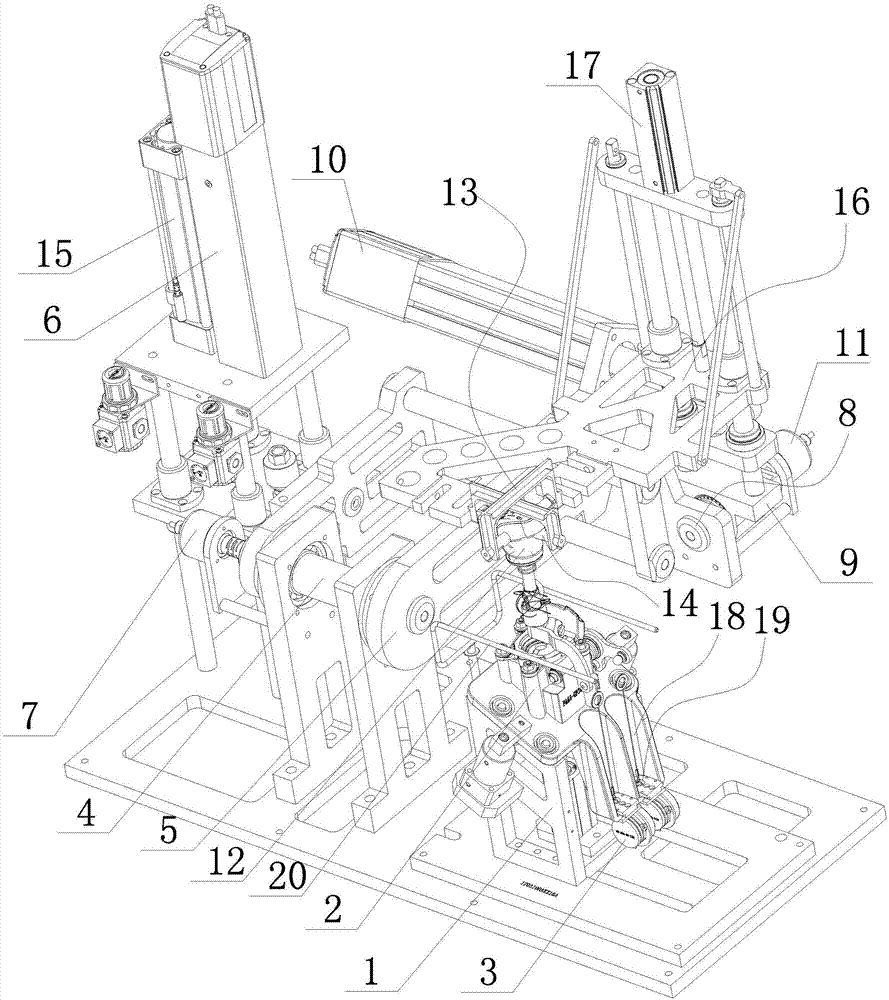

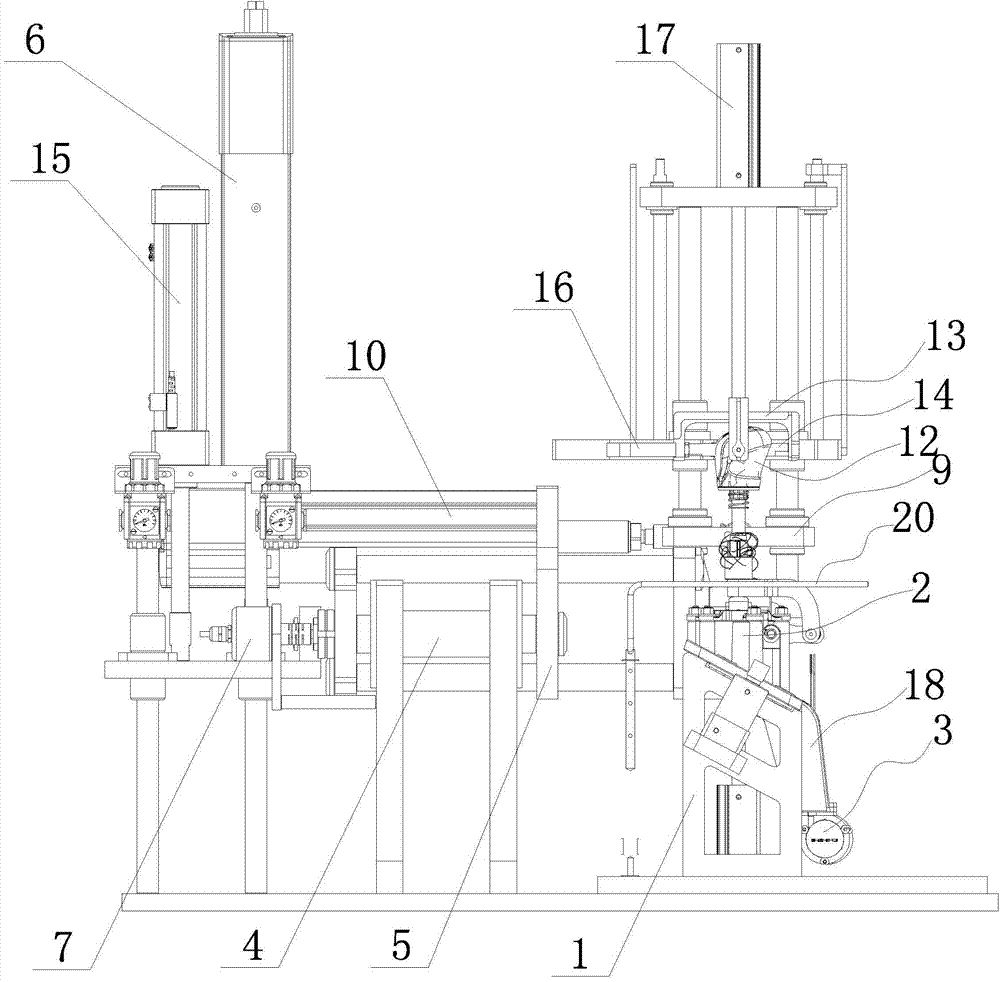

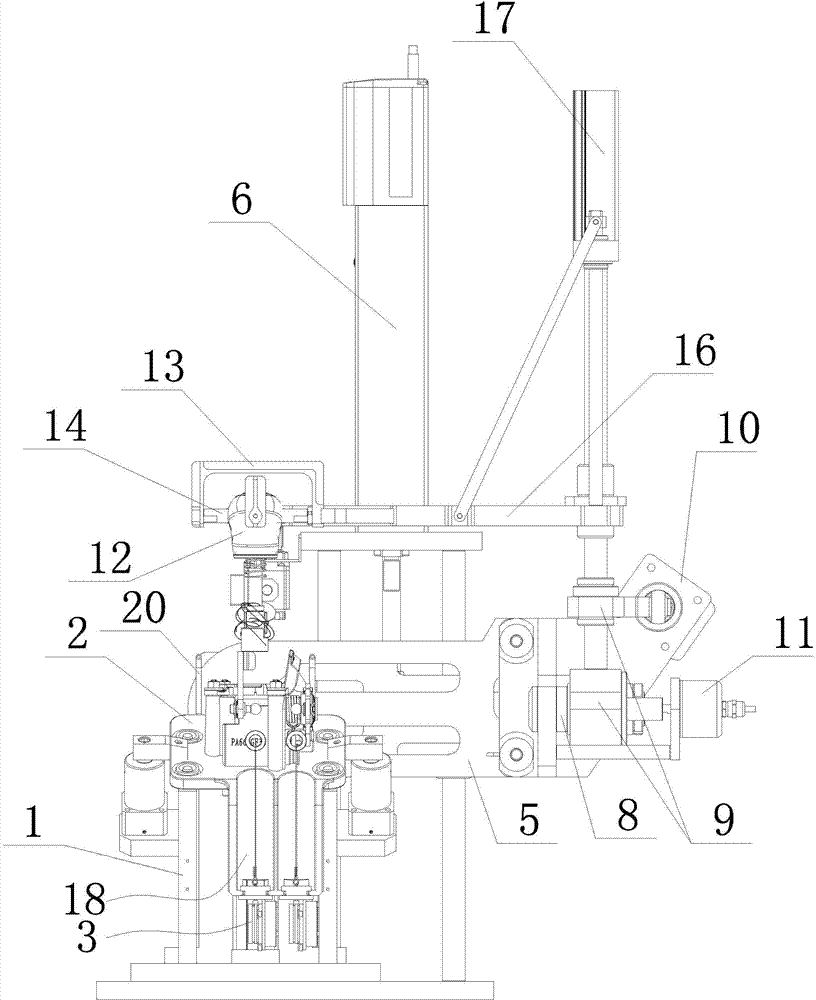

Manual-transmission testing device

InactiveCN104236904APrecise swingContinuous testingMachine gearing/transmission testingElectricityManipulator

The invention provides a manual-transmission testing device capable of controlling the swing angle of a shift lever and acquiring signals of dragline travel distance and shift-lever handfeel at the angle. The manual-transmission testing device comprises a control unit, a manual-transmission mounting seat (1), a first swing mechanism, a second swing mechanism and a stay wire sensor (3). A first electric cylinder (6) is used for driving a first supporting piece (5) to swing around a first rotating shaft (4), and the first rotating shaft (4) is connected with a first rotating sensor (7). A second electric cylinder (10) is used for driving a second supporting piece (9) to swing around a second rotating shaft (8), and the second rotating shaft (8) is connected with a second rotating sensor (11). The second supporting piece (9) is provided with a manipulator used for fixing a gear-shifting handle (12) of a manual transmission (2). The manipulator is provided with a force sensor (14). The first rotating shaft (4) is perpendicular to the second rotating shaft (8). The stay wire sensor (3) is electrically connected with the control unit.

Owner:NINGBO AUTO CABLE CONTROLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com