Multifunctional heading machine

A roadheader and multi-functional technology, which can be used in earth moving machines/shovels, mining equipment, earth-moving drilling, etc. Improve energy utilization, improve work efficiency, good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

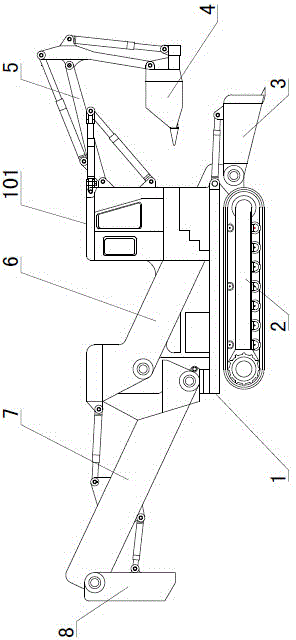

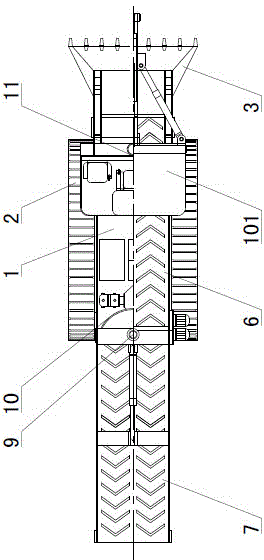

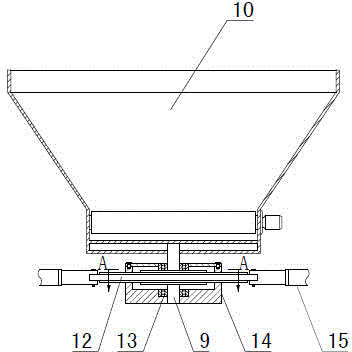

[0027] Figure 1~4 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~4 The present invention will be further described.

[0028] A multifunctional roadheader, comprising a roadheader body 1, a traveling mechanism 2 below the roadheader body 1, a power device in the middle of the roadheader body 1, and a conveying mechanism. The swing arm 5 is equipped with a crushing head 4 for crushing the hard layer and sending the crushed material into the conveying mechanism. The power unit drives the multifunctional roadheader to travel, and provides high-pressure hydraulic oil for the hydraulic cylinder on the multifunctional roadheader; the conveying mechanism transports and loads the materials broken by the crushing head 4; the crushing head 4 is mainly used for crushing hard layers And feed the material into the conveying mechanism. The multifunctional roadheader of the present invention has high working efficiency and low energy consu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com