Compact type long-span steel wire rope traction rear-mounted throwing and coating head swinging device

A swinging device and wire rope technology, applied to the device for coating liquid on the surface, coating, etc., can solve the problems of poor coating quality stability, low coating efficiency, and narrow coating space, so as to improve the strength and take into account the coating coating quality and efficiency capabilities, and the effect of expanding the coating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

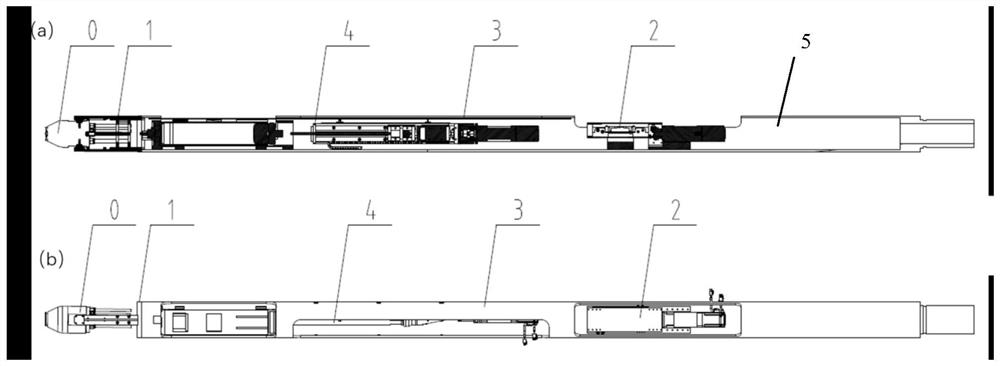

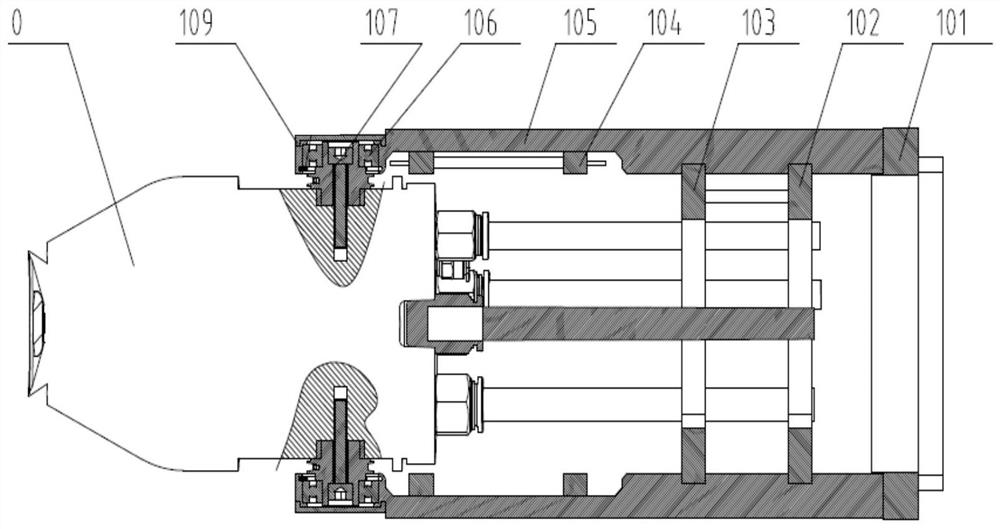

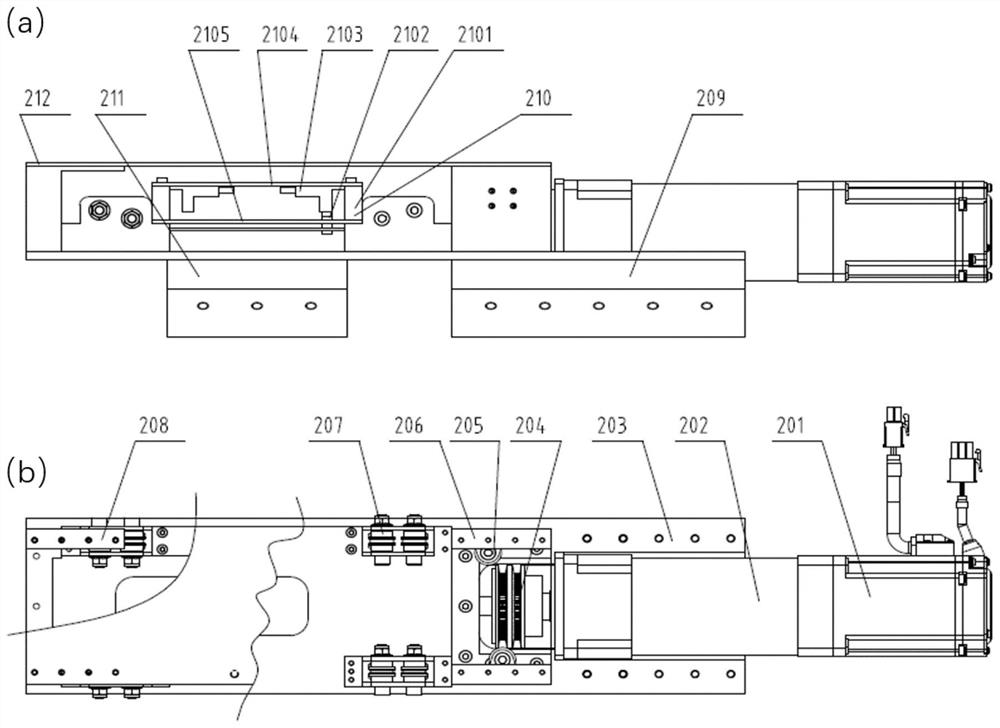

[0058] A compact long-span wire rope traction post-installed coating head swing device, mainly including a rotatable coating head module 1, a wire rope traction group module, a steel wire 3, and a throwing rod 5; in this embodiment , the throwing rod is a steel pipe with a circular cross section.

[0059] The oscillating device of the coating head of the present invention is used to apply the glue in the glue supply device 4 arranged between the rotatable coating head module 1 and the wire rope traction group module to the curved surface of the head of the engine casing; the glue supply device 4 The glue is delivered to the swivel coating head module 1 through the glue supply pipeline.

[0060] Such as figure 1 with Figure 5 As shown, the specific structure of a compact long-span steel wire rope traction post-installed coating head swing device is as follows: the rotatable coating head module 1 is installed at the front end of the throwing rod 5, through the steel wire 3 wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com