Equipment for recycling and processing construction waste

A construction waste, recycling and processing technology, applied in construction waste recycling, grain processing, recycling technology and other directions, can solve the problems of metal wear, broken or worn broken plates, metal crushing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

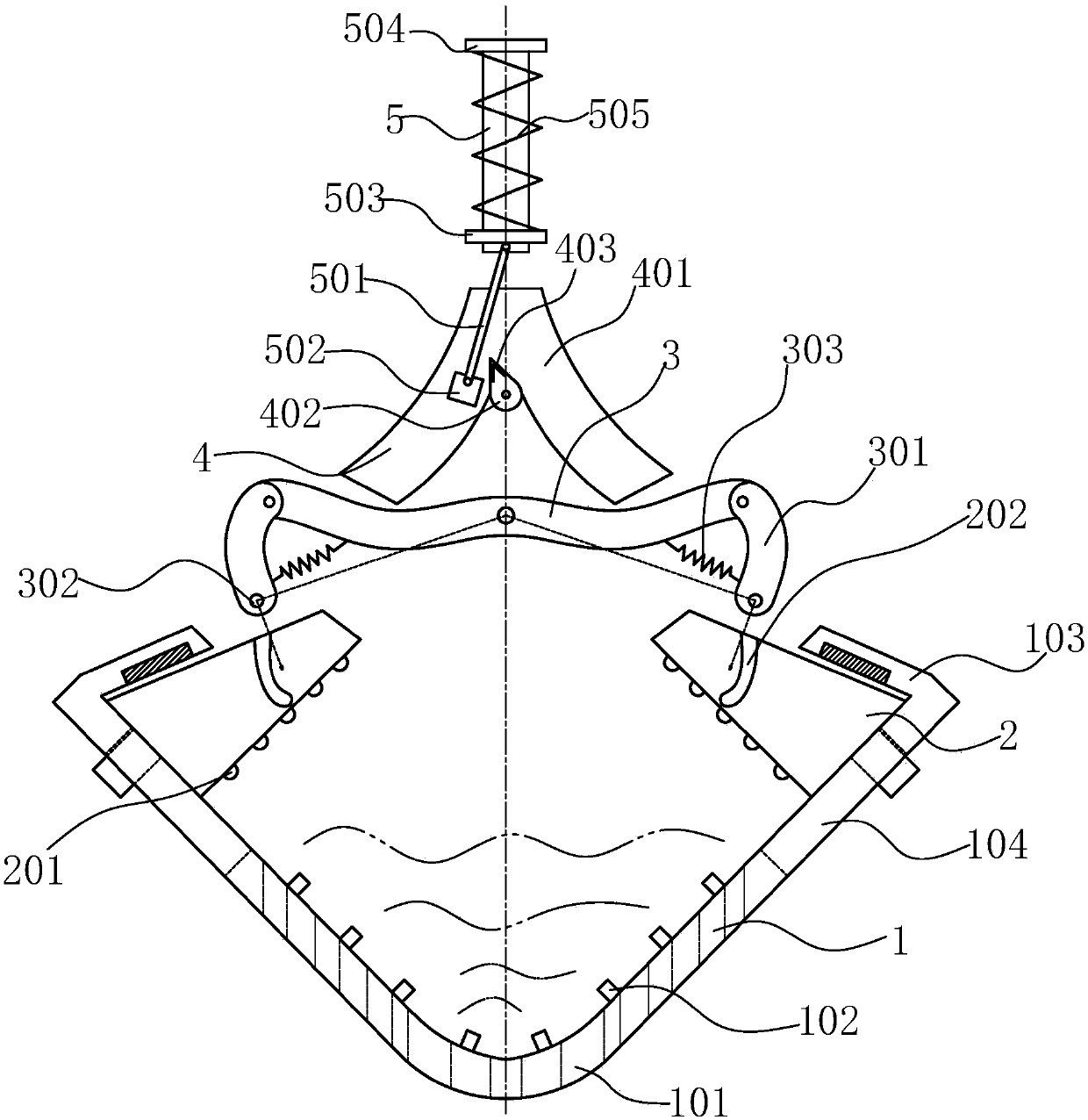

[0048] The invention is shown by way of example and is highly simplified as figure 1 As shown, a device for recycling and processing construction waste includes a hopper 1 for containing construction waste. The front end and rear end of the hopper 1 are both vertical surfaces, and the left and right sides of the hopper 1 are inclined. The angle between the left side and the right side is 90°, and the transition between the left side and the right side adopts a circular arc transition, so that the construction waste can move smoothly in the hopper 1, and the left side and the right side are evenly distributed. There are several slag holes 101 for discharging the construction slag accumulated at the bottom of the hopper 1, so that the slag generated at the bottom is directly discharged through the slag holes 101, so that the bottom remains in a slag-free state. The left side and the right side are respectively provided with a strip slideway 104, and a movable jaw plate 2 for cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com